Tips and Techniques for Drilling Through Hardened Steel

Drilling through hardened steel can be a daunting task, but with the right tips and techniques, you can make the process much easier and more efficient. Whether you’re working on a DIY project or a professional job, drilling through hardened steel requires careful planning and the right tools.

Choose the Right Drill Bit

When it comes to drilling through hardened steel, not all drill bits are created equal. You’ll need to select a drill bit that is specifically designed for drilling through hardened steel. These drill bits are typically made from high-speed steel or cobalt, which can withstand the high heat generated during the drilling process.

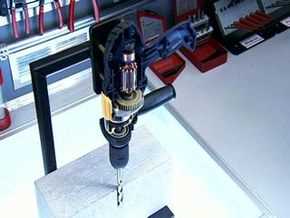

Use the Right Drilling Technique

Drilling through hardened steel requires a different technique than drilling through softer materials. Start by marking the spot where you want to drill and then use a center punch to make a small indentation in the steel. This will help guide the drill bit and prevent it from slipping. When drilling, apply steady pressure and use a slow speed to prevent the drill bit from overheating.

Drilling through hardened steel can be a challenging task, but with the right tools and techniques, you can achieve professional results. Stay focused, choose the right drill bit, and use the correct drilling technique to ensure success.

Selecting the Right Drill Bit

When drilling through hardened steel, selecting the right drill bit is crucial. The wrong drill bit can dull quickly or even break, resulting in wasted time and money. Here are some factors to consider when choosing a drill bit for hardened steel:

1. Material

The material of the drill bit is an important factor to consider. For drilling through hardened steel, it is recommended to use a drill bit made of cobalt or carbide. These materials are known for their hardness and durability, making them suitable for drilling through tough steel surfaces.

2. Bit Shape

The shape of the drill bit can also affect its performance when drilling through hardened steel. For drilling small diameter holes, a twist drill bit is commonly used. It has a pointed tip and helical flutes that help to remove chips and prevent binding. For larger diameter holes, a step drill bit or multi-purpose drill bit may be more suitable.

3. Bit Size

The size of the drill bit is determined by the diameter of the hole you want to drill. It is important to select a drill bit size that matches the desired hole size. Using a smaller or larger drill bit can result in a poorly drilled hole and may damage the drill or the workpiece.

4. Coating

Some drill bits come with a coating that can enhance their performance when drilling through hardened steel. Titanium nitride (TiN) and black oxide are common coatings used to reduce friction and increase the hardness of the drill bit. These coatings can improve the lifespan of the drill bit and make it more resistant to wear.

5. Speed and Feed Rate

When drilling through hardened steel, it is important to use the appropriate speed and feed rate to prevent overheating and premature wear of the drill bit. It is recommended to use a lower speed and a slower feed rate to allow the drill bit to cut through the steel more effectively.

6. Cutting Fluid

Using a cutting fluid can help to lubricate the drill bit and reduce heat buildup when drilling through hardened steel. The cutting fluid can also help to flush away the chips and debris, improving the drilling performance and preventing the drill bit from clogging.

By considering these factors and selecting the right drill bit, you can improve the efficiency and effectiveness of drilling through hardened steel. Remember to follow proper drilling techniques and take necessary safety precautions when working with hardened steel.

Preparing the Steel Surface

Before attempting to drill through hardened steel, it is important to properly prepare the surface. This will help ensure that the drilling process is successful and minimize the risk of damaging the drill bit or the workpiece. Here are some key steps to follow when preparing the steel surface:

- Clean the surface: Remove any dirt, grease, or other contaminants from the steel surface. This can be done using a degreaser or a solvent. Ensure that the surface is thoroughly clean before proceeding.

- Mark the drilling location: Use a marker or a punch to mark the spot where you want to drill. This will serve as a guide and help you drill accurately.

- Center punch the mark: Once the drilling location is marked, use a center punch to create a small indentation in the steel surface. This will help prevent the drill bit from wandering and provide a starting point for drilling.

- Secure the workpiece: It is important to secure the workpiece firmly in place before drilling. This can be done using clamps or a vise. Ensure that the workpiece is stable and will not move during the drilling process.

- Use cutting fluid: Applying cutting fluid to the drilling area will help keep the steel surface cool and lubricated during the drilling process. This will reduce friction and extend the life of the drill bit.

By following these preparatory steps, you can significantly improve your drilling experience and increase the chances of achieving successful results when drilling through hardened steel.

Using Lubrication and Coolants

When drilling through hardened steel, using lubrication and coolants can greatly improve the drilling process and prolong the life of your drill bit.

Lubrication

Applying a lubricant to the drill bit and the surface of the steel can help reduce friction and heat, making it easier to drill through the hardened steel. The lubricant acts as a barrier between the drill bit and the steel, reducing the chances of the bit getting stuck or damaged.

Some common types of lubricants that can be used for drilling through hardened steel include:

- Cutting fluid: Cutting fluid helps cool down the drill bit and the steel, reducing the risk of overheating and damaging the bit. It also helps to flush away metal chips and debris, making it easier to see and control the drilling process.

- Oil: Using oil as a lubricant can also help reduce heat and friction while drilling through hardened steel. Just make sure to use an oil suitable for metalworking applications.

- Grease: Grease can provide excellent lubrication and long-lasting protection for the drill bit. It is especially useful when drilling larger holes or using drill bits with a higher cutting speed.

Coolants

Coolants help to dissipate heat and keep the temperature down while drilling through hardened steel. They are especially useful when working on large or deep holes that generate a significant amount of heat.

Some commonly used coolants for drilling through hardened steel include:

- Water-based coolant: Water-based coolants are a popular choice for drilling operations as they are efficient and cost-effective. They provide excellent cooling properties and are usually mixed with water at specific ratios.

- Synthetic coolant: Synthetic coolants are formulated to provide greater lubricity and cooling, making them suitable for heavy-duty drilling operations on hardened steel.

Using Lubrication and Coolants

When using lubrication and coolants for drilling through hardened steel, it is important to follow these guidelines:

- Apply the lubricant or coolant directly to the drill bit and the surface of the steel before starting to drill.

- Use a sufficient amount of lubricant or coolant to ensure proper coverage and cooling.

- Reapply lubricant or coolant as needed during the drilling process to maintain lubrication and cooling effect.

- Use a brush or a spray bottle to apply the lubricant or coolant evenly.

- Wipe away excess lubricant or coolant after drilling is complete to prevent staining or corrosion.

By using the right lubrication and coolants, you can improve the efficiency and performance of your drilling process on hardened steel and extend the life of your drill bits.

Proper Drilling Techniques

When it comes to drilling through hardened steel, it’s important to use the right techniques to ensure success. Here are some proper drilling techniques to keep in mind:

1. Use the Right Drill Bit

Choosing the right drill bit is crucial for drilling through hardened steel. High-speed steel (HSS) drill bits are typically the best choice for this task, as they are designed to handle hard materials. Cobalt drill bits are also a good option, as they are even more durable and can withstand higher drilling speeds.

2. Start with a Pilot Hole

Before drilling the actual hole, it’s recommended to start with a pilot hole. This helps to guide the drill bit and prevent it from slipping. Use a smaller drill bit to create the pilot hole before moving on to the desired hole size.

3. Lubricate the Drill Bit

Applying lubrication to the drill bit can help reduce friction and heat buildup while drilling through hardened steel. This can extend the life of the drill bit and make the process smoother. Cutting oil or a lubricant specifically formulated for drilling through metal can be used for this purpose.

4. Use Slow Speed and High Pressure

When drilling through hardened steel, it’s important to use a slow drilling speed and apply high pressure. This helps to prevent overheating and reduces the risk of the drill bit becoming dull too quickly. Adjust the settings on your drill accordingly to achieve the optimal drilling speed and pressure.

5. Take Breaks and Cool Down

Drilling through hardened steel can generate a significant amount of heat. To prevent overheating and potential damage to the drill bit, take frequent breaks and allow the drill bit to cool down. This will help maintain its sharpness and prolong its lifespan.

6. Use Proper Safety Gear

Working with hardened steel can be hazardous, so it’s important to wear the proper safety gear. Safety glasses, gloves, and ear protection are essential to protect yourself from flying metal chips, sharp edges, and loud noise.

7. Secure the Workpiece

Before drilling, make sure the workpiece is securely clamped or held in place. This prevents the piece from moving or vibrating, which can lead to inaccurate drilling or even cause the drill bit to break.

By following these proper drilling techniques, you can increase your chances of successfully drilling through hardened steel and achieve the desired results. Remember to always prioritize safety and take your time to ensure a job well done.

Maintaining the Drill Bit

Proper maintenance of the drill bit is essential to ensure its longevity and effectiveness. Here are some tips to keep your drill bit in good condition:

-

Keep it sharp: Regularly sharpen the drill bit to maintain its sharpness and cutting efficiency. Use a grindstone or diamond wheel to remove any dull or damaged edges. Be sure to follow the manufacturer’s instructions and use proper safety precautions when sharpening.

-

Clean after use: After drilling through hardened steel, it is important to clean the drill bit thoroughly. Use a wire brush or a drill bit cleaning tool to remove any debris or metal shavings that may have accumulated. This will help prevent corrosion and maintain the drill bit’s performance.

-

Lubricate: Apply a lubricating oil or cutting fluid to the drill bit before drilling through hardened steel. This will reduce friction, heat, and wear, making the drilling process smoother and more efficient.

-

Inspect for damage: Regularly inspect the drill bit for any signs of damage or wear. If you notice any chips, cracks, or missing carbide inserts, it is important to replace the drill bit to ensure safe and accurate drilling.

-

Store properly: When not in use, store the drill bit in a dry and clean place. Avoid placing it where it may come into contact with other tools or objects that could cause damage or dullness. Consider using a protective case or container to keep the drill bit safe and organized.

By following these maintenance tips, you can extend the life of your drill bit and ensure optimal performance when drilling through hardened steel.

Safety Precautions

When drilling through hardened steel, it is important to take a number of safety precautions to protect yourself and others from injury. Follow these guidelines to ensure a safe working environment:

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles to protect your eyes from flying debris, and gloves to protect your hands from sharp edges and hot surfaces.

- Choose the Right Drill Bit: Use a drill bit specifically designed for drilling through hardened steel. Using the wrong type of drill bit can result in breakage or dulling of the bit, leading to potential accidents.

- Secure the Workpiece: Make sure the workpiece is securely clamped or held in place to prevent it from moving during drilling. This will help to maintain stability and precision while minimizing the risk of accidents.

- Use Lubrication: Apply a lubricant or cutting oil to the drill bit and the area being drilled to reduce friction and heat buildup. This will help to prolong the life of the drill bit and prevent it from overheating or breaking.

- Start with a Pilot Hole: To increase drilling accuracy and prevent the drill bit from wandering, start with a pilot hole. This smaller hole will guide the drill bit and make it easier to drill through the hardened steel.

- Drill at a Slow Speed: Drill at a low speed to minimize heat buildup and prevent the drill bit from overheating. Too much heat can cause the drill bit to dull or break, and may even cause the steel to harden further.

- Take Breaks: Drilling through hardened steel can be physically demanding. Take regular breaks to rest and prevent fatigue, which can affect your concentration and make accidents more likely to happen.

- Work in a Well-Ventilated Area: If possible, drill through hardened steel in a well-ventilated area or use a fan or exhaust system to remove any fumes or dust that may be generated during the drilling process.

- Be Mindful of Sparks: Drilling through hardened steel can produce sparks. Take precautions to ensure that sparks do not ignite flammable materials or gases in the vicinity. Keep a fire extinguisher nearby, just in case.

- Dispose of Waste Properly: Properly dispose of any waste materials, such as metal shavings or used drill bits, to prevent injuries from sharp edges and maintain a clean working environment.

By following these safety precautions, you can reduce the risk of accidents and create a safer drilling environment when working with hardened steel.

Troubleshooting Common Issues

1. Drill Bit Breakage

One common issue when drilling through hardened steel is drill bit breakage. This can be caused by a few different factors:

- The drill bit is not made of a high-speed steel or cobalt steel, which are specifically designed for drilling through hardened materials. Make sure you are using the correct type of drill bit.

- The drill speed is too high. Drilling at a high speed can cause excessive heat, leading to the drill bit becoming brittle and breaking. Try reducing the drill speed and applying cutting fluid to keep the temperature down.

- The drill bit is dull. If the drill bit is worn out or dull, it will be less effective at cutting through hardened steel and more prone to breakage. Sharpen or replace the drill bit as needed.

2. Drill Bit Skipping or Slipping

Another common issue is drill bit skipping or slipping on the hardened steel surface. This can make it difficult to create a clean and precise hole. Here are some possible solutions:

- Apply steady pressure. Maintain a consistent pressure on the drill to prevent it from skipping or slipping. Avoid pushing too hard, as this can cause the drill bit to break.

- Use a center punch. Before drilling, make an indentation with a center punch to create a starting point for the drill bit. This will help prevent slipping and ensure an accurate hole.

- Use a clamp or vise. Secure the steel piece with a clamp or vise to prevent it from moving during drilling. This will reduce the chances of the drill bit slipping on the surface.

3. Overheating

When drilling through hardened steel, overheating can be a common problem. Overheating can cause the steel to become harder and more difficult to drill. To avoid this issue:

- Use cutting fluid. Apply cutting fluid to the drill bit and the surface of the steel to lubricate and cool the area. This will help to reduce heat buildup and extend the life of the drill bit.

- Monitor the drill speed. A high drill speed can generate more heat. Adjust the drill speed accordingly to prevent overheating.

- Take breaks. If you notice the drill bit or the steel becoming overly hot, take a break to allow them to cool down. This will help ensure successful drilling without damaging the steel or the drill bit.

4. Lack of Progress

If you’re having trouble making progress while drilling through hardened steel, it could be due to a few reasons:

- The drill bit is not sharp or in good condition. Make sure to use a sharp drill bit and replace it if necessary.

- The drill speed is too low. Adjust the drill speed to a higher setting for drilling through hardened steel.

- The drill pressure is too light. Apply adequate pressure to the drill to allow it to cut into the steel effectively.

By troubleshooting these common issues, you can improve your drilling results when working with hardened steel and achieve clean and precise holes.

Post-Drilling Care for Hardened Steel

After successfully drilling through hardened steel, it is important to take proper care of the steel to maintain its integrity and prevent damage. Here are some tips for post-drilling care:

1. Remove any metal shavings or debris:

- Use a soft brush or compressed air to remove any metal shavings, chips, or debris from the drilled hole.

- Avoid using your hands or other abrasive materials to prevent scratching or damaging the drilled surface.

2. Clean the drilled hole:

- Use a suitable cleaning solution, such as a solvent or degreaser, to remove any oil, grease, or coolant residue from the drilled hole.

- Wipe the hole clean using a lint-free cloth or paper towel.

3. Inspect the drilled hole:

- Check the drilled hole for any signs of cracking or irregularities.

- If you notice any issues, consult a professional or consider re-drilling the hole to ensure its structural integrity.

4. Protect the drilled hole:

- Apply a suitable protective coating or finish to the drilled hole to prevent corrosion or rusting.

- Choose a coating that is compatible with hardened steel and follow the manufacturer’s instructions for application.

5. Properly store the hardened steel:

- Store the hardened steel in a clean, dry area away from moisture, extreme temperatures, and corrosive substances.

- Consider using protective covers or wrapping the steel in a moisture-resistant material to prevent rust or damage.

By following these post-drilling care tips, you can ensure the longevity and durability of your hardened steel and maintain its structural integrity.

FAQ:

What is hardened steel and why is it difficult to drill through?

Hardened steel is a type of steel that has undergone a heat treatment process to increase its strength and durability. It is difficult to drill through because it has a higher Rockwell hardness rating, making it resistant to drilling and requiring more force and specific techniques to penetrate.

What type of drill bit is best for drilling through hardened steel?

For drilling through hardened steel, it is recommended to use cobalt or carbide drill bits. These types of drill bits are specifically designed to handle the hardness of the steel and can withstand the heat generated during the drilling process.

What are some tips for drilling through hardened steel?

Some tips for drilling through hardened steel include using a slow speed and high torque setting on the drill, applying cutting fluid or lubricant to reduce heat and friction, using a center punch to create a starting point for the drill bit, and using steady and consistent pressure while drilling.

Can regular drill bits be used on hardened steel?

Regular drill bits are not recommended for drilling through hardened steel as they are not designed to withstand the hardness of the steel. Using regular drill bits can result in the bits becoming dull or breaking, and can also make drilling through the steel more difficult and time-consuming.

Are there any safety precautions to take when drilling through hardened steel?

Yes, there are several safety precautions to take when drilling through hardened steel. It is important to wear safety glasses to protect the eyes from any flying debris, gloves to protect the hands, and a face mask if working with cutting fluids or lubricants. Additionally, it is important to secure the workpiece properly to prevent any accidents or injuries.

Video:

![The Lapidary Bible: [3 IN 1] The Ultimate Guide for Beginners | Techniques, Tools and Tips for Turning Raw Stones into Beautiful Crafts](https://m.media-amazon.com/images/I/51g8E5SPuzL._SL160_.jpg)

![Olakin Nail Drill Tips[10 Pcs ], Nail Drill Bits Set, For Acrylic Nails, Gel And Natural, Manicure, Pedicure, Nail Care, Manicure Pedicure Set](https://m.media-amazon.com/images/I/41hgI+w6zJL._SL160_.jpg)