Step-by-Step Guide: How to Drill into a Concrete Slab

Drilling into a concrete slab may seem like a daunting task, but with the right tools and techniques, it can be a straightforward process. Whether you’re installing anchors for a new shelving system or adding electrical outlets to your garage, drilling into a concrete slab requires precision and patience. In this step-by-step guide, we will walk you through the process of drilling into a concrete slab, ensuring that you achieve professional results every time.

Step 1: Gather the Required Tools and Materials

Before you begin drilling into a concrete slab, it’s essential to gather all the necessary tools and materials. This includes a good quality hammer drill with a masonry bit, safety goggles, ear protection, a dust mask, a tape measure, and a pencil or marker. Additionally, you’ll need a broom or a vacuum cleaner to clear away any debris.

Pro tip: It’s advisable to have an extra set of drill bits on hand in case one becomes dull or breaks during the drilling process.

Step 2: Mark the Drilling Points

Before you start drilling, it’s crucial to accurately mark the drilling points on the concrete slab. Use a tape measure and a pencil or marker to mark the desired locations. Ensure that the marks are straight and aligned to prevent any errors during drilling.

Pro tip: If you’re drilling multiple holes, use masking tape to create a guide for drilling at precise intervals.

Safety Precautions for Drilling Concrete

Before you begin drilling into a concrete slab, it is important to take appropriate safety precautions to ensure your personal safety and the safety of those around you. Follow these guidelines to minimize the risk of accidents or injuries:

1. Wear Personal Protective Equipment (PPE)

When working with concrete, it is essential to wear the appropriate PPE to protect yourself from potential hazards. This should include safety glasses or goggles to protect your eyes from flying debris, a dust mask to prevent inhalation of dust particles, and ear protection to reduce noise exposure.

2. Use a Ground Fault Circuit Interrupter (GFCI)

Make sure you are using a GFCI-protected power source when drilling into concrete. This device will help protect you from electrical shock in case of contact with water or other conductive materials.

3. Inspect the Drill and Drill Bits

Before starting, make sure your drill and drill bits are in good condition. Check for any damage or wear that could affect their performance or safety.

4. Secure the Concrete Slab

Prior to drilling, ensure that the concrete slab is securely positioned and will not move or shift during drilling. This will help prevent accidents and ensure accurate drilling.

5. Mark the Drilling Points

Identify and mark the points on the concrete slab where you intend to drill. This will help ensure accurate drilling and prevent accidentally drilling into other objects or pipes.

6. Clear the Work Area

Clear the immediate area around the drilling site of any obstacles or debris. This will provide you with a safe and unobstructed workspace.

7. Use a Drill with a Side Handle

When drilling into concrete, it is recommended to use a drill with a side handle. This will provide better control and stability while drilling, reducing the risk of accidents or injury.

8. Start with a Pilot Hole

It is advisable to start with a small pilot hole when drilling into concrete. This will help guide the larger drill bit and prevent it from skidding or wandering off the desired drilling area.

9. Keep the Drill Bit Cool

Concrete drilling generates heat, which can cause the drill bit to overheat and wear out more quickly. To prevent this, periodically cool the drill bit by dipping it in water or using a cooling lubricant.

10. Work Slowly and Patiently

Take your time when drilling into concrete. Applying too much force or drilling too quickly can lead to accidents or damage to the drill bit. Use a slow and steady pace to ensure precise and safe drilling.

By following these safety precautions, you can minimize the risk of accidents and injuries while drilling into a concrete slab. Always prioritize safety and be mindful of your surroundings throughout the drilling process.

Gathering the Necessary Tools and Materials

Before you begin drilling into a concrete slab, it is important to gather all the necessary tools and materials. This will ensure that you have everything you need to complete the task successfully and efficiently.

Tools

- Hammer drill or rotary hammer: This is the main tool you will need for drilling into a concrete slab. It is designed to provide the necessary power and impact to penetrate the tough concrete surface.

- Masonry drill bit: Choose a drill bit specifically designed for drilling into concrete. These bits are typically made of carbide or hardened steel and have a special tip that can withstand the hardness of concrete.

- Protective gear: It is crucial to wear safety goggles, ear protection, and a dust mask while drilling into concrete. Concrete dust can be harmful to your eyes, ears, and lungs.

- Tape measure: Use a tape measure to determine the exact location and depth of the holes you need to drill.

- Marker or pencil: Mark the spot on the concrete slab where you need to drill your holes for accuracy.

- Vacuum or brush: After drilling, you will need to clean the holes and remove any debris or dust. A vacuum or brush will come in handy for this task.

- Extension cord (if necessary): If your drill does not have a long enough cord to reach the desired drilling location, you may need an extension cord.

Materials

- Concrete anchors or screws: These will be used to secure whatever you are mounting or installing onto the concrete slab. Make sure to choose the appropriate anchors or screws for your specific project.

- Concrete sealant (optional): If you want to protect the drilled holes or prevent any water damage, you may consider using a concrete sealant.

By gathering all the necessary tools and materials beforehand, you will be well-prepared to tackle the task of drilling into a concrete slab. This will help ensure a successful and efficient project completion.

Marking the Spot for Drilling

Before you begin drilling into a concrete slab, it’s important to mark the exact spot where you want to drill. This will ensure accuracy and prevent any unnecessary damage to the surrounding area.

Here’s how you can mark the spot for drilling:

- Clean the area: Use a broom or brush to remove any loose debris or dust from the surface of the concrete slab. This will make it easier to see the markings and will prevent any potential damage to the drill bit.

- Measure and mark: Use a measuring tape to determine the precise location where you want to drill. Make sure to double-check your measurements before marking the spot on the concrete.

- Use a pencil or chalk: Once you have determined the exact spot, use a pencil or chalk to mark a small dot or cross on the surface of the concrete. This will serve as a guide for drilling and will help you maintain accuracy.

- Double-check the placement: After marking the spot, step back and double-check the placement. Make sure it aligns with your intended purpose and ensure that there are no obstacles or hazards in the surrounding area.

By taking the time to accurately mark the spot for drilling, you can ensure that your project goes smoothly and that you achieve the desired result. Remember to always exercise caution and wear appropriate safety gear when drilling into a concrete slab.

Choosing the Right Drill Bit

When it comes to drilling into a concrete slab, choosing the right drill bit is crucial. Using the wrong drill bit can result in inefficient drilling, damaged equipment, or even personal injury. Here are some factors to consider when selecting a drill bit for concrete:

Type of Concrete

The type of concrete you are drilling into will determine the type of drill bit you should use. There are different drill bits designed for different types of concrete, such as standard concrete, reinforced concrete, or cured concrete. Make sure to choose a drill bit that is specifically designed for the type of concrete you are working with.

Drill Bit Material

The material of the drill bit will also play a role in its effectiveness. Carbide-tipped or diamond-tipped drill bits are commonly used for drilling into concrete. These materials are known for their durability and ability to withstand the hardness of concrete. High-speed steel (HSS) drill bits may also be used for less demanding drilling tasks in softer concrete.

Drill Bit Size

The size of the drill bit will depend on the diameter of the hole you need to drill. It is important to choose a drill bit that is the appropriate size for your project. Using a drill bit that is too small may result in a hole that is too narrow, while using a drill bit that is too large may cause the hole to be unstable or difficult to fill.

Flute Design

The flute design of a drill bit can affect its performance and efficiency. Drill bits with a spiral flute design are commonly used for drilling into concrete as they help to remove dust and debris from the hole as you drill. This allows for smoother drilling and prevents the bit from getting clogged.

Manufacturing Quality

The quality of the drill bit is also something to consider. Investing in a high-quality drill bit may cost more initially, but it can save you time and money in the long run. Cheap drill bits are more prone to breaking or wearing out quickly, which can lead to additional expenses in replacing them.

By considering these factors and choosing the right drill bit for your concrete drilling project, you can ensure a safer and more efficient drilling experience.

Setting up the Drill for Concrete Drilling

Step 1: Choose the right drill and drill bit

When drilling into a concrete slab, it is important to select the right drill and drill bit for the job. You will need a drill with a hammer function, also known as a hammer drill, as this is essential for drilling through the tough concrete surface.

Additionally, make sure to choose a drill bit specifically designed for concrete drilling. These drill bits often have a carbide tip, which is capable of drilling into the hard surface without wearing down quickly.

Step 2: Secure the appropriate drill bit in the drill

Before starting the drilling process, it is important to securely attach the chosen drill bit to the drill. Follow these steps to do so:

- Ensure that the drill is turned off and disconnected from the power source.

- Locate the chuck key, which is a small wrench-like tool that typically comes with the drill.

- Insert the chuck key into the holes on either side of the chuck and tighten it by turning it clockwise. This will loosen the jaws of the chuck, allowing you to insert the drill bit.

- Insert the drill bit into the chuck, making sure it is centered and straight.

- Tighten the jaws of the chuck by turning the chuck key counterclockwise until the drill bit is securely held in place.

- Remove the chuck key from the chuck, and double-check that the drill bit is tightly secured.

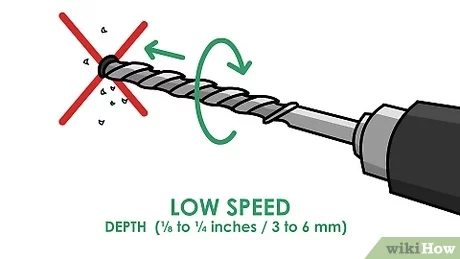

Step 3: Set the drill to the appropriate speed and mode

Concrete drilling requires the drill to be set to the correct speed and mode. Follow these instructions to set up the drill:

- Consult the manufacturer’s instructions for your specific drill to determine the correct speed setting for drilling into concrete. This speed setting is usually indicated by a symbol.

- Set the drill to the appropriate mode, which is the hammer function. This mode is usually indicated by a symbol or the word “hammer” on the drill.

- Some drills also have a variable speed control, allowing you to adjust the speed as needed. If applicable, set the drill to the desired speed for concrete drilling.

Step 4: Prepare the work area

Before you start drilling, it is important to prepare the work area. Take the following precautions:

- Clear any debris or loose material from the surface of the concrete slab to ensure a clean and stable drilling area.

- Wear safety goggles to protect your eyes from concrete dust and debris.

- Consider using hearing protection, as the drilling process can be loud.

- Have a firm and stable surface to stand on while drilling, such as a sturdy step ladder or scaffolding.

Once you have completed these steps, you are ready to start drilling into the concrete slab following the appropriate drilling technique.

Drilling into the Concrete Slab

Drilling into a concrete slab can seem like a daunting task, but with the right tools and techniques, it can be done safely and effectively. Follow these steps to drill into a concrete slab:

- Gather the necessary tools:

- Safety goggles and gloves

- Hammer drill

- Masonry drill bit

- Masonry anchors or screws

- Tape measure

- Masking tape

- Vacuum cleaner or dust brush

- Prepare the work area:

- Clear the area around the drilling location of any obstacles or debris.

- Use masking tape to mark the spot where you want to drill.

- Put on safety gear:

- Put on safety goggles and gloves to protect yourself from flying debris.

- Select the right drill bit:

- Choose a masonry drill bit that is the appropriate size for the hole you want to drill.

- Make sure the drill bit is designed for use on concrete.

- Set up the hammer drill:

- Insert the masonry drill bit into the hammer drill chuck.

- Adjust the depth setting on the hammer drill to the desired drilling depth.

- If your hammer drill has a hammer mode, switch it on for drilling into concrete.

- Drill into the concrete:

- Hold the hammer drill firmly with both hands.

- Position the drill bit on the marked spot.

- Slowly start drilling into the concrete, applying steady pressure.

- With a hammer drill, you may need to use a hammering motion to help break through the concrete.

- Keep the drill bit aligned and perpendicular to the surface.

- Clean up the debris:

- Use a vacuum cleaner or dust brush to clean up any dust or debris that has accumulated.

- Insert masonry anchors or screws:

- After drilling the hole, insert masonry anchors or screws into the hole if necessary for your project.

- Follow the instructions provided with the anchors or screws for proper installation.

Now you’re ready to drill into a concrete slab with confidence. Just remember to work slowly and carefully, and always follow safety precautions.

Removing Dust and Debris from the Hole

After drilling into the concrete slab, it is important to remove the dust and debris from the hole to ensure a secure fit for any anchors or fasteners you may be using. Here are a few steps to follow to effectively clean the hole:

1. Blow out the Dust

Using a can of compressed air or a hand-operated air blower, carefully blow out any loose dust and debris from the hole. Hold the tip of the nozzle close to the hole to ensure maximum effectiveness. Be sure to wear safety goggles and a dust mask to protect yourself from airborne particles.

2. Vacuum the Hole

Using a vacuum cleaner equipped with a hose attachment, carefully insert the hose into the hole and vacuum out any remaining dust and debris. Move the hose around the hole to ensure thorough cleaning. Empty the vacuum bag or canister to prevent clogs and maintain suction power.

3. Flush the Hole with Water

Fill a bucket with clean water and pour it into the hole. Use a small brush or a wire brush attachment on a drill to scrub the sides of the hole and remove any stubborn dust or debris. This step will also help to remove any residual concrete dust, ensuring a clean surface for anchors or fasteners.

4. Dry the Hole

Using a clean cloth or a compressed air tool, carefully dry the hole. Moisture can interfere with the adhesion of anchors or fasteners, so it is important to completely dry the hole before proceeding. Check the hole for any remaining dust or debris and repeat the cleaning process if necessary.

By taking the time to properly clean the hole, you can ensure a secure and stable fit for your anchors or fasteners, reducing the risk of them coming loose or causing damage to the concrete slab.

Tips for Successful Concrete Drilling

1. Choose the Right Drill Bit

When drilling into concrete, it is important to use a drill bit specifically designed for masonry. These drill bits are made from carbide or diamond, which can handle the hardness of the concrete. Using the wrong type of drill bit can result in dulling or breaking the bit, as well as difficulty in drilling.

2. Mark the Drilling Point

Before starting to drill, mark the exact spot where you want to drill. This can be done by using a pencil or a marker. It is crucial to be precise with the marking to ensure that the hole is drilled in the correct location.

3. Start with a Small Pilot Hole

For concrete drilling, it is recommended to start with a small pilot hole before progressing to a larger hole. This will help guide the drill bit and prevent it from wandering off the desired drilling path. The pilot hole can be made with a smaller-sized masonry bit.

4. Use Water to Keep the Drill Bit Cool

Drilling into concrete can generate a significant amount of heat. To prevent the drill bit from overheating, it is advisable to spray water on the drilling area periodically. This will help keep the drill bit cool and prolong its lifespan.

5. Apply Steady Pressure

When drilling into concrete, it is crucial to apply steady, even pressure. Pushing too hard can cause the drill bit to get stuck or break, while not applying enough pressure can result in slow progress. Maintaining a consistent pressure will help ensure smooth and efficient drilling.

6. Clean the Dust and Debris

After drilling each hole, it is important to clean out the dust and debris that accumulate in the hole. This can be done using a vacuum or a brush. Removing the debris will ensure a clean and clear hole for further work, such as inserting anchors or screws.

7. Wear Safety Gear

When drilling into concrete, it is important to wear the necessary safety gear. This includes safety glasses to protect your eyes from flying debris, a dust mask to prevent inhalation of concrete dust, and gloves to protect your hands. Safety should always be a priority when working with power tools.

8. Take Breaks

Drilling into concrete can be a physically demanding task. It is important to take breaks when needed to prevent fatigue. This will not only help maintain accuracy and efficiency but also reduce the risk of injury from overexertion.

FAQ:

What equipment do I need to drill into a concrete slab?

To drill into a concrete slab, you will need a hammer drill with a masonry bit, safety goggles, a dust mask, earplugs, a tape measure, a pencil, a vacuum cleaner, and a hammer.

What size of masonry bit should I use?

The size of the masonry bit depends on the size of the anchor or screw you plan to use. It is recommended to use a bit that is slightly smaller in diameter than the anchor or screw to ensure a secure hold.

How do I mark the drilling location on the concrete slab?

To mark the drilling location, measure and mark the spot on the concrete slab using a tape measure and a pencil. Make sure to double-check the measurement to ensure accuracy.

What safety precautions should I take when drilling into a concrete slab?

When drilling into a concrete slab, it is important to wear safety goggles to protect your eyes from flying debris, a dust mask to prevent inhaling dust particles, and earplugs to protect your hearing. It is also advisable to use a vacuum cleaner to clean up the dust after drilling.

How deep should I drill into the concrete slab?

The depth of the hole depends on the length of the anchor or screw you plan to use. It is recommended to drill the hole at least 1/4-inch deeper than the length of the anchor or screw to ensure a secure hold.

Video: