Sharpening Brad Point Drill Bits: A Complete Guide

Brad point drill bits are a popular choice for woodworking projects due to their ability to produce clean and precise holes. However, like any cutting tool, brad point drill bits can become dull over time, leading to poor performance and frustrating results. Fortunately, sharpening these drill bits is a relatively simple process that can be done at home with a few basic tools.

In this complete guide, we will walk you through the step-by-step process of sharpening your brad point drill bits. We will cover the tools and materials you will need, as well as the techniques and tips for achieving a razor-sharp cutting edge. Whether you are a seasoned woodworker looking to prolong the life of your drill bits or a beginner hoping to improve your drilling accuracy, this guide is for you.

Sharpening brad point drill bits not only improves their performance but also helps to extend their lifespan. By maintaining a sharp cutting edge, you can reduce the risk of burning the wood, reduce the amount of force required to drill, and achieve cleaner, more precise holes. So, if you are ready to bring your drill bits back to their original cutting power, let’s dive into the world of sharpening brad point drill bits.

What is Sharpening?

Sharpening is the process of restoring the cutting edge of a tool to its optimal condition. Over time, the edges of tools can become dull or worn down, reducing their effectiveness and making them less efficient. Sharpening involves removing material from the edge, creating a new, sharp edge that can effectively cut or shape material.

There are various tools and methods available for sharpening different types of tools, such as knives, scissors, chisels, and drill bits. Each tool requires a specific sharpening technique, as the angle and shape of the edge can vary. Sharpening typically involves the use of abrasive tools, such as sharpening stones, files, or grinding wheels. These tools are used to remove material from the edge of the tool, creating a new, sharp edge.

Sharpening not only improves the cutting performance of tools but also prolongs their lifespan. Dull tools can cause frustration and fatigue, as they require more effort to use. By keeping tools sharp, you can work more efficiently and with greater precision. Regular sharpening also helps to prevent accidents, as dull tools are more likely to slip and cause injuries.

It’s important to note that sharpening should be done carefully and accurately to avoid damaging the tool or creating an uneven edge. Proper technique and the use of appropriate tools are essential for achieving the best results.

In summary, sharpening is the process of restoring the cutting edge of a tool to its optimal condition. It improves cutting performance, prolongs the lifespan of tools, and helps to prevent accidents. By understanding the principles of sharpening and using the right tools and techniques, you can keep your tools sharp and efficient.

Importance of Sharpening Brad Point Drill Bits

Sharpening brad point drill bits is an essential task for any woodworker or DIY enthusiast who wants to achieve clean, accurate, and effortless drilling. A dull or improperly sharpened brad point drill bit can lead to numerous problems, such as inaccurate drilling, splintering of the wood, and even damage to the drill bit itself.

Here are some reasons why sharpening brad point drill bits is important:

- Improved drilling performance: Sharpening the brad point drill bits ensures that they can cut through the wood with ease and precision. A sharp drill bit will create clean and accurate holes without any tear-out or splintering of the wood.

- Extended tool life: When brad point drill bits are sharpened regularly, they maintain their cutting edges and overall effectiveness. By removing any dull or worn-out areas on the drill bit, sharpening helps to extend its lifespan and prevents the need for frequent replacement.

- Cost savings: By sharpening brad point drill bits instead of replacing them, woodworkers can save money in the long run. Sharpening tools can be relatively inexpensive, and with some practice, individuals can easily perform this task themselves.

- Consistency and accuracy: Properly sharpened brad point drill bits ensure consistent and accurate drilling results. This is particularly important when working on projects that require precise measurements and hole placements.

- Increase safety: Sharpened brad point drill bits reduce the likelihood of accidents or injuries. Dull drill bits are more prone to slipping, which can lead to the tool losing control and causing harm to the user or damaging the workpiece.

Regularly sharpening brad point drill bits is a simple yet important maintenance task that can greatly enhance the performance and lifespan of these tools. By investing some time and effort into sharpening, woodworkers can ensure clean holes, accurate drilling, and a smoother woodworking experience overall.

Tools and Materials Needed

- Brad point drill bits

- Bench grinder

- Grinding wheel

- Diamond file

- Sharpening jig

- Safety glasses

- Dust mask

- Workbench or table

- Vise

- Marker or pen

Before you begin sharpening your brad point drill bits, gather all the necessary tools and materials. These will ensure that you have everything you need to properly and safely sharpen your drill bits.

It’s important to have a set of brad point drill bits that need sharpening. These are the bits that you will be working on. You’ll also need a bench grinder with a grinding wheel for the initial sharpening process.

In addition to the bench grinder, you’ll need a diamond file to fine-tune the sharpened points. This will help ensure that the points are sharp and accurate.

A sharpening jig is a useful tool to have as it will hold the drill bits securely during the sharpening process. This will help maintain consistent angles and prevent slipping or accidents.

Don’t forget to prioritize safety. Wear safety glasses to protect your eyes from any debris or sparks that may be generated during sharpening. A dust mask is also recommended to protect yourself from any potential airborne particles.

To set up your work area, use a sturdy workbench or table. Make sure it’s well-lit and provides enough space for you to comfortably work on your drill bits. A vise can be helpful to secure the brad point drill bits while you’re sharpening.

Lastly, have a marker or pen handy to mark the cutting edge of the brad point drill bits. This will help you keep track of which parts you have already sharpened.

Step-by-Step Guide to Sharpening Brad Point Drill Bits

Materials Needed:

- Brad point drill bit

- Bench grinder

- Sharpening jig or angle guide

- Safety glasses

- Bench vise

- Sharpening stone or diamond file

Step 1: Prepare Your Workspace

Before starting the sharpening process, make sure you have a clean and well-lit workspace. Secure your bench grinder to a sturdy surface and ensure it is in proper working condition. Wear your safety glasses to protect your eyes from any debris or sparks.

Step 2: Secure the Drill Bit

Using a bench vise, securely clamp the brad point drill bit in place. Make sure it is held tightly and will not shift during the sharpening process. This will ensure accuracy and safety.

Step 3: Set the Angle Guide

If you are using a sharpening jig or angle guide, set it to the appropriate angle for your brad point drill bit. This angle is typically around 60 degrees, but refer to the manufacturer’s instructions or consult a sharpening chart for the exact angle.

Step 4: Grinding

Turn on your bench grinder and gently bring the brad point drill bit into contact with the grinding wheel. Move the bit back and forth across the wheel to evenly sharpen the cutting edges. Be cautious not to apply too much pressure, as this can cause excessive heat and damage to the bit.

Step 5: Check the Cutting Edges

After grinding, inspect the cutting edges of the brad point drill bit. They should be evenly sharpened and free from any chips or nicks. If necessary, repeat the grinding process until the cutting edges are sharp and uniform.

Step 6: Honing

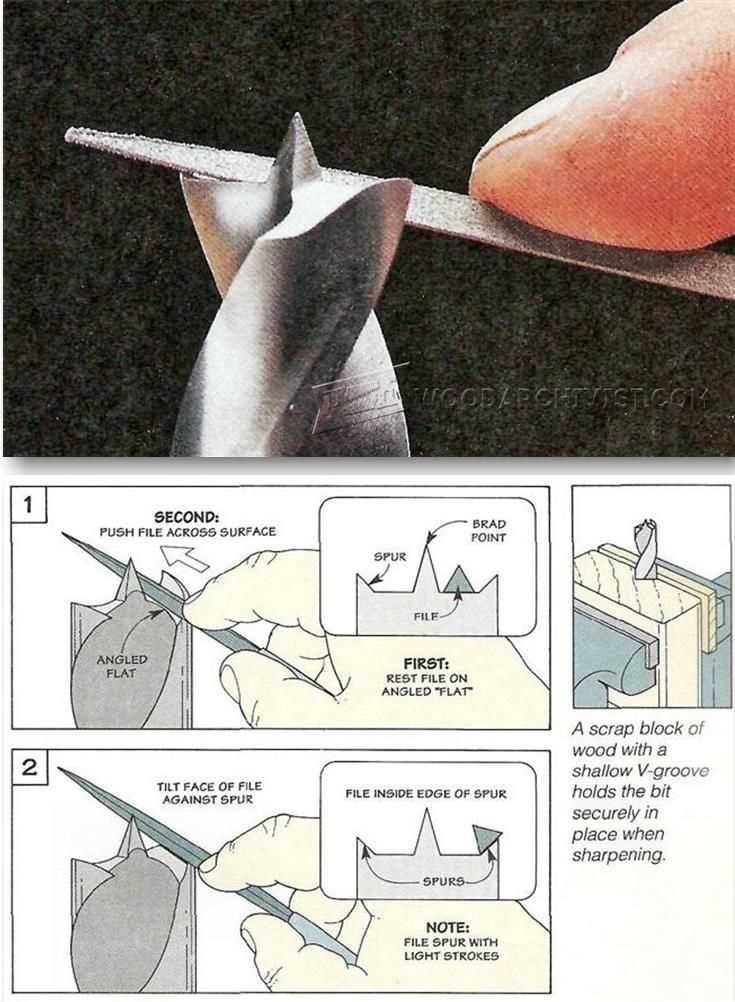

Using a sharpening stone or diamond file, lightly hone the cutting edges of the brad point drill bit. This will remove any burrs or rough areas left from the grinding process and ensure a smooth cutting action.

Step 7: Test the Bit

Before using the sharpened brad point drill bit, test it on a scrap piece of wood. Make sure it creates clean and precise holes without any tearing or splintering. If necessary, make any additional adjustments or touch-ups to achieve the desired cutting performance.

Step 8: Clean and Store

After sharpening, clean the brad point drill bit by wiping it with a clean cloth or brush. Store the sharpened bit in a secure location to prevent damage or dulling before its next use.

Tips:

- Regularly sharpen your brad point drill bits to maintain optimal cutting performance.

- Avoid overheating the drill bit while grinding, as this can cause the metal to lose its hardness.

- Follow the manufacturer’s instructions for sharpening your specific brad point drill bit, as different brands and models may require different techniques.

Conclusion

By following this step-by-step guide, you can effectively sharpen your brad point drill bits and achieve clean and precise holes in your woodworking projects. Remember to always prioritize safety and wear protective gear during the sharpening process. With proper maintenance, your brad point drill bits will continue to perform at their best for years to come.

Tips and Tricks for Sharpening Brad Point Drill Bits

1. Use a drill bit sharpener

Investing in a good quality drill bit sharpener can make the sharpening process much easier and more efficient. These sharpeners are specifically designed to sharpen drill bits and can help ensure that you maintain the correct geometry and angles of the brad point bits.

2. Clean the drill bit before sharpening

Before sharpening your brad point drill bit, it’s important to clean it thoroughly. Use a wire brush or a cleaning solution to remove any debris or buildup that may be affecting its cutting ability. This will help ensure a smooth and effective sharpening process.

3. Sharpen the cutting edges

When sharpening brad point drill bits, it’s essential to focus on the cutting edges. These are the parts of the bit that actually make contact with the material being drilled. Use a sharpening stone or a drill bit sharpener to carefully sharpen and reshape the cutting edges to restore their sharpness.

4. Maintain the correct angles

Brad point drill bits have specific angles that contribute to their drilling efficiency. When sharpening the bit, make sure to maintain these angles to preserve the bit’s performance. Pay attention to the lip angle, point angle, and relief angle while sharpening.

5. Take your time

Sharpening drill bits, especially brad point bits, requires patience and attention to detail. Take your time to ensure each cutting edge is sharpened properly. Rushing through the process may result in a poorly sharpened bit that won’t perform as desired.

6. Test the bit after sharpening

After sharpening your brad point drill bit, it’s important to test it on a scrap piece of wood or material similar to what you’ll be drilling. This will help you ensure that the bit is cutting cleanly and effectively. If you notice any issues, recheck your angles and make any necessary adjustments.

7. Regular maintenance is key

To keep your brad point drill bits performing at their best, it’s important to regularly maintain and sharpen them. Rather than waiting until a bit is completely dull, make it a habit to check and sharpen them after a certain amount of use. This will help prolong the lifespan and performance of your bits.

8. Use a honing guide for precision

If you want to achieve even more precise sharpening results, consider using a honing guide. This tool can help you maintain consistent angles and create sharp cutting edges. It’s especially useful for those who want to achieve professional-level sharpening results.

9. Follow safety precautions

When sharpening drill bits, it’s important to prioritize safety. Wear protective gloves and goggles to prevent any potential injuries. Additionally, make sure to secure the bit properly during the sharpening process to avoid any accidents.

10. Consider professional sharpening services

If you’re unsure about sharpening brad point drill bits yourself or don’t have the necessary tools, consider using professional sharpening services. These professionals have the expertise and specialized equipment to sharpen your drill bits to perfection.

By following these tips and tricks, you can ensure that your brad point drill bits are always sharp and ready to tackle any drilling task with precision and efficiency.

Common Mistakes to Avoid

When it comes to sharpening brad point drill bits, there are several common mistakes that people make. These mistakes can result in a dull or ineffective drill bit, and can even lead to accidents or damage to your workpiece. Here are some mistakes to avoid:

- Not using the correct sharpening tools: Using the wrong tools to sharpen your brad point drill bits can lead to improper sharpening and can even damage the bit. It is important to use the right tools, such as a sharpening stone or a drill bit sharpener, to ensure a proper and effective sharpening process.

- Not following the correct sharpening technique: Sharpening a brad point drill bit requires following a specific technique. Not following the correct technique can result in an uneven or ineffective sharpening job. It is important to research and understand the proper technique before attempting to sharpen your drill bits.

- Sharpening too aggressively: Sharpening a brad point drill bit requires a delicate touch. Sharpening too aggressively can remove too much material from the bit and can even alter its shape or angle. It is important to sharpen the bit gently and incrementally to ensure the best results.

- Ignoring the need for regular sharpening: Brad point drill bits, like all drill bits, will eventually become dull with use. Ignoring the need for regular sharpening can result in poor drilling performance and can even damage your workpiece. It is important to regularly inspect and sharpen your drill bits to maintain their effectiveness.

- Overlooking the importance of proper storage: Proper storage of brad point drill bits can help prevent damage and maintain their sharpness. Storing drill bits in a dry and protected environment can help prevent rust or other forms of damage. It is important to invest in proper storage solutions, such as drill bit cases or organizers, to keep your drill bits in good condition.

By avoiding these common mistakes, you can ensure the longevity and effectiveness of your brad point drill bits. Proper sharpening techniques and regular maintenance will help you achieve clean and accurate drilling results for years to come.

FAQ:

How often do I need to sharpen my brad point drill bits?

Brad point drill bits should be sharpened whenever they start to dull or become less effective. This can vary depending on how often you use them and the types of materials you are drilling into. It’s a good idea to inspect your bits regularly and sharpen them as needed to maintain their performance.

What is the best way to sharpen brad point drill bits?

There are several methods that can be used to sharpen brad point drill bits. One common method is to use a bench grinder. You can carefully hold the bit against the grinding wheel at the correct angle and rotate it as needed to sharpen the cutting edges. Another option is to use a specialized drill bit sharpener. These tools are designed specifically for sharpening drill bits and can provide consistent results.

Can I sharpen brad point drill bits by hand?

Yes, it is possible to sharpen brad point drill bits by hand. However, it can be more challenging to achieve consistent results compared to using a bench grinder or drill bit sharpener. If you choose to sharpen by hand, it’s important to maintain the correct angle and apply even pressure to ensure the cutting edges are properly sharpened.

What are the signs that my brad point drill bits need sharpening?

There are a few signs that indicate your brad point drill bits may need sharpening. If you notice that the bits are not cutting smoothly or are creating more heat than usual, this could be a sign of dullness. Additionally, if the bits are leaving rough or ragged holes instead of clean, crisp holes, it may be time to sharpen them.

Can I use a file to sharpen my brad point drill bits?

While it is possible to use a file to sharpen brad point drill bits, it is not recommended. Files are not typically designed for sharpening drill bits and may not provide the precise angle and edge required for optimal cutting performance. It is best to use a bench grinder or drill bit sharpener for sharpening brad point drill bits.

Is it necessary to sharpen both the spurs and the cutting edges of brad point drill bits?

Yes, it is important to sharpen both the spurs and the cutting edges of brad point drill bits. The spurs are responsible for starting the hole and should be sharp to ensure clean and accurate drilling. The cutting edges also need to be sharp to effectively cut through the material. Sharpening both parts of the bit will help maintain its overall performance.

Should I lubricate my drill bits while sharpening them?

Lubricating your drill bits while sharpening can help reduce friction and heat buildup, which can prolong the life of the bits. Using a lubricant like cutting oil or even water can help keep the bit cool during sharpening and prevent damage. It’s a good idea to apply a small amount of lubricant to the bit before and during the sharpening process.

Video: