Methods for Drilling Through Plexiglass Safely

Drilling through plexiglass can be a tricky task, as the material is prone to cracking and shattering if not done correctly. However, with the right techniques and tools, you can successfully drill through plexiglass without any damage. In this article, we will discuss some of the best methods for drilling through plexiglass safely.

1. Use a drill bit specifically designed for plexiglass: One of the most important steps in drilling through plexiglass is using the right drill bit. Regular drill bits can cause the material to crack or chip. Look for a special drill bit that is designed for use with plexiglass. These bits have a sharper point and lower cutting angles, which helps prevent cracking.

2. Secure the plexiglass firmly: Before drilling, make sure the plexiglass is securely clamped or held in place. This will prevent it from moving or vibrating while drilling, reducing the risk of cracking. You can use clamps, double-sided tape, or a vice to secure the plexiglass.

3. Start with a small pilot hole: Instead of drilling the final hole directly, it is advisable to start with a pilot hole. Use a smaller drill bit to create a small indentation in the plexiglass. This will make it easier for the larger drill bit to follow the path and reduce the risk of cracking.

4. Use a slow drilling speed: When drilling through plexiglass, it’s important to use a slow drilling speed. High speeds can generate excessive heat, which can cause the plexiglass to melt or crack. Set your drill to a slower speed and apply gentle pressure while drilling.

Note: It is always a good idea to practice drilling on a scrap piece of plexiglass before working on your actual project.

By following these methods, you can ensure a smooth and safe drilling experience when working with plexiglass. Remember to wear protective eyewear and gloves to protect yourself from any debris. Happy drilling!

Drilling Through Plexiglass: Safety First

Introduction

Drilling through plexiglass requires careful attention to safety procedures in order to prevent damage and injury. Plexiglass, also known as acrylic glass, is a lightweight and shatter-resistant material commonly used in various applications, such as signage, windows, and protective barriers. Unlike drilling through other materials, drilling through plexiglass requires a specific approach to avoid cracks and fractures. In this article, we will outline some safety guidelines and methods to drill through plexiglass effectively.

Safety Precautions

Before starting the drilling process, it is essential to take the following safety precautions:

- Wear safety glasses to protect your eyes from any potential flying debris.

- Wear gloves to protect your hands from sharp edges that may be created while drilling.

- Work in a well-ventilated area or use a fume extractor when drilling to prevent inhaling any potentially harmful fumes.

Tools and Materials

To drill through plexiglass safely, you will need the following tools and materials:

- Power drill: Use a drill with adjustable speed settings to ensure better control over the drilling process.

- Drill bits: Choose a drill bit specifically designed for drilling through plexiglass or use a sharp twist drill bit.

- Clamps: Use clamps to secure the plexiglass in place during drilling to prevent it from moving and causing cracks.

- Masking tape: Apply masking tape on the drilling area to reduce the risk of chipping and provide additional support.

- Lubricant: Apply a small amount of lubricant, such as silicone spray or cutting fluid, to the drill bit to reduce friction and prevent melting or cracking.

- Measuring tape and pencil: Use these tools to accurately mark the drilling points on the plexiglass.

Drilling Process

Follow these steps to drill through plexiglass safely:

- Measure and mark the drilling points on the plexiglass using a measuring tape and pencil.

- Secure the plexiglass in place using clamps, ensuring it does not move during the drilling process.

- Apply a small strip of masking tape over the drilling point to prevent chipping and provide support.

- Select the appropriate drill bit for plexiglass and insert it into the power drill.

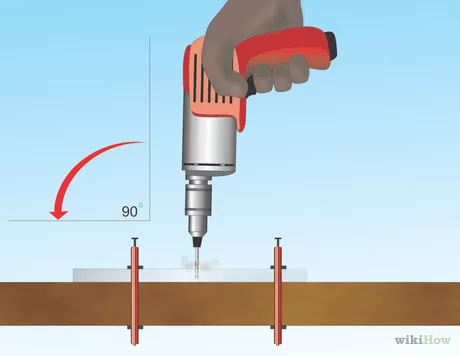

- Set the drill to a low speed to avoid overheating and melting the plexiglass. Start drilling with light pressure.

- Use a steady and controlled motion to drill through the plexiglass. Avoid applying too much pressure or drilling too quickly, as this can cause cracks.

- Periodically lift the drill bit to clear away any shavings and prevent overheating.

- Once the hole is drilled, remove the masking tape and clean any debris from the surface.

Conclusion

By following these safety guidelines and methods, you can drill through plexiglass safely while minimizing the risk of damage and injury. Remember to always prioritize safety and take your time during the drilling process. With the right tools and techniques, you can achieve clean and precise holes in plexiglass for your desired applications.

The Importance of Proper Equipment

When it comes to drilling through plexiglass, using the right equipment is crucial for ensuring a safe and effective drilling process. Using improper equipment can lead to cracked or shattered plexiglass, as well as potential injuries.

Choosing the Right Drill Bit

One of the most important pieces of equipment for drilling through plexiglass is the drill bit. It is recommended to use a drill bit specifically designed for use with plexiglass, such as a carbide-tipped drill bit or a diamond drill bit. These drill bits have a sharper cutting edge and are less likely to chip or crack the plexiglass.

Additionally, it is important to choose a drill bit with a smaller diameter than the hole you want to create. This will help prevent excessive force and reduce the risk of the plexiglass breaking.

Using a Drill Press or Clamp

Another important piece of equipment is a drill press or a clamp. These tools can help stabilize the plexiglass, preventing it from moving or vibrating during the drilling process. This is especially important because plexiglass is more prone to cracking under pressure or with rapid movements.

By using a drill press or clamp, you can ensure a more precise and controlled drilling experience, reducing the risk of accidents or damage to the plexiglass.

Applying Proper Pressure

When drilling through plexiglass, it is crucial to apply the right amount of pressure. Using too much force can cause the plexiglass to crack or shatter, while using too little force can result in an ineffective drilling process.

It is recommended to start with light pressure and gradually increase it as you drill. This helps to minimize the risk of damage and allows for better control over the drilling process. It is also important to keep the drill bit moving at a steady pace to prevent excessive heat buildup.

Using Safety Measures

Lastly, using proper safety measures is essential when drilling through plexiglass. Always wear safety goggles and protective gloves to prevent any potential injuries from flying debris or sharp edges. Additionally, consider using a dust mask to protect yourself from inhaling any fine particles.

Remember to also always work in a well-ventilated area to minimize the risk of inhaling any fumes or vapors that may be released during the drilling process. Safety should be the top priority when working with plexiglass and any other materials.

By using the right equipment and following proper safety precautions, you can ensure a safe and successful drilling experience when working with plexiglass.

Choosing the Right Drill Bit

When drilling through plexiglass, it is important to use the right type of drill bit to prevent cracking or breaking the material. Plexiglass is a type of plastic that is more brittle than other materials, so using the wrong drill bit can cause damage.

1. Carbide Tipped Drill Bit

A carbide tipped drill bit is specifically designed for drilling through hard and brittle materials like plexiglass. The carbide tip helps to reduce the risk of cracking or chipping the material, as it provides a strong and sharp cutting edge. These drill bits are widely available and can be used with a regular handheld drill or drill press.

2. Brad Point Drill Bit

A brad point drill bit is another good option for drilling through plexiglass. These bits have a sharp center point that helps to guide the bit into the material and prevent slippage. The edges of the bit are also designed to create clean and precise holes. Brad point drill bits come in various sizes and can be used with both handheld drills and drill presses.

3. Step Drill Bit

A step drill bit, also known as a cone drill bit, is a versatile option that can be used for drilling through plexiglass. These bits have a conical shape with multiple stepped levels, allowing you to drill different hole sizes with just one bit. Step drill bits are particularly useful when you need to drill multiple holes of different sizes in a short amount of time.

4. Diamond Drill Bit

If you need to drill larger or more precise holes in plexiglass, a diamond drill bit is a good choice. These drill bits have a diamond-coated tip that provides extra strength and durability. Diamond drill bits are commonly used for drilling holes in glass and other hard materials, making them suitable for plexiglass as well. However, they can be more expensive than other types of drill bits.

When choosing a drill bit for plexiglass, it’s important to consider the size of the hole you need to drill and the type of plexiglass you’re working with. It’s also a good idea to start with a smaller pilot hole and gradually increase the size to minimize the risk of cracking or shattering the material. Using the right drill bit and drilling technique will help you achieve clean and precise holes in plexiglass.

Preparing the Plexiglass Surface

Before drilling through plexiglass, it is important to properly prepare the surface to prevent cracking or chipping. The following steps will help ensure a safe and successful drilling process:

- Clean the surface: Start by cleaning the plexiglass surface using a mild soap or detergent and water. Avoid using harsh chemicals or abrasive cleaners, as they can damage the material.

- Measure and mark: Use a measuring tape and a pencil to measure and mark the desired drilling location on the plexiglass. Double-check the measurements to ensure accuracy.

- Create a drilling guide: If drilling multiple holes or a series of holes, it is helpful to create a drilling guide. This can be done by placing a piece of masking tape or painter’s tape over the marked locations and then using a pencil or marker to make a small “x” where the holes should be drilled.

- Clamp or secure the plexiglass: To prevent the plexiglass from moving during the drilling process, it is important to clamp or secure it in place. This can be done using clamps, a vise, or by securing it to a workbench with masking tape.

- Wear safety goggles: Safety goggles should be worn throughout the drilling process to protect the eyes from any flying debris or fragments.

- Choose the right drill bit: Select a drill bit specifically designed for drilling through plexiglass. Avoid using standard drill bits, as they can cause the material to crack or chip. Diamond-tipped or carbide-tipped drill bits are recommended for plexiglass.

- Use a low drill speed: Set the drill to a low speed setting to avoid overheating or melting the plexiglass. High speeds can cause friction, which can lead to cracking or melting of the material.

- Apply steady pressure: When drilling, apply steady and consistent pressure to avoid putting too much force on the plexiglass. Let the drill bit do the work and avoid forcing it through the material.

- Use lubrication: Applying a small amount of lubricant, such as water or cutting oil, to the drill bit can help reduce heat and friction during the drilling process. This can help prevent cracking or melting of the plexiglass.

- Drill at a slight angle: To avoid cracking or chipping, it is recommended to drill at a slight angle instead of drilling straight down. This can help distribute the force more evenly and reduce the risk of damage.

By following these steps and taking the necessary precautions, you can safely and effectively drill through plexiglass without damaging the material.

Practicing Proper Drilling Technique

Drilling through plexiglass requires careful technique to avoid cracking or shattering the material. By following these steps, you can ensure a successful drilling process.

1. Prepare the Work Area

Before drilling, make sure the work area is clean and well-lit. Remove any debris or obstructions that could interfere with the drilling process. Use clamps to secure the plexiglass in place, preventing it from moving during drilling.

2. Select the Right Drill Bit

Choosing the right drill bit is crucial for drilling through plexiglass. Use a high-speed steel or carbide-tipped bit that is specifically designed for drilling plastics. These bits have a sharp cutting edge and will reduce the risk of cracks or chips.

3. Mark the Drilling Point

Use a marker or a piece of tape to clearly mark the drilling point on the plexiglass. This will help guide the drill bit and ensure precise placement. Double-check the position to avoid any mistakes.

4. Start with a Pilot Hole

Begin drilling with a small pilot hole. This will help prevent the drill bit from skidding or skating across the surface of the plexiglass. Start at a low speed and apply gentle pressure as you drill the pilot hole.

5. Drill at a Slow Speed

When drilling into plexiglass, it is important to maintain a slow speed throughout the process. High speeds can generate heat and cause the material to melt or crack. Slow and steady drilling is key to avoid damaging the plexiglass.

6. Use Cooling Lubricant

Applying a cooling lubricant, such as water or drilling oil, can help reduce heat buildup during drilling. Dab a small amount of lubricant onto the drill bit or directly onto the drilling point to keep the plexiglass cool and prevent melting.

7. Backing Plate or Scrap Material

Using a backing plate or a scrap piece of plexiglass beneath the workpiece can help prevent chipping or splintering on the backside. This extra support acts as a buffer and provides stability, ensuring a clean and smooth drilling process.

8. Monitor the Drilling Process

As you drill through the plexiglass, pay close attention to the drilling process. Keep your hands steady and avoid applying excessive force. If you notice any signs of cracking or chipping, stop immediately and assess the situation.

9. Deburr and Clean

After drilling is complete, use a deburring tool to remove any burrs or rough edges around the drilled hole. Clean the plexiglass using a mild soap and water solution, or a specialized cleaner designed for plastic materials.

By following these steps and practicing proper drilling technique, you can safely and effectively drill through plexiglass without causing damage to the material.

Cooling and Lubrication for Plexiglass

Drilling through plexiglass can generate heat and friction, which can cause the material to crack or melt. To prevent this, it is important to use cooling and lubrication techniques when drilling through plexiglass.

Cooling:

Using a cooling method can help dissipate heat generated during drilling and keep the plexiglass from melting or cracking. Here are some cooling techniques to consider:

- Water: Place a container of water near the drilling area and dip the drill bit in water frequently while drilling. This will help to cool down the bit and reduce heat buildup.

- Coolant spray: Apply a coolant spray specifically designed for drilling through plexiglass. This can provide a constant cooling effect and reduce the chances of overheating.

Lubrication:

Lubrication can help reduce friction between the drill bit and the plexiglass, making the drilling process smoother and preventing cracks or melting. Here are some lubrication techniques to consider:

- Wax: Rubbing a bar of wax or a wax pencil along the drill bit can act as a lubricant. This will create a film between the bit and the plexiglass, reducing friction and heat buildup.

Precautions:

While cooling and lubrication techniques can help protect the plexiglass during drilling, it is important to take some additional precautions:

- Wear safety goggles and gloves to protect yourself from flying debris or accidental injury.

- Use a drill bit specifically designed for drilling through plexiglass. These bits have a sharper point and a slower cutting speed to prevent cracking or melting of the material.

- Start with a small pilot hole and gradually increase the size of the hole to prevent excessive heat buildup.

- Drill at a low speed and with light pressure to minimize the chances of cracking or melting the plexiglass.

By using proper cooling and lubrication techniques, along with taking necessary precautions, you can safely drill through plexiglass without damaging the material. Remember to always test any technique on a scrap piece of plexiglass before working on your final project.

Dealing with Potential Challenges

When drilling through plexiglass, there can be some potential challenges that you may encounter. It is important to be aware of these challenges and take proper precautions to ensure a safe drilling process.

1. Cracking or shattering

Plexiglass is a brittle material and can crack or shatter if not drilled properly. To prevent this, it is essential to use the correct drill bit and drilling technique. Choose a drill bit specifically designed for plexiglass, such as a carbide-tipped or diamond-tipped drill bit. These drill bits have a sharper cutting edge and are less likely to cause cracks or shattering.

To further reduce the risk of cracking or shattering, apply masking tape over the area where you plan to drill. This will help to provide additional support and prevent the plexiglass from splintering.

2. Melting or burning

Plexiglass can melt or burn if the drill bit generates too much heat during the drilling process. To prevent this, it is important to use a slow speed setting on your drill and apply steady but gentle pressure. Avoid high speeds, as they generate more heat and increase the risk of melting or burning the plexiglass.

You can also use a lubricant, such as water or cutting oil, to cool down the drill bit and reduce the heat generated. Apply the lubricant to the drill bit and the area being drilled, and periodically pause drilling to allow the plexiglass to cool down.

3. Chip or crack prevention

When drilling through plexiglass, it is important to prevent chipping or cracking around the drilled hole. One way to do this is to use a pilot hole. Start by drilling a small hole with a drill bit that is smaller than the final hole size. This will help to guide the larger drill bit and reduce the risk of chipping or cracking.

You can also use a clamping device or jig to securely hold the plexiglass in place while drilling. This will ensure stability and prevent any unintended movement that could lead to chipping or cracking.

4. Noise and vibration

Drilling through plexiglass can create noise and vibration, which can be uncomfortable and potentially unsafe. To reduce noise and vibration, consider using a drill with a rubberized handle or wearing ear protection. It is also helpful to drill at a slower speed and apply consistent pressure to minimize any sudden movements that could cause excessive vibration.

By addressing these potential challenges and taking the necessary precautions, you can drill through plexiglass safely and effectively.

Cleaning Up After Drilling

After you have finished drilling through plexiglass, it is important to clean up any debris and take proper precautions to ensure a safe and tidy work area.

1. Remove the protective covering: If you had placed a protective covering on the plexiglass surface, carefully remove it after drilling. This will help prevent any scratches or damages to the plexiglass and ensure a clean finish.

2. Collect the debris: Use a small brush or a soft cloth to collect any debris or dust that may have accumulated around the drilling area. Be gentle to avoid scratching the plexiglass surface.

3. Vacuum or blow away debris: For larger amounts of debris, use a vacuum cleaner set to a low power setting or a handheld air blower to remove the debris from the area. This will help prevent any mess or debris from spreading.

4. Wipe down the plexiglass: Use a soft, lint-free cloth or a microfiber cloth to wipe down the plexiglass surface. Dampen the cloth slightly with water or a mild glass cleaner to remove any remaining dust or residue. Avoid using harsh chemicals or abrasive materials that can damage the plexiglass.

5. Inspect for any damages: After cleaning, inspect the plexiglass for any damages or cracks that might have occurred during the drilling process. If you notice any damages, consider replacing or repairing the plexiglass to maintain its structural integrity.

6. Dispose of the debris: Properly dispose of the collected debris in a trash bag or a designated waste container. Do not leave the debris scattered around, as it can pose a safety hazard and may cause accidents.

7. Store tools and equipment safely: Finally, store your drilling tools and equipment in a safe and organized manner. This will not only help keep your work area clean but also ensure that your tools are easily accessible for future use.

By following these cleaning guidelines, you can ensure a safe and clean work area after drilling through plexiglass.

FAQ:

What are some methods for drilling through plexiglass without cracking it?

There are several methods you can use to drill through plexiglass without cracking it. One method is to use a sharp drill bit specifically designed for drilling through acrylic. Another method is to use a lubricant, such as soapy water or cutting oil, while drilling to reduce heat and friction. It’s also important to apply gentle, steady pressure and to drill at a slower speed to avoid putting too much stress on the material.

What type of drill bit should I use for drilling through plexiglass?

For drilling through plexiglass, it’s best to use a drill bit specifically designed for drilling through acrylic or plastic. These drill bits typically have a pointed tip and sharp edges that help to reduce the risk of cracking or chipping the material. They also have a flute design that helps to remove chips and debris from the hole as you drill.

Should I use a drill press or a hand drill for drilling through plexiglass?

Both a drill press and a hand drill can be used for drilling through plexiglass, but a drill press offers more stability and control. If you are drilling a large hole or need to make precise holes, using a drill press is highly recommended. However, if you are drilling small holes or need to work in tight spaces, a hand drill can be more convenient.

What precautions should I take when drilling through plexiglass?

When drilling through plexiglass, there are several precautions you should take to ensure your safety and to prevent damage to the material. First, always wear eye protection and work gloves to protect yourself from flying debris. Second, secure the plexiglass firmly in place, either with clamps or by sandwiching it between two pieces of scrap wood. Finally, start drilling with a small pilot hole and gradually increase the size of the hole to prevent damage to the material.

Can I use a regular drill bit for drilling through plexiglass?

While it is possible to use a regular drill bit for drilling through plexiglass, it is not recommended. Regular drill bits are designed for metal or wood, and they can cause the plexiglass to crack or shatter. It’s best to use a drill bit specifically designed for drilling through acrylic or plastic, as these have a sharper point and edges that reduce the risk of damage to the material.

What should I do if my plexiglass cracks while drilling?

If your plexiglass cracks while drilling, it’s best to stop immediately to prevent the crack from spreading. You can try drilling a small hole at the end of the crack to relieve stress and stop it from propagating further. If the crack is significant, you may need to start over with a new piece of plexiglass. Remember to use the proper drilling techniques and a drill bit designed for acrylic to minimize the risk of cracking.

Video: