Mastering the Drill Press Vise: Tips and Tricks for Precision Drilling

The drill press vise is a crucial tool in any woodworking or metalworking shop. It holds the material firmly in place, allowing for accurate and precise drilling. However, many DIY enthusiasts and beginners often struggle with using the drill press vise effectively. In this article, we will explore some tips and tricks to help you master the drill press vise and achieve professional-level precision drilling.

Choosing the Right Vise:

Before we dive into the tips and tricks, it is important to select the right drill press vise for your specific needs. There are various types of vises available, including bench vises, quick-release vises, and cross-slide vises. Consider the size and weight of your materials, as well as the space available in your workshop, when choosing a vise. Additionally, look for a vise with adjustable jaws and a sturdy construction to ensure stability during drilling.

Setting Up the Vise:

Once you have chosen the right vise, it’s time to set it up correctly on your drill press. Start by cleaning and lubricating the vise’s moving parts to ensure smooth operation. Position the vise jaws so that they are parallel to the drill press table. Use a combination square or a parallel set to check the alignment. Adjust the jaws if necessary, and tighten the vise securely to the table using the mounting bolts. Double-check the alignment before starting any drilling operations.

Using the Vise for Precision Drilling:

To achieve precision drilling, it is crucial to use the drill press vise correctly. Always secure your workpiece firmly between the vise jaws, making sure it is held tightly in place. Use a center punch to mark the drilling point, providing a guide for accurate hole placement. When drilling, apply steady and consistent pressure on the drill press handle, allowing the drill bit to cut through the material smoothly. Avoid excessive force, as it can cause the bit to wander off-course and compromise the accuracy of your drilling.

Troubleshooting Common Issues:

Inexperienced users may encounter some common issues while using the drill press vise, such as excessive vibrations or the workpiece slipping out of the jaws. To minimize vibrations, make sure your drill press is properly balanced and secured to the workbench. If the workpiece tends to slip, consider using non-slip adhesive pads or clamp it down with additional clamps. Additionally, maintaining sharp drill bits and cleaning the vise regularly can also improve the overall performance and accuracy of your drilling operations.

Remember, practice makes perfect when it comes to mastering the drill press vise. Experiment with different materials and drilling techniques, and always prioritize safety while working with power tools. With time and experience, you will become adept at using the drill press vise and achieve precise and professional results in your woodworking or metalworking projects.

Understanding the Drill Press Vise

What is a Drill Press Vise?

A drill press vise is a specialized tool used to hold materials in place when drilling holes with a drill press. It is typically made of sturdy metal and has jaws that can be tightened to secure the material firmly.

Types of Drill Press Vises

There are several types of drill press vises available, each designed for specific applications. The most common types include:

- Standard drill press vise: This type of vise has two parallel jaws that can be adjusted to hold materials of various sizes securely.

- Angle drill press vise: This vise allows drilling at different angles by tilting the material.

- Rotating drill press vise: This vise has a rotating base that allows drilling at different angles and positions.

- Clamp-style drill press vise: This vise uses clamps to secure the material instead of traditional jaws.

Features of a Good Drill Press Vise

When choosing a drill press vise, it is important to consider several key features:

- Jaw width: The width of the jaws determines the maximum size of the material that can be held. Choose a vise with jaws wide enough to accommodate the materials you commonly work with.

- Jaw opening: The maximum distance the jaws can open is essential to accommodate thicker materials.

- Construction: Look for a vise made of sturdy materials that can withstand the pressure and vibrations generated during drilling.

- Tightening mechanism: A good drill press vise should have a reliable and easy-to-use tightening mechanism to securely hold the material in place.

- Accuracy: The vise should be able to hold materials precisely and maintain their positioning during drilling for accurate results.

Proper Use and Care

To ensure the longevity and effectiveness of a drill press vise, it is important to follow these tips:

- Clean the vise regularly to remove any debris or build-up that may affect its performance.

- Inspect the vise for any damage or wear before each use and replace or repair any worn-out parts.

- Use the appropriate vise for the job and make sure it is securely tightened before drilling.

- Always use proper cutting tools and techniques to prevent damage to the vise and ensure safety.

- Store the vise in a clean and dry place when not in use to prevent rust and corrosion.

Conclusion

A drill press vise is an essential tool for anyone working with a drill press. Understanding the different types and features of drill press vises and using them correctly and maintaining them properly will ensure precise and efficient drilling operations.

Choosing the Right Drill Press Vise

When it comes to precision drilling, having the right drill press vise is essential. A drill press vise is a specialized tool designed to securely hold your workpiece in place while drilling. It ensures stability, accuracy, and safety during the drilling process. However, choosing the right drill press vise can be a daunting task with so many options available on the market. Here are some important factors to consider when selecting a drill press vise:

1. Size and Capacity

One of the first things to consider is the size and capacity of the drill press vise. The vise should be able to accommodate the size of your workpiece and provide a secure grip. Measure the dimensions of your workpiece and choose a vise that has a suitable jaw width and opening capacity.

2. Material and Construction

Look for a drill press vise that is made of high-quality materials, such as cast iron or steel. These materials are durable and can withstand the pressure and force exerted during drilling. Also, consider the construction of the vise, ensuring that it is solid and well-built for long-lasting use.

3. Jaw Design

- Fixed vs. Swivel Jaw

- Jaw Width and Depth

Decide whether you need a drill press vise with a fixed jaw or a swivel jaw. A fixed jaw vise provides stability and is suitable for most drilling tasks. On the other hand, a vise with a swivel jaw allows you to rotate the workpiece, making it easier to drill at different angles.

The width and depth of the jaws are also important considerations. The wider the jaws, the more surface area they can grip. The depth of the jaws determines how much of the workpiece can be secured, so make sure it is deep enough to hold your specific workpiece.

4. Mounting Options

Check the mounting options of the drill press vise. Most vises can be mounted to the drill press table using bolts or clamps. Ensure that your drill press has the appropriate mounting mechanism to accommodate the vise you choose.

5. Price and Brand

Consider your budget and choose a drill press vise that offers good value for money. It’s also worth considering reputable brands that have a track record of producing reliable tools. While cost is an important factor, prioritize quality and functionality when making your decision.

Conclusion

Choosing the right drill press vise is crucial for accurate and precise drilling. Consider the size and capacity, material and construction, jaw design, mounting options, as well as the price and brand when making your selection. Investing in a high-quality drill press vise will make a noticeable difference in the quality of your drilling projects.

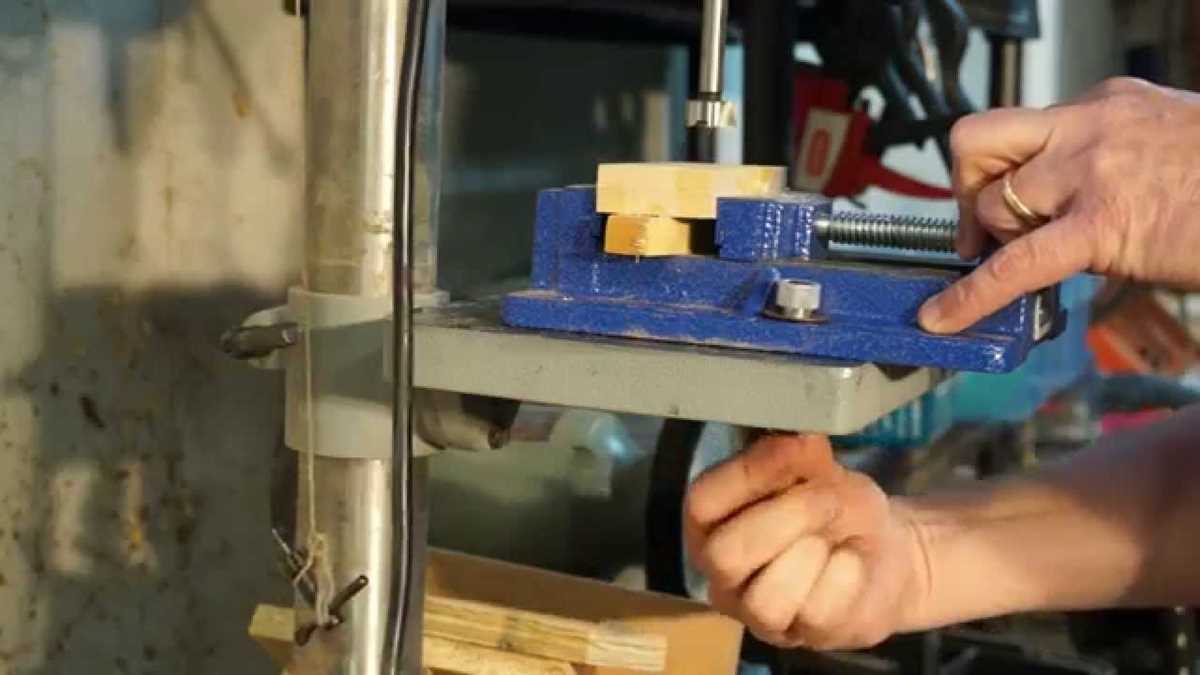

Setting Up the Drill Press Vise

Step 1: Choose the Right Size Vise

Before setting up the drill press vise, it is important to choose the right size vise for your drilling needs. The size of the vise will depend on the size of the workpiece you will be drilling. Make sure the jaws of the vise are wide enough to securely hold the workpiece in place.

Step 2: Position the Vise on the Drill Press Table

Once you have selected the appropriate vise, position it on the drill press table. Make sure to align the vise parallel to the drill press column. This will help ensure accuracy when drilling.

Step 3: Secure the Vise to the Table

After positioning the vise, use the appropriate tools to secure it to the drill press table. This will prevent the vise from shifting or moving during the drilling process, ensuring stability and precision.

Step 4: Square the Vise with the Drill Press Column

To ensure accurate drilling, it is important to square the vise with the drill press column. This can be done using a square or other measuring tools. Adjust the vise as needed until it is perfectly square with the column.

Step 5: Align the Vise Jaws

Before inserting the workpiece into the vise, make sure the vise jaws are aligned properly. Adjust the jaws as needed to create a straight and parallel grip on the workpiece. This will help prevent any movement or slippage during the drilling process.

Step 6: Check the Vise for Stability

Before drilling, double-check the vise to ensure it is securely fastened to the drill press table and stable. Give it a gentle shake or tug to make sure it doesn’t move or shift. If any adjustments are needed, make them before proceeding with the drilling operation.

Step 7: Insert and Secure the Workpiece

Once the vise is set up and stable, carefully insert the workpiece into the vise jaws. Position the workpiece so that it is aligned with the desired drilling location. Secure the workpiece tightly using the vise’s handle or other locking mechanism.

Step 8: Double-Check Alignment

Finally, double-check the alignment of the workpiece with the drill press column. Make any necessary adjustments to ensure the workpiece is centered and properly aligned. This will help prevent any drilling errors or inaccuracies.

By following these steps, you can properly set up the drill press vise for precise and accurate drilling. Remember to always prioritize safety and take the time to double-check your setup before starting any drilling operation.

Ensuring Proper Alignment

Proper alignment is crucial when using a drill press vise to ensure accurate and precise drilling. Here are some tips to help you achieve proper alignment:

1. Cleaning the vise

Before using the vise, make sure it is clean and free from any debris or dirt. Clean the vise jaws and base with a rag or brush to ensure a smooth and stable grip.

2. Squaring the vise

Ensure that the vise is square to the drill press table. Check the alignment by using a square or a precision straight edge against the side of the vise jaws and the drill press table. Adjust the vise by loosening the screws and repositioning it until it is perfectly square.

3. Aligning the workpiece

Position the workpiece securely within the vise jaws, making sure it is seated firmly against the vise’s fixed jaw. Use a combination of clamps, blocks, or shims to ensure the workpiece is level and positioned correctly.

4. Centering the drill bit

Before drilling, ensure that the drill bit is centered both horizontally and vertically. Adjust the position of the table or the drill press head to center the bit over the desired drilling location. Use a center punch to mark the drilling spot for added precision.

5. Using a centering jig

If you’re working with round or cylindrical workpieces, consider using a centering jig to ensure precise alignment. A centering jig provides a guide for centering the workpiece and helps prevent any wandering of the drill bit.

6. Regularly checking alignment

Throughout the drilling process, regularly check the alignment of the vise, workpiece, and drill bit. Make any necessary adjustments to ensure everything remains aligned correctly.

7. Applying consistent pressure

When drilling, apply consistent pressure on the workpiece while keeping your hands clear of the drill bit. This will help maintain proper alignment and prevent any movement or shifting.

By following these tips and taking the time to ensure proper alignment, you can greatly improve the accuracy and precision of your drilling projects when using a drill press vise.

Utilizing Clamping Techniques

When working with a drill press vise, properly securing your workpiece is crucial for achieving accurate and precise drilling results. Here are a few essential clamping techniques to help you maximize the effectiveness of your drill press vise:

1. Parallel Clamping

Parallel clamping involves using two parallel pieces of material to secure the workpiece. This technique ensures that the workpiece remains stable and prevents any unwanted movement or rotation during drilling. To implement parallel clamping, follow these steps:

- Place two parallel blocks or bars on either side of the workpiece.

- Align the blocks or bars so that they are parallel to each other and square with the drill press table.

- Tighten the vise jaws against the blocks or bars to secure the workpiece.

2. Step Clamping

If you are drilling a workpiece that has different levels or steps, step clamping is an effective technique for securing it. This technique allows you to drill multiple holes at different depths without the need to reposition the workpiece. Follow these steps to utilize step clamping:

- Position the workpiece in the vise so that one end is aligned with the drill bit.

- Tighten the vise jaws to secure the workpiece.

- Drill the first hole to the desired depth.

- Slide the workpiece forward or backward in the vise to position the next step aligned with the drill bit.

- Tighten the vise jaws again to secure the workpiece for drilling the next hole.

- Repeat the steps for drilling holes at different depths.

3. Auxiliary Clamps

In some cases, the drill press vise may not provide sufficient clamping force or stability. To overcome this, you can use auxiliary clamps in conjunction with the vise to enhance the clamping power. Auxiliary clamps are particularly useful when working with larger or irregularly shaped workpieces. Here’s how to utilize auxiliary clamps:

- Position the workpiece in the vise and tighten the vise jaws partially.

- Use additional clamps, such as C-clamps or bar clamps, to secure the workpiece to the drill press table or other suitable surfaces.

- Ensure that the additional clamps are positioned in a way that they do not obstruct the drilling path or interfere with the drill bit.

- Tighten the vise jaws fully to secure the workpiece along with the auxiliary clamps.

By incorporating these clamping techniques into your drilling setup, you can ensure the stability and accuracy of your workpiece. Always prioritize safety and take necessary precautions, such as wearing protective eyewear and gloves, when operating the drill press.

Maximizing Precision Drilling

1. Choose the Right Drill Bit

When it comes to precision drilling, choosing the right drill bit is crucial. Different materials require different types of drill bits, so make sure you have the appropriate bit for the material you are drilling into. For example, a twist drill bit is suitable for drilling into wood, while a carbide drill bit is better for drilling into metal.

2. Secure the Workpiece

To achieve precise drilling, it is essential to secure the workpiece firmly in the drill press vise. This will prevent any movement or wobbling during drilling, ensuring accurate and clean holes. Use clamps or other securing mechanisms to hold the workpiece securely in place.

3. Set the Depth Stop

The depth stop on the drill press can help you achieve consistent drilling depths. Before drilling, set the depth stop to the desired depth, ensuring that the drill bit will not penetrate beyond the desired point. This can be particularly useful when drilling holes at a uniform depth, such as when creating dowel joints.

4. Use a Center Punch

For precise drilling, it is important to create a starting point for the drill bit. To do this, use a center punch to make a small indentation on the surface of the workpiece. This will help to guide the drill bit and prevent it from wandering off course, resulting in a more accurate hole.

5. Slow and Steady

When drilling, it is best to take a slow and steady approach. Applying excessive force or drilling too quickly can cause the drill bit to wander or create a rough hole. Instead, apply consistent pressure and let the drill bit do the work. This will result in cleaner and more precise holes.

6. Lubricate the Drill Bit

Lubricating the drill bit can help to reduce friction and heat, resulting in smoother drilling and prolonging the life of the bit. Apply a few drops of cutting oil or a lubricant suitable for the material being drilled. This will help to prevent the bit from overheating and ensure a cleaner and more precise hole.

7. Regularly Clean the Drill Press and Vise

To maintain precision drilling, it is important to regularly clean and maintain the drill press and vise. Remove any debris or chips that may accumulate on the drill press table or in the vise. This will prevent any interference with the drilling process and help to ensure accurate results.

8. Test and Adjust

Before drilling into your final workpiece, it is always a good idea to test the setup and make any necessary adjustments. Drill a small test hole on a scrap piece of material to check for accuracy and make any necessary adjustments to the drill press vise or other settings. This will help to avoid any mistakes or inaccuracies when drilling into your final workpiece.

Maintaining and Caring for the Drill Press Vise

Clean the Vise Regularly

Keeping the drill press vise clean is essential for its smooth and precise operation. After each use, remove any debris or chips from the vise jaws and bed using a brush or compressed air. This will prevent the buildup of grime and help maintain the vise’s gripping power.

Inspect for Damage

Regularly inspect the drill press vise for any signs of damage or wear. Check the jaws for any cracks, chips, or excessive wear. Look for any loose or missing screws or other fasteners. If any damage is found, it is important to repair or replace the affected parts to ensure the vise’s reliability and safety.

Lubricate Moving Parts

To keep the drill press vise operating smoothly, lubricate the moving parts regularly. Apply a light machine oil to the threaded screw and the pivot points. This will reduce friction and allow for easier adjustment and tightening of the vise. Avoid using heavy grease or oil, as it can attract dust and debris.

Store Properly

When the drill press vise is not in use, store it in a dry and clean environment. Avoid placing heavy objects on top of the vise, as this can cause deformation or damage. Consider using a cover or case to protect the vise from dust, moisture, and other contaminants that can affect its performance.

Inspect Alignment

Periodically check the alignment of the drill press vise with the drill press table. Make sure that the vise is securely fastened and parallel to the table surface. Check for any misalignment or wobbling that could affect the accuracy of your drilling operations. Adjust or tighten the vise as necessary.

Replace Worn Jaws

If the jaws of the drill press vise become worn or damaged, it is important to replace them. Worn jaws can lead to decreased gripping power and reduced precision. Check the manufacturer’s instructions for the proper procedure to replace the jaws of your specific vise model.

Follow Safety Guidelines

Always adhere to the safety guidelines provided by the manufacturer of the drill press vise. Wear appropriate personal protective equipment, such as safety glasses and gloves, when operating the drill press and using the vise. Use proper techniques and caution to avoid accidents or injuries.

By following these maintenance and care tips, you can ensure the longevity and optimal performance of your drill press vise. Regular cleaning, inspection, lubrication, and proper storage are key to maintaining the precision and reliability of this essential workshop tool.

FAQ:

What is a drill press vise and how does it work?

A drill press vise is a clamping mechanism used to securely hold and position workpieces on a drill press table. It typically consists of two jaws that can be opened and closed using a threaded screw. The vise is attached to the drill press table and allows for precise drilling by holding the workpiece in place.

What materials can be held in a drill press vise?

A drill press vise can hold a variety of materials, including wood, metal, plastic, and other materials commonly used in woodworking and metalworking projects. The vise jaws are often lined with rubber or other materials to prevent damage to the workpiece.

Can a drill press vise be used for other tasks besides drilling?

Yes, a drill press vise can be used for other tasks besides drilling. It can also be used for tasks such as tapping, reaming, grinding, sanding, and other operations that require a secure and stable workpiece. However, it is important to ensure that the vise is suitable for the specific task and that it is properly adjusted and tightened before use.

How do you maintain a drill press vise?

To maintain a drill press vise, you should regularly clean it to remove any dust or debris that may accumulate. Lubricate the threaded screw and other moving parts with a light machine oil to ensure smooth operation. Check the alignment and condition of the vise jaws, and replace them if they become worn or damaged. Store the vise in a clean and dry area when not in use to prevent rust or corrosion.

Where can I buy a drill press vise?

A drill press vise can be purchased from various hardware stores, tool suppliers, and online retailers. Some popular places to buy a drill press vise include Home Depot, Lowe’s, Amazon, and Grainger. It is recommended to compare prices and read reviews before purchasing to ensure you are getting a quality vise that suits your specific needs.

Video: