Mastering the Drill Press: A Comprehensive Guide to Using it for Metal

The drill press is a powerful and versatile tool that can be used for a variety of tasks. When it comes to working with metal, the drill press becomes an essential part of any workshop. Whether you are a seasoned professional or a beginner, understanding how to properly use the drill press for metal is crucial.

Using the drill press for metal requires precision and attention to detail. Unlike other materials, metal is dense and can be challenging to work with. However, with the right techniques and knowledge, you can achieve accurate and clean cuts, holes, and threads on various types of metals.

In this comprehensive guide, we will cover everything you need to know about using the drill press for metal. From choosing the right drill bits to setting the correct speed, we will walk you through the step-by-step process of mastering this powerful tool. We will also discuss safety precautions and provide useful tips and tricks along the way.

Whether you are a hobbyist or a professional metalworker, this guide will serve as your go-to resource for using the drill press effectively. With the right know-how and practice, you can take your metalworking skills to the next level and achieve exceptional results with the drill press.

Understanding the Drill Press

The drill press is a powerful tool that is commonly used in metalworking. It is a machine that is designed to drill holes into metal with precision and efficiency. By understanding how the drill press functions, you can better utilize it for your metalworking projects.

Components of a Drill Press

To understand the workings of a drill press, it is important to familiarize yourself with its various components. These include:

- Base: The base is the foundation of the drill press. It helps provide stability and support to the machine.

- Column: The column is the vertical support structure that holds the other components of the drill press.

- Table: The table is the flat working surface of the drill press. It can be adjusted for height and angle to accommodate various metalworking tasks.

- Drill Head: The drill head houses the motor, spindle, and other moving parts of the drill press. It is responsible for providing power and movement to the drill bit.

- Spindle: The spindle is a vertical metal rod located at the center of the drill head. It holds the drill bit and controls its movement.

- Chuck: The chuck is a device that holds the drill bit in place and allows for easy removal and replacement of bits.

Operating the Drill Press

Operating the drill press involves following a set of steps to ensure safe and accurate drilling. Here is a general procedure to keep in mind:

- Securely clamp the metalwork to the table to prevent movement during drilling.

- Select the appropriate speed and adjust it on the drill press. Factors such as the type of metal and the size of the drill bit can affect the ideal speed.

- Place the drill bit into the chuck and tighten it securely.

- Align the drill bit with the desired drilling location on the metalwork.

- Lower the drill bit down by turning the feed handle. Start drilling at a slow speed to prevent overheating and ensure accuracy.

- Apply a steady and even pressure to the handle to maintain control.

- Once the drilling is complete, raise the drill bit and turn off the drill press.

- Remove the metalwork from the table and inspect the drilled hole for any irregularities.

Tips for Using the Drill Press

To make the most of your drill press, consider the following tips:

- Wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from metal shavings and debris.

- Use cutting fluids or lubricants to improve the drilling process and extend the life of the drill bit.

- Keep the drill press clean and well-maintained to ensure optimal performance.

- Experiment with different drill bits and speeds to find the combination that works best for your specific metalworking needs.

- Practice proper drilling techniques, such as using a center punch to create a starting point for the drill bit and using a coolant to prevent overheating.

Conclusion

Understanding the drill press is key to using it effectively for metalworking. By familiarizing yourself with its components, following proper operating procedures, and implementing helpful tips, you can master the drill press and achieve precise, accurate results in your metal projects.

Types of Drill Presses

When it comes to drill presses, there are several types available on the market. Each type has its own unique features and benefits, making them suitable for different types of metalworking projects. Here are some of the most common types of drill presses:

Benchtop Drill Press

The benchtop drill press is the most common type of drill press and is designed to be mounted on a workbench or table. It is small in size, making it portable and convenient for home workshops or small metalworking projects. Benchtop drill presses usually have a motor ranging from 1/4 to 1 horsepower, making them suitable for drilling holes of various sizes in metal.

Floor Drill Press

The floor drill press is a larger and more powerful version of the benchtop drill press. It is designed to be placed directly on the floor and is ideal for heavy-duty metalworking projects. Floor drill presses usually have a motor ranging from 1/2 to 1 horsepower, allowing them to handle larger drill bits and drill through thicker metal materials.

Magnetic Drill Press

A magnetic drill press, also known as a mag drill, is a specialized type of drill press that uses a magnetic base to securely attach itself to metal surfaces. This type of drill press is commonly used in metal fabrication, construction, and other industries where drilling on vertical, horizontal, or angled metal surfaces is required. Magnetic drill presses are typically portable and have a strong magnetic base that ensures stability during drilling.

Radial Arm Drill Press

The radial arm drill press is a versatile type of drill press that features an adjustable arm that can rotate and move vertically along a fixed column. This allows the user to position the drill bit precisely in relation to the workpiece. Radial arm drill presses are commonly used in metalworking shops and are ideal for drilling holes in large or heavy workpieces.

Pedestal Drill Press

The pedestal drill press, also known as a free-standing drill press, is similar to the floor drill press but is mounted on a pedestal or stand. The pedestal provides extra stability and can be adjusted to different heights, allowing the user to work comfortably. Pedestal drill presses are commonly used in industrial settings where heavy-duty drilling is required.

Mini Drill Press

The mini drill press is a compact and portable version of the benchtop drill press. It is designed for small-scale metalworking projects and is ideal for hobbyists, jewelry makers, and crafters. Mini drill presses are lightweight, easy to use, and usually have a motor ranging from 1/8 to 1/4 horsepower.

Tabletop Drill Press

The tabletop drill press is a small and lightweight drill press that can be placed directly on a tabletop or any other flat surface. It is designed for light-duty drilling tasks and is ideal for small-scale metalworking projects. Tabletop drill presses are portable, easy to store, and suitable for hobbyists and DIY enthusiasts.

Cross Slide Drill Press

The cross slide drill press is a versatile type of drill press that features a cross slide table or vise. This allows the user to move the workpiece in different directions and positions, making it suitable for precise drilling, milling, and other metalworking tasks. Cross slide drill presses are commonly used in metalworking shops and provide a high level of accuracy and precision.

Multi-Spindle Drill Press

A multi-spindle drill press is a specialized type of drill press that features multiple spindles or drill heads. This allows the user to drill multiple holes simultaneously, increasing productivity and efficiency. Multi-spindle drill presses are commonly used in mass production and manufacturing industries.

Drill Press Accessories

In addition to the different types of drill presses, there are also various accessories available that can enhance the functionality and versatility of a drill press. Some common drill press accessories include drill press vices, drill press clamps, drill press tables, drill press jigs, and drill press tapping attachments.

When choosing a drill press, it’s important to consider the specific requirements of your metalworking projects as well as your budget and available space. Each type of drill press has its own advantages and limitations, so it’s essential to choose the one that best suits your needs.

Choosing the Right Drill Press for Metal

When it comes to drilling holes in metal, having the right drill press can make all the difference. A drill press specifically designed for metalworking tasks offers increased power, stability, and precision compared to a regular drill. Here are some factors to consider when choosing a drill press for metal:

1. Power

Power is an important factor to consider when drilling holes in metal. Look for a drill press with a high horsepower motor that can handle the demands of drilling through various types of metal. A drill press with a minimum power rating of 1 horsepower (HP) is recommended for most metalworking tasks.

2. Speed Control

Drilling through metal requires different speeds depending on the type of metal and the size of the hole. Look for a drill press with variable speed control, which allows you to adjust the speed according to your specific needs. This feature is essential for achieving clean and accurate holes in metal.

3. Table Size and Stability

Make sure the drill press has a table that is large enough to accommodate the size of the metal workpieces you’ll be drilling. Additionally, the table should be stable and sturdy to prevent vibrations while drilling. Look for a table with adjustable height and tilt options to accommodate different metalworking angles.

4. Depth Stop and Depth Gauge

A depth stop and depth gauge are essential features for precise drilling in metal. The depth stop allows you to set the drilling depth, while the depth gauge helps you measure and adjust the depth accurately. These features are important for consistent and repeatable drilling results.

5. Chuck Size

The chuck size determines the maximum diameter of drill bits that can be used with the drill press. For drilling into metal, a drill press with a chuck size of at least 1/2 inch is recommended. This size allows you to use a wide range of drill bits for different hole sizes.

6. Additional Features

Consider additional features that can enhance your metalworking experience, such as built-in work lights for better visibility, laser guides for precise drilling alignment, and built-in cooling systems to prevent overheating during prolonged use.

| Factor | Recommended Specification |

|---|---|

| Power | Minimum 1 HP motor |

| Speed Control | Variable speed control |

| Table Size | Large enough to accommodate workpieces |

| Stability | Sturdy and stable table |

| Depth Stop | With depth stop feature |

| Depth Gauge | With depth gauge feature |

| Chuck Size | At least 1/2 inch |

By considering these factors, you can choose the right drill press for metal that meets your specific requirements and provides optimal performance in your metalworking projects.

Preparing the Drill Press for Metalwork

Before starting any metalwork on a drill press, it is important to properly prepare the machine. This includes making sure the drill press is set up correctly and all necessary safety precautions are taken. Follow these steps to prepare your drill press for metalwork:

1. Clean and Inspect the Drill Press

Start by thoroughly cleaning the drill press to remove any dust, debris, or previous metal shavings. Use a brush or compressed air to clean the drill press table, base, chuck, and spindle. Inspect the machine for any signs of damage or loose parts that may affect its operation.

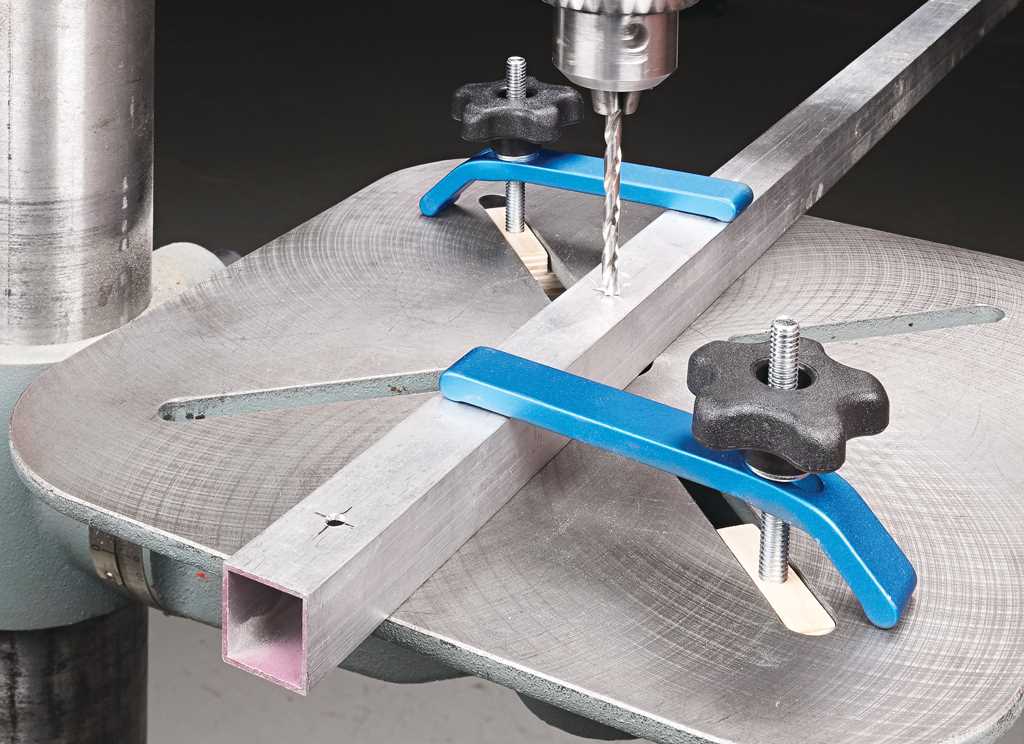

2. Secure the Metalwork Piece

Choose a suitable workpiece for your metalwork project and secure it tightly to the drill press table. Use clamps or a vise to hold the workpiece securely in place, ensuring that it will not move during drilling. This will help maintain accuracy and prevent accidents.

3. Select the Proper Drill Bit

Select a drill bit that is appropriate for drilling into metal. High-speed steel (HSS) drill bits are commonly used for metalwork and are available in various sizes. Choose a drill bit that matches the size and type of hole you need to drill in the metal.

4. Set the Speed and Depth

Refer to the drill press manual or the manufacturer’s recommendations to determine the appropriate speed and depth for drilling into metal. Set the drill press speed to match the material and thickness of the metal being drilled. Adjust the depth stop to control the depth of the hole.

5. Wear Personal Protective Equipment (PPE)

Prior to starting any metalwork on the drill press, it is crucial to wear the appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from metal shavings and debris, as well as gloves to protect your hands.

6. Clear the Workspace

Before starting the drill press, clear the immediate workspace of any unnecessary tools, materials, or clutter. This will help prevent accidents and ensure a safe working environment. Keep the area around the drill press clean and organized.

7. Familiarize Yourself with the Drill Press Controls

Take a moment to familiarize yourself with the drill press controls and their operation. Understand how to start and stop the drill press, as well as how to adjust the speed and depth. Knowing how to operate the machine safely will help prevent accidents and ensure accurate drilling.

8. Test the Drill Press

Before drilling into the metalwork piece, test the drill press on a scrap piece of metal. This will allow you to ensure that the machine is set up correctly and that the drill bit is suitable for the material. Make any necessary adjustments before proceeding with your actual metalwork.

By following these steps to prepare your drill press for metalwork, you can ensure safe and accurate drilling results. Always prioritize safety and take the necessary precautions when working with metal on a drill press.

Mastering the Drill Press Techniques

1. Safety First

Before you begin using a drill press, it is essential to prioritize safety. Here are some safety tips to keep in mind:

- Always wear safety glasses to protect your eyes from debris.

- Wear appropriate clothing and avoid loose jewelry or accessories.

- Ensure that the drill press is properly secured to the workbench or floor.

- Never leave the drill press unattended while it is running.

- Keep your hands and fingers away from the drill bit and rotating parts.

2. Drill Bit Selection

Choosing the right drill bit is crucial for achieving the desired results. Consider the following factors when selecting a drill bit:

- Material: Different materials require different types of drill bits. Make sure to use the appropriate bit for the metal you are working with.

- Diameter: The diameter of the drill bit determines the size of the hole. Measure the hole size you need and select a bit accordingly.

- Coating: Some drill bits come with coatings that help reduce friction and heat buildup. Consider using coated bits for longer tool life and smoother drilling.

3. Setting up the Drill Press

Proper setup is essential for accurate and safe drilling with a drill press. Follow these steps to set up your drill press:

- Secure the workpiece in a drill press vise or clamps.

- Adjust the height of the drill press table to ensure the workpiece is at a comfortable working height.

- Check that the drill press is set to the desired speed for the material being drilled.

- Align the drill bit with the center of the desired hole location.

- Bring the drill bit down into contact with the workpiece gently, then tighten the depth stop to control the drilling depth.

4. Drilling Techniques

Once the drill press is set up, it’s time to start drilling. Here are some important techniques to master:

- Apply steady pressure: Apply even and consistent pressure to the workpiece as you drill to ensure a smooth and clean hole.

- Clear the chips: Clear away chips and debris from the hole regularly to prevent clogging and overheating.

- Go slow and steady: Avoid rushing the drilling process. Gradually increase the drilling speed as needed, but never force the drill bit through the material.

- Use coolant: For metal drilling, you may need to use a coolant to lubricate the drill bit and reduce heat buildup. Follow the manufacturer’s instructions for coolant usage.

5. Maintenance and Care

Proper maintenance will ensure the longevity and performance of your drill press. Here are some tips for maintenance and care:

- Keep the drill press clean and free from debris.

- Regularly lubricate the moving parts to prevent rust and ensure smooth operation.

- Check and tighten all bolts and screws to maintain stability and accuracy.

- Periodically check the belt tension and replace it if necessary.

- Follow the manufacturer’s instructions for any specific maintenance requirements.

| Technique | Tips |

|---|---|

| Drill Bit Selection | Consider material, diameter, and coating. |

| Setting up the Drill Press | Secure workpiece, adjust table height, align bit, set speed. |

| Drilling Techniques | Apply steady pressure, clear chips, go slow and steady, use coolant. |

| Maintenance and Care | Keep clean, lubricate, check bolts and screws, monitor belt tension. |

Safety Measures and Precautions

1. Personal Protective Equipment (PPE)

When operating a drill press, it is important to always wear the appropriate personal protective equipment (PPE) to ensure your safety. This includes:

- Safety goggles or a face shield: to protect your eyes from flying debris

- Hearing protection: such as earplugs or earmuffs to protect your hearing from the noise produced by the drill press

- Gloves: to protect your hands from sharp edges and hot surfaces

- Protective clothing: such as long sleeves and pants to protect your skin from coming into contact with rotating parts

2. Work Area

Before operating the drill press, make sure the work area is clean, well-lit, and free from any obstructions. This will minimize the risk of accidents and allow you to work more efficiently.

Ensure that the drill press is placed on a stable and level surface to prevent it from tipping over during operation. Additionally, keep the floor around the drill press clear of any tripping hazards.

3. Machine Inspection

Before using the drill press, inspect it for any signs of damage or wear. Check the power cord for any fraying or exposed wires, and make sure all safety guards are in place and functioning properly.

If you notice any issues with the drill press, such as loose screws or belts, do not use it and have it repaired by a qualified technician before operating it again.

4. Secure the Workpiece

Always secure the workpiece firmly before drilling. This can be done using clamps or a vise to prevent it from moving or spinning while drilling. If the workpiece is small or irregularly shaped, consider using a jig or fixture to hold it in place.

5. Adjustments and Settings

When making adjustments or changing settings on the drill press, always ensure that the machine is turned off and the power is disconnected. This will prevent accidental startups and reduce the risk of injury.

Read and follow the manufacturer’s instructions carefully when adjusting the speed, depth, or any other settings on the drill press. Using the machine incorrectly can result in damage to the workpiece or serious injury.

6. Safe Operation

When operating the drill press, keep your hands and fingers away from the rotating parts. Use a clamp or push stick to hold the workpiece and feed it into the drill press.

Avoid wearing loose clothing or jewelry that could get caught in the machine. Tie back long hair and remove any neckties or scarves.

7. Emergencies

In case of an emergency, such as a power failure or a jammed workpiece, do not panic. Keep your hands away from the machine and wait for it to come to a complete stop before assessing the situation.

Have a fire extinguisher nearby in case of fires and know the location of the emergency shut-off switch or button. Familiarize yourself with the drill press’s safety features and procedures for handling emergencies.

8. Training and Supervision

Lastly, it is important to receive proper training on the safe operation of a drill press before using it. If you are new to using a drill press or unfamiliar with its operation, seek guidance from an experienced operator or take a training course.

Always operate the drill press under the supervision of a knowledgeable individual until you are confident in your abilities.

By following these safety measures and precautions, you can ensure a safe and enjoyable experience when using a drill press for metalworking tasks.

Maintenance and Troubleshooting Tips

Maintenance Tips

- Regularly clean the drill press table and base to remove dust and debris that could affect the machine’s performance.

- Inspect the power cord for any damages, and replace it if necessary.

- Check the belts for any signs of wear or damage, and replace them if needed.

- Lubricate the moving parts of the drill press, such as the bearings and quill, to ensure smooth operation.

- Inspect the chuck jaws and make sure they are clean and in good condition. Replace them if they are worn out.

- Periodically check the alignment of the drill press components, such as the table, quill, and drill bit, and adjust as needed.

Troubleshooting Tips

1. The drill bit keeps breaking or getting stuck:

- Check if the drill bit is properly secured in the chuck and tighten if necessary.

- Ensure that you are using the correct drill bit for the type of material you are drilling.

- Reduce the drilling speed or use lubrication to prevent overheating.

2. The drill press is making strange noises:

- Check if the belts are properly tensioned and aligned. Adjust or replace them if necessary.

- Inspect the motor and bearings for any signs of wear or damage. Replace them if needed.

- Make sure the drill press is securely mounted to a stable surface.

3. The drill press is vibrating excessively:

- Ensure that the workpiece is securely clamped to the table to minimize vibrations.

- Check if the drill bit is dull or improperly sharpened. Replace or sharpen it accordingly.

- Inspect the quill and spindle for any misalignment or damage. Adjust or replace them if necessary.

| Task | Frequency |

|---|---|

| Cleaning the drill press | Weekly |

| Inspecting power cord and belts | Monthly |

| Lubricating moving parts | Every 3-6 months |

| Checking alignment | Annually |

| Replacing chuck jaws | As needed |

FAQ:

Why is a drill press important for working with metal?

A drill press is important for working with metal because it provides stability and accuracy. It allows for precise drilling and avoids any accidental movements that may occur when using a handheld drill.

What types of drill bits are suitable for use with a drill press for metal?

When using a drill press for metal, it is best to use high-speed steel (HSS) drill bits or cobalt drill bits. These types of bits are designed to withstand the high temperatures generated when drilling into metal and are less likely to become dull or break.

Is it necessary to use lubrication when drilling metal with a drill press?

Yes, it is highly recommended to use lubrication when drilling metal with a drill press. The lubrication helps to reduce friction and heat, which can cause the drill bit to become dull or even break. It also helps to extend the life of the drill bit.

What safety precautions should be taken when using a drill press for metal?

When using a drill press for metal, it is important to wear safety glasses or goggles to protect your eyes from any flying chips or debris. It is also recommended to wear gloves to protect your hands. Additionally, make sure to secure the workpiece properly and adjust the drill press speed and depth according to the metal you are working with.

How do I choose the right drill press for metalworking?

When choosing a drill press for metalworking, you will want to consider the horsepower of the motor, the maximum drilling capacity, the spindle speed range, and the construction quality of the press. It is also important to choose a drill press that has a sturdy table and a reliable chuck for securing the drill bit.

Can a drill press be used for other materials besides metal?

Yes, a drill press can be used for various materials besides metal. It can be used for drilling holes in wood, plastic, and other materials. However, it is important to adjust the speed and choose the appropriate drill bit for the specific material being drilled. Always refer to the manufacturer’s guidelines for the recommended settings.

What are the main advantages of using a drill press for metal compared to a handheld drill?

Using a drill press for metal has several advantages over a handheld drill. Firstly, it provides greater stability and accuracy, allowing for precise drilling without any accidental movements. Secondly, it can handle larger and deeper holes due to its larger size and higher capacity. Finally, it reduces the risk of injury as the workpiece is secured firmly, reducing the chances of it slipping or spinning on the drill bit.

Video:

![Mastering Pasta: The Art and Practice of Handmade Pasta, Gnocchi, and Risotto: The Art and Practice of Handmade Pasta, Gnocchi, and Risotto [A Cookbook]](https://m.media-amazon.com/images/I/51AIdJHulmL._SS520_.jpg)