Mastering the Art of Drilling Through Steel: Top Techniques and Tips

Drilling through steel is a task that requires precision, skill, and the right tools. Whether you are a professional contractor or a DIY enthusiast, mastering this art is essential for various projects, such as building structures, installing fixtures, or creating metalwork. However, drilling through steel can be a challenging process due to the material’s strength and hardness. In this article, we will explore the top techniques and tips to help you become proficient in drilling through steel.

One of the most important factors to consider when drilling through steel is choosing the right drill bit. The hardness of steel requires a drill bit that is specifically designed to tackle this tough material. High-speed steel (HSS) drill bits are commonly used for general drilling purposes, and they can be effective for drilling through softer steels. However, for drilling through hardened or stainless steel, cobalt or carbide drill bits are recommended. These drill bits are engineered to withstand the extreme hardness of steel and provide superior performance.

Another crucial technique to master is the drilling speed. When drilling through steel, it is essential to use a slow and consistent drilling speed. Avoid using high-speed settings, as they can cause the drill bit to overheat and dull quickly. Instead, start drilling at a lower speed and gradually increase it as needed. This will ensure that the drill bit stays cool and maintains its sharpness, resulting in clean and precise holes.

Proper lubrication is also key to successfully drilling through steel. Applying cutting fluid or oil to the drilling area helps to reduce friction and heat during the drilling process. It also prolongs the life of the drill bit by preventing it from overheating and becoming dull. Additionally, lubrication helps to remove metal shavings and debris, allowing for smoother and faster drilling.

In conclusion, mastering the art of drilling through steel requires the right tools, techniques, and attention to detail. By choosing the appropriate drill bit, maintaining a slow and consistent drilling speed, and using proper lubrication, you can successfully tackle any steel drilling project. Remember to wear appropriate safety gear, such as safety goggles and gloves, and always follow manufacturer guidelines for your specific tools and equipment. With practice and experience, you can become proficient in this essential skill and accomplish your steel drilling tasks with ease.

Important Factors to Consider Before Drilling

1. Material Type

Before drilling through steel, it is important to consider the type of material you are working with. Different types of steel have different hardness levels and may require different drilling techniques and tools. It is essential to choose the appropriate drill bit designed for the specific type of steel you are drilling.

2. Drill Bit Selection

Choosing the right drill bit is crucial for successfully drilling through steel. High-speed steel (HSS) drill bits are suitable for most steel drilling applications. However, for harder steel materials, cobalt or carbide-tipped drill bits may be more effective. It is important to select a drill bit that matches the hardness of the steel to minimize wear and maximize drilling efficiency.

3. Understanding the Steel Thickness

Drilling through steel requires knowledge of the steel’s thickness. Thin steel sheets or plates can be drilled through easily, while drilling through thick steel requires more power and may need specialized tools like a magnetic drill press. Understanding the thickness of the steel will help you choose the appropriate drilling equipment and techniques.

4. Lubrication

Lubrication plays a vital role in successful drilling through steel. Applying a suitable lubricant or coolant while drilling reduces heat and friction, prolonging the life of the drill bit and improving drilling performance. Lubrication also helps prevent the buildup of chips and debris, allowing smoother drilling and better hole quality.

5. Safety Precautions

Drilling through steel can be hazardous, so it is essential to take safety precautions. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection. Ensure that the work area is clear of obstacles and secure the workpiece properly before drilling. Following safety guidelines and using proper techniques will help prevent accidents and injury.

6. Speed and Feed Rates

The speed and feed rates at which you drill through steel are critical factors to consider. Using the correct speeds and feeds for the specific type of steel being drilled ensures efficient drilling and prolongs the life of the drill bit. Consult the manufacturer’s guidelines for recommended drilling speeds and feeds for the best results.

7. Pilot Holes

For drilling larger holes in steel, it is advisable to start with a pilot hole. A pilot hole provides a guide for the larger drill bit and reduces the chances of the bit wandering or slipping off the desired drilling location. The pilot hole should be smaller in diameter than the final hole and should accurately align with the desired location.

8. Holding Devices and Fixtures

Using appropriate holding devices and fixtures can enhance the drilling process and improve accuracy. Clamps, vices, or magnetic holding systems can secure the workpiece more effectively, reducing vibrations and movement during drilling. This ensures precision and helps prevent damage to the workpiece and drill bit.

9. Drill Press vs. Hand Drilling

When drilling through steel, using a drill press is often the preferred method over hand drilling. Drill presses provide greater stability, precision, and control, especially when drilling through harder steel or larger holes. Hand drilling may be suitable for smaller holes or less demanding applications, but a drill press is generally more efficient and accurate.

10. Regular Maintenance

To achieve optimal drilling results and prolong the life of your drilling equipment, regular maintenance is essential. Keep your drill bits sharp and clean, and replace any worn or damaged bits. Clean the drill press or handheld drill regularly to remove debris and lubricate moving parts as recommended by the manufacturer. Regular maintenance will ensure continued drilling performance and prevent unnecessary wear and tear.

Choosing the Right Drill Bit for Steel

When it comes to drilling through steel, having the right drill bit is crucial. The wrong drill bit can result in poor performance, damage to the material, and even personal injury. To ensure successful drilling in steel, it is important to choose the right drill bit for the job.

Type of Drill Bit

There are various types of drill bits available for drilling through steel, each designed for different purposes. The most common types include twist drill bits, cobalt drill bits, and carbide drill bits.

Twist drill bits are the most commonly used for general purpose drilling in steel. They are made of high-speed steel and have a sharp point with flutes that remove the material as it drills. Twist drill bits are cost-effective and can be used for a wide range of steel drilling applications.

Cobalt drill bits are designed for drilling through hard metals like stainless steel and cast iron. They are made of a special alloy called cobalt steel, which is able to withstand high temperatures and provide excellent performance in tough materials.

Carbide drill bits are the most durable and resistant to high temperatures. They are ideal for drilling through hardened steel and other abrasive materials. Carbide drill bits are more expensive than twist drill bits or cobalt drill bits, but they can last much longer and provide superior results.

Size of Drill Bit

The size of the drill bit is another important factor to consider when drilling through steel. Choosing the right size will depend on the specific application and the size of the hole you need to drill. Drill bits are available in various sizes, usually measured in inches or millimeters. It is important to select a drill bit that matches the desired hole size to avoid any issues during drilling.

Coating on Drill Bit

Some drill bits come with a special coating that helps to reduce friction and increase the lifespan of the bit. These coatings can include titanium nitride, black oxide, or cobalt oxide. The coating also helps to dissipate heat, which is particularly important when drilling through steel. Choosing a drill bit with a suitable coating can greatly improve performance and increase the overall efficiency of the drilling process.

Summary

Choosing the right drill bit for steel is essential for successful drilling. Consider the type of drill bit, the size of the bit, and any coatings that may improve performance. With the right drill bit, you can ensure clean, precise, and efficient drilling through steel.

Essential Techniques for Drilling through Steel

When it comes to drilling through steel, it is important to use the right techniques to ensure effective and efficient results. Here are some essential techniques to keep in mind:

1. Use the Appropriate Drill Bit

Choosing the right drill bit for steel is crucial. Use high-speed steel (HSS) or cobalt drill bits specifically designed for drilling through metal. These drill bits are harder and have a sharper cutting edge to withstand the hardness of steel.

2. Apply Lubrication

Applying lubrication to the drill bit and the surface of the steel can reduce heat and friction. This helps to prolong the life of the drill bit and increase drilling speed. Cutting fluid or a light oil can be used as lubrication.

3. Mark the Drilling Spot

Before drilling, it is important to mark the spot on the steel where you want the hole to be. This helps to ensure accurate drilling and prevents the drill bit from wandering on the surface. Use a center punch or a marker to make a clear mark.

4. Start with a Pilot Hole

For larger holes, it is recommended to start with a pilot hole. A pilot hole serves as a guide for the larger drill bit and helps to prevent the drill bit from slipping or wandering. Choose a smaller drill bit size than the final hole size and drill a pilot hole before proceeding with the larger bit.

5. Use Proper Drilling Speed and Pressure

When drilling through steel, it is important to maintain a consistent drilling speed and apply adequate pressure. Too much speed can cause the drill bit to overheat and wear out quickly, while too little speed can result in inefficient drilling. Applying too much pressure can also lead to drill bit breakage or damage.

6. Use Clamps or Workholding Devices

To ensure stability and accuracy while drilling through steel, it is recommended to use clamps or workholding devices to secure the piece. This prevents the steel from moving or vibrating during drilling, resulting in precise and clean holes.

7. Clear Chips Frequently

Steel chips can accumulate during drilling and cause the drill bit to bind or the hole to become rough. To prevent this, clear out the chips frequently by retracting the drill bit, cleaning the hole, and continuing the drilling process. This helps to maintain drilling efficiency and accuracy.

By following these essential techniques, you can master the art of drilling through steel and achieve professional results. Remember to always prioritize safety and wear appropriate protective gear when working with power tools.

Top Tips for Successful Drilling

1. Choose the Right Drill Bit

One of the most important factors in successful drilling is choosing the right drill bit. Different materials require different types of bits, so make sure you have the appropriate bit for drilling through steel. For steel, high-speed steel (HSS) bits or cobalt bits are recommended.

2. Use Lubrication

When drilling through steel, it’s important to use lubrication to reduce heat and friction. Apply a cutting oil or a lubricant specially designed for metal drilling to the surface of the steel before drilling. This will not only help extend the life of your drill bit, but also make the drilling process smoother and more efficient.

3. Start with a Pilot Hole

To improve accuracy and prevent wandering, it’s a good idea to start drilling through steel with a small pilot hole. This will help guide the larger drill bit and prevent it from slipping or veering off course. Choose a drill bit that is slightly smaller than the desired hole size, and drill a small pilot hole before moving on to a larger bit.

4. Slow and Steady Wins the Race

Drilling through steel requires a slower drilling speed compared to drilling through other materials. This is because steel is a tough material that generates a lot of heat when drilled too fast. Use a slower speed setting on your drill and apply steady pressure to prevent overheating and extend the life of your drill bit.

5. Clear Chips and Debris

While drilling, it’s important to regularly clear away chips and debris from the hole. This will help prevent the drill bit from getting clogged and losing its cutting effectiveness. Use a brush or compressed air to remove debris from the hole, and periodically retract the bit to clear away any built-up chips.

6. Use Clamps or Vices

When drilling through steel, securing the material in place is crucial for accuracy and safety. Use clamps or a vice to firmly hold the steel in place, ensuring it doesn’t move or wobble during drilling. This will help prevent accidents and make the drilling process more controlled and precise.

7. Wear Safety Gear

Drilling through steel can produce sharp metal shavings and debris, making safety gear essential. Wear safety glasses to protect your eyes from flying particles, and use gloves to protect your hands from sharp edges. Additionally, consider wearing ear protection if drilling with a loud power drill.

8. Take Breaks and Cool Down

If you’re drilling through multiple holes or drilling for an extended period, it’s important to take breaks and allow the drill and drill bit to cool down. Continuous drilling can generate a lot of heat, which can damage the bit and reduce its lifespan. Give the drill and bit time to cool down between drilling sessions.

9. Keep Spare Drill Bits on Hand

Even with proper technique and care, drill bits will eventually wear out and become dull. To avoid interruptions and delays in your drilling project, it’s a good idea to have spare drill bits on hand. This will allow you to quickly replace a worn-out bit and continue drilling without having to stop and purchase a new one.

10. Practice Makes Perfect

Drilling through steel can be a challenging task, especially for beginners. Don’t get discouraged if you encounter difficulties at first. Like any skill, drilling takes practice to master. Keep experimenting with different techniques, drill bits, and speeds until you find what works best for your project.

Safety Precautions for Drilling through Steel

1. Wear Personal Protective Equipment (PPE)

When drilling through steel, it is crucial to wear the appropriate Personal Protective Equipment (PPE) to protect yourself from potential hazards. This includes:

- Safety glasses: To shield your eyes from flying debris.

- Ear protection: To reduce exposure to loud noises generated during drilling.

- Gloves: To protect your hands from cuts and abrasions.

- Respiratory mask: To prevent inhalation of harmful dust particles.

- Steel-toe boots: To protect your feet from falling objects or accidental foot injuries.

2. Secure the Workpiece

Before drilling through steel, ensure that the workpiece is securely clamped or fastened in place. This prevents the material from moving, which can lead to accidents or damage to the drilling equipment.

3. Use the Correct Drill Bit

Using the correct drill bit for drilling through steel is essential for both safety and efficiency. Choose a high-quality, cobalt or carbide-tipped drill bit specifically designed for metal drilling. Ensure the drill bit is sharp and in good condition before beginning.

4. Start with a Pilot Hole

When drilling through steel, it is recommended to start with a pilot hole. A pilot hole creates a guide for the larger drill bit and helps prevent slipping or wandering of the bit. The pilot hole should be smaller in diameter than the final hole size.

5. Apply Adequate Pressure

While drilling through steel, apply steady and moderate pressure to the drill. Avoid excessive force or leaning on the drill, as this can lead to loss of control and cause accidents. Let the drill bit do the work and allow it to cut through the steel at its own pace.

6. Use Cooling Lubricant

Using a cooling lubricant, such as cutting oil or water, is beneficial when drilling through steel. It helps to keep the drill bit cool, reduces friction, and helps prolong the life of the drill bit. Apply the lubricant to the drilling area frequently during the drilling process.

7. Beware of Heat and Sparks

Drilling through steel can generate heat and sparks. Ensure you are in a well-ventilated area and keep flammable materials away. Avoid drilling near any potentially explosive materials or gases. If necessary, use a heat-resistant material or shield to protect surrounding surfaces.

8. Keep Fingers and Body Clear

Always keep your fingers, hands, and body clear from the drilling area. Avoid distractions and focus on the task at hand. Never attempt to hold the material being drilled by hand while drilling.

9. Power Off and Inspect

Once you have finished drilling through the steel, power off the drill and inspect the workpiece and surroundings. Remove any metal shavings or debris to prevent slipping or injuries. Check for any damages to the drill or drill bit and address them accordingly.

10. Seek Professional Help if Unsure

If you are unsure about drilling through steel or encounter a complicated drilling project, it is best to seek professional assistance. A professional with experience in metal drilling can provide guidance, ensure safety, and help you achieve the desired results.

By following these safety precautions, you can minimize the risk of accidents and injuries when drilling through steel. Remember to always prioritize safety and take the necessary precautions to protect yourself and those around you.

Common Mistakes to Avoid

1. Using the Wrong Drill Bit

One of the most common mistakes when drilling through steel is using the wrong drill bit. Steel is a tough material, and not all drill bits are designed to handle its hardness. Using a regular drill bit can result in dulling the bit quickly or even breaking it. To avoid this mistake, make sure to use a drill bit specifically designed for drilling through steel. These bits are made from high-speed steel or cobalt, which can withstand the hardness of steel.

2. Not Using Proper Lubrication

Lack of proper lubrication is another common mistake when drilling through steel. Drilling through steel generates a lot of heat, which can cause the drill bit to overheat and wear out faster. Using cutting fluid or a lubricant specifically designed for metal drilling can help reduce heat and friction, extending the life of your drill bit. Apply the lubrication directly to the drill bit and the surface of the steel before drilling.

3. Applying Too Much Pressure

When drilling through steel, it’s important to let the drill bit do the work. Applying too much pressure can cause the drill bit to break or result in an uneven hole. Instead, apply a moderate amount of pressure and let the drill bit cut through the steel at its own pace. If you feel the need to use excessive force, it may be a sign that your drill bit or technique needs adjustment.

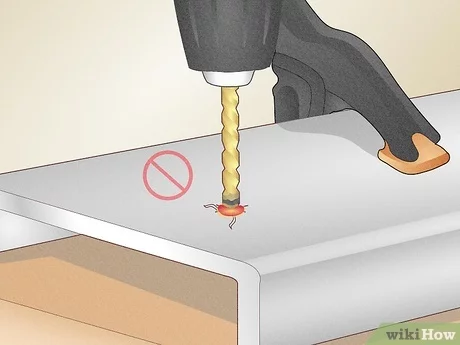

4. Not Using Proper Technique

Using the wrong drilling technique is another common mistake when drilling through steel. It’s important to start drilling at a slow speed and gradually increase the speed as the hole deepens. This helps prevent the drill bit from slipping or wandering off course. Additionally, make sure to keep the drill bit perpendicular to the surface of the steel to ensure a straight and accurate hole.

5. Neglecting Safety Precautions

Neglecting safety precautions is a mistake that should never be made when drilling through steel. Steel drilling can produce sharp metal shavings and debris, which can cause injuries if proper safety measures are not taken. Always wear safety goggles, gloves, and a face mask to protect yourself. Additionally, securely clamp down the steel material to prevent it from moving or slipping during drilling.

6. Rushing the Process

Finally, rushing the drilling process is a common mistake that can lead to subpar results. Take your time and go slow when drilling through steel. Rushing can cause mistakes, such as crooked holes or damaged drill bits. Remember, mastering the art of drilling through steel takes practice and patience.

Avoiding these common mistakes will help you achieve better results when drilling through steel. Remember to use the right drill bit, apply proper lubrication, use the correct technique, prioritize safety, and take your time. With practice and attention to detail, you’ll become a skilled master of drilling through steel.

FAQ:

What techniques can I use to effectively drill through steel?

There are several techniques that you can use to effectively drill through steel. One technique is to start with a small pilot hole and gradually increase the size using larger drill bits. Another technique is to use a cutting fluid or lubricant to reduce friction and heat buildup. Additionally, using a slower drilling speed and applying steady pressure can also help you drill through steel more effectively.

What type of drill bit should I use when drilling through steel?

When drilling through steel, it is best to use a high-speed steel (HSS) drill bit. HSS drill bits are designed to withstand the heat and friction generated when drilling through hard materials like steel. Cobalt drill bits are also a good option as they are harder and can maintain their hardness at higher temperatures, making them more durable when drilling through steel.

How can I prevent the drill bit from slipping on the steel surface?

To prevent the drill bit from slipping on the steel surface, you can start by making a small indentation or mark on the surface with a center punch. This will provide a guide for the drill bit and help prevent it from wandering. It is also important to apply steady pressure and keep the drill perpendicular to the surface to minimize the chance of slipping.

What are some safety precautions to follow when drilling through steel?

When drilling through steel, it is important to wear safety goggles to protect your eyes from flying debris. Additionally, wearing gloves can help protect your hands from sharp edges and prevent injuries. It is also advisable to secure the material you are drilling to prevent it from moving or vibrating during the drilling process. Finally, make sure to work in a well-ventilated area to avoid inhaling any dust or fumes.

Are there any special considerations for drilling through hardened steel?

When drilling through hardened steel, the drilling process can be more challenging. It is important to use a carbide or cobalt drill bit specifically designed for drilling through hardened materials. These specialized drill bits are harder and can withstand the increased hardness of the steel. Additionally, applying cutting fluid or lubricant and using a slower drilling speed can help reduce heat buildup and prolong the life of the drill bit.

Video: