Mastering the Art of Drilling Out a Barrel Lock

Barrel locks are a common type of lock used in many applications, including doors, cabinets, and padlocks. However, there may come a time when you need to gain access to a locked barrel, and you don’t have the key. In such cases, drilling out the barrel lock can be a useful skill to have.

Drilling out a barrel lock, also known as destructive entry, involves using a drill to remove the internal components of the lock, allowing you to open it without a key. This method should only be used as a last resort, as it can permanently damage the lock and render it unusable. It’s important to note that drilling out a barrel lock may be illegal in some jurisdictions without proper authorization.

Before attempting to drill out a barrel lock, it’s essential to have the right tools and equipment. A high-quality drill with a variety of drill bits is necessary to successfully remove the lock’s internal components. Additionally, protective gear, such as safety goggles and gloves, should be worn to prevent injury during the process.

One critical factor to consider when drilling out a barrel lock is the drill bit’s size and type. The size of the drill bit will depend on the lock’s dimensions, so it’s essential to measure the lock accurately before selecting the appropriate drill bit. Diamond-coated drill bits are often recommended for drilling through metal locks, as they provide excellent cutting power and durability.

Disclaimer: It’s important to note that drilling out a barrel lock should only be done legally and with proper authorization. This article is purely for informational purposes and does not endorse or encourage any illegal activities. Always consult with a professional locksmith or legal authority before attempting to drill out a lock.

Understanding the Mechanics of Barrel Locks

A barrel lock is a type of lock that consists of a cylindrical barrel and a key that rotates within the barrel to unlock it. These locks are commonly used in various applications, such as vending machines, utility meters, and security systems.

Components of a Barrel Lock

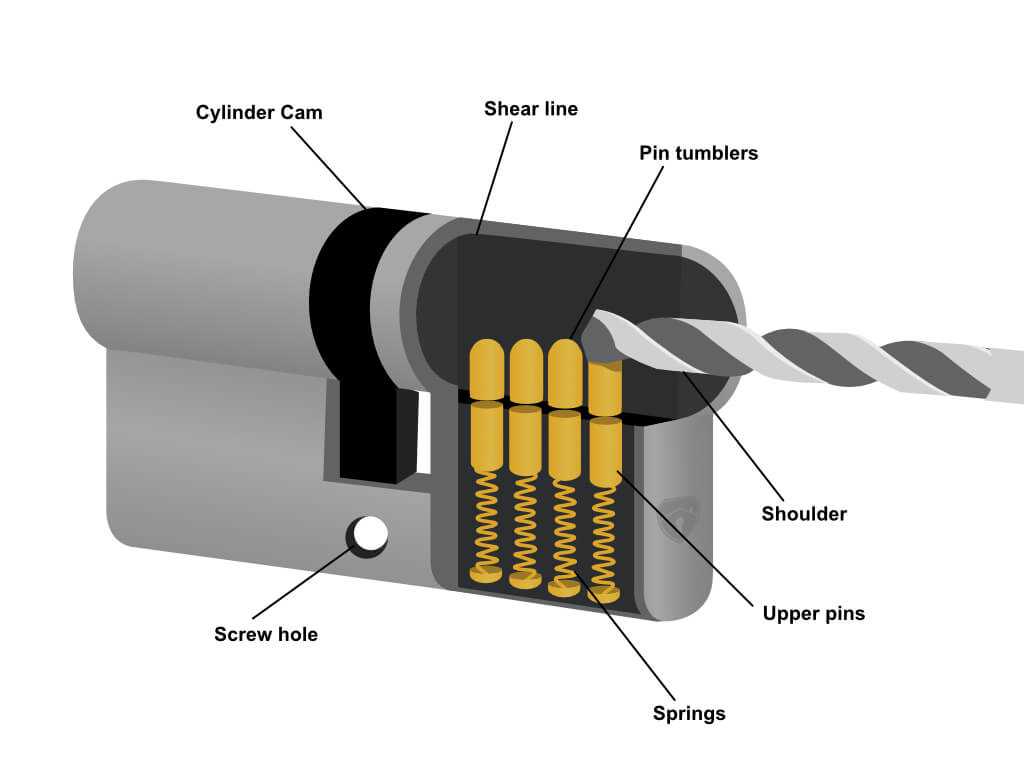

A barrel lock typically consists of the following components:

- Barrel: The main cylindrical body of the lock that houses the keyway.

- Keyway: The channel or groove within the barrel where the key is inserted.

- Spring-loaded pins: Small pins or tumblers within the barrel that align with the cuts or grooves on the key.

- Driver pins: Pins that are pushed up by springs to block the rotation of the barrel when the wrong key is inserted.

- Chamber: The space between the driver pins and the springs.

Working Principle of a Barrel Lock

Understanding the working principle of a barrel lock is essential for effectively drilling it out. Here is a step-by-step overview of how a barrel lock operates:

- Inserting the key: The key is inserted into the keyway, and the cuts or grooves on the key align with the spring-loaded pins within the barrel.

- Aligning the pins: When the correct key is inserted, the pins align, creating a gap between the driver pins and the springs.

- Rotating the barrel: With the pins aligned, the barrel can be rotated, allowing the lock to be unlocked.

Note: If the wrong key is inserted, the pins will not align, and the barrel will not rotate.

Drilling Out a Barrel Lock

Drilling out a barrel lock is a method used to bypass the lock when the key is lost or unavailable. This process involves carefully drilling through the various components of the lock to disable it. It is important to exercise caution and use the right tools and techniques to avoid damaging the surrounding mechanism and causing further complications.

| Tool | Description |

|---|---|

| Drill | Power tool used to create holes |

| Drill bits | Cutting tools for drilling holes of various sizes |

| Protective gear | Safety equipment, such as goggles and gloves |

Before attempting to drill out a barrel lock, it is advisable to consult a professional or seek proper training to ensure safety and minimize damage to the lock and its surrounding components.

Remember, it is important to adhere to laws and regulations regarding lock drilling and seek permission when necessary.

Tools and Equipment for Drilling Out a Barrel Lock

When it comes to drilling out a barrel lock, having the right tools and equipment is crucial. Here are some of the essential items you will need:

1. Drill

A high-quality drill with a variable speed setting is essential for drilling out a barrel lock. It is important to choose a drill that has enough power to penetrate the lock, but also allows for precise control.

2. Drill Bits

Specialized drill bits are necessary for drilling out a barrel lock. Diamond-coated or carbide-tipped drill bits are the most effective for cutting through the metal of the lock. It is recommended to have a variety of sizes to ensure compatibility with different types of locks.

3. Lubricant

Applying lubricant to the drill bit and lock while drilling can help reduce friction and prevent overheating. This not only prolongs the life of the drill bit but also makes the drilling process smoother and more efficient.

4. Safety Glasses

Protecting your eyes is essential when drilling out a barrel lock. Tiny metal shavings and debris can be expelled during the drilling process, so wearing safety glasses is a must to avoid potential eye injuries.

5. Gloves

Wearing gloves is recommended to protect your hands from sharp metal edges and to provide a better grip on the drill while drilling. Choose gloves that are resistant to cuts and abrasions.

6. Vise

Using a vise to secure the lock in place is highly recommended. This will ensure stability during the drilling process and prevent the lock from moving around, resulting in a more precise drilling operation.

7. Needle Files or Dremel Tool

After successfully drilling out the barrel lock, you may need to clean up the hole or make adjustments. Needle files or a Dremel tool with appropriate attachments can help smooth out any rough edges or remove any remaining metal shards.

8. Pliers

If the lock is still intact after drilling, you may need a pair of pliers to turn the lock and open the mechanism. This can be particularly useful in situations where the lock is jammed or not functioning properly.

Remember, drilling out a barrel lock should only be done in legal and ethical situations, such as when you have lost the key to your own lock or in other legitimate scenarios. Improper use of these tools can lead to damage or injury, so always exercise caution and follow proper safety protocols.

Step-by-Step Guide to Drilling Out a Barrel Lock

Materials Needed:

- Power drill

- Drill bits (ranging from 1/8 inch to 1/2 inch)

- Protective goggles

- Work gloves

Step 1: Prepare the Work Area

Before you begin drilling out a barrel lock, it’s important to prepare the work area. Clear any debris or obstructions around the lock to ensure a safe and unobstructed drilling process.

Step 2: Put on Protective Gear

Always prioritize safety when drilling out a lock. Put on protective goggles to shield your eyes from any flying debris, and wear work gloves to protect your hands.

Step 3: Select the Correct Drill Bit

Choose a drill bit that is slightly larger than the lock’s pin diameter. It’s best to start with a smaller drill bit and gradually increase the size if needed. This will help prevent damage to the lock mechanism.

Step 4: Insert the Drill Bit

Insert the chosen drill bit into your power drill. Ensure that it is securely tightened to the drill.

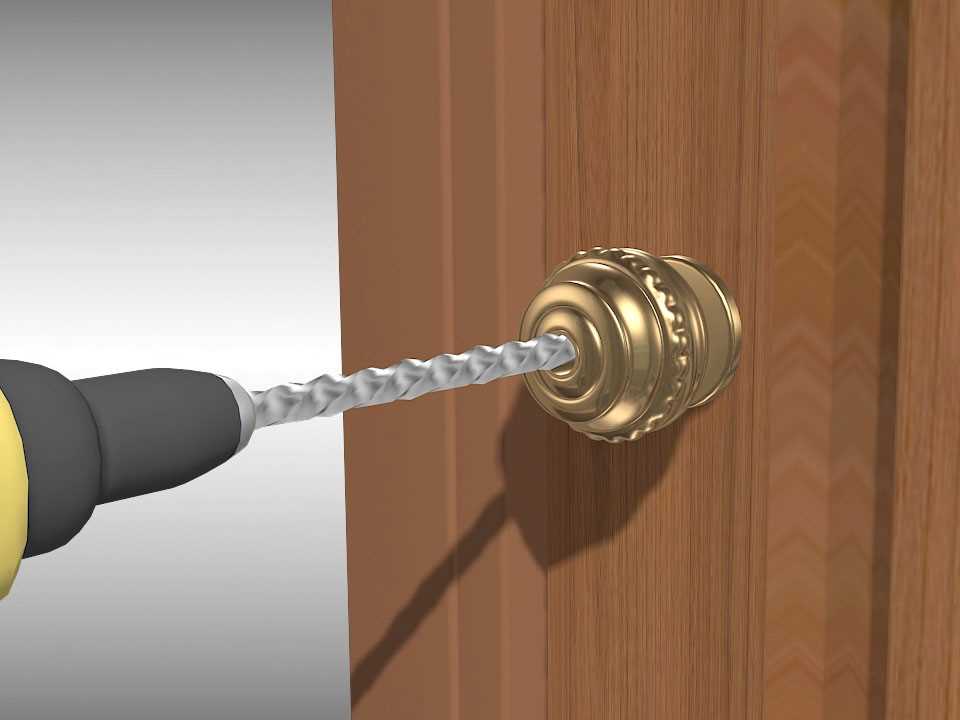

Step 5: Position the Drill Bit

Position the drill bit on the center of the lock’s pin. Apply light pressure to keep the drill bit in place while drilling.

Step 6: Start Drilling

Start the power drill and apply steady pressure to the lock. Begin drilling, aiming to penetrate the lock and create a hole in the pin.

Step 7: Increase Drill Bit Size

If the drill bit is not large enough to completely remove the pin, stop drilling and switch to a larger drill bit. Repeat steps 5 and 6 until the pin is fully removed.

Step 8: Remove the Lock

Once the pin has been drilled out, you should be able to easily remove the lock from its position. Dispose of the lock properly.

Step 9: Test the Lock

If you are replacing the lock, be sure to test the new lock before fully installing it. This will ensure that the new lock is functioning properly and has been installed correctly.

Step 10: Clean Up

After completing the drilling process, clean up any debris or metal shavings that may have been generated. Dispose of them safely to avoid any accidents or injuries.

Conclusion

By following these step-by-step instructions, you can successfully drill out a barrel lock. Remember to prioritize safety and take your time during the drilling process to prevent any damage to the lock or surrounding area.

Tips and Techniques for Successful Drilling

1. Use the Right Tools

Having the right tools is crucial for successful drilling. Make sure you have a high-quality drill with a sharp bit that is suitable for the material you are drilling. For barrel locks, a drill with a small diamond or carbide bit works best.

2. Start with a Pilot Hole

Before drilling the main hole, it is advisable to start with a pilot hole. This small hole will help guide the drill bit and reduce the chances of it slipping or wandering off track.

3. Apply Steady Pressure

When drilling, it is important to apply steady pressure to the drill. Let the drill do the work and avoid pushing too hard, as this can cause the bit to get stuck or break. Maintain a consistent speed throughout the drilling process.

4. Use Lubrication

Using lubrication can make drilling easier and reduce friction. Apply a small amount of cutting oil or lubricant to the drill bit and the surface being drilled. This will help keep the bit cool and prevent it from overheating.

5. Take Breaks and Cool Down

Drilling can generate a lot of heat, especially when drilling through metal. It is important to take breaks and cool down the drill bit to prevent overheating and prolong its lifespan. Dip the bit in cool water or use a cooling spray during breaks.

6. Secure the Workpiece

Before drilling, make sure the workpiece is securely clamped or held in place. This will prevent it from moving or spinning during drilling, which can lead to inaccurate holes or injuries.

7. Measure and Mark the Hole

Precision is key when drilling out a barrel lock. Use a measuring tool, such as a caliper, to accurately measure the size and position of the hole. Mark the spot using a center punch or a pencil to ensure accurate drilling.

8. Practice Patience

Drilling can be a slow and meticulous process, especially when dealing with barrel locks. Take your time and be patient. Rushing or forcing the drilling can result in damaged locks or broken drill bits.

9. Work in a Well-Lit Area

Adequate lighting is essential for successful drilling. Set up your work area in a well-lit space or use additional lighting to ensure clear visibility of the workpiece and the drilling area.

10. Clean and Maintain Your Tools

After drilling, clean and maintain your drill and drill bits. Remove any debris or shavings from the drill, as this can affect its performance. Regularly sharpen or replace drill bits to ensure clean and efficient drilling.

By following these tips and techniques, you can improve your drilling skills and increase the chances of successfully drilling out a barrel lock.

Potential Challenges and How to Overcome Them

Lack of Proper Tools

One potential challenge when drilling out a barrel lock is the lack of proper tools. Without the right tools, it can be difficult to effectively remove the lock and access the contents of the barrel.

To overcome this challenge, it is recommended to invest in a quality lock picking set that includes drills and bits specifically designed for barrel locks. These tools will ensure that you have the necessary equipment to successfully drill out the lock.

Breaking Drill Bits

Another challenge that may arise is the risk of breaking drill bits. Barrel locks can be made of tough materials such as hardened steel, which can easily damage drill bits if not handled properly.

To prevent breaking drill bits, it is important to use bits made from high-quality materials such as cobalt or carbide. These materials are more durable and less likely to break during the drilling process. It is also crucial to use the correct sized bit for the lock to minimize the risk of breakage.

Lock Malfunction

In some cases, the barrel lock may malfunction or become damaged, making it even more challenging to drill out. This could be due to factors such as rust, corrosion, or wear and tear over time.

If you encounter a lock malfunction, it is advisable to try lubricating the lock with a penetrating oil or lock lubricant. This may help loosen any rust or debris that may be causing the lock to malfunction. In more severe cases, it may be necessary to seek the assistance of a professional locksmith.

Time and Patience

Drilling out a barrel lock can be a time-consuming process that requires patience and precision. It is important to approach the task with a calm and steady hand to avoid damaging the lock or surrounding areas.

To overcome the challenge of time and patience, it is essential to allocate enough time for the drilling process. It is also recommended to take breaks and rest your hand to maintain a steady grip. Rushing the process can lead to mistakes and may result in a less successful outcome.

Safety Concerns

Lastly, drilling out a barrel lock can pose safety concerns if not done carefully. Flying debris, damaged drill bits, and potential injury to fingers and hands are all risks that should be taken into consideration.

To ensure safety, it is important to wear protective eyewear and gloves when drilling out a barrel lock. This will help protect against any flying debris and reduce the risk of injury. Additionally, it is crucial to maintain a secure grip on the drill to prevent accidents.

Conclusion

Mastering the art of drilling out a barrel lock comes with its own set of challenges. However, with the right tools, techniques, and precautions, these challenges can be overcome. By being prepared and patient, you can successfully drill out a barrel lock and gain access to the contents of the lock.

Safety Precautions when Drilling Out a Barrel Lock

1. Wear Protective Gear

Before drilling out a barrel lock, ensure that you are wearing the necessary protective gear. This includes safety goggles to protect your eyes from dust and debris, gloves to protect your hands from sharp edges, and a face mask to prevent inhaling any harmful particles.

2. Choose the Right Drill Bit

Using the wrong drill bit can lead to accidents and damage to the lock or surrounding area. Make sure to use a drill bit that is specifically designed for drilling through metal. It should be sharp and the correct size for the lock you are working on.

3. Secure the Lock Properly

Before starting the drilling process, ensure that the lock is securely positioned and stable. Use clamps or vices to hold the lock in place to prevent it from moving or spinning during drilling. This will help increase precision and reduce the risk of accidents.

4. Work in a Well-Ventilated Area

Drilling out a barrel lock can produce dust and fumes, so it is important to work in a well-ventilated area. Open windows or use exhaust fans to ensure proper ventilation. If working in a confined space, consider using a portable ventilation system or wearing a respirator to protect yourself from harmful fumes.

5. Use Proper Technique

When drilling out a barrel lock, it is important to use the correct drilling technique. Apply steady pressure and start drilling at a slow speed, gradually increasing the speed as necessary. Avoid excessive force, as this can lead to breaking the drill bit or damaging the lock.

6. Keep a Fire Extinguisher Nearby

Accidents can happen, so it is always a good idea to have a fire extinguisher nearby when working with power tools. In the event of a fire caused by sparks or other ignition sources, you can quickly extinguish it before it becomes a serious hazard.

7. Dispose of Waste Properly

After successfully drilling out a barrel lock, dispose of any waste materials properly. This includes used drill bits, metal shavings, and any other debris. Place them in a designated container or bag and dispose of them according to local regulations.

8. Practice Caution and Patience

Drilling out a barrel lock requires precision and careful attention to detail. Take your time and proceed with caution to minimize the risk of accidents. If you are not confident in your skills or experience, consider seeking professional assistance to ensure the task is completed safely.

By following these safety precautions, you can minimize the risks associated with drilling out a barrel lock and complete the task safely and successfully.

FAQ:

What is a barrel lock?

A barrel lock is a type of lock that is commonly used to secure utility meters, such as water, gas, or electric meters.

Why would someone need to drill out a barrel lock?

There are a few reasons why someone might need to drill out a barrel lock. One possible reason is if they have lost the key to the lock and need to open it. Another reason could be if they are trying to gain unauthorized access to a secured area.

What tools are needed to drill out a barrel lock?

To drill out a barrel lock, you will typically need a drill with a metal-cutting drill bit, a wrench, and a screwdriver.

What is the process for drilling out a barrel lock?

The process for drilling out a barrel lock involves first applying pressure to the lock with a wrench to keep it steady. Then, using a drill with a metal-cutting drill bit, you carefully drill into the lock until it is completely drilled out. Finally, you can use a screwdriver to remove any remaining pieces of the lock and gain access.

Is drilling out a barrel lock legal?

No, drilling out a barrel lock without proper authorization is not legal. It is important to only use these techniques in situations where you have the legal right to do so, such as in the case of a lost key or other valid reason for opening the lock.

Are there any risks or dangers involved in drilling out a barrel lock?

Yes, there are risks involved in drilling out a barrel lock. If you are not careful, you could damage the surrounding area or cause injury to yourself. Additionally, as previously mentioned, it is important to only drill out a barrel lock in situations where you have the legal right to do so.

Can a professional locksmith drill out a barrel lock?

Yes, a professional locksmith has the necessary skills and tools to safely and efficiently drill out a barrel lock if needed. It is often recommended to hire a professional locksmith to ensure that the task is done properly and legally.

Video: