Mastering the Art of Drilling into Granite Rock

Drilling into granite rock requires a certain level of expertise and skill. This type of rock is known for its hardness and durability, which makes it challenging to penetrate. However, with the right tools and techniques, it is possible to successfully drill into granite rock.

One of the key factors in drilling into granite rock is choosing the right drill bit. Diamond-tipped drill bits are the most effective for drilling into granite, as they are able to withstand the hardness of the rock. These drill bits are made with industrial-grade diamonds, which are the hardest substance known to man. The diamonds in the drill bit help to create friction and generate heat, which aids in the drilling process.

In addition to using the right drill bit, it is important to use the appropriate drilling technique when working with granite rock. It is recommended to start drilling at a slow speed and gradually increase the speed as you go deeper into the rock. This helps to prevent the drill bit from overheating and prolongs its lifespan. It is also important to apply constant pressure while drilling, as this helps the drill bit to bite into the rock and create a hole.

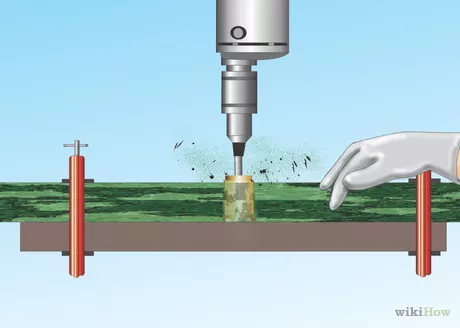

Another important aspect of drilling into granite rock is ensuring that the drill is held securely in place. Using a drill press or a clamp can help to stabilize the drill and prevent it from slipping or moving around while drilling. This ensures accuracy and prevents the drill bit from getting damaged or breaking.

In conclusion, drilling into granite rock requires the right tools, techniques, and expertise. By choosing the right drill bit, using the appropriate drilling technique, and ensuring that the drill is held securely in place, it is possible to master the art of drilling into granite rock.

Understanding Granite Rock Composition

Granite is a common type of igneous rock that is widely used in construction and other industries. Understanding its composition is crucial for successfully drilling into it. Granite is composed mainly of three minerals: quartz, feldspar, and mica.

Quartz

Quartz is one of the most abundant minerals found in granite. It is a hard, crystalline mineral made up of silicon and oxygen atoms. Quartz crystals give granite its glossy appearance and contribute to its resistance to heat and pressure.

Feldspar

Feldspar is another major mineral found in granite. It is a group of minerals that make up about 60% of the Earth’s crust. Feldspar is made up of aluminum, silicon, and oxygen atoms and can be found in different colors, including pink, white, and gray. It provides granite with its characteristic grains and helps improve its mechanical properties.

Mica

Mica is a unique mineral that is easily distinguishable in granite. It is characterized by its perfect cleavage, allowing it to split into thin, flexible sheets. Mica gives granite its shimmering appearance and enhances its aesthetic value.

Other Minerals

In addition to quartz, feldspar, and mica, granite may contain small amounts of other minerals, such as amphibole, biotite, and hornblende. These minerals can vary in composition and affect the overall properties of the granite.

Overall Composition

The exact composition of granite can vary depending on its origin. However, on average, granite is composed of approximately 20-60% quartz, 10-65% feldspar, and 5-15% mica. The remaining percentages are made up of other minerals and substances, such as amphibole and biotite.

Choosing the Right Tools for Drilling

When it comes to drilling into granite rock, having the right tools is crucial for success. Granite is an incredibly hard and durable material, so using the wrong tools can result in damage to the drill bit or even the entire drilling machine. To ensure that you choose the right tools for drilling, consider the following factors:

1. Diamond Drill Bits

When drilling into granite, diamond drill bits are the most effective choice. Diamond bits are specifically designed to handle the hardness of granite and provide clean and accurate holes. They are made with industrial-grade diamonds bonded to the tip of the bit, which allows them to cut through the granite with ease. Diamond drill bits are available in various sizes and shapes to accommodate different drilling needs.

2. Drill Speed and Torque

Granite is a tough material that requires high drill speeds and torque to penetrate effectively. When selecting a drilling machine, make sure to choose one that offers adjustable speed settings and high torque. This will give you the power and control necessary to drill through the granite without exerting excessive force or causing damage to the drill bit.

3. Water Cooling System

Drilling into granite generates a significant amount of heat, which can cause the drill bit to overheat and become dull. A water cooling system is essential for keeping the drill bit cool and lubricated during the drilling process. Look for a drilling machine that has a built-in water cooling system or use a separate water source to ensure proper cooling.

4. Safety Equipment

When working with granite rock, it’s important to prioritize safety. Make sure to wear appropriate safety gear, such as safety glasses, gloves, and a dust mask, to protect yourself from flying debris and dust. Additionally, consider using a drilling jig or clamp to secure the granite in place and prevent any accidents or injuries.

5. Accessories and Attachments

In addition to the main drilling tools, there are various accessories and attachments that can aid in the drilling process. For example, using a drill guide can help ensure precise hole placement, while a depth stop attachment can control the depth of the hole. Consider your specific drilling needs and look for accessories that can enhance the accuracy and efficiency of your drilling tasks.

By considering these factors and selecting the right tools for drilling, you can maximize your chances of successfully drilling into granite rock. Remember to always follow proper drilling techniques and prioritize safety to achieve the best results.

Preparation and Safety Measures

Gather the Necessary Equipment

Before beginning any drilling project in granite rock, it is important to gather all the necessary equipment. This may include:

- A high-quality diamond-tipped drill bit specifically designed for drilling into granite

- A power drill that is compatible with the chosen drill bit

- Safety glasses to protect your eyes from any flying debris

- Ear protection to minimize the noise produced during drilling

- Dust mask to avoid inhaling granite dust

- Work gloves to protect your hands

- A tape measure and a pencil for marking the drilling spots

Choose the Right Drilling Technique

There are several drilling techniques that can be used to drill into granite rock, depending on the specific requirements of the project. These techniques include:

-

Percussion Drilling: This technique involves using a hammering action in combination with the rotation of the drill bit to break through the granite rock. It is commonly used for smaller holes and less dense granite.

-

Rotary Drilling: This technique involves the continuous rotation of the drill bit to create the hole. It is typically used for larger holes and denser granite.

-

Dual Rotary Drilling: This technique combines elements of both percussion drilling and rotary drilling. It is effective for drilling through tough granite formations.

Ensure Proper Safety Measures

When drilling into granite rock, it is essential to follow proper safety measures to prevent accidents and injuries. Some important safety measures to consider include:

- Wear appropriate personal protective equipment, including safety glasses, ear protection, dust mask, and work gloves.

- Secure the granite rock firmly in place to prevent it from slipping or moving during drilling.

- Use clamps or a vise to secure the granite rock if necessary.

- Start drilling at a slow speed and gradually increase the speed as needed. This helps to prevent the drill bit from overheating and breaking.

- Regularly check the drill bit for any signs of wear or damage. Replace the drill bit if necessary.

- Keep the work area clean and free of any debris to avoid tripping hazards.

- Dispose of granite dust properly to prevent inhalation or contamination.

- If you are not experienced in drilling into granite rock, consider seeking guidance from a professional or attending a training program to learn the proper techniques and safety precautions.

Conclusion

By following the preparation steps and implementing the necessary safety measures, you can ensure a safe and successful drilling project into granite rock. Remember to always prioritize safety and take necessary precautions to minimize any risks associated with drilling into this hard material.

Proper Drilling Techniques

1. Select the Right Drill Bit

Choosing the correct drill bit is crucial when drilling into granite rock. The most effective drill bits for granite are diamond-tipped or carbide-tipped. These strong and durable bits are specifically designed for drilling into hard materials like granite. Make sure to use a high-quality drill bit that is suitable for granite rock.

2. Mark the Drilling Spot

Before starting the drilling process, mark the spot where you want to drill on the surface of the granite. Use a pencil or a marker to clearly indicate the drilling point. This will ensure accuracy and precision during the drilling process.

3. Use Water Cooling

Drilling into granite can generate a significant amount of heat, which can dull the drill bit and damage the surface of the rock. To prevent this, it is essential to use water cooling. You can either spray water onto the drilling spot or use a wet sponge to keep the drill bit and the drilling area cool. This will prolong the life of the drill bit and improve drilling efficiency.

4. Start with a Pilot Hole

It is recommended to start drilling with a smaller pilot hole before moving on to a larger one. This will help guide the drill bit and prevent skidding or slipping on the surface of the granite. Start with a smaller drill bit and gradually increase the size until you reach the desired diameter of the hole.

5. Apply Steady Pressure

When drilling into granite, it is important to apply steady and consistent pressure. Avoid excessive force or pushing too hard, as this can cause the drill bit to break or damage the rock. Apply firm but controlled pressure to maintain accuracy and prevent accidents.

6. Drill at a Slow Speed

Granite rock requires drilling at a slower speed than other materials. High-speed drilling can generate excessive heat, leading to damage or breakage of the drill bit. Set your drill to a slow speed and maintain a consistent pace throughout the drilling process.

7. Clean the Hole

After drilling, it is important to clean the hole to remove any debris or dust. Use compressed air or a vacuum cleaner to remove loose particles from the hole. This will ensure a clean and smooth surface for any further applications or installations.

8. Lubricate the Drill Bit

To ensure smooth and efficient drilling, it is advisable to periodically lubricate the drill bit. Apply a small amount of cutting oil or water-based lubricant to the drill bit to reduce friction and heat. This will help prolong the life of the drill bit and improve drilling performance.

By following these proper drilling techniques, you can master the art of drilling into granite rock. Remember to use the correct drill bit, mark the drilling spot, use water cooling, start with a pilot hole, apply steady pressure, drill at a slow speed, clean the hole, and lubricate the drill bit for optimal results.

Dealing with Common Challenges

1. Hardening of the Granite

Granite is an incredibly hard and dense rock, which can make drilling into it a challenging task. The hardness of the rock can cause the drill bit to wear out quickly, leading to increased drilling time and decreased efficiency.

Tip: Use carbide-tipped drill bits that are specifically designed for drilling into granite. These drill bits are harder and more durable, allowing them to withstand the hard granite surface.

Tip: Apply a constant and steady pressure while drilling, allowing the drill bit to gradually penetrate the granite. Avoid excessive force, as it can cause the drill bit to break or get stuck.

2. Heat Generation

Drilling into granite can generate a significant amount of heat due to the friction between the drill bit and the rock. This heat can cause the drill bit to overheat and become less effective.

Tip: Use water or a cooling lubricant to keep the drill bit and the granite cool during the drilling process. This will help prevent overheating and prolong the life of the drill bit.

Tip: Take breaks during the drilling process to allow the drill bit to cool down. This will also prevent overheating and ensure the drill bit’s effectiveness.

3. Dust and Debris

Drilling into granite produces a large amount of dust and debris, which can be hazardous to health and equipment.

Tip: Wear appropriate personal protective equipment, such as goggles and a dust mask, to protect yourself from the dust and debris generated during drilling.

Tip: Use a wet-dry vacuum or a dust extraction system to remove the dust and debris from the drilling area. This will help maintain a clean and safe working environment.

4. Stability of the Rock

The stability of the granite rock can also pose a challenge during drilling, as it may contain natural fissures or cracks that can cause the drill bit to deviate from its intended path.

Tip: When drilling into granite, start with a pilot hole to ensure the drill bit stays on track. This will help prevent any deviation caused by unstable areas of the rock.

Tip: Use a stabilizing agent, such as grout or epoxy, to fill any cracks or fissures in the granite. This will help strengthen the rock and provide a more stable drilling surface.

5. Noise and Vibration

Drilling into granite can generate high levels of noise and vibration, which can be disruptive and potentially harmful.

Tip: Wear hearing protection, such as earplugs or earmuffs, to protect your ears from the loud noise generated during drilling.

Tip: Use a drill with anti-vibration features or attach a vibration dampening device to reduce the vibration transmitted to your hands and arms.

By following these tips, you can effectively deal with the common challenges associated with drilling into granite rock and achieve successful results.

Maintaining Drill Bits and Equipment

1. Regular Cleaning

In order to maintain drill bits and equipment, it is important to regularly clean them after each use. This helps remove any debris, dust, or material buildup that may have accumulated during drilling. Use a brush or compressed air to clean the drill bits and equipment thoroughly.

2. Lubrication

Applying lubrication to the drill bits and equipment helps reduce friction and heat during drilling. This can be done by using a suitable lubricant such as cutting oil or grease. Apply the lubricant to the drill bit’s surface before drilling into granite rock.

3. Sharpening

Over time, drill bits can become dull and less effective in drilling into granite rock. To maintain their performance, it is necessary to sharpen them regularly. Use a drill bit sharpener or a grinding wheel to sharpen the edges of the drill bits. Make sure to follow the manufacturer’s instructions for sharpening and wear appropriate safety gear.

4. Inspecting for Damage

Regularly inspect drill bits and equipment for any signs of damage or wear. Check for any bent, cracked, or broken parts. Replace any damaged drill bits or equipment immediately to prevent further damage or accidents during drilling.

5. Proper Storage

When not in use, it is important to store drill bits and equipment properly. Place them in a clean and dry area, away from any moisture or harsh environmental conditions. This helps prevent corrosion, rust, or other damage that can affect their performance.

6. Maintenance Schedule

Establish a regular maintenance schedule for drill bits and equipment. This ensures that they are consistently well-maintained and ready for use. Create a checklist or calendar to track when maintenance tasks should be performed.

7. Training and Education

Properly maintain drill bits and equipment by educating yourself and your team on best practices. Stay updated on new techniques, technologies, and safety measures. Attend training sessions or workshops to enhance your skills and knowledge in maintaining drilling equipment.

8. Reliable Suppliers

Choose reliable suppliers for drill bits and equipment. Purchase high-quality products from reputable manufacturers. This ensures that you are using durable and reliable equipment that is easier to maintain.

9. Recordkeeping

Maintain records of your drill bits and equipment, including purchase dates, maintenance history, and any issues or incidents that may have occurred. This recordkeeping helps identify patterns, track performance, and make informed decisions for future maintenance and replacement.

10. Collaboration and Feedback

Encourage collaboration and feedback among your team members. Regularly discuss and share experiences related to drill bit and equipment maintenance. Learn from each other’s insights and implement improvements to optimize the maintenance process.

Conclusion

Proper maintenance of drill bits and equipment is essential for efficient and effective drilling into granite rock. By following the above tips, you can ensure the longevity of your drill bits and equipment, enhance their performance, and achieve successful drilling results.

Finishing and Polishing Techniques

Drilling into granite rock is just the first step in the process of creating a smooth and polished surface. After drilling, it is important to focus on finishing and polishing techniques to achieve the desired outcome. Here are some commonly used techniques:

1. Grinding

Grinding is an essential step in the finishing process. It involves using a coarse grit diamond cup wheel to remove any rough surfaces or uneven areas. The grinder should be moved in a back and forth motion until the desired level of smoothness is achieved. Care should be taken to ensure that the granite does not overheat during the grinding process.

2. Honing

Once the grinding is complete, honing is done to further refine the surface of the granite. Honing involves using a finer grit diamond cup wheel to smooth out any remaining rough areas and create a more uniform finish. This step helps to prepare the granite for the polishing process.

3. Polishing

Polishing is the final step in the finishing process and gives the granite a glossy and reflective appearance. There are different techniques and tools that can be used for polishing, including diamond polishing pads and polishing compounds. The granite surface should be wet during the polishing process to minimize heat and avoid damaging the stone.

4. Sealing

After the granite has been finished and polished, it is important to protect it by applying a sealant. The sealant helps to prevent staining and enhances the overall durability of the granite. There are different types of sealants available, and it is essential to choose one that is suitable for granite.

By employing these finishing and polishing techniques, it is possible to transform a raw and rough granite surface into a smooth and polished masterpiece. These techniques require skill and precision, so it is recommended to hire professionals with experience in working with granite to achieve the best results.

Expert Tips and Tricks

1. Choose the Right Drill Bit

When drilling into granite rock, it is crucial to select the appropriate drill bit. Diamond-tipped or carbide-tipped drill bits are recommended for their durability and ability to cut through hard materials. These specialized drill bits are designed to withstand the tough nature of granite and provide clean and precise holes.

2. Use Water as a Lubricant

Granite is a dense and hard stone, which means drilling into it can generate a lot of heat. To prevent overheating and prolong the life of your drill bit, it is advisable to use water as a lubricant. Pour water onto the drilling area or use a spray bottle to keep the drill bit and the granite cool during the drilling process.

3. Start with a Pilot Hole

Creating a pilot hole before drilling into granite can help guide the drill bit and prevent it from slipping or wandering off course. Use a smaller drill bit, such as a 1/8-inch bit, to create a pilot hole in the desired location. Once the pilot hole is established, you can switch to a larger drill bit for the final hole.

4. Work at a Slow Speed

Due to the hardness of granite, it is essential to drill at a slow speed to prevent the drill bit from overheating, chipping, or breaking. Set your drill to a low speed setting and apply gentle pressure while drilling into the granite. Take regular breaks to allow the drill bit and the granite to cool down.

5. Maintain a Steady Hand

Drilling into granite requires precision and control. It is crucial to maintain a steady hand throughout the drilling process to ensure accurate hole placement and prevent damage to the stone. Use both hands to hold the drill firmly and apply even pressure to create a smooth and clean hole.

6. Clean the Drilled Hole

After drilling into granite, it is important to remove any debris or dust from the hole. Use compressed air or a small brush to clean out the drilled hole thoroughly. This will help ensure a secure fit for any anchors or fasteners that you may need to insert into the hole.

7. Wear Safety Gear

When working with power tools and drilling into hard materials like granite, wearing appropriate safety gear is crucial. Always wear safety glasses to protect your eyes from flying debris and dust. Additionally, consider wearing gloves and a dust mask to protect your hands and respiratory system.

8. Practice Patience and Persistence

Drilling into granite can be a challenging task that requires patience and persistence. Take your time and proceed slowly to achieve the best results. If you encounter any difficulties, such as the drill bit getting stuck or the hole not forming as expected, do not force it. Take a step back, reassess, and adjust your approach if necessary.

9. Seek Professional Help if Needed

If you are unsure about drilling into granite or if the project requires high precision and expertise, it is always advisable to seek professional help. Professional contractors or stone experts have the necessary tools, knowledge, and experience to handle granite drilling projects of any scale.

By following these expert tips and tricks, you will be well-equipped to master the art of drilling into granite rock. Remember to prioritize safety, take your time, and remain persistent in order to achieve the desired results.

FAQ:

What tools are needed to drill into granite rock?

To drill into granite rock, you will need a hammer drill equipped with a masonry bit designed for granite. Additionally, you will need safety goggles, ear protection, and a dust mask.

Is it difficult to drill into granite rock?

Drilling into granite rock can be challenging due to the hardness of the material. However, with the right tools and techniques, it is possible to achieve successful results.

Can I use a regular drill to drill into granite rock?

No, a regular drill is not suitable for drilling into granite rock. Granite is a dense and hard material that requires a specialized hammer drill with a masonry bit designed for granite to effectively penetrate the surface.

Video: