Learn How to Drill a Hole Through Metal

Drilling a hole through metal can be a challenging task, especially if you are new to DIY projects or general maintenance. Whether you are working on a small craft project or repairing a broken metal object, having the right tools and the knowledge of how to use them is essential.

One of the first things to consider when drilling through metal is the type of metal you are working with. Different metals require different drilling techniques and tools. For example, drilling through aluminum requires a different approach than drilling through steel or copper.

Another important factor to consider is the size of the hole you need to drill. The size of the hole will dictate the type of drill bit you should use. For smaller holes, a twist drill bit is usually sufficient, while larger holes may require a hole saw or step drill bit.

Before you start drilling, it’s crucial to take safety precautions. Metal filings and shards can be hazardous, so wearing safety goggles and gloves is highly recommended. Additionally, securing the metal piece to prevent it from moving or spinning during the drilling process is essential for accuracy and safety.

Once you have chosen the appropriate drill bit and safety gear, you can start drilling. Apply gentle pressure to the drill and let the bit do the work. It’s important to avoid applying too much pressure, as it can cause the drill bit to overheat or dull prematurely. If necessary, you can use cutting fluid or lubricant to cool down the bit and extend its lifespan.

Drilling through metal requires patience and practice. By following these tips and techniques, you can learn how to drill a hole through metal effectively and safely, opening up a world of possibilities for your DIY projects and repairs.

Choosing the Right Drill Bit for Metal

Drilling a hole through metal requires the use of a specialized drill bit. The right drill bit will make the process easier and ensure that you achieve clean and accurate holes without damaging the material.

Types of Drill Bits for Metal

There are several types of drill bits that are commonly used for drilling through metal:

- High-Speed Steel (HSS) Bits: These are the most common type of drill bits used for metal. They are made of high-speed steel and can work efficiently on a wide range of metals.

- Cobalt Drill Bits: Cobalt drill bits are made of a special type of steel with a high cobalt content. They are ideal for drilling through hard metals such as stainless steel and cast iron.

- Titanium Drill Bits: Titanium drill bits are coated with a layer of titanium nitride, making them extremely durable and resistant to heat. They are suitable for drilling through metal as well as wood and plastic.

Size and Shank Type

When choosing a drill bit for metal, you should also consider the size and shank type:

- Size: The size of the drill bit is determined by its diameter. For general metal drilling applications, a range of sizes from 1/16 inch to 1/2 inch should cover most needs.

- Shank Type: The shank is the part of the drill bit that fits into the drill chuck. Common shank types for metal drill bits include round, hexagonal, and 3-flat shanks. It’s important to choose a drill bit with a shank that is compatible with your drill.

Choosing the Right Drill Bit for Your Metalworking Project

When selecting a drill bit for your metalworking project, consider the type of metal you are working with and the size of the hole you need to drill. Additionally, keep in mind the speed and feed rates recommended for the specific drill bit and material.

Remember to always use cutting oil or lubricant while drilling through metal to reduce heat and extend the life of your drill bit.

| Drill Bit Type | Best For |

|---|---|

| High-Speed Steel (HSS) Bits | General metal drilling |

| Cobalt Drill Bits | Hard metals like stainless steel and cast iron |

| Titanium Drill Bits | Metal, wood, and plastic |

Preparing the Metal Surface

Before drilling a hole through metal, it’s important to prepare the metal surface. This step ensures clean and accurate drilling without damaging the metal or the drill bit. Here are some key steps to follow in preparing the metal surface:

1. Choose the Appropriate Drill Bit

Selecting the right drill bit is crucial for successfully drilling through metal. High-speed steel (HSS) drill bits are commonly used for drilling through metal surfaces. These bits are highly durable and can withstand the heat generated during the drilling process. It’s important to choose a drill bit that is suitable for the type of metal you are drilling.

2. Secure the Metal

Before drilling, it’s important to ensure that the metal piece is securely fixed in place. This can be done using clamps or a vise. Securing the metal prevents it from moving or vibrating during the drilling process, which could lead to inaccurate drilling or damage to the metal piece.

3. Mark the Drilling Spot

Using a center punch or a marker, mark the exact spot where you want to drill the hole. This step helps to guide the drill bit and ensure accurate drilling. Double-check the placement of the mark to avoid any mistakes that may lead to undesired holes.

4. Apply Lubrication

Applying lubrication to the drilling area helps to reduce friction and heat generated during drilling. This is particularly important when drilling through harder metals. Use a lubricant like cutting fluid or a light oil and apply it to the drilling spot. This will help prolong the life of the drill bit and protect the metal surface.

5. Put on Safety Equipment

Prior to drilling, always wear appropriate safety equipment such as safety goggles or a face shield to protect your eyes from flying metal chips. Additionally, wearing gloves can help prevent injuries and provide a better grip while handling the metal piece.

6. Check Drill Speed and Pressure

Ensure that the drill is set to an appropriate speed for drilling through metal. Refer to the manufacturer’s guidelines or start with a slower speed and increase gradually if needed. Apply consistent and moderate pressure while drilling, as excessive pressure can cause the drill bit to break or damage the metal.

7. Clear Away Metal Shavings

Throughout the drilling process, metal shavings will accumulate around the drilling area. Periodically stop drilling to remove these shavings using a brush or compressed air. This prevents the build-up of debris that could hinder the drilling process or damage the metal surface.

8. Take Breaks

If you are drilling multiple holes or drilling through thick metal, take breaks in between to prevent the drill or the metal from overheating. Letting the drill and metal cool down can help prolong the life of the drill bit and prevent damage to the metal.

By following these steps to prepare the metal surface, you can ensure a smooth and successful drilling process when drilling through metal.

Securing the Metal for Drilling

Before you begin drilling a hole in metal, it’s important to secure the piece properly to ensure stability and accuracy. Here are a few methods you can use to secure the metal:

Using clamps:

Clamps are a common tool used to secure metal when drilling. They can be attached to a workbench or another stable surface to hold the metal in place. Make sure to position the clamps securely so that they provide enough support and prevent any movement during drilling.

Tip: If you’re working with a large piece of metal, use multiple clamps at various points to distribute the force evenly and increase stability.

Using a vise:

A vise is another handy tool for securing metal when drilling. It’s a mechanical device that tightens and holds the metal firmly in place. Simply place the metal between the jaws of the vise and tighten the handle until it’s securely held. This will provide stability and prevent any unwanted movement during drilling.

Using adhesive:

In some cases, clamps or a vise may not be suitable, especially when working with delicate or irregularly shaped objects. Instead, you can use adhesive to secure the metal. Apply a strong adhesive, such as epoxy or double-sided tape, to the back of the metal piece and press it firmly against a stable surface, like a piece of wood or metal block. This will create a temporary bond and prevent the metal from shifting during drilling.

Caution: When using adhesive, make sure to align the metal correctly before pressing it against the surface, as repositioning may be difficult or damage the adhesive bond.

Using a workbench with clamps or a vise:

If you have access to a sturdy workbench, you can secure the metal piece by attaching clamps or using a vise directly to the workbench. This setup provides a stable drilling platform and allows you to easily adjust the positioning of the metal if needed.

Remember, the key to successful drilling is to secure the metal properly to prevent any movement that may lead to inaccurate holes or potential injury. Choose the method that suits your project best and ensure that the metal is firmly held in place before you begin drilling.

Using Proper Technique to Drill

When it comes to drilling through metal, it is important to use proper technique. Using the correct technique will ensure that you are able to drill clean and precise holes without damaging the metal or the drill bit. Here are some key steps to follow:

Choose the Right Drill Bit

Before you start drilling, make sure you have the right drill bit for the job. Different types of metal require different types of drill bits. For softer metals like aluminum, a high-speed steel (HSS) or cobalt bit will work well. For harder metals like steel or stainless steel, a carbide bit or a cobalt bit is recommended. Using the wrong drill bit can result in unsatisfactory results or even damage to the metal.

Secure the Metal

When drilling through metal, it is essential to secure the piece firmly in place. You can use clamps or a vise to hold the metal securely. This will prevent it from moving or vibrating during the drilling process, which can cause the drill bit to slip or make an inaccurate hole.

Use Lubrication

Applying lubrication is another important step in drilling through metal. Lubricants such as cutting oil or a multipurpose oil like WD-40 can help to reduce friction and heat generated during the drilling process. This will not only make the drilling smoother and more efficient, but also increase the lifespan of the drill bit.

Start with a Pilot Hole

For larger holes, it is recommended to start with a pilot hole. A pilot hole is a small hole that you drill initially to guide the larger drill bit. It helps to keep the bit in place and prevents it from wandering or slipping on the metal’s surface. Starting with a pilot hole also makes it easier to drill the larger hole accurately.

Drill at a Slow Speed

Drilling through metal requires a slow and steady approach. Using a high-speed setting on your drill can cause the metal to heat up and potentially damage the drill bit. Start drilling at a low speed and gradually increase the speed if necessary. This will help to prolong the life of the drill bit and ensure a clean and precise hole.

Clear Swarf Regularly

Swarf refers to the metal chips or shavings that are created during the drilling process. It is important to clear them away regularly while drilling. Accumulated swarf can obstruct the drilling path and cause the drill bit to bind or break. Use a brush or a vacuum to remove the swarf and keep the drilling area clean.

Proper Safety Measures

Lastly, always remember to wear appropriate safety gear when drilling through metal. This includes safety glasses to protect your eyes from flying metal chips and gloves to protect your hands. Additionally, make sure to read and follow the manufacturer’s instructions and guidelines for your specific drill and drill bits.

| Step | Description |

|---|---|

| Choose the Right Drill Bit | Select the appropriate drill bit for the metal. |

| Secure the Metal | Use clamps or a vise to hold the metal firmly. |

| Use Lubrication | Apply cutting oil or multipurpose oil for smooth drilling. |

| Start with a Pilot Hole | Drill a small pilot hole before drilling the larger hole. |

| Drill at a Slow Speed | Start drilling at a low speed and gradually increase if needed. |

| Clear Swarf Regularly | Remove metal chips or shavings from the drilling area. |

| Proper Safety Measures | Wear safety glasses and gloves, and follow instructions. |

By following these proper drilling techniques, you can achieve precise and clean holes when drilling through metal. Remember to always take your time and exercise caution to ensure the best results.

Maintaining Proper Safety Measures

1. Wear the necessary safety equipment

When drilling a hole through metal, it is crucial to wear the appropriate safety gear to protect yourself from potential injuries. This includes:

- Safety glasses: Wear safety glasses to protect your eyes from debris and metal shavings.

- Gloves: Use gloves to protect your hands from sharp edges or hot metal.

- Ear protection: If you are using a power drill, it is recommended to wear ear protection to prevent hearing damage.

- Protective clothing: Wear long sleeves and long pants to protect your skin from metal fragments.

2. Ensure a stable work surface

Make sure your work surface is stable and secure to prevent accidents or injury while drilling. Consider using a workbench or clamps to secure the piece of metal you are drilling into.

3. Mark the drilling point

Prior to drilling, mark the exact point where you want to create the hole. This will help you maintain accuracy and prevent drilling in the wrong place.

4. Start with a pilot hole

When drilling large holes, it is recommended to start with a smaller pilot hole. This will help guide the drill bit and prevent it from slipping off the metal surface.

5. Use the right drill bit

Ensure you are using the correct type of drill bit for the metal you are drilling. Different metals may require different types of drill bits, such as high-speed steel or cobalt bits. Using the wrong drill bit can result in less effective drilling or even damage to the metal.

6. Apply cutting lubricant

When drilling through metal, it is essential to use a cutting lubricant to reduce friction and prevent overheating. Apply a small amount of lubricant to the drilling area to enhance the drilling process.

7. Drill at a slow speed

When drilling through metal, it is best to use a slower drilling speed to prevent the drill bit from overheating or becoming dull. A slower speed will also give you better control over the drilling process.

8. Take breaks if needed

If you are drilling through a thick piece of metal or performing a prolonged drilling task, take breaks to prevent overheating or fatigue. This will help maintain safety and ensure better drilling results.

9. Clean up thoroughly

After drilling through metal, make sure to clean up the work area and remove any metal shavings or debris. This will help prevent accidents and ensure a safer working environment.

10. Follow manufacturer’s instructions

Always refer to the manufacturer’s instructions and guidelines for your specific drill and drill bit. Following the recommended safety precautions and operating procedures will help ensure a safer and more effective drilling experience.

Troubleshooting Common Issues

1. Dull Drill Bit

A common issue that can arise when drilling through metal is using a dull drill bit. If your drill bit is not sharp enough, it will struggle to penetrate the metal effectively. This can result in slower drilling progress, increased heat, and even potential damage to the drill bit or the metal surface.

Solution: To resolve this issue, you can either sharpen the drill bit yourself or replace it with a new one. Make sure to use a drill bit specifically designed for metal drilling to ensure optimal performance.

2. Excessive Heat

Drilling through metal generates friction, which can lead to excessive heat buildup. Excessive heat not only decreases drilling efficiency but can also damage the metal and even cause injury to the operator.

Solution: To prevent excessive heat, you can use a lubricant or cutting oil to cool down the drill bit and minimize friction. Applying the lubricant or cutting oil to the drilling area can greatly improve the drilling process while reducing heat buildup.

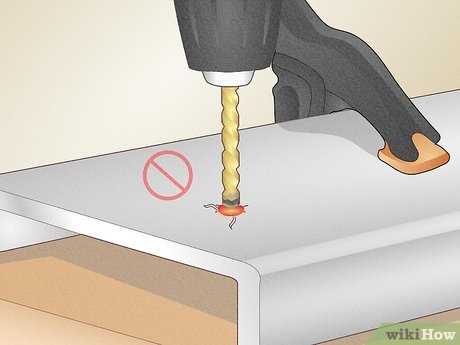

3. Drilling in the Wrong Location

One of the simplest but common issues is drilling in the wrong location. If you drill in the wrong spot, it can affect the structural integrity of the metal or cause damage that cannot be easily repaired.

Solution: Before drilling, double-check the location to ensure you are drilling in the right spot. Use a marking tool or center punch to clearly mark the drilling position. Take your time to accurately position the drill bit before initiating the drilling process.

4. Incorrect Drill Speed

Using the incorrect drill speed can also lead to issues when drilling through metal. High drill speeds can cause the drill bit to overheat and dull faster, while low drill speeds can result in slow progress and inefficient drilling.

Solution: Adjust the drill speed based on the type of metal and drill bit being used. Generally, harder metals require slower drill speeds, while softer metals can handle higher drill speeds. Follow the manufacturer’s recommendations for drill speed settings or consult an expert if you are unsure.

5. Inadequate Clamping

If the metal workpiece is not adequately clamped, it may move or vibrate during drilling, affecting the accuracy and quality of the hole. This can result in a misaligned or enlarged hole.

Solution: Use clamps or a vise to secure the metal workpiece firmly in place before drilling. Ensure that it is stable and cannot move during the drilling process. This will help maintain accuracy and prevent the metal from shifting or vibrating during drilling.

6. Breaking Drill Bit

Another common issue when drilling through metal is the drill bit breaking. This can occur due to excessive pressure, improper cutting technique, or using the wrong type of drill bit for the metal being drilled.

Solution: Apply steady and even pressure when drilling to prevent excessive strain on the drill bit. Use the appropriate cutting technique, such as peck drilling for thicker metals, to reduce the risk of the drill bit breaking. Make sure the drill bit is designed for metal drilling and is capable of handling the specific metal you are working with.

7. Lack of Safety Precautions

When drilling through metal, it is essential to take proper safety precautions to prevent accidents and injuries. Failure to do so can result in severe harm.

Solution: Always wear appropriate safety equipment, such as safety glasses and gloves, to protect yourself from potential hazards. Keep your work area clean and organized to minimize the risk of accidents. Familiarize yourself with safe drilling practices and follow them diligently when working with metal.

Finishing and Finishing Up the Process

Step 6: Remove the Burr

After drilling the hole, you may have a burr or metal shavings on the edges of the hole. This can affect the appearance and functionality of the hole, so it’s important to remove it.

- Use a deburring tool to remove the burr. Hold the tool at a slight angle and slide it along the edge of the hole to smooth out any rough edges.

- Alternatively, you can use a file or sandpaper to remove the burr. Just make sure to use gentle and controlled motions to avoid damaging the metal.

- Once the burr is removed, clean the hole with a cloth or compressed air to remove any remaining debris.

Step 7: Check the Hole

Before considering the drilling process complete, it’s important to check the hole for any imperfections or irregularities.

- Inspect the hole visually to ensure it has a clean and rounded shape.

- Measure the diameter of the hole using a caliper or a measuring tape to verify that it meets the required specifications.

- If the hole does not meet the desired standards, you may need to repeat the drilling process or make necessary adjustments.

Step 8: Clean Up

Finally, it’s important to clean up the work area and properly store the tools after completing the drilling process.

- Remove any metal shavings, debris, or coolant from the work area to prevent accidents or damage to other materials.

- Store the drilling tools and accessories in a safe and organized manner to avoid any injuries or misplacement.

- Dispose of any used coolant or other chemicals according to local regulations and guidelines.

Conclusion

Drilling a hole through metal requires careful preparation, the right tools, and the correct technique. By following the steps outlined in this guide, you can learn how to drill a hole through metal effectively and safely. Remember to prioritize safety, use appropriate protective gear, and consult professional assistance if needed.

FAQ:

What tools and equipment do I need to drill a hole through metal?

To drill a hole through metal, you will need a power drill, a drill bit suitable for metal (such as a high-speed steel or cobalt bit), a clamp or vise to secure the metal, safety goggles, and lubricant (such as cutting oil or motor oil).

What is the best type of drill bit to use for drilling through metal?

The best type of drill bit to use for drilling through metal is a high-speed steel (HSS) bit or a cobalt bit. These types of bits are specifically designed to withstand the high heat and provide more durability when drilling hard materials like metal.

Do I need to use lubricant when drilling a hole through metal?

Yes, it is highly recommended to use lubricant when drilling a hole through metal. The lubricant helps to reduce friction and heat, which can increase the life of the drill bit and make the drilling process smoother. Cutting oil or motor oil can be used as effective lubricants.

How do I choose the right drill bit size for drilling through metal?

When choosing the right drill bit size for drilling through metal, you should consider the size of the hole you want to create. Measure the diameter of the hole, and then choose a drill bit that matches that size. If you are unsure, start with a smaller bit and gradually increase the size until you reach the desired hole diameter.

What safety precautions should I take when drilling through metal?

When drilling through metal, it is important to take the following safety precautions: wear safety goggles to protect your eyes from metal shavings, use clamps or a vise to secure the metal in place and prevent it from moving, and work in a well-ventilated area to avoid inhaling any fumes or particles.

Can I use a regular wood drill bit to drill through metal?

No, using a regular wood drill bit to drill through metal is not recommended. Wood drill bits are not designed to withstand the hardness of metal and may break or become dull quickly. It is best to use a drill bit specifically designed for drilling through metal, such as a high-speed steel or cobalt bit.

What are some common techniques for drilling through metal?

Some common techniques for drilling through metal include marking the drilling spot with a center punch or awl to create a starting point, using slow and steady pressure when drilling to avoid overheating the drill bit, and using lubricant to reduce friction. It is also important to periodically withdraw the drill bit to clear away metal shavings and prevent the drill bit from getting clogged.

Video: