Key Factors to Consider When Choosing a Drill Press

When it comes to choosing a drill press, there are several key factors that you should consider to ensure you make the right choice for your needs. A drill press is a versatile and essential tool for any workshop, whether you are a professional woodworker or a DIY enthusiast. It allows you to make precise holes in a variety of materials, including wood, metal, and plastic.

One of the most important factors to consider is the power and speed of the drill press. The power of the motor determines how easily the drill press can cut through different materials. A drill press with a high horsepower motor will be able to handle tougher materials with ease. Similarly, the speed of the drill press is important for different applications. A drill press with variable speed settings will allow you to adjust the speed to match the material and the size of the hole you need to make.

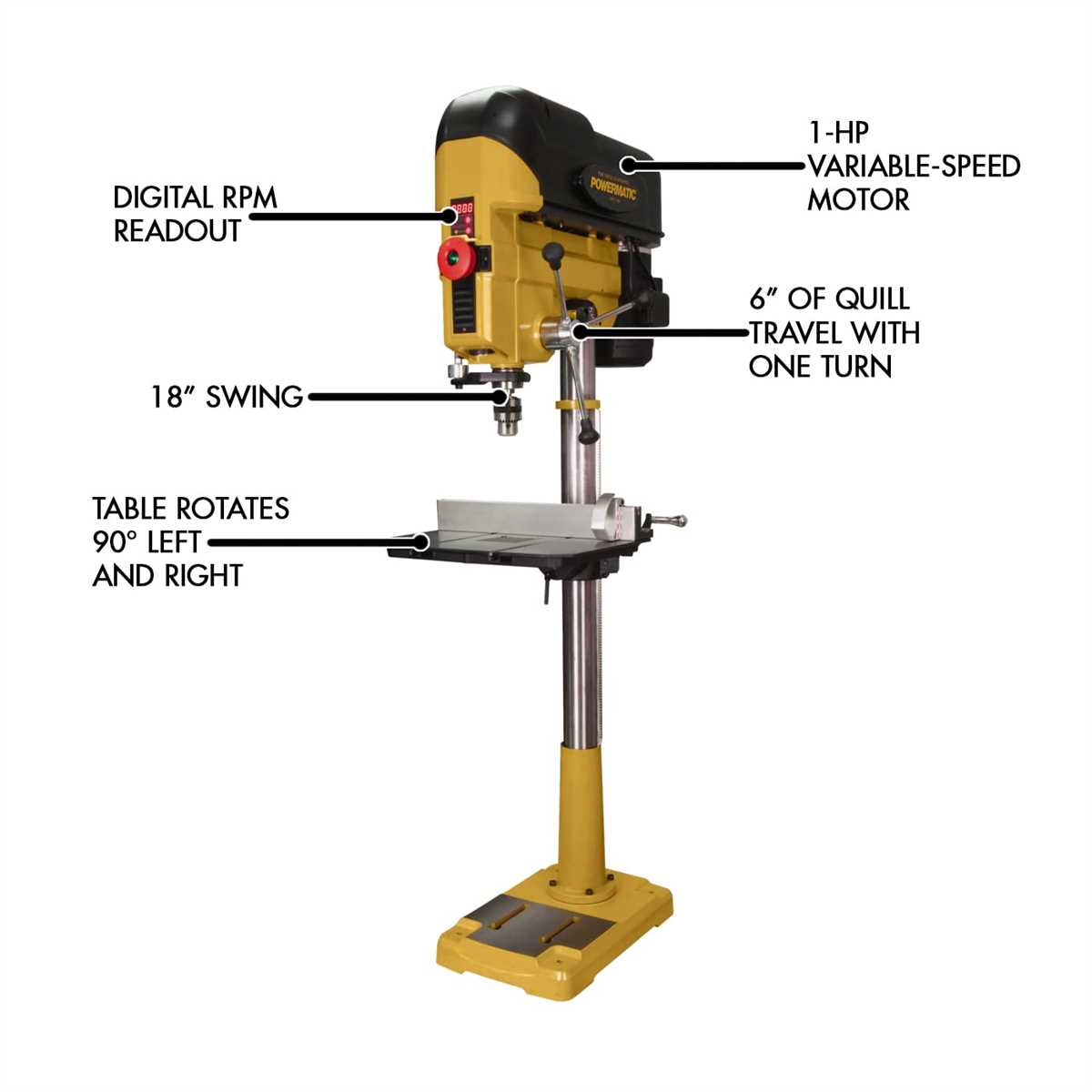

Another factor to consider is the size and capacity of the drill press. The size of the drill press refers to the distance between the center of the chuck and the column, which determines the maximum size of material that can be drilled. The capacity of the drill press refers to the maximum size of the drill bit that can be used. It’s important to choose a drill press with a size and capacity that meets your needs, whether you are working on small projects or larger ones.

Additional features to consider when choosing a drill press include the table size, the depth stop feature, and the visibility of the workpiece. A large table size will provide ample working space and support for your materials. A depth stop feature allows you to set the depth of the hole to ensure consistent and accurate results. Good visibility of the workpiece is important for precise drilling, especially when working with small or delicate materials.

Factors to Consider for Choosing a Drill Press

1. Power and Speed

One of the key factors to consider when choosing a drill press is its power and speed capabilities. The power of a drill press is typically measured in horsepower (HP). A higher HP rating indicates a more powerful motor, which can handle tougher materials and larger drill bits. Additionally, drill presses with variable speed settings allow you to adjust the speed to match the specific drilling task. Having a wide range of speed options is beneficial since different materials and drill bit sizes require different drilling speeds for optimal results.

2. Size and Capacity

The size and capacity of the drill press are important considerations, especially if you plan on working with larger workpieces. The throat distance or the distance between the drill bit and the column of the press determines the size of the workpiece that the drill press can accommodate. Similarly, the spindle travel or the maximum distance the drill bit can be raised or lowered defines the depth of the holes you can drill. Make sure to choose a drill press with adequate throat distance and spindle travel to handle the size and depth requirements of your projects.

3. Construction Quality

The overall construction quality of a drill press affects its durability and performance. Look for a drill press made from sturdy materials such as cast iron or steel, as these materials provide stability and reduce vibration during operation. Check for precision machining and tight tolerances to ensure accurate drilling. Also, consider the build quality of the quill and spindle assembly, as well as the rigidity of the table and base. A well-built drill press will last longer and provide more consistent results.

4. Table Adjustability and Stability

The adjustability and stability of the drill press table are important for precise drilling. Look for a drill press with a table that can be adjusted for height, tilt, and rotate 360 degrees. This allows you to position the workpiece correctly and make angled or curved holes. Additionally, a stable and rigid table is essential to prevent wobbling and ensure accurate drilling. Look for tables with solid locking mechanisms and smooth movement for ease of use.

5. Accessories and Extra Features

Consider the availability and usefulness of accessories and extra features when choosing a drill press. Some drill presses come with built-in work lights, laser guides, or digital speed readouts, which can enhance your drilling experience and accuracy. Other accessories to consider may include drill chucks, adjustable fences, or depth stops. Determine which features are essential for your specific needs and choose a drill press that offers the desired accessories and extra features.

6. Budget

Finally, consider your budget when choosing a drill press. Determine how much you are willing to spend and look for options that fall within your budget range. Keep in mind that higher-priced drill presses typically offer more power, precision, and additional features. However, you can still find reliable drill presses that offer satisfactory performance at a more affordable price point. Compare prices, read reviews, and consider the value provided by each drill press before making a final decision.

By considering these key factors, you can choose a drill press that meets your specific needs and provides the functionality, durability, and performance required for your drilling projects.

Power and Performance

When it comes to choosing a drill press, one of the key factors to consider is the power and performance of the machine. A drill press with sufficient power and performance will ensure that you can efficiently and effectively complete your drilling tasks.

Motor Power

The motor power of a drill press is measured in horsepower (HP). A higher horsepower generally indicates a more powerful machine that can drill through tougher materials with ease. It is important to choose a drill press with motor power that matches the type of drilling you plan to do. For light-duty drilling, a drill press with a lower horsepower will suffice. However, for heavy-duty drilling or drilling through tough materials like metal, a drill press with higher horsepower is recommended.

Speed Range

Another important factor to consider is the speed range of the drill press. Different drilling tasks may require different speeds, and a drill press with a wide speed range will offer greater versatility. Look for a drill press that offers both high and low speed settings, as well as the ability to adjust the speed according to your specific needs. Some drill presses even offer variable speed control, allowing you to fine-tune the speed for maximum precision.

Table and Spindle Travel

A drill press with a sturdy and adjustable table is essential for achieving accurate and precise drilling. Look for a table that can be easily adjusted in height and tilt angle to accommodate different workpieces. Additionally, consider the spindle travel of the drill press, which refers to the vertical movement of the spindle. A drill press with greater spindle travel will allow you to drill deeper holes or work with thicker materials.

Additional features

Lastly, consider any additional features that may enhance the power and performance of the drill press. Some drill presses offer built-in work lights to improve visibility, laser guides for precise drilling, and digital displays for easy speed and depth adjustments. These additional features can greatly improve your overall drilling experience and make your work more efficient.

By considering the power and performance factors mentioned above, you can choose a drill press that meets your specific drilling needs and ensures excellent results.

Size and Portability

Consider the Size

When choosing a drill press, it is important to consider the size of the machine. The size of the drill press can determine the types of projects it can handle and the space it will require in your workshop. Larger drill presses typically have more power and can handle larger workpieces, while smaller drill presses are more compact and portable.

If you have limited space in your workshop or plan to move the drill press around frequently, a smaller and more portable drill press may be a better choice. On the other hand, if you have a dedicated workshop with ample space and plan to work on larger projects, a larger and more powerful drill press may be necessary.

Consider the Portability

Portability is another important factor to consider when choosing a drill press. Depending on your needs, you may require a drill press that can be easily moved from one location to another.

If you need to take the drill press to various job sites or need to store it in a compact space when not in use, a portable drill press with wheels or a lightweight design may be ideal. These types of drill presses are typically smaller and more lightweight, making them easier to transport.

However, if you have a dedicated workshop and don’t need to move the drill press often, a larger and more stable drill press may be a better choice. These drill presses are usually more robust and offer greater stability, which is beneficial for precision drilling.

Consider the Weight

The weight of the drill press is another important consideration, especially if you plan to move it around frequently. Lightweight drill presses are easier to handle and transport, but they may be less stable and offer less power. On the other hand, heavier drill presses are typically more stable and powerful, but they can be more difficult to move and require more space.

It is important to find a balance between portability and stability when considering the weight of a drill press. Consider your needs and the types of projects you will be working on to determine the optimal weight for your drill press.

Speed Options

When choosing a drill press, one important factor to consider is the speed options that the machine offers. Different materials and drilling tasks require different speeds, and having multiple speed options can greatly increase the versatility and effectiveness of your drill press.

Variable Speed vs. Fixed Speed

Some drill presses come with fixed speed settings, while others offer variable speed options. Fixed speed drill presses operate at a single speed, typically determined by the manufacturer. These machines are generally less expensive and simpler to operate, but they may not be suitable for all types of drilling tasks.

On the other hand, drill presses with variable speed settings allow you to adjust the speed of the drill bit according to your specific needs. This feature is particularly useful when working with different materials or when performing various drilling techniques. Variable speed drill presses give you more control and flexibility, but they are usually more expensive.

Speed Range

When considering the speed options of a drill press, it’s important to look at the speed range that the machine offers. The speed range is typically measured in revolutions per minute (RPM) and indicates the range of speeds that the drill press can achieve.

A wider speed range gives you more flexibility to work with different materials and perform different drilling tasks. For example, drilling through metal requires lower speeds, while drilling through wood or plastics can be done at higher speeds. Therefore, a drill press with a broad speed range is usually more versatile and suitable for a wider range of projects.

Speed Control Mechanisms

Drill presses have different mechanisms for adjusting the speed. Some models have a simple belt and pulley system that allows you to manually change the speed by adjusting the position of the belt on the pulleys. These machines typically require manual belt changes, which can be time-consuming and inconvenient.

Other drill presses feature a more advanced speed control mechanism, such as an electronic variable speed system. These systems use electronic controls to adjust the speed, often allowing for quick and easy adjustments without any manual belt changes. However, drill presses with electronic speed control mechanisms tend to be more expensive.

| Pros | Cons |

|---|---|

| Variable speed allows for more control and flexibility | Variable speed drill presses are usually more expensive |

| Drill presses with a wide speed range are more versatile | Fixed speed drill presses may not be suitable for all tasks |

| Advanced speed control mechanisms make speed adjustments easier | Manual belt changes can be time-consuming |

Chuck Type

One important factor to consider when choosing a drill press is the type of chuck it has. The chuck is the mechanism that holds the drill bit in place. There are two main types of chucks that you will come across: keyed chucks and keyless chucks.

Keyed Chucks

A keyed chuck requires the use of a special key to tighten and loosen the chuck. This type of chuck typically provides a stronger grip on the drill bit, making it less likely to slip during operation. Keyed chucks are often used in heavy-duty applications that require drilling through tough materials like metal or hardwood. However, the process of changing drill bits in a keyed chuck can be time-consuming and may require additional tools.

Keyless Chucks

Keyless chucks, as the name suggests, do not require a key to secure the drill bit. Instead, they have a mechanism that allows for easy one-handed tightening and loosening of the chuck. Keyless chucks are more convenient to use, as changing drill bits can be done quickly and without the need for any extra tools. However, they may not provide as strong a grip on the drill bit compared to a keyed chuck, which can result in the bit slipping in certain situations.

When choosing a drill press, consider the type of work you will be doing and the materials you will be drilling through. If you anticipate working with tough materials or require a strong grip on the drill bit, a drill press with a keyed chuck may be the better option. On the other hand, if convenience and ease of use are a priority, a drill press with a keyless chuck may be more suitable for your needs.

Table and Base Stability

Importance of Table and Base Stability

Table and base stability is an essential factor to consider when choosing a drill press. The stability of the table and base can greatly affect the accuracy and precision of your drilling operations. If the table and base are not stable, the drill press may vibrate or move during operation, resulting in inaccurate holes or even potential safety hazards.

Factors Affecting Table and Base Stability

There are several factors that can affect the stability of the table and base:

- Material: The material used for the table and base can determine the overall stability. Cast iron is a common material that provides excellent stability and durability.

- Weight: The weight of the table and base also plays a significant role in stability. Heavier tables and bases tend to be more stable and less prone to vibrations.

- Construction: The construction of the table and base should be sturdy and well-designed. Look for features such as ribbing or reinforcement that can enhance stability.

Testing Stability

Before purchasing a drill press, it’s important to test the stability of the table and base to ensure it meets your requirements. Here are a few methods to evaluate stability:

- Visual Inspection: Inspect the construction and material of the table and base. Check for any signs of poor workmanship or flimsy components.

- Vibration Test: Power on the drill press and observe if there is any excessive vibration or movement during operation. Excessive vibrations can indicate poor stability.

- Weight: Lift and move the drill press to gauge its weight. A heavier drill press often indicates a more stable table and base.

- Customer Reviews: Read customer reviews and feedback to get an idea of the overall stability of the drill press.

Conclusion

When choosing a drill press, prioritize table and base stability to ensure accurate and safe drilling operations. Consider factors such as material, weight, and construction to evaluate stability. Performing tests and reading customer reviews can also help you make an informed decision. A stable table and base will provide better control and precision, resulting in high-quality drilling results.

Depth and Height Adjustments

When choosing a drill press, it is important to consider the depth and height adjustments it offers. These features allow you to control the drilling depth and the height of the work surface, providing you with flexibility and precision in your drilling projects.

Depth Adjustment

The depth adjustment feature allows you to set the drilling depth according to your needs. This is particularly useful when you need to drill holes of a specific depth, such as when creating dowel joints or when drilling holes for switches or knobs.

Look for a drill press that offers a depth stop mechanism, which allows you to set and lock the drilling depth. This ensures consistent and accurate drilling results, as you can easily repeat the same drilling depth for multiple holes.

Height Adjustment

The height adjustment feature allows you to adjust the work surface of the drill press to match the height of your workpiece. This is important for maximizing comfort and minimizing fatigue during operation.

Consider a drill press with a table that can be adjusted up and down. This allows you to easily position your workpiece at a comfortable height and ensures that you have proper control and visibility during drilling. Look for a table that is easy to adjust and locks securely in place.

Some drill presses also offer a tilting table, which allows you to adjust the angle of the work surface. This can be useful when drilling angled holes or when working on projects that require angled drilling.

Other Considerations

- Check the range of depth and height adjustments offered by the drill press.

- Look for clear and easy-to-read depth and height scales.

- Consider the stability and durability of the depth and height adjustment mechanisms.

- Make sure the drill press has a locking mechanism to secure the depth and height adjustments in place.

Overall, depth and height adjustments are key factors to consider when choosing a drill press. These features provide flexibility, precision, and comfort, allowing you to tackle a wide range of drilling projects with ease.

Safety Features

When choosing a drill press, it is crucial to consider the safety features it offers. These features are designed to protect the user from accidents and injuries. Here are some key safety features to look for:

1. Emergency Stop Button

A drill press with an emergency stop button allows you to quickly and easily stop the machine in case of an emergency. This can help prevent serious injuries by immediately shutting off the power to the drill press.

2. Clear Safety Guards

A drill press should have clear safety guards that cover the drill bit and prevent accidental contact with it. These guards should be easy to adjust and should not obstruct your view of the workpiece. They should also be sturdy enough to protect against flying debris.

3. Depth Stop

A depth stop feature allows you to set a specific drilling depth, ensuring precise and consistent holes. This feature can also prevent the drill bit from going too deep, reducing the risk of damaging the workpiece or causing accidents.

4. Speed Control

Having control over the drilling speed is important for both safety and accuracy. A drill press with variable speed settings allows you to choose the appropriate speed for different materials and drill bit sizes, reducing the likelihood of accidents caused by overspeeding.

5. Stable Base and Table

A drill press should have a stable base and table that provide solid support during operation. A wobbly or unstable drill press can increase the risk of accidents and injuries. Look for a drill press with a wide, heavy-duty base and a sturdy table that can be easily locked in place.

6. Safety Key or Lockout Key

Some drill presses come with a safety key or lockout key feature, which requires the key to be inserted before the machine can be turned on. This can prevent unauthorized use and accidental start-ups, reducing the risk of injuries.

7. Overload Protection

An overload protection feature can help prevent overheating and motor burnout. This feature automatically stops the drill press when it is overloaded, protecting the machine and reducing the risk of accidents.

Remember, it is essential to follow proper safety precautions when using a drill press, regardless of the safety features it has. Always wear appropriate safety gear, such as safety glasses and hearing protection, and read the manufacturer’s instructions before operating the machine.

Price and Warranty

Price and warranty are important considerations when choosing a drill press. Here are some key factors to keep in mind:

Price

- Set a budget for your drill press purchase. Determine how much you are willing to spend based on your needs and preferences.

- Compare prices from different manufacturers and suppliers. Look for any ongoing promotions or discounts that may be available.

- Consider the features and quality of the drill press in relation to its price. It’s important to find a balance between affordability and functionality.

- Keep in mind that a higher price doesn’t always guarantee better quality. Read reviews and seek recommendations to ensure you’re getting a reliable product within your budget.

Warranty

A warranty is an important factor to consider as it provides assurance and protection for your investment. Here are some points to consider:

- Check the duration of the warranty. Some manufacturers offer limited warranties, while others provide more extensive coverage.

- Review the terms and conditions of the warranty. Make sure you understand what is covered and what is not, as well as any requirements or limitations.

- Consider the reputation and reliability of the manufacturer. A strong warranty is only valuable if the company is known for honoring it and providing good customer service.

- Look for options to extend the warranty or purchase additional coverage for added peace of mind.

By considering both price and warranty, you can make an informed decision and choose a drill press that meets your needs and offers good value for money.

FAQ:

What are the key factors to consider when choosing a drill press?

When choosing a drill press, there are several key factors to consider. First, you should consider the size and power of the drill press. This will depend on the type of work you will be doing and the materials you will be drilling into. You should also consider the speed options and adjustability of the drill press, as well as any additional features such as laser guides or digital displays. Finally, you should consider the reputation and reliability of the brand and read reviews from other users to ensure you are getting a high-quality drill press.

How do I determine the size and power requirements for a drill press?

Determining the size and power requirements for a drill press will depend on the type of work you will be doing. If you will be mainly drilling small holes in soft materials, a smaller and less powerful drill press may be sufficient. However, if you will be drilling larger holes or working with harder materials such as metal, you will need a drill press with more power. It’s important to consider the maximum drilling capacity and the horsepower of the motor when determining the size and power requirements for your drill press.

What are some additional features to consider when choosing a drill press?

When choosing a drill press, there are several additional features you may want to consider. One feature is a laser guide, which projects a beam of light to help you align your drill bit accurately. Another feature is a digital display, which can give you precise readouts of speed and depth. Some drill presses also have built-in work lights or adjustable tables for added convenience. These additional features can enhance your drilling experience and make your work more accurate and efficient.

How can I ensure that I am selecting a high-quality drill press?

To ensure that you are selecting a high-quality drill press, it’s important to consider the reputation and reliability of the brand. Look for brands that have a good track record and positive customer reviews. You can also read product descriptions and specifications to get an idea of the materials and construction of the drill press. It may be helpful to visit a physical store and try out different models to get a feel for the build quality and ease of use. Additionally, consider the warranty and customer support offered by the manufacturer, as this can be an indicator of the drill press’s quality.

Video: