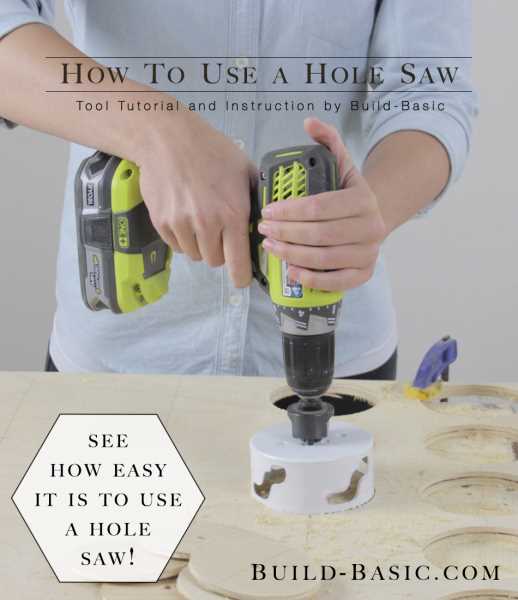

How to Use a Hole Saw Drill Bit: Tips and Techniques

Using a hole saw drill bit can be a great way to create precise and clean holes in a variety of materials. Whether you are a beginner or a seasoned DIY enthusiast, it’s important to familiarize yourself with the proper techniques to achieve the best results. In this article, we will discuss some tips and techniques that will help you master the art of using a hole saw drill bit.

1. Choose the Right Hole Saw Drill Bit:

Before you start drilling, it’s essential to select the right hole saw drill bit for the job. Consider the size and type of material you will be drilling through. Hole saw drill bits come in various sizes and are designed for different materials such as wood, metal, or plastic. Make sure to choose a drill bit that matches your project requirements.

2. Mark the Center Point:

Before drilling, mark the center point of the hole on the material using a pencil or a marker. This will help you guide the drill bit accurately and ensure that the hole is centered. Measure and mark the desired diameter of the hole as well.

3. Drill at a Low Speed:

When using a hole saw drill bit, it’s important to start drilling at a low speed. This will help you maintain control and prevent the drill bit from slipping or getting stuck. Once the hole starts to form, you can gradually increase the speed to achieve faster drilling.

4. Use Lubrication:

Using lubrication while drilling can help reduce heat and friction, extending the life of your hole saw drill bit. Apply a few drops of cutting oil or water to the drill bit to keep it cool and lubricated. This will also help prevent the material from getting damaged or overheated during drilling.

5. Clear the Chips:

While drilling, it’s important to periodically stop and clear away the chips and debris that accumulate in the hole saw. This will prevent the drill bit from getting clogged and ensure smooth drilling. Use a brush or a compressed air blower to remove the chips.

By following these tips and techniques, you can effectively use a hole saw drill bit and achieve professional-quality results. Remember to prioritize safety and wear appropriate protective gear, such as safety glasses and gloves, while drilling. Happy drilling!

Tips for Using a Hole Saw Drill Bit

- Choose the right size: Make sure to select a hole saw drill bit that matches the diameter of the hole you want to create. Using the wrong size can result in an uneven or oversized hole.

- Mark the center: Before starting to drill, mark the center of the hole on the surface using a pencil or a punch. This will help guide the drill and ensure accurate positioning.

- Use a pilot hole: For larger holes, it can be helpful to create a pilot hole with a smaller drill bit before using the hole saw. This will make it easier to start the hole and prevent the saw from wandering.

- Secure the workpiece: When using a hole saw, it’s important to securely clamp or hold down the workpiece. This will prevent it from moving or spinning during drilling, which can cause accidents or result in an uneven hole.

- Apply steady pressure: While drilling, apply steady and even pressure to the hole saw. Avoid forcing it or applying too much pressure, as this can lead to overheating, dulling the saw, or breaking it.

- Use lubrication: For metal or harder materials, using a lubricant such as cutting oil can help reduce friction and heat buildup. This will extend the life of the hole saw and improve cutting efficiency.

- Clear debris regularly: As you drill, debris can accumulate inside the hole saw. Clear it out regularly to prevent clogging and maintain cutting performance. You can use a brush or compressed air for this purpose.

- Take breaks: If drilling multiple holes or working on a large project, take breaks to allow the hole saw and drill bit to cool down. This will prevent overheating and prolong the lifespan of the tools.

- Properly maintain the hole saw: After use, clean the hole saw and inspect it for any damage or wear. Replace any worn or damaged parts to ensure safe and efficient future use.

Selecting the Right Hole Saw for the Job

- Determine the Material: The first step in selecting the right hole saw is to determine the material you will be drilling into. Different materials require different types of hole saws. For example, wood and plastic may require an ordinary bi-metal hole saw, while metal may require a carbide-tipped hole saw.

- Consider the Size: Hole saws come in a variety of sizes, so it is important to consider the size of the hole you need to drill. Measure the diameter of the hole you will be drilling and select a hole saw that matches that size. Keep in mind that hole saws typically range in size from 1/4 inch to 6 inches.

- Think about the Depth: In addition to the size of the hole, you should also consider the depth of the hole you will be drilling. Hole saws have different depths, so make sure to select a hole saw that can drill to the required depth. If you need to drill a deeper hole, you may need to purchase an extension or use a hole saw with a longer cutting depth.

- Check for Compatibility: Before purchasing a hole saw, check for compatibility with your drill or power tool. Most hole saws are designed to be used with specific types of drills or power tools, so make sure to check the specifications and make sure it will work with your equipment.

- Consider Additional Features: Some hole saws come with additional features that can be useful in certain situations. For example, some hole saws have a built-in arbor that eliminates the need for a separate arbor. Others may have a pilot drill bit included or a quick-change system for easy removal and replacement. Consider these additional features and choose a hole saw that meets your specific needs.

By considering the material, size, depth, compatibility, and additional features, you can select the right hole saw for the job at hand. Choosing the right hole saw will ensure that you achieve clean and accurate holes with minimal effort.

Preparing the Work Surface

Before using a hole saw drill bit, it is important to properly prepare the work surface to ensure accurate and safe drilling. Follow these steps to prepare the work surface:

- Mark the center: Use a pencil or marker to mark the center of the hole on the surface where you plan to drill. This will serve as a guide when positioning the hole saw.

- Secure the workpiece: If possible, clamp the workpiece securely to a workbench or use a vice grip. This will prevent it from moving or rotating during the drilling process, ensuring accuracy and safety.

- Protect the surrounding area: Place a drop cloth or protective covering around the work area to catch any debris or wood shavings that may be created during the drilling process. This will help keep your work area clean and prevent any damage to nearby surfaces.

- Wear safety gear: Always wear appropriate safety gear, such as safety glasses and gloves, when using a hole saw drill bit. This will protect your eyes from flying debris and prevent any injuries to your hands.

By properly preparing the work surface before using a hole saw drill bit, you can ensure accurate and safe drilling, as well as protect yourself and your work area from any potential hazards.

Marking the Drill Hole

Before using a hole saw drill bit, it is essential to mark the exact location where you want the hole to be drilled. This step is crucial to ensure accuracy and prevent any mistakes.

To mark the drill hole:

- Measure and mark: Use a tape measure or ruler to measure the desired distance from the edge or any other reference point. Mark the spot with a pencil or marker. Take your time to ensure the measurements are accurate.

- Use a center punch: For a more precise and secure mark, use a center punch to create an indentation at the center of the drill hole. This will help prevent the drill bit from wandering or slipping during the drilling process.

Remember to always double-check your measurements and markings before proceeding with drilling the hole. Taking the time to mark the drill hole accurately will save you time and make the drilling process easier.

Securing the Workpiece

Before you begin using a hole saw drill bit, it’s important to secure the workpiece in place. This ensures the safety of both the operator and the project being worked on. Here are some tips on how to properly secure the workpiece:

- Use clamps: Clamps are an effective way to hold the workpiece securely in place. They come in various sizes and types, including bar clamps, C-clamps, and spring clamps. Choose the appropriate clamp for your project and use it to secure the workpiece to a stable surface.

- Use a vise: A vise is another option for securing the workpiece. It consists of two jaws that can be tightened to hold the workpiece firmly. Vises are particularly useful for working on smaller objects or when you need both hands free to operate the drill.

- Create a jig: If you’re working with a small or irregularly-shaped workpiece, creating a jig can provide stability and support. A jig is a custom-made tool that holds the workpiece in place while you drill. It can be as simple as a piece of plywood with holes drilled in it to match the size of your workpiece.

- Apply double-sided tape: For lighter or less delicate materials, you can use double-sided tape to secure the workpiece temporarily. This method can be useful when you don’t have clamps or a vise available. Make sure to apply the tape to both the workpiece and the surface it will be attached to for a secure hold.

Whichever method you choose, always make sure the workpiece is firmly secured before using a hole saw drill bit. This will prevent the workpiece from moving or spinning during the drilling process, reducing the risk of accidents or damage to the project.

Using Proper Technique

Selecting the Right Hole Saw Diameter

When using a hole saw drill bit, it is important to select the right diameter for your specific application. Choose a hole saw that matches the size of the hole you need to create. Too small of a hole saw will require multiple passes and may cause the bit to bind, while too large of a hole saw may remove too much material and weaken the structure.

Preparing the Workpiece

Before using a hole saw, it is essential to properly prepare the workpiece. Start by securely clamping the workpiece to prevent it from moving during drilling. This will ensure accuracy and reduce the risk of injuries.

Next, mark the center of the desired hole on the workpiece using a pencil or a punch. This will serve as a guide for drilling and help you achieve a precise hole.

Using Proper Safety Gear

When using a hole saw drill bit, always prioritize safety. Wear appropriate safety gear, including safety glasses, gloves, and hearing protection, to protect yourself from potential hazards such as flying debris and loud noises.

Applying Steady Pressure

When drilling with a hole saw, it is important to apply steady pressure to guide the saw into the workpiece. Avoid applying excessive force, as it can cause the hole saw to bind or the drill to become unstable. Apply constant, moderate pressure to maintain control and ensure smooth cutting.

Using Lubrication

Lubrication is essential when using a hole saw drill bit, as it helps to reduce friction and prolong the life of the bit. Apply a suitable cutting fluid or lubricant to the cutting edges of the hole saw before drilling. This will help keep the saw cool and prevent it from overheating.

Clearing Chips and Debris

Regularly clear away chips and debris while using a hole saw to maintain optimal cutting performance. Stop drilling periodically to remove the accumulation of chips from the hole saw and the workpiece. Using a brush or compressed air can help with this process.

Inspecting the Hole Saw

After using a hole saw, inspect it for any signs of damage or wear. Check for any dull or missing teeth, as these can affect the cutting performance. Replace any damaged or worn-out hole saws to ensure clean and accurate cuts in future projects.

Cleaning and Maintenance

Proper cleaning and maintenance of your hole saw drill bit are crucial for its longevity. After each use, clean the hole saw thoroughly to remove any debris or residue. Store the bit in a dry and safe place to prevent corrosion. Regularly sharpening the teeth or replacing them as needed will also help to maintain the cutting efficiency of the hole saw.

| Tip | Technique |

|---|---|

| 1 | Select the right hole saw diameter for your application |

| 2 | Securely clamp the workpiece before drilling |

| 3 | Wear appropriate safety gear |

| 4 | Apply steady pressure while drilling |

| 5 | Use lubrication to reduce friction |

| 6 | Regularly clear away chips and debris |

| 7 | Inspect the hole saw for damage or wear |

| 8 | Clean and maintain the hole saw for longevity |

Using Coolant or Lubricant

When using a hole saw drill bit, it is important to use coolant or lubricant to prolong the life of the bit and ensure smooth cutting. Here are some tips and techniques for using coolant or lubricant:

1. Choose the Right Coolant or Lubricant

There are various types of coolant or lubricant that can be used with a hole saw drill bit, including cutting oil, WD-40, or even plain water. It is important to choose the right one for the material you are cutting. For example, cutting oil is suitable for metal, while water can be used for wood.

2. Apply the Coolant or Lubricant

Before you start drilling, make sure to apply the coolant or lubricant to the area where you will be cutting. You can use a spray bottle or a brush to evenly distribute the coolant or lubricant. Ensure that the entire cutting area is covered.

3. Monitor the Cooling or Lubricating Process

While drilling, it is important to continuously monitor the cooling or lubricating process. Make sure that the coolant or lubricant is being applied adequately and that the cutting area is not getting too hot. If necessary, pause drilling and reapply the coolant or lubricant.

4. Clean the Drill Bit

After you have finished drilling, clean the hole saw drill bit and remove any residue from the coolant or lubricant. This will help to prolong the life of the bit and prevent any build-up that could affect future drilling operations.

5. Use Personal Protective Equipment

When using a coolant or lubricant, it is important to wear personal protective equipment such as safety glasses and gloves. This will protect you from any splashes or spills that could potentially cause harm.

Following these tips and techniques will help you use coolant or lubricant effectively when using a hole saw drill bit, resulting in smoother cuts and a longer lifespan for the bit.

Clearing Debris while Drilling

When using a hole saw drill bit, it is essential to clear any debris that accumulates during the drilling process. Failing to remove the debris can lead to overheating of the bit, decreased cutting performance, and potentially dangerous situations.

Here are some tips for clearing debris while drilling:

- Use a backing plate: Placing a backing plate behind the material you are drilling can help catch and collect the debris as it is expelled from the hole saw. This prevents the debris from scattering around and makes the cleanup process easier.

- Utilize a dust extraction system: If you have access to a dust extraction system, such as a vacuum cleaner with a nozzle attachment, position it close to the drilling point. This will help capture the debris as it is generated, minimizing the mess and maximizing visibility.

- Periodically stop and remove the saw: As you drill, periodically stop to remove the hole saw from the material and clear any debris that has accumulated in the saw’s teeth. Use a wire brush or a blast of compressed air to dislodge the debris. This will help maintain the cutting efficiency of the hole saw and prevent it from getting clogged.

- Exercise caution when removing the saw: When removing the hole saw from the material, be careful to avoid contact with the sharp teeth. Use pliers or a specialized tool to grasp the hole saw securely and twist it in the reverse direction of drilling to disengage it from the hole.

- Wear appropriate protective gear: Debris generated during drilling can be sharp and potentially hazardous. To protect yourself from flying debris, always wear safety goggles, a face shield, and work gloves.

By following these tips for clearing debris while drilling with a hole saw drill bit, you can ensure smooth drilling operations, prolong the life of your drill bit, and maintain a cleaner work area.

Safety Precautions

- Always wear safety goggles or a face shield to protect your eyes from flying debris.

- Wear ear protection, such as earplugs or earmuffs, to reduce noise levels and protect your hearing.

- Wear a dust mask to prevent inhalation of dust particles.

- Ensure that there are no obstructions or loose clothing near the drilling area.

- Secure the workpiece firmly in a vise or clamp to prevent it from moving during the drilling process.

- Inspect the hole saw drill bit before each use to ensure it is in good condition and free from any damage or wear.

- Do not force the hole saw through the material. Apply steady pressure and allow the teeth to do the cutting.

- Avoid drilling on curved or uneven surfaces as it may cause the hole saw to bind or break.

- Keep your hands and fingers away from the cutting edge and rotating parts of the drill.

- Do not touch the hole saw immediately after use as it may be hot.

- Always unplug the drill or turn off the power before changing hole saws or making any adjustments.

- Follow the manufacturer’s instructions for the specific hole saw drill bit you are using.

- Dispose of used hole saws responsibly and keep them out of reach of children.

By following these safety precautions, you can reduce the risk of accidents and injuries while using a hole saw drill bit.

FAQ:

What is a hole saw drill bit?

A hole saw drill bit is a tool that is used to cut circular holes in various materials such as wood, metal, plastic, and more.

Can I use a hole saw drill bit on any material?

No, you cannot use a hole saw drill bit on any material. It is specifically designed to cut through certain materials such as wood, metal, plastic, and even ceramics.

How do I choose the right size hole saw drill bit?

To choose the right size hole saw drill bit, you need to measure the diameter of the hole you want to create. Then, select a hole saw drill bit that has a slightly larger diameter.

Video: