How to Strip Wire with a Drill

Stripping wire can be a time-consuming and tedious task, especially if you’re dealing with a large amount of wire. However, with the right tools and technique, you can strip wire quickly and easily with a drill. Using a drill to strip wire not only saves time but also ensures a clean and precise cut.

The first step in stripping wire with a drill is to gather the necessary tools and materials. You will need a wire stripper attachment for your drill, which is readily available at most hardware stores. Additionally, make sure you have a pair of safety glasses and gloves to protect yourself during the process.

Once you have the tools and materials ready, secure the wire in a vise or clamp to keep it steady and prevent any accidental movement. Attach the wire stripper attachment to your drill, making sure it is securely fastened. Place the wire into the stripper attachment, making sure it is positioned properly.

Start the drill at a slow speed, allowing the wire stripper attachment to gradually cut into the insulation. As the attachment spins, it will remove the insulation from the wire, leaving you with a clean and stripped wire. Make sure to apply light pressure to the wire to avoid damaging it.

Understanding the Basics of Wire Stripping

Wire stripping is a common technique used in electrical work and DIY projects to remove the insulation from wires. This process allows for easier connection and termination of wires, as well as reduces the risk of electrical short circuits or damage to the wires.

Why is Wire Stripping Important?

When working with wires, it is important to remove the insulation because:

- Insulation can interfere with a secure electrical connection;

- Insulation can cause resistance, leading to heat buildup;

- Insulation prevents proper visual inspection of the wire;

- Insulation can hinder the proper functioning of connectors.

Tools for Wire Stripping

There are various tools available for wire stripping, including:

- Wire strippers – these specialized tools are designed to cut and strip wires;

- Craft knife or utility knife – these knives can be used to carefully cut away the insulation;

- Drill with a wire stripping attachment – this option allows for quick and efficient wire stripping.

The Wire Stripping Process

The wire stripping process involves these basic steps:

- Choose the appropriate tool for wire stripping;

- Identify the section of wire that needs to be stripped;

- Position the tool around the wire, ensuring it is firmly held;

- Apply pressure to the tool and rotate it around the wire;

- Gently pull the wire stripper or the insulation to remove it;

- Inspect the stripped wire for any remaining insulation or damage.

Important Considerations

When stripping wire, it is important to keep the following in mind:

- Do not use too much force, as it may damage the wire;

- Be cautious not to cut into the wire strands;

- Choose the appropriate wire gauge for your stripping tool;

- Dispose of the stripped insulation properly to maintain a clean work area.

Conclusion

Understanding the basics of wire stripping is essential for anyone working with electrical wires. Always use the appropriate stripping tool and follow the proper steps to ensure a clean and secure connection, while minimizing the risk of electrical shorts or damage to the wire.

Choosing the Right Drill for Wire Stripping

When it comes to wire stripping, using a drill can make the process much quicker and easier. However, not all drills are suitable for this task. Here are some factors to consider when choosing the right drill for wire stripping:

Power

One of the most important factors to consider is the power of the drill. Wire stripping requires a drill with enough power to cut through the insulation without damaging the wire inside. Look for a drill with a high RPM (revolutions per minute) rating, as this indicates that it will have enough power to strip wires efficiently.

Chuck Size

The chuck size of the drill is another important consideration. The chuck is the part of the drill that holds the drill bit or wire stripping attachment. For wire stripping, you’ll need a drill with a chuck size that can accommodate the wire stripping attachment you plan to use. Most wire stripping attachments are designed to fit in chucks that are 3/8-inch or 1/2-inch in size.

Variable Speed

Having a drill with variable speed settings can be beneficial for wire stripping. Different types of wire or different thicknesses of insulation may require different speeds for optimal results. Being able to adjust the speed of the drill can help prevent the wire from being damaged during the stripping process.

Comfort and Ergonomics

Wire stripping can be a repetitive task, so it’s important to consider the comfort and ergonomics of the drill. Look for a drill with a comfortable grip and a lightweight design. This will help reduce fatigue and make the wire stripping process more comfortable and efficient.

Attachments

Finally, consider the attachments that are available for the drill. Some drills come with wire stripping attachments included, while others may require you to purchase them separately. Make sure to choose a drill that has compatible attachments available, as this will make the wire stripping process much easier and more effective.

By considering these factors and choosing a drill that meets your needs and preferences, you can ensure a smooth and successful wire stripping experience.

Preparing the Wire for Stripping

Before you can begin the process of stripping wire with a drill, you need to make sure that the wire is properly prepared. This involves a few simple steps:

1. Gather the necessary tools

Before you start, gather all the tools you will need for the job. This includes a drill with a stripping attachment, wire cutters, and a wire stripper or utility knife.

2. Inspect the wire for damage

Before stripping the wire, inspect it carefully for any signs of damage or wear. Look for any frayed or exposed wires, as these can be dangerous to work with. If you find any damaged wires, it is best to replace the wire rather than attempt to strip it.

3. Measure and mark the length you need

Next, use a tape measure or ruler to measure the length of wire you need for your project. Once you have determined the correct length, use a marker or pen to mark the spot where you will make your cut. This will help ensure that you strip the wire to the correct length.

4. Cut the wire to the desired length

Using wire cutters, carefully make a clean, straight cut at the marked spot. Take your time and try to make the cut as precise as possible to ensure a neat finish.

5. Remove any insulation or sheathing

If your wire has any insulation or sheathing on it, you will need to remove it before you can begin using the drill to strip the wire. You can use a wire stripper or a utility knife to carefully cut away the insulation or sheathing, revealing the bare wire underneath.

6. Straighten out any kinks or bends

If the wire has any kinks or bends in it, use your hands to gently straighten it out. This will make it easier to work with and ensure a cleaner stripping process.

7. Ensure a secure grip

Before you start stripping the wire with a drill, make sure you have a secure grip on both ends of the wire. This will help prevent any accidents or injuries while the wire is spinning in the drill.

By following these steps to prepare the wire, you will ensure a smooth and efficient stripping process using a drill.

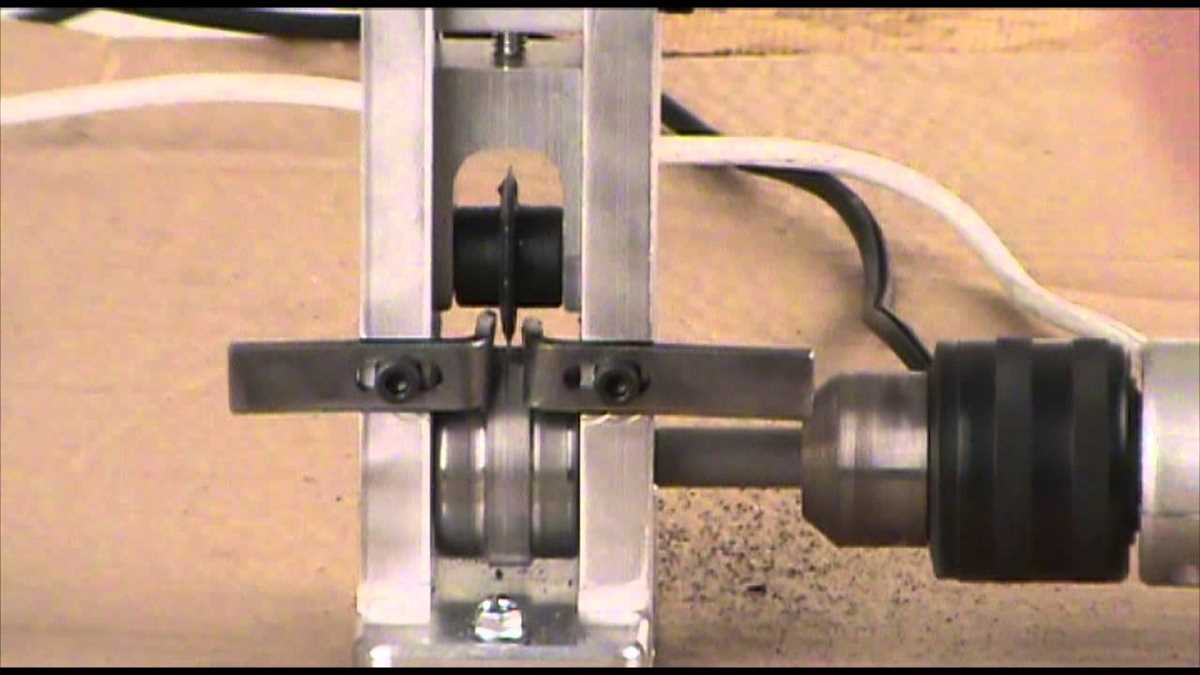

Attaching a Wire Stripping Attachment to the Drill

When it comes to stripping wire with a drill, using a wire stripping attachment can make the process much more efficient and effective. Here’s how you can attach a wire stripping attachment to your drill:

Step 1: Gather the necessary materials

Before you begin, make sure you have all the materials you need. This includes a wire stripping attachment, a compatible drill, and the appropriate safety equipment such as gloves and safety goggles.

Step 2: Prepare the drill

Ensure the drill is turned off and unplugged from any power source. This will prevent any accidents or injuries during the attachment process. Also, remove any drill bits or other attachments that may be currently attached to the drill.

Step 3: Align the wire stripping attachment

Take the wire stripping attachment and align it with the chuck of the drill. The chuck is the part of the drill that holds the attachment in place. Make sure the attachment is properly lined up and centered with the chuck.

Step 4: Insert the wire stripping attachment

Once the attachment is properly aligned, insert it into the chuck by turning it clockwise. Continue turning until the attachment is securely fastened and does not move or wobble when lightly tugged.

Step 5: Tighten the chuck

Using the chuck key or the tightening mechanism on your drill, tighten the chuck securely. This will ensure that the wire stripping attachment is held firmly in place and will not come loose during use.

Step 6: Test the attachment

Now that the wire stripping attachment is attached to the drill, it’s a good idea to test it before using it on actual wires. Turn on the drill and check if the attachment spins smoothly without any wobbling or misalignment. If everything looks and feels good, you’re ready to start stripping wire with your newly attached wire stripping attachment!

Tips and Warnings:

- Always wear appropriate safety equipment, such as safety goggles and gloves, when working with drills and wire stripping attachments.

- Make sure the drill is turned off and unplugged before attaching or removing any attachments.

- If you’re unsure about how to attach the wire stripping attachment to your specific drill, refer to the manufacturer’s instructions for your drill and the attachment.

- Practice using the wire stripping attachment on scrap wire before working on actual projects to get a feel for its operation and ensure accuracy.

Using the Drill to Strip the Wire

Stripping wire is a common task when working with electrical projects. While there are various methods to strip wire, using a drill can be a quick and efficient way to get the job done. Follow these steps to learn how to strip wire using a drill:

Step 1: Gather the materials

- Wire to be stripped

- Drill with a chuck (preferably a cordless drill)

- Wire stripper attachment or a small piece of sandpaper

Step 2: Prepare the wire stripper attachment

If you have a wire stripper attachment for your drill, attach it securely onto the chuck. Make sure it is tight and won’t come loose while in use. If you don’t have a wire stripper attachment, you can use a small piece of sandpaper instead.

Step 3: Determine the stripping length

Decide how much insulation you want to remove from the wire. This will depend on the specific project you are working on. Measure and mark the desired stripping length using a tape measure or ruler.

Step 4: Secure the wire

Hold the wire firmly in one hand, making sure it is taut and won’t move around while stripping. You can use a vise or clamp to secure the wire if needed.

Step 5: Start the drill

Turn on the drill and set it to a medium speed. Hold the drill with the wire stripper attachment or sandpaper against the insulation of the wire, making sure it is aligned with the marked stripping length.

Step 6: Apply light pressure

Apply light pressure to the drill and move it back and forth along the marked stripping length. The rotation of the drill combined with the pressure will gradually strip off the insulation from the wire.

Step 7: Inspect the stripped wire

Stop the drill and inspect the stripped wire. Make sure the insulation is completely removed and there are no nicks or cuts on the wire strands. Trim any excess insulation if necessary with a pair of wire cutters.

Step 8: Repeat the process

If you have more wires to strip, repeat the process for each wire. Make sure to adjust the stripping length if needed for different wires.

Step 9: Turn off the drill

Once you have finished stripping all the wires, turn off the drill and safely put it away. Dispose of any waste material properly.

Using a drill to strip wire can be a time-saving method, especially when working with a large number of wires. However, always exercise caution and follow safety guidelines to prevent accidents or injuries.

Cleaning and Maintaining the Wire Stripping Attachment

The wire stripping attachment is a valuable tool that can help you quickly and efficiently strip wire using a drill. To keep your attachment in good working condition and extend its lifespan, it’s important to clean and maintain it regularly.

1. Regular Cleaning

- After each use, remove any excess wire strands or debris from the stripping attachment.

- Use a soft brush or cloth to gently clean the cutting blades and jaws of the attachment.

- Avoid using abrasive materials or harsh chemicals, as they can damage the attachment.

2. Lubrication

- Regularly lubricate the moving parts of the wire stripping attachment to ensure smooth operation.

- Apply a small amount of lubricant or oil to the cutting blades and jaws.

- Wipe off any excess lubricant to prevent it from attracting dust and debris.

3. Inspection

- Inspect the cutting blades and jaws for any signs of wear or damage.

- If you notice any dull or damaged blades, replace them immediately to maintain the efficiency of the attachment.

- Check the alignment of the blades and jaws to ensure they are properly aligned for effective wire stripping.

4. Storage

- Store the wire stripping attachment in a clean and dry place to prevent rust or corrosion.

- Consider using a protective case or cover to keep the attachment safe from dust and dirt.

- Avoid placing heavy objects on top of the attachment, as it can damage the delicate cutting blades.

5. Safety Precautions

- Always wear appropriate safety gear, such as gloves and safety goggles, when using the wire stripping attachment.

- Follow the manufacturer’s instructions and guidelines for safe and proper use of the attachment.

- Keep the attachment away from children and pets to prevent accidents or injuries.

By following these tips for cleaning and maintaining your wire stripping attachment, you can ensure its longevity and optimal performance. Regular maintenance will help you strip wire efficiently and safely, saving you time and effort in your electrical projects.

Safety Tips for Wire Stripping with a Drill

Wire stripping with a drill can be a convenient and efficient way to remove insulation from wires. However, it is important to follow proper safety precautions to avoid accidents and injuries. Here are some essential safety tips to keep in mind when performing wire stripping with a drill:

- Wear safety goggles: Always wear safety goggles to protect your eyes from flying debris or metal fragments that may be generated during the wire stripping process.

- Wear gloves: Use appropriate gloves to protect your hands from any sharp edges on the wire or the stripping tool. This will reduce the risk of cuts or punctures.

- Use the right size drill bit: Ensure that you are using a drill bit that is specifically designed for wire stripping. Using the wrong size can cause damage to the wire or lead to accidents.

- Secure the wire: Before stripping, make sure the wire is properly secured in a bench vise or held firmly in place. This will prevent the wire from moving or getting tangled during the stripping process.

- Keep fingers away from the drill bit: It is important to keep your fingers away from the drill bit while operating the drill. Accidental contact can result in serious injuries.

- Control the drill speed: Use a variable speed drill and adjust the speed to a level that allows for precise and controlled wire stripping. Excessive speed can cause the wire to heat up or become damaged.

- Inspect the wire: Before stripping, carefully inspect the wire for any signs of damage, such as frayed insulation or exposed wires. Damaged wires should be repaired or replaced before attempting to strip them.

- Work in a well-ventilated area: Wire stripping can produce fumes or dust, especially if the wire insulation contains hazardous materials. Make sure to work in a well-ventilated area or use a dust extraction system to minimize exposure.

Remember, safety should always be your top priority when performing any kind of electrical work. By following these safety tips, you can safely and effectively strip wire with a drill.

FAQ:

What is the easiest way to strip wire?

The easiest way to strip wire is by using a wire stripper tool. However, if you don’t have one, another option is to use a drill.

Can I use a drill to strip wire?

Yes, you can use a drill to strip wire. It is a useful method, especially if you don’t have a wire stripper tool available.

What do I need to strip wire with a drill?

To strip wire with a drill, you will need a drill, a drill bit that matches the diameter of the wire, and a pair of pliers.

Is it safe to strip wire with a drill?

Stripping wire with a drill can be safe as long as you take the necessary precautions. Make sure to wear safety goggles to protect your eyes, and be cautious when handling the wire and drill.

Video: