How to Safely Drill Holes in Plexiglass Without Cracking

Drilling holes in plexiglass can be a tricky task. Plexiglass is a type of acrylic plastic that is known for its transparency and durability. However, it can also be prone to cracking if not drilled properly. Cracks can make the plexiglass weak and potentially compromise its structural integrity.

To safely drill holes in plexiglass without cracking it, there are a few important steps to follow. First, it is crucial to choose the right drill bit. Plexiglass is a softer material than metal or wood, so a regular drill bit can exert too much pressure and cause cracks. It is recommended to use a drill bit specifically designed for drilling plastics, such as an acrylic or plexiglass drill bit.

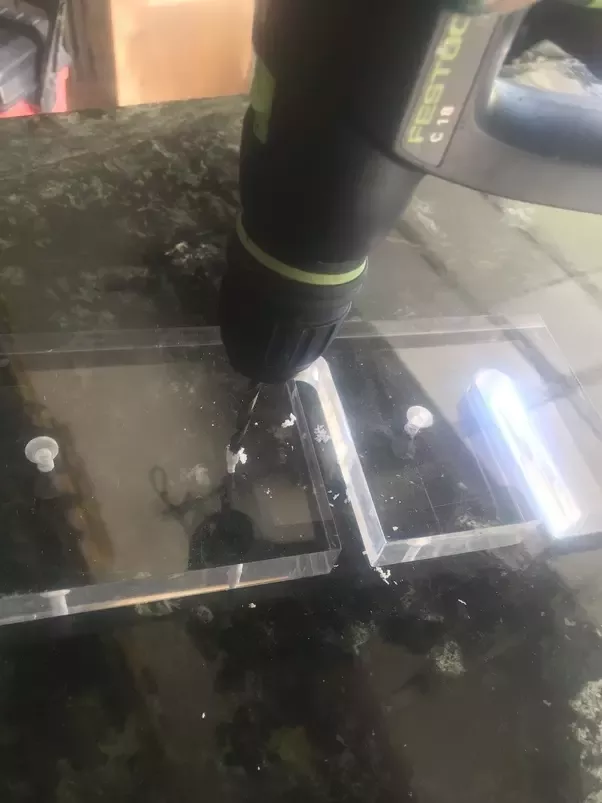

Secondly, it is important to secure the plexiglass properly to prevent it from bending or vibrating during the drilling process. This can be done by clamping the plexiglass securely to a workbench or using a custom jig to hold it in place. The goal is to provide stability and support to the plexiglass, reducing the risk of cracking.

When drilling, it is crucial to go slow and steady. Applying excessive force or drilling too quickly can cause the plexiglass to crack. It is recommended to start with a small pilot hole before gradually increasing the size of the hole. This allows the drill bit to penetrate the material without applying excessive pressure all at once.

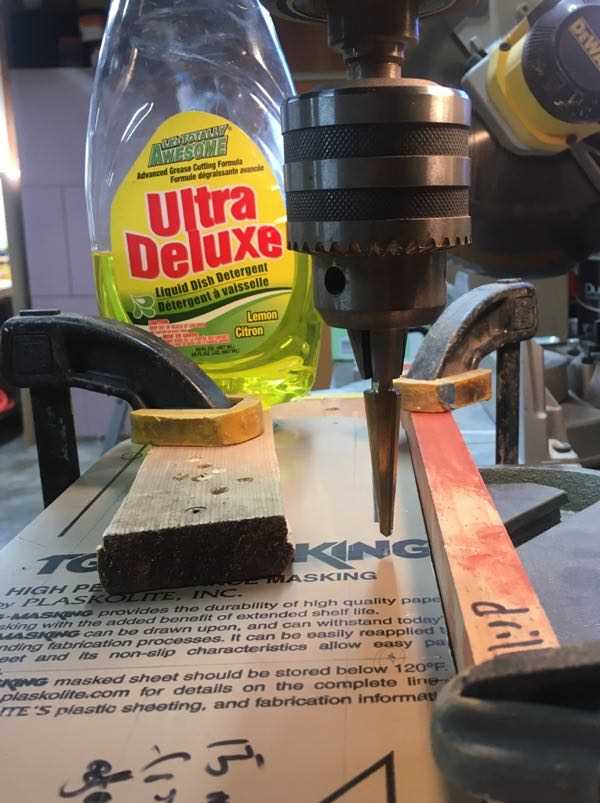

Additionally, using a lubricant can help reduce the friction between the drill bit and the plexiglass, further minimizing the risk of cracking. A lubricant such as water or a specialized plastic drilling lubricant can be applied to the drill bit and the surface of the plexiglass. This lubricant acts as a coolant and reduces the chances of overheating the plexiglass, which can lead to cracks.

By following these steps and taking necessary precautions, you can drill holes in plexiglass safely and effectively without cracking. Remember to choose the right drill bit, secure the plexiglass properly, go slow and steady, and use a lubricant to minimize friction. With practice and patience, you can master the art of drilling holes in plexiglass without compromising its integrity.

Prepare the Surface

Before drilling holes in Plexiglass, it is important to properly prepare the surface to minimize the risk of cracking or shattering. Here are some steps to follow:

1. Clean the Plexiglass

- Use a mild soap or detergent and warm water to clean the surface of the Plexiglass.

- Gently wipe the surface with a soft, non-abrasive cloth or sponge.

- Make sure to remove any dirt, dust, or residue from the surface.

2. Mark the Hole Locations

- Use a ruler or measuring tape to determine the precise locations where you want to drill the holes.

- Use a fine-tip permanent marker or a pencil to make small dots at the desired hole locations.

- Ensure that the markings are accurate and symmetrical, if applicable.

3. Apply Masking Tape

- Carefully apply strips of masking tape over the marked hole locations.

- Make sure the tape is securely adhered to the surface of the Plexiglass.

- The masking tape serves as a protective barrier that helps prevent cracking or chipping during the drilling process.

4. Set Up a Work Area

- Choose a well-lit and well-ventilated area to work in.

- Place a soft, non-slip mat or a piece of scrap wood underneath the Plexiglass to provide support and traction.

- Ensure that the work area is clear of any obstructions or hazards.

5. Gather the Necessary Tools

- Collect the appropriate drilling tools, such as a drill press or a handheld drill with a drill bit specifically designed for use on Plexiglass.

- Have a supply of cooling lubricant, such as water or a specialized acrylic lubricant, to keep the drill bit cool during the drilling process.

- Wear safety goggles and gloves to protect your eyes and hands.

By following these steps and taking the necessary precautions, you can prepare the surface of the Plexiglass to ensure a safe drilling process without cracking or damaging the material.

Choose the Right Tools

When it comes to drilling holes in plexiglass, using the right tools can make all the difference in preventing cracks. Here are some tools that you should consider:

1. Drill Bits

When drilling holes in plexiglass, it is important to use drill bits specifically designed for acrylic materials. These drill bits have a special geometry that reduces the chance of cracking. Additionally, they have sharp edges that cut through the material smoothly and evenly.

2. Drill Press

Using a drill press can greatly improve your chances of drilling holes in plexiglass without cracking. A drill press provides more control and stability compared to handheld drills. This helps to prevent any sudden movements that could lead to cracks in the material.

3. Clamps

Before drilling, it is recommended to secure the plexiglass firmly in place using clamps. This will help to reduce vibrations and movement during the drilling process, minimizing the risk of cracks.

4. Lubricant

Using a lubricant, such as cutting oil or water, can help to keep the drill bit cool and prevent the plexiglass from overheating. This can reduce the likelihood of cracks forming due to excessive heat.

5. Safety Equipment

Always prioritize safety when drilling plexiglass. Wear safety goggles to protect your eyes from any flying debris. It is also a good idea to wear gloves to protect your hands while handling the material.

By choosing the right tools and taking necessary precautions, you can increase your chances of drilling holes in plexiglass without cracking the material.

Clean the Plexiglass

Before drilling holes in the plexiglass, it is important to clean it thoroughly to ensure that no dirt or debris interferes with the drilling process. Follow these steps to clean the plexiglass:

- Gather the necessary materials: You will need a mild dish soap, a soft cloth, and warm water.

- Mix the cleaning solution: Fill a small container with warm water and add a few drops of mild dish soap. Mix it to create a soapy solution.

- Dip the cloth: Dip the soft cloth into the soapy solution, ensuring that it is well saturated.

- Gently wipe the plexiglass: Carefully wipe the surface of the plexiglass with the soapy cloth, applying gentle pressure. Be sure to clean both sides of the plexiglass if necessary.

- Rinse with clean water: After wiping the plexiglass, rinse it thoroughly with clean water to remove any soap residue.

- Dry the plexiglass: Use a clean, dry cloth to dry the plexiglass completely. Ensure that no moisture remains on the surface.

Note: It is important to avoid using abrasive cleaners, such as those containing ammonia or alcohol, as they can damage the plexiglass. Stick to mild dish soap and water for effective and safe cleaning.

Mark the Drilling Points

Before drilling holes in plexiglass, it is important to mark the drilling points accurately. This will help ensure that the holes are drilled in the right locations and prevent any potential cracking or damage to the plexiglass.

To mark the drilling points, follow these steps:

- Clean the surface of the plexiglass with a mild soap and water solution to remove any dirt or debris. Make sure to dry it completely before proceeding.

- Place the plexiglass sheet on a flat and stable surface. You can use clamps to secure it in place if necessary.

- Using a ruler or measuring tape, carefully measure and mark the exact locations where you want to drill the holes. Double-check your measurements to ensure accuracy.

- For small holes, you can use a sharp pencil to make the marks. For larger holes, you may want to use a center punch or awl to create a small indentation as a guide for the drill bit.

- If you need to drill multiple holes, use a template or create a guide by drilling a pilot hole in a scrap piece of plexiglass first. This will allow you to position the template or guide accurately on the main piece of plexiglass.

By marking the drilling points accurately, you will minimize the risk of cracking or shattering the plexiglass when drilling holes. Take your time and be precise in your measurements to ensure the best results.

Measure and Mark

Before drilling holes in plexiglass, it is important to carefully measure and mark the exact location where the holes need to be drilled. This will ensure accurate placement and prevent any errors or mistakes.

Here are the steps to measure and mark the holes on the plexiglass:

1. Gather the necessary tools

Before starting, make sure you have the following tools:

- Measuring tape or ruler

- Pencil or marker

- Straight edge or square

2. Place the plexiglass on a flat surface

Find a clean and flat surface to work on, such as a workbench or table. Ensure that the plexiglass is secure and does not move around while measuring and marking.

3. Measure and mark the hole locations

Using the measuring tape or ruler, determine the exact location where the holes need to be drilled. Measure the distance accurately and make light pencil marks on the plexiglass to indicate the spots.

For multiple holes, use the straight edge or square to ensure that the hole locations are aligned properly. This will help maintain consistency and accuracy in the spacing.

4. Double-check the measurements

Before proceeding with drilling, double-check the measurements to ensure they are accurate. Use the measuring tape or ruler to confirm that the distances between the hole marks are correct.

Make any adjustments if necessary, and re-measure to ensure accuracy.

By measuring and marking the hole locations accurately, you will be able to proceed with drilling without the risk of cracking or damaging the plexiglass.

Use Masking Tape

To help prevent cracking and provide additional support while drilling holes in plexiglass, it is recommended to use masking tape. Masking tape creates a protective barrier between the drill bit and the plexiglass, reducing the risk of the material cracking or shattering.

Follow these steps to use masking tape when drilling holes in plexiglass:

- Clean the surface of the plexiglass where the hole will be drilled.

- Measure and mark the desired location of the hole on the masking tape.

- Cut a piece of masking tape slightly larger than the marked area.

- Place the masking tape over the marked area on the plexiglass, ensuring it is flat and tightly adhered.

- Use a pen or pencil to mark the center point of the hole on the masking tape.

- Secure the plexiglass to a worktable or other stable surface.

- Select the appropriate drill bit for the size of the hole needed.

- Apply medium pressure to the drill while making sure it is at a low speed.

- Begin drilling at a slow and steady pace, applying consistent pressure.

- Take breaks as needed to prevent overheating of the plexiglass.

- Continue drilling until the desired depth or completely through the plexiglass.

- Once the drilling is complete, remove the masking tape carefully.

Using masking tape helps to protect the plexiglass from cracking or splintering during the drilling process. It is important to take your time and use a slow and steady drilling technique to avoid applying too much pressure or heat to the plexiglass, which could result in cracking. With the use of masking tape and proper drilling techniques, you can safely drill holes in plexiglass without causing damage.

Choose the Right Drill Bit

When drilling holes in plexiglass, it is important to choose the right drill bit to prevent cracking or chipping. Plexiglass is a type of acrylic plastic that is sensitive to heat and pressure, so using the wrong drill bit can easily damage the material.

Here are a few types of drill bits that are commonly used for drilling holes in plexiglass:

- Brad Point Drill Bits: These drill bits have a sharp, pointed tip that helps prevent the bit from wandering and provides a clean hole. They are often used for woodworking and are a good choice for drilling holes in plexiglass.

- Spade Drill Bits: Spade drill bits have a flat, paddle-like shape and are commonly used for drilling large holes in wood. However, they are not recommended for plexiglass, as they can cause cracking and splintering.

- Step Drill Bits: Step drill bits have multiple cutting edges and are used for enlarging existing holes. While they can be used for plexiglass, they can also create a lot of friction and heat, which may cause cracking.

- Countersink Drill Bits: Countersink drill bits are used for creating a conical recess for a screw head. They can also be used for drilling small holes in plexiglass, but caution should be taken to avoid applying too much pressure.

When choosing a drill bit for plexiglass, it is important to select one with sharp cutting edges and a low-speed setting on your drill. Additionally, it is recommended to use a lubricant, such as water, to keep the drill bit cool and reduce heat buildup during the drilling process.

Consider the Size and Type

When drilling holes in plexiglass, it’s essential to consider the size and type of hole you need. This will affect the tools and techniques you use to prevent cracking or damaging the material. Here are a few things to keep in mind:

1. Hole Size

The size of the hole you need will determine the type of drill bit you should use. For smaller holes, a twist drill bit or brad point bit is often sufficient. However, for larger holes, a hole saw or spade bit may be necessary.

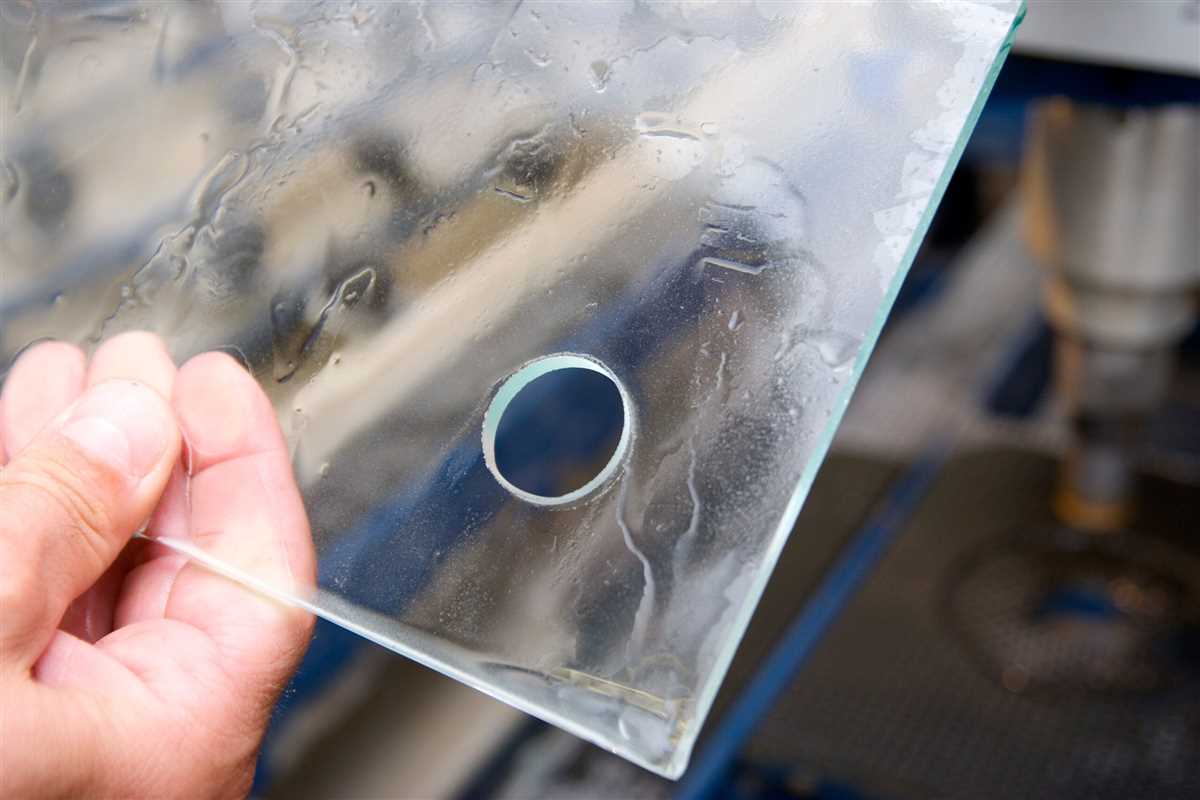

It’s important to choose a drill bit with a diameter slightly larger than the size of the hole you need. This will help prevent cracking and ensure a clean, smooth hole.

2. Hole Type

Consider the type of hole you need to drill in the plexiglass. Will it be a through-hole or a countersunk hole? A through-hole goes straight through the material, while a countersunk hole is larger at the top to accommodate a screw head.

If you’re drilling a through-hole, you can use a regular drill bit or a step drill bit. However, for countersunk holes, you may need a special countersink drill bit to create the correct shape.

3. Material Thickness

The thickness of the plexiglass also plays a role in drilling holes safely. Thicker plexiglass requires a slower drilling speed and more care to avoid cracking. Thinner plexiglass is generally easier to drill without issues.

When drilling through thick plexiglass, it can be helpful to use a speed hole punch or step drill bit to gradually increase the hole size. This reduces the stress on the material and minimizes the risk of cracking.

4. Lubrication

Using a lubricant can help reduce heat and friction when drilling holes in plexiglass. Applying a few drops of mineral oil or water to the drill bit can help keep it cool and prevent the material from melting or cracking.

However, it’s important to use lubrication sparingly and avoid excessive amounts. Too much liquid can cause the drill bit to slip or make it harder to control the drilling process.

5. Clamping and Support

To prevent the plexiglass from cracking or vibrating during the drilling process, it’s essential to securely clamp and support the material. Use clamps or a vise to hold the plexiglass in place, making sure it’s stable and won’t move while drilling.

You can also place a scrap piece of plywood or another sturdy material underneath the plexiglass to provide additional support. This helps distribute the pressure and reduce the risk of cracking.

6. Practice and Test

Before drilling into your final piece of plexiglass, it’s a good idea to practice on a scrap piece or test the drilling method on a small, inconspicuous area. This allows you to become familiar with the drilling process and determine the best technique to use for your specific project.

By considering the size and type of hole, as well as following proper techniques and precautions, you can safely drill holes in plexiglass without cracking or damaging the material.

Insert the Drill Bit Correctly

Properly inserting the drill bit is crucial for ensuring a safe drilling process on plexiglass. Follow these steps to insert the drill bit correctly:

- Choose the right type of drill bit: Select a drill bit specifically designed for drilling plexiglass. A twist drill bit with a sharp point and a wide angle is recommended.

- Secure the plexiglass: Place the plexiglass on a stable surface and clamp it down securely. This will prevent it from flexing or moving during the drilling process.

- Mark the drilling point: Use a pencil or a marker to mark the exact spot where you want to drill the hole. This will help you drill accurately and avoid any mistakes.

- Put on safety gear: Before starting the drilling process, make sure to wear safety glasses and gloves to protect yourself from any potential hazards.

- Create a pilot hole: Start by creating a small pilot hole with a smaller drill bit. This will help guide the larger drill bit and prevent any cracking or chipping of the plexiglass.

- Switch to the larger drill bit: Once the pilot hole is created, switch to the larger drill bit that matches the desired hole size. Carefully insert the drill bit into the pilot hole.

- Drill at a slow speed: Plexiglass is prone to cracking if drilled too quickly. Set your drill to a slower speed and apply steady, gentle pressure to the drill.

- Use a lubricant: To prevent overheating and reduce friction, apply a small amount of lubricant such as water or cutting oil to the drill bit while drilling.

- Drill with caution: Continue drilling at a slow pace, allowing the drill bit to cut through the plexiglass gradually. Avoid applying excessive force or tilting the drill, as this can increase the risk of cracking.

- Remove any burrs: After drilling the hole, use sandpaper or a deburring tool to remove any rough edges or burrs around the hole. This will give the hole a clean and smooth finish.

By following these steps and inserting the drill bit correctly, you can safely drill holes in plexiglass without cracking or damaging it.

Drill at the Right Speed

When drilling holes in plexiglass, it is important to use the right speed to prevent cracking. Plexiglass is a brittle material that can easily crack if too much pressure or heat is applied. By drilling at the right speed, you can minimize the risk of cracking and achieve a clean, smooth hole.

Selecting the Speed

The speed at which you should drill plexiglass depends on the thickness of the material and the size of the hole you want to create. As a general rule, slower speeds are more suitable for drilling plexiglass. The ideal speed range is typically between 500 and 2,000 RPM (revolutions per minute).

For smaller holes (up to 1/4 inch), a slower speed of around 500-1,000 RPM is recommended. This helps to reduce friction and heat buildup, which can cause the plexiglass to melt or crack. For larger holes or thicker plexiglass, you can increase the speed to around 1,000-2,000 RPM.

Using a Variable Speed Drill

If possible, it is best to use a variable speed drill when drilling plexiglass. This will allow you to adjust the speed based on the size of the hole and the thickness of the material. Start at a lower speed and gradually increase it as needed. This will help you maintain control and avoid applying excessive force.

Using a Drill Press

When drilling larger holes or working with thick plexiglass, using a drill press can provide better stability and control. A drill press allows you to set a specific speed and maintain consistent pressure, reducing the risk of cracking. Make sure to secure the plexiglass firmly in place before drilling to prevent it from vibrating or moving during the drilling process.

Remember to always wear safety goggles and protective gloves when working with power tools and plexiglass. These precautions will help protect your eyes and hands from any flying debris or accidental contact with the drill bit.

FAQ:

What is the best type of drill bit to use for drilling holes in Plexiglass?

When drilling holes in Plexiglass, it is recommended to use a drill bit specifically designed for use with Plexiglass or other plastics. These drill bits typically have a pointed tip and a sharp cutting edge that helps to reduce the chance of cracking or chipping the material.

Are there any specific safety measures I should take when drilling holes in Plexiglass?

Yes, there are a few safety measures you should take when drilling holes in Plexiglass. First, it’s important to wear safety goggles to protect your eyes from any flying debris. Secondly, you should secure the Plexiglass firmly to prevent it from slipping or moving during the drilling process. Lastly, it’s recommended to use a slow drilling speed and apply consistent, even pressure to the drill to prevent excessive heat buildup, which can also cause cracking.

Is it necessary to use lubrication when drilling holes in Plexiglass?

Using lubrication while drilling holes in Plexiglass is not necessary, but it can help reduce the chance of cracking or chipping. If you choose to use lubrication, it’s important to use a lubricant that is compatible with Plexiglass, such as water-based lubricants or silicone lubricants. Avoid using oil-based lubricants as they can cause damage to Plexiglass.

What should I do if the Plexiglass cracks while drilling a hole?

If the Plexiglass cracks while drilling a hole, stop drilling immediately to prevent further damage. Depending on the size and location of the crack, you may be able to salvage the piece by using clear epoxy or acrylic cement to seal the crack. If the crack is too severe, you may need to start over with a new piece of Plexiglass.

Video: