How to Drill Through a Lock: A Step-by-Step Guide

If you’ve found yourself locked out and need to gain access to a locked door or container, drilling through the lock may be your only option. While it’s important to note that drilling through a lock should only be done when absolutely necessary and legal, understanding the process can be helpful in emergency situations. In this guide, we’ll walk you through the steps to drill through a lock and unlock it successfully.

Before you begin, it’s essential to determine whether drilling through the lock is the best course of action. Assess the situation and consider alternatives such as calling a locksmith or obtaining a spare key. Remember, drilling through a lock should only be done if you have the legal right to access the locked item. Once you’ve determined that drilling is necessary, you can proceed with caution.

The first step in drilling through a lock is to gather the necessary tools. You’ll need a power drill, a drill bit suitable for the material the lock is made of (most locks are made of metal), safety goggles, and ear protection. Make sure you have a firm grip on the drill and secure the area around the lock to prevent any damage to surrounding surfaces.

Next, select a drill bit that is slightly smaller in diameter than the keyway of the lock. This will allow you to create a hole without damaging the inner workings of the lock. Position the drill bit at a slight angle, aiming towards the center of the keyway. Apply consistent pressure and slowly drill into the lock cylinder. As you drill, be mindful of any resistance or changes in sound, which may indicate that you are approaching the pins inside the lock.

Continue drilling until you feel the drill bit break through the pins and the lock cylinder. Once the drill bit has pierced through, carefully remove it from the lock. You can now use a flathead screwdriver or a similar tool to manually turn the lock mechanism and unlock the door or container. Keep in mind that drilling through a lock will damage it, rendering it useless for future use. Therefore, it’s recommended to replace the lock after gaining access.

The Importance of Lock Drilling

Lock drilling is an essential skill that every locksmith should possess. It allows locksmiths to gain access to locked doors and safes in emergency situations when other methods, such as picking or bypassing the lock, are not feasible.

1. Emergency Situations:

- In emergency situations, such as when someone is trapped inside a locked room or during a home intrusion, time is of the essence. Lock drilling provides a quick and effective solution to gain access and rescue individuals or secure the premises.

- In cases where lock bypass techniques fail or are not possible due to the complexity of the lock, drilling becomes the only viable option.

2. Lockout Services:

- Lock drilling is an essential service provided by locksmiths when individuals are locked out of their homes, cars, or businesses. It allows the locksmith to quickly and efficiently open the lock and restore access to the property.

- Lockout situations can happen at any time, and having the ability to drill locks enables locksmiths to offer prompt assistance to those in need.

3. Lock Replacement:

- Lock drilling is also important for lock replacement services. When a lock is damaged, outdated, or needs to be upgraded, drilling allows the locksmith to remove the existing lock and install a new one.

- This is especially crucial in situations where the lock is malfunctioning or compromised, as it ensures the security of the property and prevents unauthorized access.

4. Expertise and Versatility:

- Lock drilling showcases the expertise and versatility of locksmiths. It requires precision, knowledge of lock mechanisms, and the proper tools to successfully drill through a lock without causing excessive damage.

- Locksmiths who are skilled in lock drilling can handle a wide range of locks, including traditional pin tumbler locks, high-security locks, and electronic locks.

5. Honesty and Professionalism:

- Lock drilling is a service that should only be performed by licensed, professional locksmiths. It requires specialized skills and training to ensure the lock is drilled safely and without causing unnecessary damage.

- Professional locksmiths prioritize the safety and security of their clients, which is why they use lock drilling as a last resort and explore other options first. They will always communicate openly and honestly with the client about the necessity of lock drilling and the potential consequences.

In conclusion, lock drilling is an important skill that allows locksmiths to provide emergency assistance, lockout services, lock replacement, and showcase their expertise and professionalism. It should be used judiciously and with the utmost care to ensure the safety and security of the client’s property.

Choosing the Right Lock Drilling Tools

Drilling through a lock is a delicate task that requires the use of specific tools. It is important to choose the right tools to ensure a successful drilling process. Here are some important considerations when selecting lock drilling tools:

1. Drill

A drill is the primary tool used for drilling through a lock. Make sure to choose a drill with sufficient power and a variable speed setting. A corded drill is usually the best option as it provides consistent power throughout the drilling process. Additionally, consider using a drill with a reversible feature, which allows you to easily remove broken or jammed drill bits from the lock.

2. Drill Bits

The drill bits are the cutting tools that will create the hole in the lock. It is important to select the right drill bit size based on the type of lock you are working with. For most standard locks, a 1/8-inch to 1/4-inch drill bit will suffice. However, for more robust locks, such as high-security or commercial locks, you may need larger drill bits.

3. Lubricant

Using a lubricant when drilling through a lock can help reduce friction and extend the life of your drill bits. Apply a small amount of lubricant to the drill bit before starting the drilling process. This will help keep the drill bit cool and prevent it from getting stuck or breaking inside the lock.

4. Safety Equipment

When drilling through a lock, it is important to protect yourself with the appropriate safety equipment. Wear safety goggles to protect your eyes from any flying debris. Additionally, consider wearing gloves to protect your hands from sharp edges or any potential injury during the drilling process.

5. Locksmith Tools

Locksmith tools, such as plug spinners, can be used to manipulate the lock before drilling. These tools are designed to rotate the plug of the lock to the unlocked position without actually drilling through it. Using locksmith tools can help minimize damage to the lock and potentially avoid the need for drilling altogether.

Remember, drilling through a lock should only be done when all other options have been exhausted, and it is legal and ethical to do so. Always consult with a professional locksmith or law enforcement before attempting to drill through a lock.

Preparing the Lock

Before you begin drilling through a lock, you should take some time to prepare. Here are the steps to take:

- Gather your tools: To drill through a lock, you will need a few specific tools. Make sure you have the following items on hand:

- A power drill

- A drill bit suitable for metal

- A screwdriver

- Safety goggles

- Gloves

- A protective mat or cloth

- Choose the right location: Select a safe and convenient location where you can work on the lock without being disturbed. It’s important to have enough space to maneuver the drill and tools.

- Secure the lock: If the lock is attached to a door or a cabinet, make sure to secure it properly before starting the drilling process. This will prevent any accidental damage to the surrounding area.

- Put on safety gear: Before you start drilling, put on your safety goggles and gloves. These will protect your eyes and hands from any potential debris or metal shavings that may fly during the drilling process.

- Prepare the drill bit: Install the appropriate drill bit in your power drill. Make sure the size of the bit matches the type of lock you are drilling through.

- Protect the surrounding area: Place a protective mat or cloth underneath the lock to catch any metal shavings that may fall during the drilling process. This will make cleanup easier later.

By following these steps to prepare the lock, you will ensure that you have everything you need and that you are taking the necessary precautions before beginning the drilling process. Remember to stay focused and work safely throughout the entire procedure.

Marking the Drilling Spot

Once you have decided to drill through a lock, the first step is to accurately mark the drilling spot. This is crucial to ensure that you drill precisely in the right place and minimize any potential damage to the lock mechanism.

Here’s how you can mark the drilling spot:

- Inspect the lock: Carefully examine the lock and identify the dead center of the keyway. This is typically the part where the key enters the lock.

- Prepare the lock: If necessary, remove any outer components or covers that may obstruct your view of the keyway. This will give you a clear line of sight to mark the drilling spot.

- Use a marker: Use a permanent marker or a center punch to mark the dead center of the keyway. Make sure the mark is clearly visible and easily distinguishable.

- Double-check your mark: Take a moment to verify the accuracy of your mark. This will help ensure that you drill in the correct position and avoid damaging any other parts of the lock.

Remember, precision is key when marking the drilling spot. Take your time and double-check your mark before proceeding to the next step.

Drilling the Pilot Hole

Before starting the drilling process, it is important to find the correct spot to drill the pilot hole. Look for an area on the lock where there is less resistance or weakness, such as the bottom or top. This will make the process easier and faster.

Here are the steps to follow when drilling the pilot hole:

- Choose the right drill bit: Select a drill bit that is appropriate for the lock material. For most locks, a high-speed steel or cobalt drill bit should work fine. Make sure the drill bit is slightly smaller than the diameter of the lock cylinder.

- Secure the lock: Use clamps or a vice to hold the lock in place securely. This will prevent it from moving or rotating during the drilling process.

- Wear protective gear: Put on safety glasses and gloves to protect yourself from any flying debris that may result from drilling.

- Mark the spot: Use a marker or a sharp object to mark the exact spot where you’ll be drilling the pilot hole. This will help you maintain accuracy and prevent any damage to other parts of the lock.

- Start drilling: Position the drill bit at the marked spot and apply gentle pressure. Begin drilling slowly, using a low speed setting on your drill. Gradually increase the speed as you make progress.

- Monitor the progress: Pay close attention to the depth of the hole as you drill. Stop drilling once you’ve reached the desired depth for the pilot hole. Be careful not to drill too deep, as it may damage the lock mechanism.

Once the pilot hole is drilled, you can proceed with enlarging it to the desired size using a larger drill bit. This will create enough space for the lock bypass tool to be inserted and manipulate the lock mechanism.

Drilling the Main Hole

Once you have gathered all the necessary tools and materials, you are ready to start drilling the main hole in the lock. Follow these steps:

- Position the lock securely: Place the lock in a vice or securely clamp it to a stable surface. This will prevent any movement or potential accidents during the drilling process.

- Select the right drill bit: Choose a drill bit that is appropriate for the material of the lock. For most locks, a high-speed steel twist bit with a diameter of 1/4 inch or 3/8 inch is suitable. However, it is always best to refer to the lock manufacturer’s guidelines for the recommended drill bit size.

- Protect yourself: Before drilling, put on safety goggles to protect your eyes from any flying debris. It is also advisable to wear work gloves to protect your hands.

- Mark the drilling spot: Use a marker or a pen to mark the exact spot where you want to drill. Make sure the mark is clearly visible and centered on the lock’s keyway.

- Start drilling: Position the drill bit at a 90-degree angle to the lock’s surface, directly over the mark. Apply steady pressure and start drilling slowly. Allow the drill bit to do the work and avoid applying excessive force, as it may cause the drill bit to break or damage the lock.

- Monitor progress: Keep an eye on your drilling progress, and periodically stop to remove any wood or metal shavings that may accumulate around the drill bit. This will prevent the drill bit from getting clogged and allow it to continue drilling smoothly.

- Drill until you break through: Continue drilling until you feel the drill bit break through the lock’s core. Once you have broken through, release the pressure on the drill and carefully remove it from the lock.

At this point, you have successfully drilled the main hole in the lock. However, there may still be components inside the lock that need to be removed to gain access. The next section will cover how to remove these components to unlock the door.

Cleaning Up the Hole

After successfully drilling through the lock, it’s important to clean up the hole to ensure smooth operation of the lock. Here are some steps to follow:

- Remove any debris: Use a brush or compressed air to remove any wood or metal shavings that may be present around the hole. This will help prevent interference with the lock mechanism.

- Inspect the edges: Check the edges of the hole for any jagged or uneven surfaces. Use a file or sandpaper to smoothen out the edges, ensuring that they are clean and free from any sharp edges that could cause damage to the lock.

- Clean the hole: Use a damp cloth or paper towel to clean the inside of the hole. This will help remove any remaining debris or dust that may have accumulated during the drilling process.

- Apply lubricant: Once the hole is clean and dry, apply a small amount of lubricant to the inside of the hole. This will help reduce friction and ensure smooth operation of the lock.

By following these steps, you can clean up the hole after drilling through a lock, ensuring that the lock functions properly and smoothly. Remember to always exercise caution and wear appropriate safety gear when working with power tools.

Testing the Lock

Before you start drilling, it’s important to properly test the lock to ensure that it is indeed locked and cannot be opened by other means. This step is crucial in determining whether drilling is necessary or if there are other options available to unlock the lock.

To test the lock, follow these steps:

- Insert the key into the lock and turn it clockwise to see if it unlocks the mechanism. If the lock opens easily with the key, then drilling may not be necessary.

- If the key doesn’t open the lock, try applying pressure with a screwdriver or any other thin object to turn the lock in both clockwise and counterclockwise directions. This method, known as tensioning or tension wrenching, is commonly used by locksmiths to determine if a lock can be manipulated without drilling.

- If tensioning doesn’t work or there are no other alternative methods available, then drilling becomes the last resort. Proceed to the drilling steps outlined in the next section.

It’s important to note that drilling the lock should only be done as a last resort and with the proper authorization. Always ensure that you have the legal right to drill the lock before proceeding, as unauthorized lock drilling can be illegal and result in criminal charges.

Considerations and Additional Tips

1. Safety First

Before attempting to drill through a lock, it is essential to prioritize safety. Here are a few important considerations:

- Wear protective eyewear to shield your eyes from flying metal particles.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Ensure that you have a fire extinguisher on hand in case of any accidental fires.

2. Use the Right Drill Bits

Choosing the appropriate drill bits is crucial to effectively drilling through a lock. Follow these tips:

- Opt for high-speed steel (HSS) drill bits, as they are durable and can withstand the rigid materials found in locks.

- Select drill bits with a diameter slightly larger than the lock’s pins to ensure easy penetration.

3. Apply Moderate Pressure

While drilling, it is important to maintain steady and moderate pressure. Excessive force may cause the drill bit to break or damage the lock mechanism. Apply pressure in a gentle and controlled manner to gradually penetrate the lock.

4. Start with a Pilot Hole

Starting with a small pilot hole can help guide the drill bit and prevent it from slipping off the targeted area. Use a smaller drill bit to create a pilot hole before switching to a larger bit for the main drilling process.

5. Consider Lubrication

Applying lubrication to the drill bit can help reduce friction and overheating. Use a lubricant specifically designed for drilling metal to ensure smooth drilling process and extend the life of your drill bits.

6. Have Spare Locks Ready

Keep a few spare locks handy in case your drilling attempts are unsuccessful or irreversibly damage the lock. This will allow you to replace the drilled lock without compromising the security of the locked area.

7. Practice on a Non-Functioning Lock

If you are new to lock drilling, it is recommended to practice on a non-functioning lock first. This will help you get familiar with the drilling process and gain confidence before attempting to drill through a fully functional lock.

8. Seek Professional Help if Needed

If you encounter any difficulties or are unsure about drilling through a lock, it is best to seek professional assistance. Locksmiths have the expertise and tools to handle lock-related issues safely and efficiently.

Remember, drilling through a lock should only be done as a last resort and with the necessary legal permissions. Always respect the laws and regulations regarding lock-picking and locksmithing in your jurisdiction.

FAQ:

What tools do I need to drill through a lock?

To drill through a lock, you will need a drill, drill bits specifically made for metal, lubricant, and safety goggles.

What should I do before drilling through a lock?

Before drilling through a lock, you should first attempt to pick the lock or use a lock bypass technique. If those methods fail, drilling becomes a last resort.

Is it legal to drill through a lock?

Drilling through a lock is generally not illegal if you are the owner of the lock or if you have the owner’s permission. However, it is important to check your local laws and regulations regarding lock picking and breaking and entering.

Is drilling through a lock the most effective method of unlocking it?

Drilling through a lock is a last resort and should only be used when other methods, such as picking the lock, have failed. It can damage the lock and may require you to replace it afterwards.

What are the risks involved in drilling through a lock?

There are several risks involved in drilling through a lock. It can damage the lock beyond repair, cause injury if not done safely, and potentially attract unwanted attention if drilling in a public or unauthorized area.

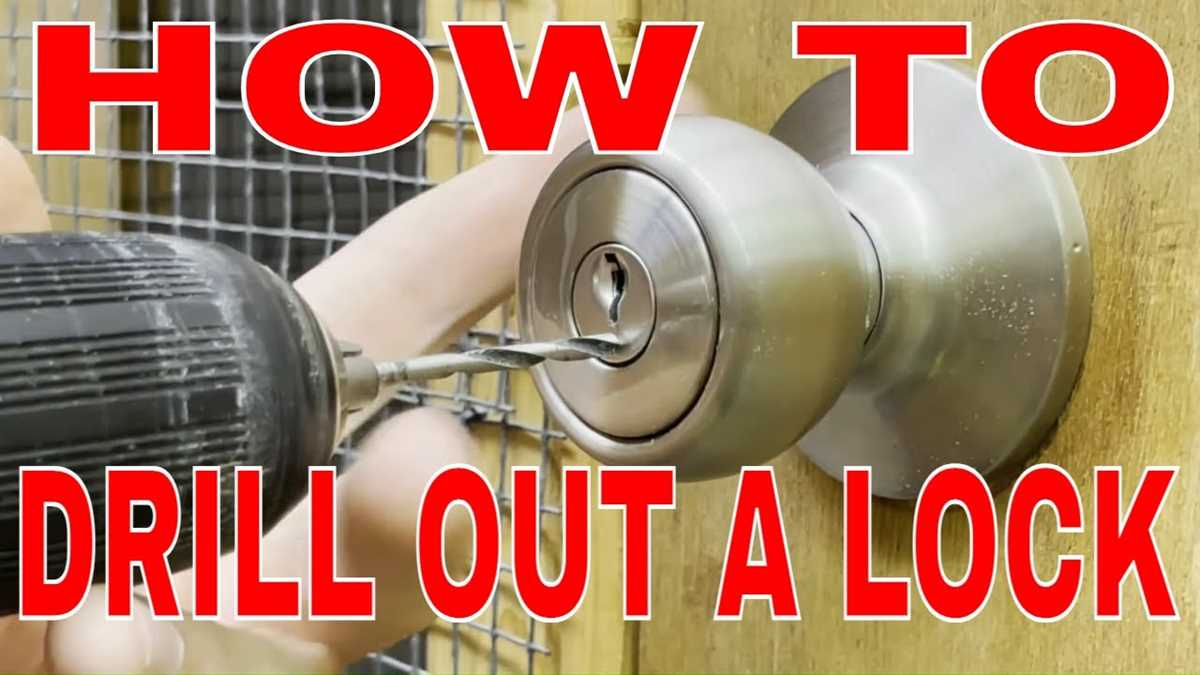

Video: