How to Drill Holes Through Metal: A Comprehensive Guide

Drilling holes through metal may seem like a daunting task, but with the right tools and techniques, it can be easily accomplished. Whether you’re a DIY enthusiast working on a home improvement project or a professional metalworker, this comprehensive guide will provide you with the knowledge and tips you need to drill holes through metal effectively and safely.

First and foremost, it’s important to select the right drill bit for the job. For drilling holes through metal, you’ll need a drill bit specifically designed for metal. These bits are made from high-speed steel (HSS) or cobalt, which are able to withstand the high temperatures generated when drilling through metal. They also have a sharp point and helical flutes to efficiently remove metal shavings.

Before you begin drilling, it’s crucial to secure the workpiece in a stable position. This can be done using clamps or a vise to prevent the metal from moving during the drilling process. Additionally, it’s recommended to mark the spot where you want to drill the hole using a marker or center punch. This helps guide the drill and ensures accuracy.

When drilling through metal, it’s important to use lubrication. This helps reduce heat and friction, prolonging the life of the drill bit and improving drilling efficiency. Cutting fluid or even a few drops of oil can be used as a lubricant. Simply apply it to the drill bit and the spot where you’ll be drilling the hole. Remember to take breaks while drilling to allow the drill bit and metal to cool off.

Preparing for Drilling

- Choose the right drill bit: Before starting the drilling process, it is important to select the appropriate drill bit for the type of metal you are drilling through. Different metals require different types of drill bits, such as high-speed steel (HSS) bits for softer metals like aluminum and cobalt bits for harder metals like stainless steel. Using the wrong drill bit can result in ineffective drilling and damage to the material.

- Gather the necessary tools: In addition to a drill and the appropriate drill bit, gather all the necessary tools and equipment for the drilling process. This may include safety glasses, work gloves, a marker or center punch for marking the drilling point, a measuring tape or ruler, and a clamp or vise to secure the metal piece in place.

- Choose the right drilling location: Selecting the right location for drilling is crucial to avoid any damage to the surrounding area or potential injuries. If possible, choose a well-ventilated area with a sturdy work surface, away from any flammable materials or delicate objects. Additionally, ensure that the metal piece is securely clamped or held in a vise to prevent it from moving during drilling.

- Take safety precautions: Drilling through metal can create sharp burrs, flying metal fragments, and heat. To protect yourself, always wear safety glasses to shield your eyes from potential debris and sparks. Additionally, consider wearing work gloves to protect your hands and avoid any accidental cuts or burns.

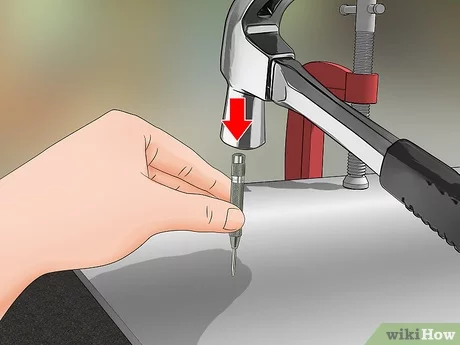

- Mark the drilling point: Before drilling, use a marker or center punch to mark the exact location where you want the hole to be. This will help you guide the drill and ensure accuracy. For precise drilling, you can also use a center punch to create a small indentation at the drilling point, which will prevent the drill bit from wandering or slipping off the mark.

- Secure the metal piece: To prevent the metal piece from moving or vibrating during drilling, it is essential to secure it properly. For small pieces, you can use a clamp to hold it in place. For larger pieces, a vise or a workbench with clamps can be used to provide stability. Make sure the metal piece is firmly secured before starting the drilling process.

Choosing the Right Drill Bit

When it comes to drilling holes through metal, it’s important to choose the right drill bit. The right drill bit will ensure that you can drill smoothly and effectively without damaging the material or your tools. Here are some factors to consider when choosing the right drill bit for your metal drilling needs:

1. Material

The first thing to consider is the material you will be drilling into. Different metals require different types of drill bits. Some common types of metal include:

- Steel

- Aluminum

- Copper

- Brass

- Cast iron

- Stainless steel

Each of these metals may require a specific type of drill bit designed to drill through them effectively.

2. Bit Type

There are several different types of drill bits that are specifically designed for drilling through metal. Some common types include:

- Twist drill bits

- Step drill bits

- Tile bits

- Spade bits

Each of these drill bit types has its own characteristics and is suitable for different metal drilling applications. Do some research to determine which type of drill bit is best for your specific needs.

3. Bit Size

The size of the drill bit is an important consideration. The right bit size will depend on the size of the hole you need to drill. It’s important to choose a drill bit that is slightly smaller than the desired hole size, as this will allow for more precise drilling and reduce the risk of the hole becoming too large or misshapen.

Consider using a drill bit size guide or consult the manufacturer’s recommendations for the specific project you are working on to determine the appropriate drill bit size.

4. Coating

Some drill bits come with coatings that provide additional benefits such as increased durability, reduced friction, and improved heat resistance. Common coatings include:

- Titanium Nitride (TiN)

- Black Oxide

- Cobalt

Consider using coated drill bits for more demanding drilling tasks or when working with harder metals.

5. Bit Shank

Lastly, consider the type of shank on the drill bit. Common shank types include round shank, hex shank, and SDS shank. The shank type will determine the type of drill chuck required to hold the bit securely in place.

Consider the type of drill you will be using and ensure that the drill bit has a compatible shank type.

By taking into account these factors, you can choose the right drill bit for your metal drilling needs and ensure accurate and efficient drilling through metal.

Selecting the Appropriate Speed and Pressure

When drilling holes through metal, it is important to select the appropriate speed and pressure to achieve the desired results. The speed and pressure at which you drill can affect the quality of the hole, the lifespan of the drill bit, and the overall safety of the operation. Here are some factors to consider when selecting the appropriate speed and pressure for drilling through metal:

Material Type

The type of metal you are drilling will determine the appropriate speed and pressure to use. Different metals have different hardness and brittleness levels, which can affect the drilling process. For example, softer metals like aluminum may require a higher speed to prevent the drill bit from getting stuck, while harder metals like steel may require a slower speed to prevent overheating and dulling of the drill bit.

Drill Bit Size

The size of the drill bit also affects the speed and pressure at which you should drill. Smaller drill bits require higher speeds and lower pressure, while larger drill bits require lower speeds and higher pressure. This is because smaller drill bits have less surface area to absorb heat, so they can be operated at higher speeds without overheating. Conversely, larger drill bits have more surface area, so they can be operated at lower speeds to prevent overheating.

Drilling Technique

The drilling technique you employ can also impact the speed and pressure at which you should drill. For example, if you are using a handheld drill, you may need to apply more pressure to ensure the drill bit bites into the metal. If you are using a drill press, on the other hand, you can rely more on the downward force of the machine and use less pressure.

Recommended Speed and Pressure Guidelines

Below are some general guidelines for selecting the appropriate speed and pressure for drilling through metal:

- Use a lower speed for thicker and harder metals, and a higher speed for thinner and softer metals.

- Apply steady and even pressure to prevent the drill bit from skidding or slipping.

- Reduce the pressure when nearing the end of the hole to prevent breakthrough damage.

- Refer to the manufacturer’s recommendations for specific speed and pressure settings.

Conclusion

Selecting the appropriate speed and pressure is crucial for drilling holes through metal effectively and safely. Consider factors such as the material type, drill bit size, drilling technique, and follow recommended guidelines to ensure optimal results.

Marking the Hole Location

Before you begin drilling, it’s important to properly mark the location of the hole on the metal surface. This will ensure that the hole is placed accurately and will prevent any mistakes or damage to the material.

Here are some steps to follow when marking the hole location:

- Clean the surface: Use a clean cloth to wipe away any dirt or debris from the area where you want to drill the hole. This will provide a clean surface for marking and drilling.

- Measure and mark: Use a measuring tape or ruler to determine the exact position of the hole. Mark this point with a pencil or a marker. You may also use a center punch to create a small indentation at the center of the hole location.

- Double-check the measurements: Before proceeding, double-check the measurements and the position of the marked hole. Make sure it is aligned correctly and at the desired location.

Additionally, if you need to drill multiple holes in a specific pattern, you can use a template or create a guide using masking tape or a piece of cardboard. This will help ensure consistency and accuracy in hole placement.

Remember that precision is key when marking the hole location. Take your time and be as accurate as possible to achieve the desired results.

Securing the Metal

Before you begin drilling holes in the metal, it’s important to secure it properly to ensure stability and prevent any accidents or damage. There are several methods you can use to secure the metal, depending on the specific project and the type of metal you are working with.

Clamping

One of the most common ways to secure metal is by using clamps. Clamps provide a strong grip and hold the metal firmly in place, preventing it from moving or shifting during the drilling process. Make sure to choose clamps that are appropriate for the thickness and shape of the metal.

When using clamps, position them on either side of the area where you plan to drill the hole, ensuring that they are tightly secured. This will help minimize vibrations and ensure that the metal remains stable while you drill.

Using a Vise

If you have a vise available, it can be a great tool for securing metal. Vises provide a stable and secure hold, allowing you to drill with more precision and control. Simply place the metal between the jaws of the vise and tighten them securely.

It’s important to position the metal in a way that allows easy access to the area you want to drill. Adjust the vise as necessary to ensure a secure hold and to prevent the metal from moving or rotating while drilling.

Using a Workbench

If you don’t have clamps or a vise, you can secure the metal by using a workbench. Place the metal on the workbench and use heavy objects or weights to hold it down. This will help prevent any movement or vibration during the drilling process.

Make sure to position the metal in a way that allows for easy access to the area you want to drill. Additionally, ensure that the workbench is sturdy and can support the weight of the metal.

Protective Measures

While securing the metal, it’s essential to take certain protective measures to ensure your safety. Always wear protective gloves and safety glasses to protect your hands and eyes from any potential debris or metal shavings.

If you are working with particularly hard or thick metal, wearing ear protection may also be necessary to protect your hearing from the loud noise produced during drilling.

By properly securing the metal and taking the necessary protective measures, you can ensure a safe and successful drilling process.

Drilling Techniques for Different Types of Metal

1. Steel

Drilling through steel requires the use of high-speed steel or cobalt drill bits. These drill bits are designed to withstand the hardness of steel and provide clean holes. Here are a few techniques to keep in mind when drilling through steel:

- Use a center punch to create a starting point for the drill bit.

- Apply cutting oil or lubricant to reduce heat and friction.

- Drill at a slow speed and apply steady pressure to prevent the drill bit from overheating.

- Use a clamp or vise to hold the steel in place.

- If drilling a large hole, start with a smaller pilot hole to guide the larger drill bit.

2. Aluminum

Aluminum is a soft metal that can easily be drilled using standard high-speed steel drill bits. However, there are a few tips to ensure a successful drilling process:

- Use a center punch to create a starting point for the drill bit to prevent slippage.

- Apply cutting oil or lubricant to reduce friction and facilitate the drilling process.

- Drill at a higher speed compared to drilling through steel.

- Secure the aluminum material with a clamp or vise to prevent it from moving during drilling.

- If drilling a larger hole, start with a smaller pilot hole.

3. Stainless Steel

Drilling through stainless steel can be more challenging due to its hardness. Here are some techniques to help you drill through stainless steel:

- Use cobalt or carbide drill bits designed for drilling through stainless steel.

- Apply cutting oil or lubricant to reduce heat and friction during drilling.

- Drill at a slow speed and apply constant pressure to prevent the drill bit from overheating.

- Use a center punch to create a starting point and prevent the drill bit from wandering.

- If drilling a larger hole, start with a smaller pilot hole and gradually increase the size.

4. Copper

Drilling through copper is relatively easy due to its softness. Follow these techniques when drilling through copper:

- Use high-speed steel or cobalt drill bits for best results.

- Apply cutting oil or lubricant to prevent the drill bit from overheating.

- Drill at a moderate speed, as high speeds can cause the drill bit to seize.

- Secure the copper material with a clamp or vise to prevent it from moving during drilling.

- Start with a smaller pilot hole and gradually increase the size for larger holes.

Conclusion

By using the appropriate drill bits and following the correct techniques, drilling through different types of metal can be accomplished successfully. Remember to always prioritize safety by wearing protective eyewear and using clamps or vises to secure the metal material. Happy drilling!

Cooling and Lubricating the Drill Bit

When drilling holes through metal, it is important to use a cooling and lubricating agent to prevent overheating and extend the life of the drill bit. Heat can cause the drill bit to become dull quickly and reduce its effectiveness in drilling through tough metal surfaces. Additionally, excessive heat can damage the metal being drilled and create burrs or other imperfections.

Choosing a Cooling and Lubricating Agent

There are several options available for cooling and lubricating the drill bit during metal drilling:

- Cutting Oil: Cutting oil is a commonly used lubricant for metal drilling. It helps to reduce friction and heat by creating a barrier between the drill bit and the metal. It also helps to remove chips and debris from the cutting area. Cutting oil can be applied by either dipping the drill bit in it or using a spray bottle to coat the drilling area.

- Coolant: Coolant is another effective option for cooling and lubricating the drill bit. Coolants are typically water-based and help to dissipate heat quickly. They can be used in a mist form, which is applied directly to the drilling area using a spray bottle or coolant system.

- Tapping Fluid: Tapping fluid is a specialized lubricant used primarily for tapping or thread cutting operations. However, it can also be used during drilling to reduce friction and heat. Tapping fluid is usually oil-based and can be applied using a brush or by dipping the drill bit.

Applying the Cooling and Lubricating Agent

Regardless of the type of cooling and lubricating agent you choose, it is important to apply it properly to ensure effective cooling and lubrication. Here are some tips for applying the agent:

- Apply Sufficient Amount: Ensure that an adequate amount of cooling and lubricating agent is applied to the drill bit and the drilling area. This will help to create a consistent barrier and prevent overheating.

- Reapply as Needed: Depending on the duration and intensity of the drilling operation, the cooling and lubricating agent may evaporate or get depleted. It is important to reapply the agent as needed to maintain effective lubrication and cooling.

- Monitor Heat: Keep an eye on the temperature of the drill bit and the metal being drilled. If you notice excessive heat, stop drilling and apply more cooling and lubricating agent as necessary.

By properly cooling and lubricating the drill bit during metal drilling, you can reduce heat and friction, prolong the life of the drill bit, and achieve better drilling results.

Safety Precautions

- Always wear appropriate safety equipment, including safety goggles, gloves, and ear protection, when drilling holes through metal.

- Ensure that the work area is well-ventilated to prevent the accumulation of dust and fumes.

- Use clamps or a vise to secure the metal piece before drilling to prevent accidental slipping or movement.

- Inspect the metal for any cracks or damage before drilling. Avoid drilling through compromised areas as it may cause the metal to break or shatter.

- Use the correct drill bit for the type of metal you are drilling. Different metals require different drill bits, so make sure to consult the manufacturer’s instructions or do proper research.

- Start drilling at a slow speed and gradually increase the speed as needed. This will help prevent the drill bit from overheating and breaking.

- Apply steady and consistent pressure when drilling to avoid any sudden jerks or slips that could lead to injury.

- Keep your fingers and hands away from the drill bit and rotating parts. Always maintain a safe distance from the drilling area.

- If using a power drill, make sure to disconnect it from the power source before changing the drill bit or making any adjustments.

- Properly dispose of any metal shavings or debris generated during the drilling process. Use a brush or vacuum to clean up the workspace to prevent accidents or injuries.

FAQ:

What types of metal can be drilled using these techniques?

You can drill holes through various types of metal including steel, aluminum, brass, and copper.

What type of drill bit should I use for drilling through metal?

For drilling through metal, it is recommended to use high-speed steel (HSS) drill bits, as they are designed to withstand the heat generated during the drilling process.

What are some tips for drilling holes through metal?

Some tips for drilling holes through metal include using cutting fluid to lubricate the drill bit, using a center punch to create a starting point, and applying consistent pressure while drilling.

Can I use a regular drill for drilling through metal?

Yes, you can use a regular drill for drilling through metal as long as you have the appropriate drill bit and technique. However, a drill press is often preferred for more precise and accurate drilling.

What are the potential challenges of drilling through metal?

Some potential challenges of drilling through metal include the generation of heat, the risk of the drill bit slipping, and the possibility of the metal workpiece becoming damaged or deformed.

How do I determine the correct drill bit size for drilling through metal?

The correct drill bit size for drilling through metal can be determined by considering the diameter of the hole you need to drill and using a drill bit slightly larger than that size. You can also consult a drill bit size chart for guidance.

Video: