How to Determine the Correct Size Drill Bit to Use

Choosing the right size drill bit is crucial for any drilling task. Whether you are a professional or a DIY enthusiast, using the correct size drill bit ensures accurate drilling and prevents damage to the materials you are working with. Determining the correct size can be a bit daunting, especially if you are new to drilling. However, with a little knowledge and understanding, you can easily select the right size drill bit for your needs.

The first step is to consider the type of material you will be drilling into. Different materials require different drill bit sizes. For example, drilling into wood requires a different size drill bit than drilling into metal or concrete. In general, soft materials like wood or plastic require smaller drill bits, while harder materials like metal or concrete require larger drill bits.

Next, you need to know the size of the hole you want to create. This will depend on the project you are working on and the type of fasteners you will be using. If you are using screws or bolts, you will need to select a drill bit that is slightly smaller than the diameter of the fastener. This ensures a tight fit and prevents the fastener from slipping or wiggling in the hole.

Remember to take into account the thickness of the material as well. If the material is thin, you will need a shorter drill bit to avoid drilling through the other side. On the other hand, if the material is thick, you may need a longer drill bit to reach the desired depth. Measuring the thickness of the material and adding it to the length of the drill bit will give you an estimate of the overall length you need.

Lastly, it’s important to keep in mind that drill bits come in different types and shapes. The most common types are twist drill bits and spade bits. Twist drill bits are versatile and can be used for many applications, while spade bits are specifically designed for drilling large, flat-bottomed holes. Depending on the type of task you are working on, you may need to choose a specific type of drill bit.

By considering the material, hole size, thickness, and type of drill bit, you will be able to determine the correct size drill bit to use for your drilling projects. Remember to always double-check your measurements and take safety precautions when drilling. Happy drilling!

Choosing the Right Drill Bit Size

When it comes to drilling holes, using the correct drill bit size is essential. The right size drill bit will ensure that your hole is the right diameter for whatever you are installing or fastening. Here are some tips for choosing the right drill bit size:

1. Determine the material you are drilling into

Before selecting a drill bit size, you need to consider the material you are drilling into. Different materials require different drill bit sizes. For example, drilling into wood may require a different size drill bit than drilling into metal or concrete.

2. Check the manufacturer’s recommendations

Most manufacturers provide recommendations for the drill bit size to use with their products. These recommendations take into account the size of the fastener or anchor you are using and the material you are drilling into. It’s important to follow these recommendations to ensure a secure and properly sized hole.

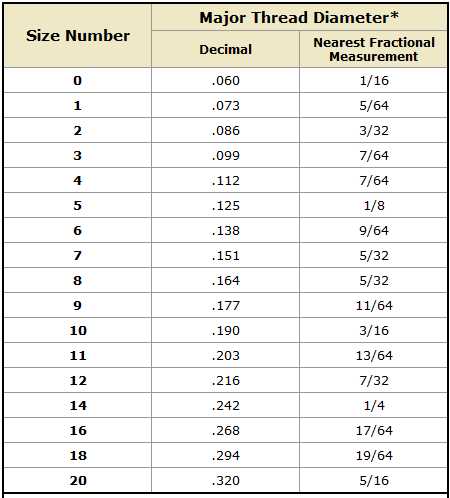

3. Use a drill bit size chart

If you are unsure of the correct drill bit size to use, you can consult a drill bit size chart. These charts provide a reference for the recommended drill bit size based on the diameter of the hole you need to drill. You can find drill bit size charts online or in hardware stores.

4. Consider the depth of the hole

In addition to the diameter of the hole, you should also consider the depth of the hole you need to drill. Some drill bits have a specific length or depth capacity, so be sure to choose a drill bit that can accommodate the depth of your hole.

5. Start with a smaller size drill bit

If you are unsure of the correct drill bit size, it’s safer to start with a smaller size bit and gradually increase the size if needed. This allows you to test the size of the hole and ensure that it is the right fit for your installation or fastening.

Remember, using the correct drill bit size is crucial for ensuring proper installation and preventing damage. Take the time to determine the correct size and follow the recommended guidelines for the best results.

Understanding Drill Bit Sizes

When it comes to choosing the correct drill bit for your project, understanding drill bit sizes is essential. Drill bits come in various sizes, and it’s important to select the right size for the job to ensure accurate and precise drilling.

Numerical Sizes

Drill bit sizes are typically measured in numerical sizes. These sizes range from small diameters to larger ones, with each size representing a specific diameter. The smaller the numerical size, the smaller the diameter of the drill bit.

For example, a drill bit with a numerical size of 1 is smaller than a drill bit with a numerical size of 10. The numerical sizes typically start from 1 and go up to 80, with each size increment representing a difference in diameter.

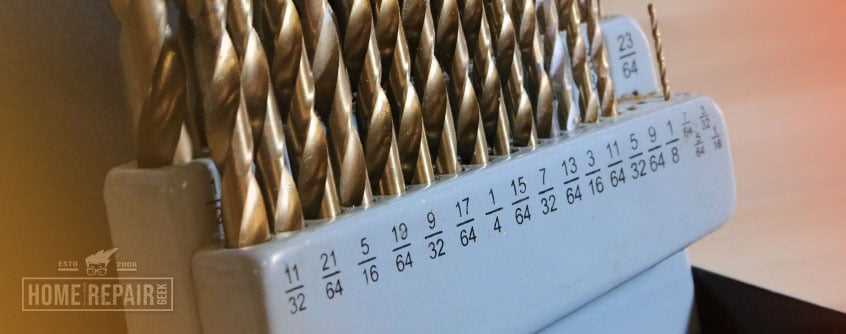

Fractional Sizes

In addition to numerical sizes, drill bits are also available in fractional sizes. Fractional sizes are represented as fractions of an inch and are commonly used in the United States. These sizes are expressed as a numerator over a denominator, such as 1/4 or 1/2.

For example, a drill bit with a fractional size of 1/4 has a diameter of 1/4 inch. Fractional sizes are useful when working with measurements that are based on inches.

Letter Sizes

Another type of drill bit sizing system is based on letter sizes. Letter sizes range from A to Z, with each letter corresponding to a specific diameter. These sizes are typically used in smaller drill bits, such as those used for jewelry-making or precision work.

It’s important to note that different brands and manufacturers may have slight variations in their sizing systems. Therefore, it’s always a good idea to consult the manufacturer’s specifications or use a drill bit sizing chart to ensure accuracy when choosing the right drill bit size for your project.

Conclusion

Understanding drill bit sizes is crucial for selecting the correct bit for your drilling needs. Whether using numerical, fractional, or letter sizing systems, knowing how to choose the right size drill bit will result in accurate and precise holes.

Remember to consult the manufacturer’s specifications or refer to a drill bit sizing chart to ensure accuracy and compatibility with your drilling equipment. With the right size drill bit, you can achieve professional results in your woodworking, metalworking, or DIY projects.

Factors to Consider

- Material: The type of material you are drilling into is an important factor in determining the correct size drill bit to use. Different materials require different drill bit sizes. For example, drilling into wood may require a different size drill bit than drilling into metal or concrete.

- Size of the hole: The size of the hole you want to create also plays a role in selecting the correct drill bit size. If you need a larger hole, you will need a larger drill bit.

- Depth of the hole: The depth of the hole you need to drill is another factor to consider. If you are drilling a deep hole, you may need a longer drill bit to reach the desired depth.

- Type of drill: The type of drill you are using can also affect the size of the drill bit you need. Different drills may have different chuck sizes, which can limit the size of the drill bit that can be used.

- Desired finish: The desired finish of the hole can also impact the size of the drill bit you choose. If you want a clean and precise hole, you may need a smaller drill bit.

- Project requirements: Finally, it is important to consider the specific requirements of your project. Take into account any guidelines or recommendations provided by the manufacturer or instructions for the equipment or material you are working with.

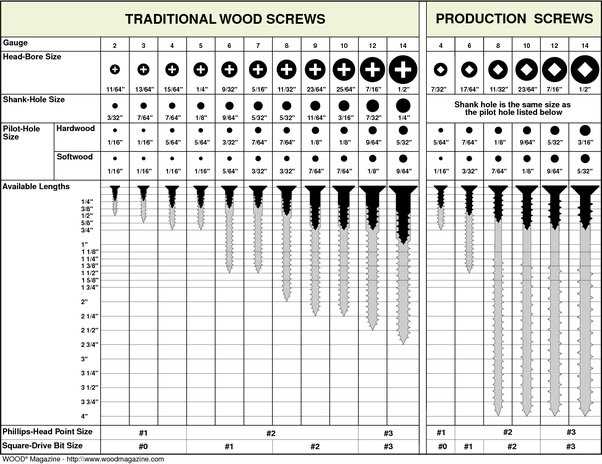

Measuring Screw Sizes

When it comes to choosing the right drill bit for a screw, it is important to accurately measure the size of the screw. The size of a screw is determined by its diameter and length. Here are some techniques for measuring screw sizes:

1. Use a Screw Sizer Gauge

A screw sizer gauge is a handy tool that allows you to quickly identify the size of a screw. It consists of a series of metal plates with various size holes. To use it, simply insert the screw into the holes until you find the one that fits snugly. The number printed next to the hole indicates the size of the screw.

2. Measure the Diameter

If you don’t have a screw sizer gauge, you can measure the diameter of the screw using a ruler or caliper. Simply place the ruler or caliper across the widest part of the screw’s threads and read the measurement. Keep in mind that screws are typically measured in either inches or millimeters, so make sure to use the appropriate unit.

3. Determine the Length

The length of a screw refers to the distance from the tip to the end of the threaded portion. To measure the length, place the screw flat on a surface and use a ruler or tape measure to measure from the tip to the end. Alternatively, you can measure the length of the entire screw if you need to determine the overall size.

4. Consult a Screw Size Chart

If you’re unsure about the size of a screw or are having trouble measuring it accurately, you can consult a screw size chart. These charts provide a comprehensive list of screw sizes along with their corresponding diameter and length measurements. This can be especially useful when dealing with non-standard or specialty screws.

By accurately measuring the size of a screw, you can ensure that you choose the right drill bit and avoid damaging the screw or the material you are working with. Whether you use a screw sizer gauge, measure the diameter and length manually, or consult a screw size chart, taking the time to determine the correct size will result in more precise and efficient drilling.

Selecting the Right Bit for Woodworking

Woodworking requires a precise and accurate approach to achieve desired results. One crucial factor in woodworking is using the correct drill bit for the specific task at hand. The type and size of the drill bit can greatly affect the outcome of your woodworking project. This article will guide you on how to choose the right bit for your woodworking needs.

1. Consider the Material

Before selecting a drill bit, consider the type of material you will be working with. Different materials require different types of bits. For woodworking, you will mostly be working with wood, so you will need wood drill bits. These bits are specifically designed to cut through wood fibers effortlessly.

2. Choose the Correct Size

Once you have determined the type of material, you need to select the appropriate bit size. The size of the bit will depend on the hole diameter you want to create. Woodworking often requires different hole sizes, so it’s essential to have a set of drill bits with various sizes. Common sizes for woodworking include 1/8 inch, 1/4 inch, 3/8 inch, and 1/2 inch.

3. Consider the Shank Type

The shank is the part of the drill bit that attaches to the drill. When selecting a drill bit for woodworking, consider the shank type. The two main shank types are straight shank and hex shank. Straight shank bits are compatible with standard drill chucks, while hex shank bits are more commonly used with impact drivers and quick-change systems.

4. Evaluate the Bit Coating

Some drill bits come with a coating that can enhance their durability and performance. For woodworking, you may want to consider bits with a coating such as titanium or carbide. These coatings can improve the bit’s lifespan and reduce friction during drilling, resulting in cleaner and smoother holes.

5. Test the Bit Before Use

Before using the selected drill bit on your woodworking project, it’s always a good idea to test it on a scrap piece of wood. This will allow you to evaluate the performance of the bit and make any necessary adjustments before working on your actual project.

Conclusion

Choosing the right drill bit is essential for achieving precise and accurate results in woodworking. Consider the material, choose the correct size, evaluate the shank type and bit coating, and always test the bit before use. By following these guidelines, you’ll be able to select the right bit for your woodworking needs and significantly improve the quality of your projects.

Choosing the Correct Bit for Metalworking

Introduction

When it comes to metalworking, selecting the right drill bit is essential for achieving precise and clean holes. Whether you are working with steel, aluminum, or other metal materials, having the correct bit can make a world of difference in the outcome of your project. This article will guide you through the process of choosing the correct drill bit for metalworking.

Types of Drill Bits for Metalworking

There are several types of drill bits designed specifically for metalworking. Below are some common types:

- Twist Drill Bits: These are the most common type of drill bits, featuring a spiral shape. They are versatile and suitable for most metalworking applications.

- Step Drill Bits: These bits are designed to create holes with different diameters, thanks to their stepped design. They are ideal for enlarging existing holes.

- Countersink Drill Bits: Countersink bits are used to create a conical recess that allows screws to sit flush with the material’s surface. They are commonly used in metalworking projects.

- Spotting Drill Bits: Spotting bits are used to create a starting point for other drill bits by making a small indentation on the surface of the material. They provide better accuracy and prevent the drill bit from slipping.

Factors to Consider

When choosing a drill bit for metalworking, there are a few factors to consider:

- Material: Different drill bits are designed for specific types of metal. Ensure you select a bit that is suitable for the material you are working with.

- Coating: Some drill bits come with coatings that reduce friction and increase the durability of the bit. Consider using coated drill bits for improved performance.

- Size: Selecting the correct bit size is crucial for achieving the desired hole diameter. Measure the hole size or refer to the project specifications to determine the appropriate bit size.

- Speed and Feed: Proper speed and feed rates are essential for achieving clean and accurate holes. Consult the manufacturer’s guidelines or refer to metalworking references for the recommended speed and feed rates for your drill bit.

- Quality: Investing in high-quality drill bits can result in more precise and longer-lasting performance. Consider purchasing from reputable manufacturers to ensure durability and reliability.

Conclusion

Choosing the correct drill bit for metalworking can significantly impact the success of your projects. By considering factors such as material, coating, size, speed, feed, and quality, you can ensure the best results. Remember to always follow safety precautions and consult professional advice when necessary. Happy metalworking!

Picking the Right Bit for Masonry Projects

When it comes to masonry projects, having the right drill bit is essential for achieving clean and precise holes. Whether you are working with bricks, concrete, or stone, using the correct bit will make a significant difference in the outcome of your project. Here are some factors to consider when picking the right bit for masonry projects:

1. Material

The first consideration when choosing a drill bit for masonry is the material you will be drilling into. Different materials will require different types of drill bits. For example:

- Brick: For drilling into brick, a masonry bit with a carbide or diamond tip is ideal. These bits are specially designed to handle the hard surface of bricks.

- Concrete: When drilling into concrete, a masonry bit made of carbide is the best choice. These bits are designed to withstand the abrasive nature of concrete.

- Stone: For drilling into stone, a masonry bit with a diamond tip is recommended. Diamond bits are known for their durability and ability to cut through hard materials.

2. Size

Once you have determined the appropriate bit type for your material, you will need to consider the size of the hole you want to drill. Masonry bits come in various sizes, ranging from 1/8 inch to 1 inch or larger. The size of the hole you need will depend on your specific project requirements.

It’s important to note that larger diameter bits are generally better for drilling larger holes, while smaller diameter bits are more suitable for smaller holes.

3. Shank Type

The shank type of the drill bit is another factor to consider. Masonry bits usually come with three types of shanks:

- Straight Shank: These bits have a straight, smooth shank and work with most standard drills.

- Hex Shank: Bits with a hexagonal shank are designed to fit into impact drivers or hammer drills, providing additional strength and stability.

- SDS Shank: SDS bits have a specific shank design that is compatible with SDS drills, which are commonly used for heavy-duty masonry projects.

4. Speed and Power

Lastly, it’s important to consider the speed and power of your drill when choosing a bit for masonry projects. Masonry drilling requires higher speed and power compared to drilling into wood or metal. Make sure your drill has the necessary speed and power capabilities to handle the selected bit and the material you are working with.

By considering these factors, you can confidently pick the right drill bit for your masonry projects. Remember to always wear appropriate safety gear and follow proper drilling techniques to ensure successful and safe results.

Using the Right Bit for Glass and Tile

When drilling into glass or tile, it’s important to use the right bit to prevent cracking or chipping. These materials are delicate and require a specific type of drill bit to ensure a clean and accurate hole.

Glass Bits

Glass bits are designed with a carbide or diamond tip that allows them to cut through glass without causing damage. They typically have a spear-shaped or spade-shaped tip to make a clean entry point and reduce the likelihood of cracking.

Here are some tips for using glass bits:

- Use lubrication while drilling to keep the bit cool and prevent additional stress on the glass.

- Start drilling at a slow speed, gradually increasing the speed as needed.

- Apply gentle, consistent pressure to avoid putting too much stress on the glass.

- Use a drill with a variable speed setting to have better control over the drilling process.

Tile Bits

Tile bits are specifically designed to drill through ceramic, porcelain, or glass tiles. These bits have a carbide or diamond tip that can withstand the hardness of tile surfaces without causing cracks or chips.

Here are some tips for using tile bits:

- Make sure to use a drill with a slow speed setting to avoid damaging the tile.

- Apply light pressure and let the bit do the work, allowing it to gradually penetrate the tile.

- Use water or a lubricant to keep the bit cool and reduce friction.

- Consider using a drill guide or template to ensure accurate drilling and minimize the risk of slipping.

By using the right bit and following these tips, you can successfully drill into glass and tile without causing any damage. Remember to always wear protective eyewear and gloves when working with power tools.

FAQ:

How do I choose the right size drill bit for my project?

Choosing the right size drill bit for your project depends on the type of material you are drilling into and the size of the hole you want to create. You can start by checking the size of the screw or fastener you are using, and then find a drill bit that matches that diameter. Alternatively, you can use a drill bit set that includes a range of sizes and select the one that is closest to the diameter you need.

What happens if I use the wrong size drill bit?

Using the wrong size drill bit can lead to several problems. If the drill bit is too small, it may not create a hole large enough for the screw or fastener to fit properly, resulting in a loose connection. On the other hand, if the drill bit is too large, it can weaken the material and cause the screw or fastener to strip or pull out easily. It’s important to use the correct size drill bit to ensure a secure and tight connection.

Can I use a smaller drill bit than the size of the screw?

While it is generally recommended to use a drill bit that matches the size of the screw, in some cases, you can use a slightly smaller drill bit. This can provide a tighter fit and increase the holding power of the screw. However, it’s important to be cautious as using a significantly smaller drill bit can result in a weak connection and may cause the screw to split the material or break. It’s always best to follow the manufacturer’s guidelines for the specific screw or fastener you are using.

Is it better to use a larger drill bit or a smaller one?

Whether to use a larger or smaller drill bit depends on the specific requirements of your project. If you want a tighter fit or increased holding power, you can use a slightly smaller drill bit. However, if you need more space for the screw or fastener to move and adjust, using a slightly larger drill bit may be appropriate. It’s important to consider the specific needs of your project and choose the drill bit size accordingly.

Can I use a drill bit with a different shape?

While most drill bits have a standard round shape, there are also specialty drill bits with different shapes, such as spade bits or hole saws. These types of drill bits are designed for specific purposes, such as creating large holes or cutting through certain materials. If your project requires a different shape, you can choose a drill bit that is specifically designed for that purpose. It’s important to use the right drill bit for the job to ensure accurate and efficient drilling.

What should I do if I don’t have the right size drill bit?

If you don’t have the right size drill bit, you have a few options. You can try using a slightly smaller or larger drill bit, depending on the specific requirements of your project. Another option is to purchase a drill bit set that includes a range of sizes, so you have more options available. If neither of these options is feasible, you can consider borrowing or renting the right size drill bit from a friend or a local hardware store.

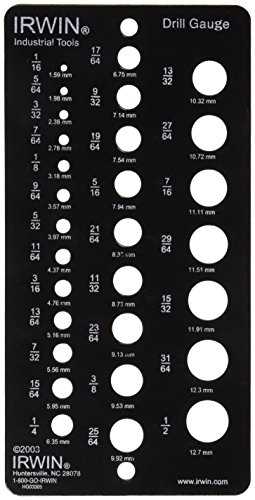

How can I determine the size of an existing hole?

To determine the size of an existing hole, you can use a drill bit gauge or a set of calipers. A drill bit gauge is a handy tool that allows you to quickly and accurately measure the diameter of a hole. If you don’t have a drill bit gauge, you can use calipers to measure the diameter of the hole directly. This measurement can help you choose the right size drill bit to match the existing hole.

Video: