How to Determine if a Drill Bit is Suitable for Metal

When it comes to drilling through metal, not all drill bits are created equal. Different drilling tasks require different types of drill bits, and using the wrong one can result in damage to the drill bit, the workpiece, or even yourself. So, how do you determine if a drill bit is suitable for metal? Here are a few key factors to consider.

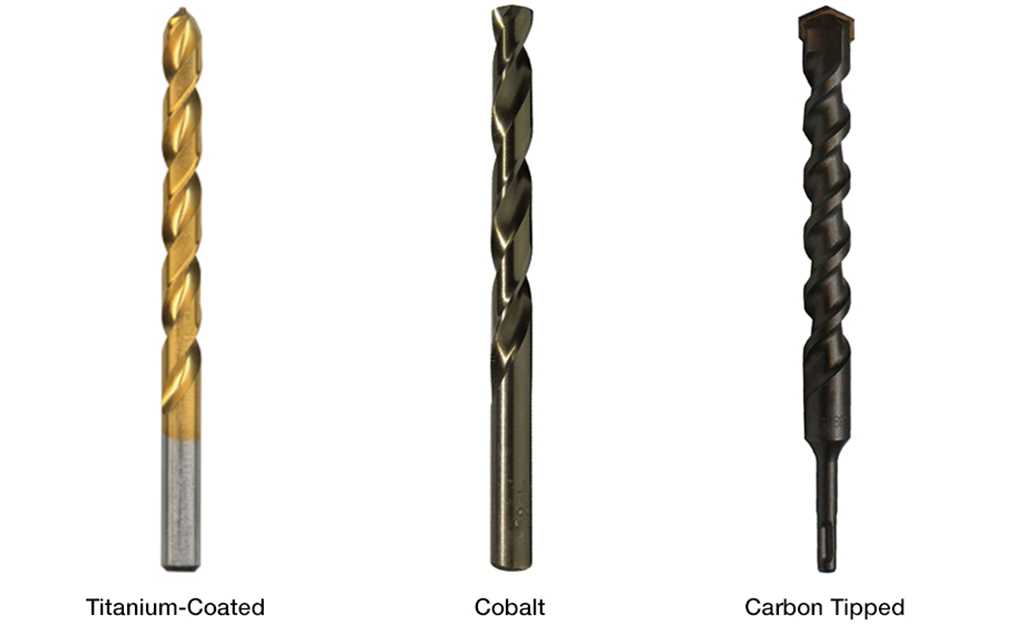

Material: The first thing to look at when determining whether a drill bit is suitable for metal is the material it is made of. The most common drill bit materials are high-speed steel (HSS) and cobalt. HSS bits are suitable for drilling through soft metals like aluminum, while cobalt bits are better suited for drilling through hard metals like stainless steel. Titanium-coated drill bits are also great for metal work as the coating reduces friction and increases durability.

Point angle: The point angle of a drill bit refers to the angle at which the cutting edge meets the workpiece. For drilling through metal, a sharper point angle is generally preferred. A point angle of 135 degrees is ideal for drilling through harder metals, while a point angle of 118 degrees is better for softer metals. This sharper point angle helps to reduce walking or skidding when drilling into metal and allows for better control.

Flute design: The flute design of a drill bit refers to the spiraling grooves on its surface. For drilling through metal, a drill bit with a wide, open flute design is usually recommended. This allows for the easy removal of chips and debris from the hole, preventing the bit from getting clogged, overheated, or dull. A flute design with a 35-degree helix angle is often the most efficient for drilling through metal.

Size: Lastly, the size of the drill bit should also be considered when determining its suitability for metal work. While small drill bits are great for precision work and starting pilot holes, larger drill bits are better for drilling larger holes or through thicker metal pieces. Make sure to select a drill bit size that matches your specific drilling needs.

Remember, safety should always be your top priority when drilling through metal. Always wear proper safety goggles, gloves, and work in a well-ventilated area. If you have any doubts about the suitability of a drill bit for your metal drilling project, consult with a professional or do some research to ensure you have the right tool for the job.

Factors to Consider

- Material: One of the most important factors to consider when choosing a drill bit for metal is the material of the drill bit itself. It is important to choose a drill bit that is specifically designed to work with metal. Common types of drill bits for metal include high-speed steel (HSS) drill bits, cobalt drill bits, and carbide drill bits.

- Size: The size of the drill bit is another important factor to consider. The size of the drill bit you choose will depend on the specific task at hand. Smaller drill bits are typically used for creating pilot holes or for drilling small holes, while larger drill bits are used for drilling larger holes or for creating larger openings in metal surfaces.

- Point Angle: The point angle of the drill bit refers to the angle at the tip of the drill bit. Different point angles are suitable for different materials. When drilling through metal, it is generally recommended to use a drill bit with a point angle of 118 degrees.

- Coating: Some drill bits for metal may come with a coating, such as titanium or black oxide. These coatings help to reduce heat and friction during drilling, which can extend the life of the drill bit and improve drilling performance.

- Flute Design: The flute design refers to the grooves on the drill bit. The flute design will affect the chip evacuation and drilling speed. For drilling through metal, it is recommended to choose a drill bit with a spiral flute design, as this design helps to remove chips more effectively.

- Quality: Lastly, it is important to consider the quality of the drill bit. Investing in a high-quality drill bit will ensure better performance, durability, and longevity. It is worth spending a bit more for a quality drill bit that will deliver better results and last longer.

Material Composition of the Drill Bit

The material composition of a drill bit is a crucial factor in determining its suitability for metal drilling. Different materials have different hardness, heat resistance, and wear resistance properties, which directly affect the performance of the drill bit.

High-Speed Steel (HSS)

High-speed steel (HSS) is the most commonly used material for drill bits. It is an alloy of steel with varying amounts of tungsten, molybdenum, cobalt, and vanadium. HSS drill bits are known for their durability, versatility, and affordability. They can effectively drill through a wide range of materials, including metal.

Cobalt Steel

Cobalt steel is a type of high-speed steel that contains a higher percentage of cobalt. This composition enhances the hardness, heat resistance, and wear resistance of the drill bit. Cobalt steel drill bits are ideal for drilling hard metals, such as stainless steel, cast iron, and titanium.

Carbide

Carbide drill bits are made from tungsten carbide, a compound of tungsten and carbon. This material is extremely hard and offers excellent heat resistance. Carbide drill bits are best suited for drilling through hard and abrasive materials like stainless steel, hardened steel, and cast iron. However, they are relatively more expensive than HSS or cobalt steel drill bits.

Titanium Coated

Titanium-coated drill bits have a high-speed steel or cobalt steel construction, but with a thin layer of titanium nitride coating. This coating improves the hardness and lubricity of the drill bit, providing better performance and longer life. Titanium-coated drill bits are suitable for general-purpose metal drilling.

Diamond Coated

Diamond-coated drill bits, as the name suggests, have a diamond coating on the drill tip. This coating significantly enhances the hardness and wear resistance of the drill bit, making it ideal for drilling through extremely hard materials like tungsten carbide, ceramic, and glass. However, diamond-coated drill bits are quite expensive and should be used with caution to avoid chipping or cracking the materials being drilled.

| Material | Pros | Cons |

|---|---|---|

| High-Speed Steel (HSS) | • Durable • Affordable • Versatile |

• May lose sharpness quickly when drilling through hard metals |

| Cobalt Steel | • Harder and more heat-resistant than HSS • Ideal for hard metals |

• Relatively more expensive |

| Carbide | • Extremely hard • Excellent heat resistance |

• Relatively more expensive • Brittle |

| Titanium Coated | • Improved hardness and lubricity • Longer life |

• Not suitable for very hard metals |

| Diamond Coated | • Exceptionally hard and wear-resistant | • Expensive • Requires careful handling |

Drill Bit Coating

Drill bit coating refers to the material that is applied to the surface of the drill bit to enhance its performance and durability when drilling through metal. The coating can provide several benefits, including increased hardness, reduced friction, and improved heat dissipation.

Types of Drill Bit Coatings

There are several types of coatings that can be applied to drill bits for metal drilling:

- Titanium Nitride (TiN): This is one of the most common coatings used for drill bits. TiN coating is known for its high hardness, which helps to protect the drill bit from wear and extend its lifespan. It also reduces friction, allowing for smoother drilling and preventing the bit from overheating.

- Cobalt: Cobalt coating is often used for high-speed steel (HSS) drill bits. It provides increased hardness and heat resistance, making it suitable for drilling through harder metals like stainless steel and cast iron.

- Black Oxide: Black oxide coating is applied to drill bits to improve their lubricity and corrosion resistance. It also helps to reduce friction and dissipate heat, allowing the drill bit to last longer and maintain its sharpness.

- Titanium Aluminum Nitride (TiAlN): TiAlN coating is a more advanced type of coating that offers superior hardness and heat resistance compared to TiN. It is commonly used for drilling through tough materials like hardened steel and superalloys.

- Diamond Coating: Diamond coating is the hardest and most durable type of drill bit coating. It is typically used for specialty drill bits designed for drilling through extremely hard materials like glass, ceramics, and stone.

Choosing the Right Drill Bit Coating

When choosing a drill bit for metal drilling, the type of coating is an important factor to consider. The coating should be selected based on the specific metal being drilled, the desired cutting speed, and the level of heat resistance required.

For general purpose metal drilling, TiN or black oxide coatings are commonly used and provide great performance and versatility. If you are drilling through harder metals or need increased heat resistance, a cobalt or TiAlN coating may be more suitable.

It is also important to consider the quality and thickness of the coating, as a thicker and more uniform coating will generally provide better performance and durability. In addition, proper cutting speeds and cutting fluids should be used in conjunction with the coated drill bit to maximize its effectiveness and prolong its lifespan.

In conclusion

Drill bit coatings play a crucial role in enhancing the performance and durability of drill bits when drilling through metal. By choosing the right coating for the specific metal and drilling requirements, you can ensure efficient drilling and prolong the lifespan of your drill bits.

Drill Bit Design

The design of a drill bit plays a crucial role in its suitability for drilling into metal. There are several factors to consider when evaluating a drill bit’s design for metal drilling:

- Point Angle: The point angle of a drill bit refers to the angle formed by the cutting edges at the tip of the bit. For drilling into metal, a point angle of 118 degrees is commonly recommended. This angle provides a good balance of cutting efficiency and resistance to wear.

- Flute Design: The flutes on a drill bit are the spiral grooves that allow for the removal of chips during drilling. For metal drilling, drill bits with a higher number of flutes are generally preferred. More flutes provide better chip evacuation and reduce the amount of heat generated during drilling.

- Material: The material used to make a drill bit can greatly affect its performance when drilling into metal. For drilling into soft metals, such as aluminum, a high-speed steel (HSS) drill bit is usually sufficient. However, for drilling into harder metals, such as stainless steel, a drill bit made from cobalt or carbide is more suitable due to their increased hardness and heat resistance.

- Coating: Many drill bits designed for metal drilling come with a coating that provides additional lubrication and heat resistance. Common coatings include titanium nitride (TiN) and black oxide. These coatings can enhance the overall performance and lifespan of the drill bit.

- Shank Type: The shank is the part of the drill bit that fits into the drill chuck. When drilling metal, it is important to ensure that the drill bit has a shank that is compatible with the drill’s chuck size. Most metal drilling bits have a round shank design.

By considering these design factors, you can select a drill bit that is suitable for drilling into metal and achieve optimal results in your drilling operations.

Drill Bit Size

Drill bit size is an important factor to consider when determining if a drill bit is suitable for metal. The size of the bit will affect the size of the hole it creates in the metal and ultimately, the success of the drilling process.

Drill bit sizes are typically measured in fractions of an inch or in millimeters. The most common drill bit sizes for metal range from 1/16 inch to 1/2 inch or 1.5 mm to 13 mm.

Choosing the Right Size

- Smaller drill bits are ideal for drilling small holes or creating pilot holes for larger drill bits. These smaller sizes are generally more suitable for thinner metals or when precision is required.

- Larger drill bits are better suited for drilling larger holes in thicker metals. They allow for more material to be removed and can help speed up the drilling process.

Drill Bit Size Chart

A drill bit size chart can be a useful tool when determining the appropriate drill bit size for a specific project. The chart will typically list the drill bit sizes in both inches and millimeters, making it easy to find the right size for the job.

| Drill Bit Size (inch) | Drill Bit Size (mm) |

|---|---|

| 1/16 | 1.5 |

| 1/8 | 3 |

| 3/16 | 5 |

| 1/4 | 6 |

| 5/16 | 8 |

| 3/8 | 10 |

| 7/16 | 11 |

| 1/2 | 13 |

It’s important to note that the specific drill bit sizes needed may vary depending on the project and the type of metal being drilled. It’s always recommended to refer to the manufacturer’s guidelines or consult with a professional for the most accurate drill bit size recommendations.

Testing the Drill Bit

Once you have selected a drill bit that is suitable for metal, it is important to test its capabilities before fully committing to the task at hand. Testing the drill bit will help ensure that it is up to par and will not cause any issues during use. Here are a few steps to follow when testing a drill bit for metal:

- Inspect the drill bit: Before testing the drill bit, carefully inspect it for any signs of wear or damage. Look for any dullness, chips, or cracks in the cutting edges. If you notice any flaws, it is best to replace the drill bit.

- Secure the material: When testing the drill bit, it is important to secure the metal material you will be drilling into. This can be done by clamping it down securely or placing it in a vise. Ensuring that the material is stable will help prevent accidents and provide more accurate test results.

- Set the drilling speed: Adjust the drilling speed on your drill to a suitable level for drilling metal. This will depend on the thickness and hardness of the metal you are working with. It is important to follow the manufacturer’s instructions and guidelines for your specific drill model.

- Start the drilling process: Once everything is set up, carefully position the drill bit on the marked spot and apply gentle pressure to start the drilling process. Make sure to use a slow and steady motion to prevent overheating and ensure a clean and accurate hole.

- Observe the results: While drilling, pay close attention to how the drill bit performs. Look for signs of overheating, such as discoloration or smoking, as this can indicate that the drill bit is not suitable for the metal being drilled. Additionally, observe the quality of the hole being created. If the drill bit is producing clean, round holes without difficulty, it is likely suitable for metal.

By following these steps and closely observing the performance of the drill bit, you can determine if it is suitable for metal or if you need to choose a different bit for the task at hand. Remember to prioritize safety during the testing process and always wear appropriate protective gear, such as safety glasses and gloves.

Performing a Scratch Test

A scratch test is one of the most common methods used to determine if a drill bit is suitable for metal. It involves using the drill bit to create a scratch on a metal surface and observing the result. Here is how you can perform a scratch test:

- Choose a metal surface to test the drill bit on. It is recommended to use a spare piece of the same type of metal that you will be drilling.

- Secure the metal surface firmly, either by clamping it down or holding it securely.

- Insert the drill bit into the drill chuck and tighten it securely.

- Position the drill bit on the metal surface and apply light pressure.

- Start the drill and move it in a horizontal or vertical motion to create a scratch on the metal surface.

Once you have created the scratch, you can examine it to determine if the drill bit is suitable for metal. Here are some factors to consider:

- Depth of the Scratch: If the scratch is deep and penetrates the metal easily, it indicates that the drill bit is suitable for metal. If the scratch is shallow and does not penetrate the metal effectively, the drill bit may not be suitable.

- Smoothness of the Scratch: A smooth scratch indicates that the drill bit is cutting through the metal smoothly. If the scratch is rough or jagged, it may indicate that the drill bit is not suitable for metal.

- Ability to Maintain Sharpness: After performing the scratch test, check the drill bit for any signs of dullness or wear. If the drill bit remains sharp and intact, it indicates that it is suitable for metal and can withstand the rigors of drilling.

It is important to note that a scratch test can give you a general indication of a drill bit’s suitability for metal, but it may not provide definitive results. You should consider other factors such as the drill bit’s material, coating, and design to ensure optimal performance when drilling into metal.

Testing on a Small Piece of Metal

Once you have identified a potential drill bit for metal, it is important to test it on a small piece of metal before using it on a larger project. This will help you determine if the drill bit is suitable for the type of metal you are working with and ensure that it will produce the desired results.

Here is a step-by-step guide for testing a drill bit on a small piece of metal:

- Select a small piece of metal: Choose a small scrap piece of the same type of metal that you will be drilling into for your project. This will give you a better idea of how the drill bit will perform on the actual material.

- Secure the metal: Use clamps or a vise to securely hold the small piece of metal in place. This will prevent it from moving or vibrating while you are drilling.

- Mark the drilling point: Use a marker or scribe to mark the exact spot where you want to drill the hole. This will help you stay on target and ensure accuracy.

- Choose the appropriate speed and pressure: Refer to the drill bit’s manufacturer guidelines to determine the recommended speed and pressure for drilling into metal. Adjust your drill accordingly.

- Start drilling: Position the tip of the drill bit on the marked spot and start drilling. Maintain a steady hand and apply even pressure to ensure a smooth drilling process.

- Observe the results: Pay close attention to how the drill bit performs. Is it able to penetrate the metal easily? Does it produce clean and accurate holes? Note any issues or concerns that arise during the drilling process.

- Inspect the hole: After drilling, carefully examine the hole. Is it the right size and shape? Are there any signs of damage to the metal or the drill bit? This will give you an indication of the drill bit’s suitability for metal.

By testing the drill bit on a small piece of metal, you can determine if it is suitable for your specific metalworking needs and make any necessary adjustments before starting your main project.

Ensuring Safety

Safety should always be a top priority when working with drill bits and metal. Here are some important safety tips to follow:

1. Wear Protective Gear

Before starting any drilling project, make sure to wear the appropriate protective gear. This includes safety glasses or goggles to protect your eyes from flying debris, as well as gloves to safeguard your hands.

2. Secure the Workpiece

When drilling into metal, it is important to secure the workpiece properly. Use clamps or a vice to firmly hold the metal in place, ensuring that it doesn’t move or rotate during the drilling process.

3. Start with a Pilot Hole

When drilling into metal, it is a good practice to start with a pilot hole. This smaller hole is created using a smaller drill bit and serves as a guide for the larger drill bit. It helps prevent the larger drill bit from slipping or wandering off course.

4. Use the Correct Speed and Pressure

Using the correct speed and pressure is crucial when drilling into metal. Too much pressure can cause the drill bit to overheat, wear out quickly, or break. On the other hand, too little pressure may result in inefficient drilling. Refer to the manufacturer’s guidelines or experiment cautiously to find the optimal speed and pressure for your specific drill bit and metal.

5. Keep the Drilling Area Clean

Make sure to keep the drilling area clean and free from clutter. Metal shavings and chips can be sharp and pose a safety hazard. Use a brush or vacuum to remove any debris from the work area to prevent slipping or injury.

6. Cool Down the Drill Bit

When drilling into metal for extended periods, the drill bit can become hot. It is essential to give the drill bit time to cool down periodically. This helps prevent excessive wear on the bit and reduces the risk of injury from handling a hot tool.

7. Be Mindful of Cutting Fluids

When drilling through metal, the use of cutting fluids can help to lubricate the drill bit and reduce heat buildup. However, some cutting fluids can be harmful if inhaled or come into contact with the skin. Always follow the manufacturer’s instructions and use cutting fluids in well-ventilated areas while wearing appropriate protective gear.

By following these safety tips, you can ensure a safer and more successful drilling experience when working with metal.

FAQ:

What should I consider when choosing a drill bit for metal?

When choosing a drill bit for metal, you should consider the type of metal you will be drilling into, the size of the hole you need, and the speed at which you will be drilling.

Can I use a regular drill bit for metal?

You can use a regular drill bit for softer metals like aluminum, but for harder metals like steel or iron, it is best to use a drill bit specifically designed for metal.

How can I tell if a drill bit is suitable for metal?

You can tell if a drill bit is suitable for metal by checking its material, its design, and its coating. Drill bits made of high-speed steel or cobalt are best for metal, and they should have a sharp point and flutes that are shaped to clear away metal shavings. Additionally, a drill bit with a titanium or black oxide coating is ideal for improved durability and heat resistance.

What can happen if I use the wrong drill bit for metal?

If you use the wrong drill bit for metal, you may experience problems such as dulling or breaking of the drill bit, difficulty in drilling through the metal, and a poor-quality hole with rough edges. Using the wrong drill bit can also increase the risk of accidents or injuries.

Are there any specific drill bits recommended for drilling through stainless steel?

Drilling through stainless steel can be challenging, so it is recommended to use a high-speed steel or cobalt drill bit specifically designed for stainless steel. These drill bits have a harder cutting edge and can withstand the heat generated by the drilling process. It is also advisable to use cutting fluid or lubricant while drilling through stainless steel to reduce friction and prevent overheating.

Video: