How long does it take to drill a well?

Drilling a well is a complex process that involves a series of carefully planned and executed steps. The duration of the drilling process can vary depending on several factors, such as the depth and complexity of the well, the type of equipment used, and the geological conditions of the site.

The drilling process typically begins with the preparation of the drilling site, which involves clearing the area and setting up the drilling rig. Once the site is ready, the drilling rig is used to drill a hole into the ground. The drilling rig is equipped with various tools and equipment, including drill bits, mud pumps, and drilling fluids, which are used to break up the rock and extract the drilling cuttings.

The speed at which a well can be drilled depends on the efficiency of the drilling equipment and the expertise of the drilling crew. In general, a well can be drilled at an average rate of 100 to 300 feet per day. However, this rate can vary significantly depending on the specific conditions and challenges encountered during the drilling process.

In some cases, drilling a well can be a time-consuming process that can take weeks or even months to complete. Factors such as drilling through hard rock formations, encountering unexpected geological conditions, or dealing with equipment breakdowns can contribute to delays in the drilling process. It is important for drilling companies to carefully plan and manage the drilling operations to minimize downtime and ensure the efficient completion of the well.

The process of drilling a well

1. Site preparation

Before drilling can begin, the site needs to be prepared. This involves clearing the area of any obstacles, ensuring there is sufficient space for the drilling equipment, and conducting a comprehensive survey to determine the most suitable location for the well.

2. Setting up the drilling rig

Once the site is prepared, the drilling rig is brought in and set up. This includes assembling the various components of the rig, such as the derrick, drill pipe, and drilling mud system. The rig is typically anchored securely to ensure stability during the drilling process.

3. Drilling the wellbore

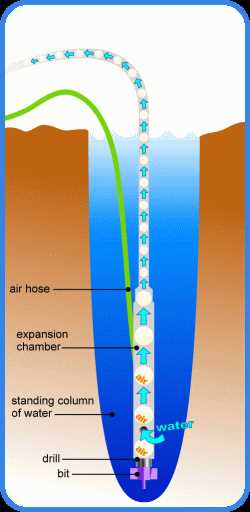

The drilling process begins by lowering the drill bit into the ground. As the drill rotates, it creates a hole in the earth’s crust, known as the wellbore. The drill bit is often equipped with cutting elements, such as diamond or tungsten carbide, to break through rocks and formations.

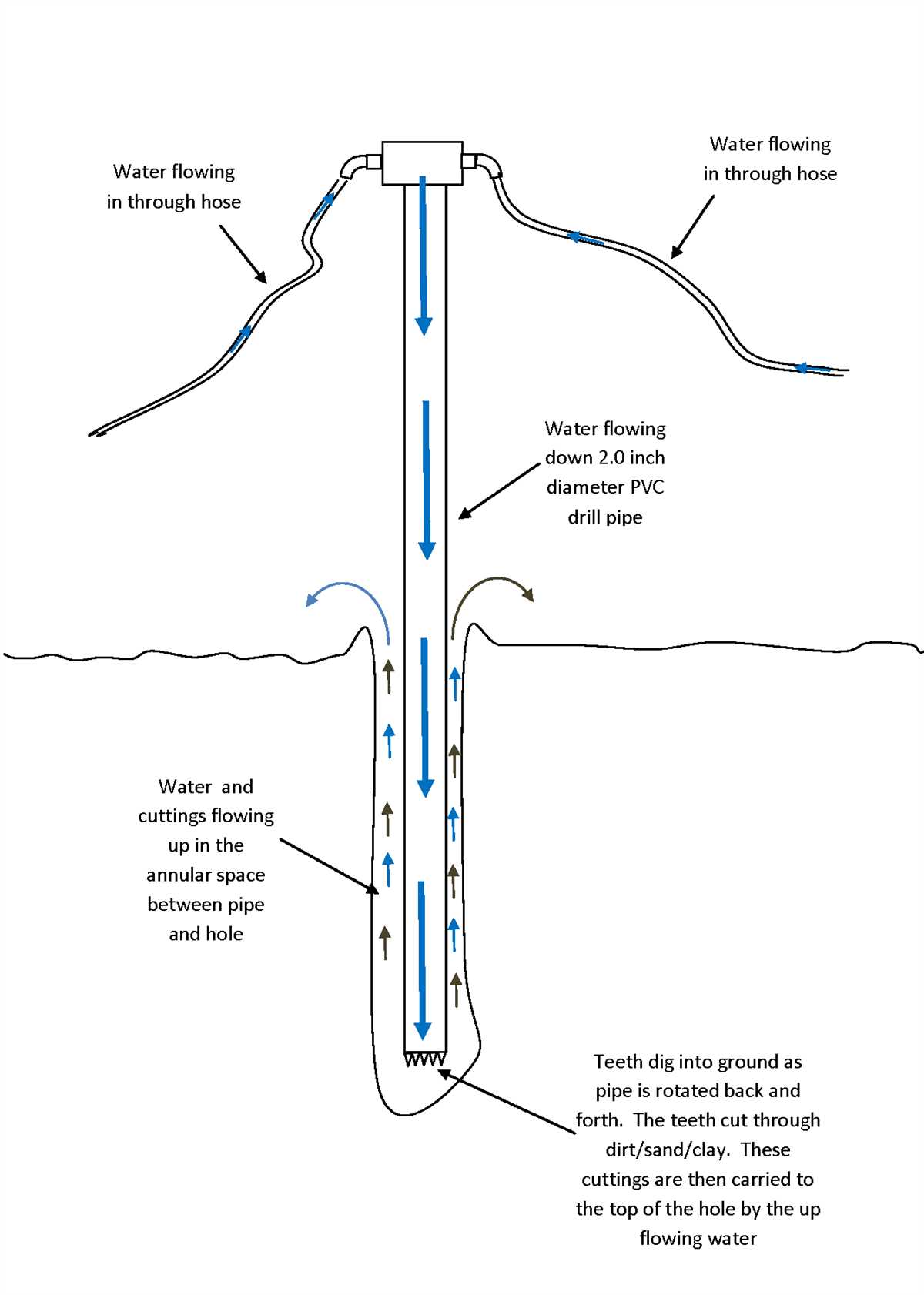

4. Using drilling mud

Drilling mud is continuously pumped down the drill pipe and out of the drill bit to aid in the drilling process. The drilling mud serves several purposes: cooling the drill bit, carrying out rock cuttings to the surface, maintaining pressure in the wellbore, and providing stability to prevent the walls of the wellbore from collapsing.

5. Running casing and cementing

As the drilling progresses, sections of steel pipe called casing are inserted into the wellbore to provide structural integrity and prevent the well from collapsing. Once the desired depth is reached, the casing is cemented in place to ensure a sealed and secure wellbore.

6. Well completion

After the wellbore has been drilled and the casing is in place, the drilling rig is typically replaced with a completion rig. This rig is used to install production equipment, such as tubing, pumps, and wellheads, as well as perform any necessary well testing or stimulation procedures.

7. Well maintenance and operation

Once the drilling and completion processes are finished, the well enters the production phase. It will require regular maintenance and operation to ensure optimal production levels and the longevity of the well. This includes routine inspections, servicing of equipment, and monitoring of production rates.

8. Plugging and abandonment

At the end of the well’s productive life, or if it becomes uneconomical or unsafe to continue production, the well must be properly plugged and abandoned. This involves sealing the wellbore with cement to prevent any leakage of fluids or gases into surrounding formations or the environment.

Conclusion

Drilling a well involves a complex and time-consuming process that requires careful planning and execution. From site preparation to well abandonment, each step must be carefully managed to ensure the successful drilling of a well.

Factors influencing drilling time

Drilling a well is a complex process that requires careful planning, equipment, and expertise. The time it takes to drill a well can vary depending on several factors:

1. Geology

The geology of the area where the well is being drilled plays a significant role in drilling time. Different types of rock formations can be more or less challenging to drill through. Hard, abrasive formations may require slower drilling speeds and frequent bit changes, which can increase drilling time. On the other hand, softer formations may allow for faster drilling progress.

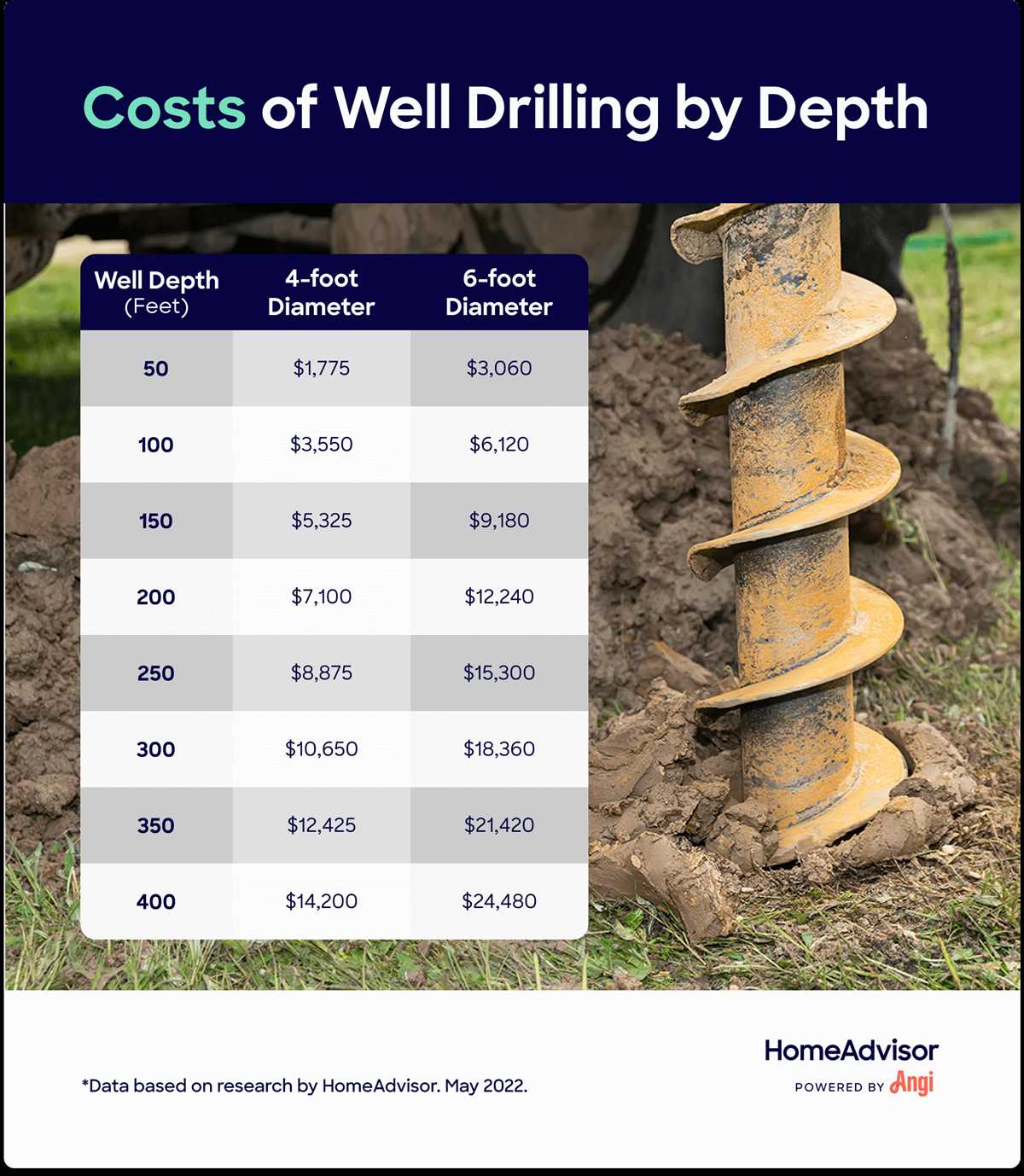

2. Well depth

The depth of the well is another critical factor that influences drilling time. Deeper wells require more time to drill as the drilling equipment needs to go further into the ground. The deeper the well, the more time it typically takes to drill and complete the well. Delays can also occur if unexpected obstacles or formations are encountered along the way.

3. Equipment and technology

The type and condition of the drilling equipment used can significantly affect the drilling time. Well-equipped rigs with advanced technology and efficient drilling methods can reduce drilling time. Conversely, outdated equipment or equipment malfunctions can cause delays and increase the overall drilling time.

4. Weather conditions

Weather conditions can also impact drilling time. Inclement weather, such as heavy rain or snow, can slow down the drilling process and make the work more challenging. Extreme heat or cold temperatures can also affect the performance of equipment and personnel, causing delays and increasing drilling time.

5. Operator experience and efficiency

The operator’s experience and efficiency in drilling wells can have a significant impact on drilling time. Experienced operators who are familiar with the geological conditions of the area and efficient drilling techniques can often complete wells more quickly. Inexperienced operators or those unfamiliar with the area may require more time to complete the drilling process.

6. Permitting and regulatory requirements

The time required for obtaining necessary permits and meeting regulatory requirements can add to the overall drilling time. Depending on the location, there may be various permits, environmental assessments, and other regulatory processes that need to be completed before drilling can commence. Delays in the permitting process can significantly extend the overall drilling time.

7. Well complexity

The complexity of the well design can also affect drilling time. Wells with multiple branches or directional drilling require more time and specialized equipment to complete. The presence of certain formations, such as faults or unstable formations, can also add complexity to the drilling process and increase drilling time.

Considering these factors and properly planning for them can help optimize drilling time and ensure that the well is completed efficiently.

Drilling techniques and their impact on time

When drilling a well, the choice of drilling technique can have a significant impact on the time it takes to complete the project. Different techniques have varying levels of efficiency and complexity, which ultimately influence the overall drilling duration.

1. Rotary drilling

Rotary drilling is a popular and widely used technique in the oil and gas industry. It involves the use of a rotating drill bit to create a hole in the ground. The drilling fluid, known as mud, is pumped into the wellbore to cool the bit, remove cuttings, and provide stability.

This technique is known for its versatility and speed. It can penetrate various formations, including hard rock, and allows for quick drilling progress. Rotary drilling is often employed in the initial stages of well construction.

2. Cable tool drilling

Cable tool drilling, also known as percussion drilling, is an older and less common technique. It involves a heavy drilling bit that impacts the ground vertically through a repeated up-and-down motion. The cuttings are brought to the surface using a rope or cable and periodically removed.

Cable tool drilling is typically slower compared to rotary drilling but can be more effective in certain geological formations, particularly loose or unconsolidated soils. It is often used for shallow wells or when samples of the formation are required at different depths.

3. Directional drilling

Directional drilling is a specialized technique used to deviate the wellbore from its vertical path. It allows for reaching targets located in hard-to-reach areas or maximizing the production from a single well by accessing multiple areas of the reservoir.

While directional drilling can significantly increase the complexity and time required for drilling, it offers numerous advantages. By reducing the number of wells needed to access a reservoir, it can lead to cost savings and minimize the environmental impact.

4. Continuous coring

Continuous coring is a technique used when obtaining a continuous sample of the formation is crucial, such as in geological or scientific investigations. It involves the use of a core bit attached to a rotating barrel that extracts a continuous cylindrical sample of the formation as it drills.

This technique is generally slower compared to other drilling methods as it requires careful retrieval and examination of the core samples. However, it provides invaluable information about the composition and properties of the rock formations being drilled.

| Technique | Speed | Complexity |

|---|---|---|

| Rotary drilling | Fast | Low |

| Cable tool drilling | Slow | Low |

| Directional drilling | Varies | High |

| Continuous coring | Slow | High |

Overall, the choice of drilling technique depends on various factors, including the geological conditions, project objectives, and budgetary constraints. By considering the speed and complexity of each method, drilling engineers can select the most appropriate technique to optimize drilling time and achieve project goals.

Typical duration of drilling a well

Drilling a well is a complex process that involves several stages and can take anywhere from a few days to several months, depending on various factors. These factors include the depth of the well, geological conditions, equipment used, and the expertise of the drilling team.

Exploration phase

The first stage of drilling a well is the exploration phase. During this phase, geologists and engineers study the geological conditions of the site to determine the best location for the well. This phase typically takes several weeks to a few months.

Preparation and mobilization

Once the site has been selected, the drilling company will prepare the equipment and mobilize it to the location. This involves setting up the drilling rig, ensuring all necessary supplies and materials are available, and conducting safety checks. The preparation and mobilization phase can take a few days to a week.

Drilling

The drilling phase is the most time-consuming part of the process. It involves using a drilling rig to bore through various layers of rock and sediment to reach the target depth. The speed at which the well is drilled depends on several factors, including the hardness of the rock and the drilling method used. On average, drilling a well can take anywhere from a few days to several weeks.

Completion and testing

Once the well has been drilled to the desired depth, it must be completed and tested to ensure it is capable of producing water or oil. This involves installing casings, perforating the well, and conducting tests to measure its capacity and flow rates. The completion and testing phase can take anywhere from a few days to a few weeks.

Cleanup and restoration

After the well is completed and tested, the drilling site must be cleaned up and restored to its original condition. This involves removing equipment, filling in any holes or trenches, and conducting environmental remediation measures if necessary. The cleanup and restoration phase typically takes a few days to a week.

Overall, the typical duration of drilling a well can range from several weeks to several months, depending on the complexities involved. It is important to note that unexpected challenges or delays can arise during the drilling process, which may extend the overall duration.

Challenges that may prolong the drilling process

Drilling a well is a complex and time-consuming process, and there can be various challenges that may prolong the drilling process. Some of these challenges include:

1. Geological difficulties

One of the main challenges in drilling a well is encountering geological difficulties. These can include hard rock formations, unstable formations, or unexpected changes in the subsurface structure. These geological challenges can slow down the drilling process as additional time and effort are required to overcome them.

2. Technical issues

Technical issues with drilling equipment can also lead to delays in the drilling process. Equipment malfunctions, breakdowns, or the need for repairs and maintenance can all cause significant delays. Additionally, the availability of the required drilling equipment may also impact the timeline of the drilling process.

3. Environmental considerations

Environmental considerations can also affect the drilling process. For example, if the drilling site is located in a sensitive ecological area, additional precautions and measures may need to be taken to minimize environmental impact. This can include obtaining permits, conducting environmental assessments, and implementing mitigation measures, all of which can prolong the drilling process.

4. Weather conditions

Weather conditions can play a significant role in the drilling process. Adverse weather, such as heavy rain, snow, or storms, can make the drilling site inaccessible or unsafe for operations. In these cases, drilling may need to be halted until the weather improves, leading to delays in the overall timeline.

5. Logistical challenges

Logistical challenges, such as difficulties in transporting equipment and materials to the drilling site, can also impact the drilling process. This is particularly true in remote or inaccessible locations where the infrastructure is limited. Delays in the delivery of equipment and supplies can cause delays in the drilling process.

6. Regulatory requirements

Regulatory requirements and permitting processes can also prolong the drilling process. Obtaining the necessary permits and approvals from regulatory agencies can take time and may involve fulfilling specific requirements or conditions. Any delays in obtaining these permits can delay the start or progress of drilling operations.

7. Safety considerations

Safety considerations are of utmost importance in drilling operations. If safety issues or concerns arise during the drilling process, work may need to be stopped or modified until the necessary safety measures are in place. This can lead to interruptions and delays in the drilling process.

Overall, drilling a well involves various challenges that can prolong the process. Overcoming these challenges requires careful planning, expertise, and adaptability to ensure successful completion of the drilling project.

Methods to expedite the drilling time

To expedite the drilling process and reduce the time it takes to drill a well, various methods and techniques can be employed. These methods focus on increasing drilling efficiency and productivity, minimizing downtime, and improving overall performance.

1. Advanced drilling technologies

Utilizing advanced drilling technologies can significantly speed up the drilling process. Technologies such as rotary steerable systems, measurement while drilling (MWD) systems, and logging while drilling (LWD) systems can provide real-time data and information, allowing drilling engineers to make faster and more informed decisions.

2. Enhanced drill bits

By using enhanced drill bits, such as polycrystalline diamond compact (PDC) bits, the drilling process can be expedited. PDC bits are known for their durability, efficiency, and improved rate of penetration (ROP). They can withstand extreme drilling conditions and have the ability to drill faster, resulting in reduced drilling time.

3. Well planning and design

A well-planned and well-designed drilling program can help expedite the drilling process. By conducting thorough geologic surveys and using advanced drilling simulations, engineers can determine the optimal well path, minimize drill string failures, and avoid potential drilling hazards. This pre-planning helps streamline the drilling process and improves efficiency.

4. Efficient mud management

Mud management plays a crucial role in drilling operations. Using high-quality drilling fluids and proper mud maintenance can prevent drilling problems, such as sticking, wellbore instability, and excessive formation damage. By maintaining an effective mud system, drilling operations can proceed smoothly, reducing downtime and speeding up the overall drilling time.

5. Automated drilling systems

Implementing automated drilling systems can greatly enhance drilling efficiency. These systems can continuously make adjustments to drilling parameters, such as weight on bit (WOB), rotary speed, and mud flow rate, to optimize drilling performance. By automating certain processes, drilling crews can focus on other aspects of the operation, resulting in faster drilling times.

6. Simultaneous operations

To expedite the drilling process, simultaneous operations can be employed. This involves performing multiple tasks simultaneously, such as drilling while running casing, conducting logging operations while drilling, or completing cementing operations while drilling the next section. By combining these operations, significant time savings can be achieved.

7. Continuous improvement and training

An essential aspect of expediting the drilling time is continuous improvement and training. Regularly evaluating drilling operations, identifying areas for improvement, and providing training to drilling crews can enhance their skills and efficiency. This continuous improvement mindset helps optimize the drilling process and reduce the overall drilling time.

By implementing these methods and techniques, drilling operators can expedite the drilling time, improve operational efficiency, and ultimately reduce drilling costs.

Case study: time frame for drilling a deep well

Introduction:

In the oil and gas industry, drilling a deep well is a complex and time-consuming process. This case study examines the time frame involved in drilling a deep well to highlight the various stages and factors that can affect the overall duration.

Exploratory Phase:

The first stage in drilling a deep well is the exploratory phase. This involves conducting geological surveys and studies to determine the location and potential reserves of oil or gas. The exploratory phase can take several weeks to several months, depending on the complexity of the geological formations and the availability of data.

Preparation Phase:

Once the location has been identified, the preparation phase begins. This includes securing permits and licenses, acquiring drilling equipment, and mobilizing the drilling rig to the site. The preparation phase typically takes several weeks to a few months, depending on the logistical challenges and regulatory requirements.

Drilling Phase:

The drilling phase is the most time-consuming part of drilling a deep well. It involves creating a borehole by rotating a drill bit and using drilling fluid to remove the cuttings. The duration of the drilling phase can vary significantly depending on the depth of the well, the type of formation being drilled, and the drilling techniques employed. On average, it can take several weeks to several months to complete the drilling phase.

Completion Phase:

Once the desired depth has been reached, the completion phase begins. This involves casing the well to prevent collapse and installing production equipment such as tubing, wellhead, and valves. The completion phase can take a few days to a few weeks, depending on the complexity of the well design and the required equipment.

Testing and Production Phase:

After the well has been completed, testing and production activities are carried out to evaluate the productivity of the well and begin commercial production. This phase can vary in duration depending on the size and complexity of the well, as well as the testing protocols and production schedule. It may take several weeks to several months to fully evaluate the well’s potential and establish continuous production.

Conclusion:

Drilling a deep well is a time-consuming process, often lasting several months or more. The overall time frame depends on a variety of factors, including the geological complexity, logistical challenges, regulatory requirements, and the size and design of the well. By understanding the different stages and factors that influence the duration, stakeholders in the oil and gas industry can better plan and manage the drilling process.

FAQ:

How long does it typically take to drill a well?

The duration of drilling a well can vary depending on various factors such as the depth of the well, geological conditions, technical equipment used, and the experience of the drilling team. On average, it can take anywhere from a few days to several weeks to drill a well.

What factors influence the drilling time for a well?

Several factors can influence the drilling time for a well. These include the depth of the well, the type of formation being drilled through, the availability of equipment, the complexity of the drilling project, and any unforeseen challenges encountered during the drilling process.

Are there any ways to expedite the drilling process?

There are a few techniques that can be used to expedite the drilling process. This includes using more advanced and efficient drilling equipment, employing experienced drillers who can optimize the drilling strategy, and conducting thorough geological studies to better understand the subsurface conditions before drilling.

What is the average time needed to drill a shallow well?

The time required to drill a shallow well can be relatively short compared to deeper wells. Shallow wells typically range from a few tens to a few hundred feet in depth. Depending on the specific conditions and equipment used, drilling a shallow well can take anywhere from a few hours to a couple of days.

How long does it take to drill a deep offshore well?

Drilling a deep offshore well can be a complex and time-consuming process. Deep offshore wells can go thousands of feet below the seabed. It can take several months to even years to complete the drilling and production phases of a deep offshore well, due to the challenges of operating in harsh offshore environments.

Video: