How Does an Oil Drill Work: A Detailed Explanation

Oil drilling is a complex process that involves the extraction of underground oil reserves, which are essential for fuel and energy production. The process of oil drilling involves various stages and requires advanced equipment and technical expertise. In this article, we will provide a detailed explanation of how an oil drill works, from the initial site preparation to the extraction of oil.

Site Preparation: Before oil drilling can begin, extensive site preparation is necessary. Geologists and engineers study geological data to identify potential oil reserves. Once a promising site is identified, the oil company obtains the necessary permits and begins clearing the area. This involves removing trees, leveling the ground, and constructing access roads and drilling pads. The location is also equipped with necessary facilities, such as storage tanks and crew accommodations.

Drilling Process: The actual drilling process begins with the placement of the drilling rig on the prepared site. The drilling rig is a large structure that houses the equipment and machinery needed for drilling. The first step is to drill a small-diameter hole, known as a pilot hole, using a drill bit. This hole allows the drilling team to collect geological data and analyze the rock formation. Once the pilot hole is complete, a larger drill bit is used to enlarge the hole to the desired diameter.

“Oil drilling is a complex process that involves the extraction of underground oil reserves, which are essential for fuel and energy production.”

Well Casing and Cementing: After the hole is drilled, a metal casing is inserted into the wellbore. This casing provides structural support and prevents the collapse of the hole. It also serves as a barrier to prevent the migration of oil or gas into other formations. The casing is then cemented in place to secure it and protect the well from contamination. Multiple layers of casing and cement are often used to ensure proper sealing.

Extraction: Once the wellbore is prepared, the extraction process begins. A drilling fluid, usually a mixture of water, clay, and chemicals, is pumped into the well to lubricate the drill bit and remove rock cuttings. This fluid also helps to control the pressure within the well and prevent blowouts. As the drilling progresses, a rotary drilling method is used to create a hole deep enough to reach the oil or gas reservoir. When the target depth is reached, the drilling rig is removed, and a production wellhead is installed. This wellhead allows for the extraction of oil or gas from the reservoir.

In conclusion, oil drilling is a complex and intricate process that requires significant planning, expertise, and technology. From site preparation to extraction, each step in the drilling process is carefully executed to maximize efficiency and safety. Understanding how an oil drill works provides valuable insight into the production of one of the world’s most valuable resources.

Understanding the Basics of Oil Drilling

Introduction

Oil drilling is a complex process that involves drilling through layers of rock and sediment to reach underground oil reserves. This article will provide a detailed explanation of the basic principles and techniques involved in oil drilling.

Types of Oil Drilling

There are two main types of oil drilling: onshore drilling and offshore drilling.

- Onshore drilling: This type of drilling is conducted on land, usually in areas where oil reserves are found beneath the surface. Onshore drilling rigs are typically portable and can be moved from one location to another.

- Offshore drilling: This type of drilling is conducted in bodies of water, such as oceans or seas. Offshore drilling rigs are fixed platforms or floating vessels that are anchored to the seabed. They are specially designed to withstand the harsh conditions of the marine environment.

The Oil Drilling Process

The oil drilling process involves several key steps:

- Site Preparation: The first step is to identify a potential drilling site. Geologists and geophysicists study rock formations and use seismic surveys to determine the presence of oil reserves. Once a suitable site is found, the land or sea is prepared for drilling.

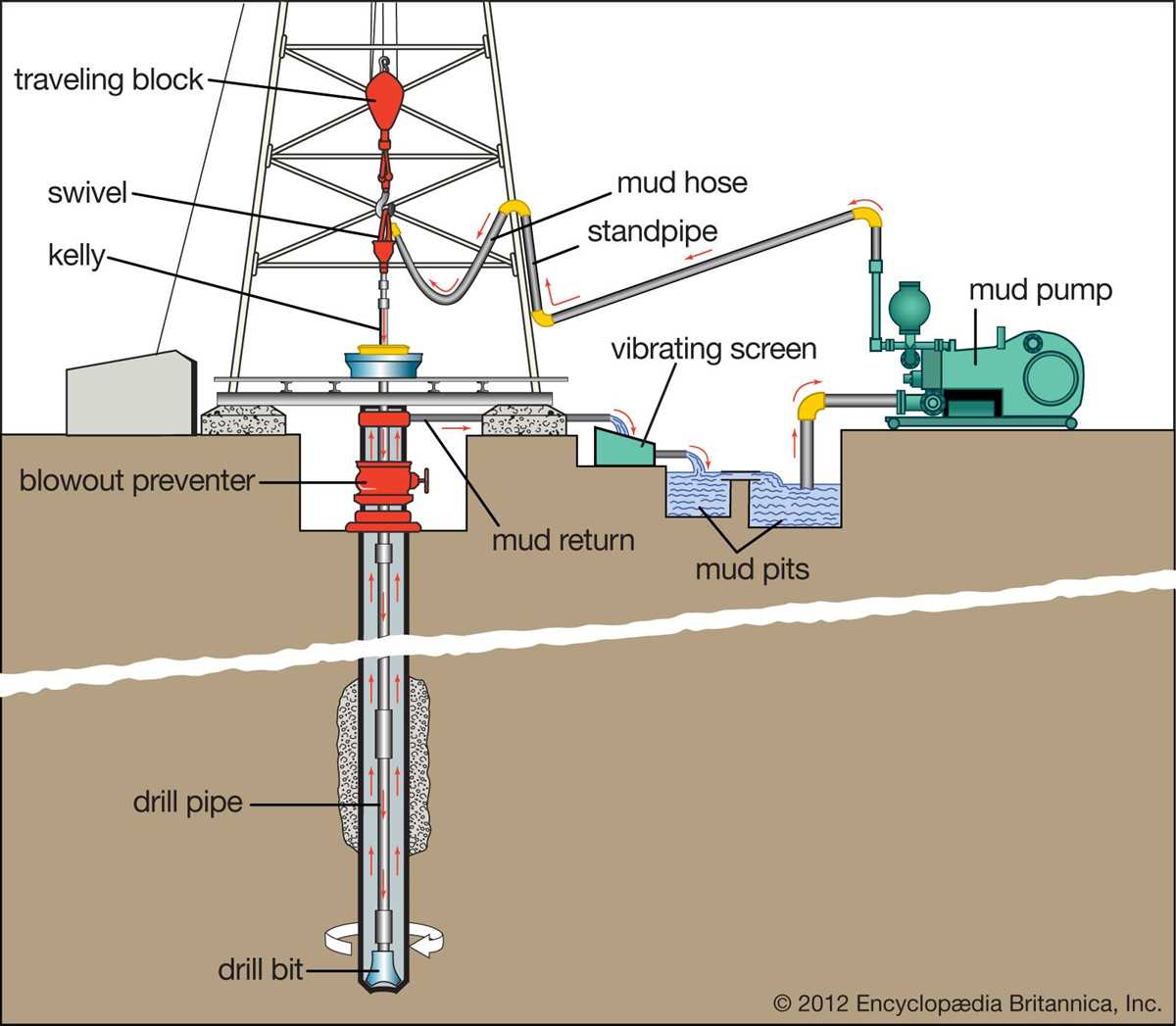

- Drilling Rig Setup: A drilling rig is set up at the chosen site. The rig consists of various equipment, including a derrick, drill pipe, and a drilling mud system. The derrick is a tall structure that supports the drilling apparatus.

- Drilling the Well: The drill bit is lowered into the ground or seabed, and the drilling process begins. The drill bit rotates and cuts through the layers of rock and sediment. As the drilling progresses, the drill pipe is lengthened to reach greater depths.

- Casing and Cementing: Once the desired depth is reached, a steel casing is inserted into the well to provide structural support. Cement is then pumped into the well to seal the space between the casing and the wellbore, preventing oil or gas from leaking into groundwater.

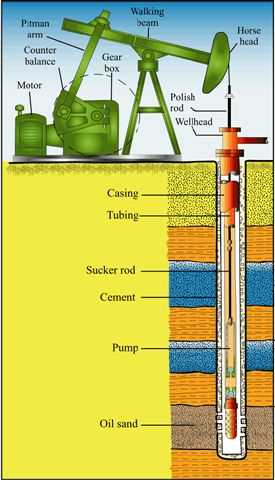

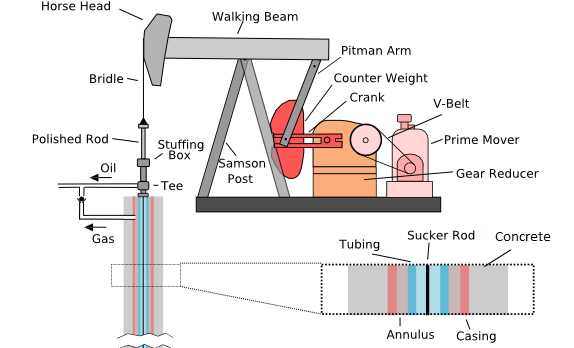

- Completion: After the cement has set, the well is completed by installing production equipment, such as pumps and valves, at the surface. This equipment allows for the extraction and transportation of oil from the well.

Environmental Considerations

Oil drilling can have a significant impact on the environment, particularly in offshore drilling. Measures are taken to minimize these impacts, such as the use of systems to capture and prevent oil spills, the implementation of wildlife protection programs, and compliance with environmental regulations.

Conclusion

Understanding the basics of oil drilling is essential to comprehend how this complex process works. From site preparation to completion, each step requires careful planning and skilled professionals to ensure the extraction of valuable oil reserves.

The Purpose of an Oil Drill

An oil drill is a complex and powerful piece of equipment used to extract oil and gas from the ground. The primary purpose of an oil drill is to reach and tap into oil reservoirs deep beneath the Earth’s surface. It plays a crucial role in the oil and gas industry as it allows for the extraction of these valuable resources for various purposes.

Exploring for Oil

Oil drills are used in the exploration phase of oil and gas production. Geological surveys and studies are first conducted to identify potential oil-rich areas. Once a site is selected, an exploratory well is drilled to determine if oil and gas are present in commercially viable quantities.

An exploratory well is typically drilled using a smaller and less powerful drilling rig. It allows geologists and engineers to collect samples of the rock and evaluate its characteristics, including porosity and permeability, to assess the potential for oil and gas extraction.

Extracting Oil and Gas

Once a viable oil reservoir is identified, a larger and more powerful drilling rig is used for production drilling. This rig is capable of drilling deeper and at higher pressures to reach the oil-bearing formations.

The drilling process begins by drilling a vertical wellbore, which is then followed by the drilling of horizontal or directional wells. These wells allow for maximum contact with the oil reservoir, increasing extraction efficiency.

The purpose of an oil drill during extraction is to create a pathway for the oil and gas to flow to the surface. This is achieved by using drill bits specially designed to cut through the rock formations and by circulating drilling mud, a mixture of fluids, to remove cuttings and maintain wellbore stability.

Well Completion and Production

Once the oil drill reaches the desired depth and the well is drilled, it undergoes completion processes to prepare it for production. This involves casing the well, which involves inserting steel pipes into the wellbore and sealing them with cement to prevent any leakage.

Production starts by applying pressure to the wellbore, allowing the oil and gas to flow through the well and up to the surface. The oil and gas are then separated, and the oil is transported to refineries for processing.

Economic Importance

The purpose of an oil drill is closely tied to the economic importance of oil and gas extraction. The oil and gas industry plays a significant role in fueling various industries and economies worldwide. It provides energy for transportation, heating, electricity generation, and the production of countless products.

An oil drill allows for the extraction of oil and gas, contributing to global energy security and creating job opportunities. It also generates revenue through the sale and export of these resources, impacting national and international economies.

The Components of an Oil Drill

1. Drill Bit

The drill bit is a cutting tool that is attached to the end of the drill string. It is responsible for creating a hole in the ground by rotating and cutting through the rocks and soil.

2. Drill Collars

Drill collars are heavy, thick-walled steel pipes that provide weight to the drill bit and improve the drilling efficiency. They are placed between the drill bit and the rest of the drill string.

3. Drill Pipe

The drill pipe is a long hollow tube that connects the surface drilling equipment to the drill bit. It serves as a pathway for drilling mud and provides flexibility and strength to the drill string.

4. Drill Mud

Drill mud, or drilling fluid, is a mixture of water, clay, and other additives. It is pumped downhole through the drill pipe and drill bit to lubricate the drilling operation, cool the drill bit, and carry the rock cuttings back to the surface.

5. Blowout Preventer (BOP)

A blowout preventer is an important safety device that is installed at the wellhead to prevent the uncontrolled release of oil or gas from the well during drilling operations. It consists of a series of valves that can be closed to seal the well in case of an emergency.

6. Rotary Table

The rotary table is a large rotating device that provides the rotational force necessary to turn the drill string and drill bit. It is powered by a motor and is located on the rig floor.

7. Derrick

The derrick is a tall, vertical structure that supports the drilling apparatus and provides a workspace for the drill crew. It is typically made of steel or other sturdy materials and is used to hoist and lower the drill string.

8. Mud Pump

The mud pump is a high-pressure pump that is used to circulate drilling mud downhole. It helps to create the necessary pressure for the mud to flow through the drill string, drill bit, and back up to the surface.

9. Mud Tanks

Mud tanks are large containers that hold the drilling mud on the rig. They are designed to separate and remove contaminants from the mud, ensuring that it is in proper condition for drilling.

10. Crown Block

The crown block is a stationary assembly located near the top of the derrick. It is used to support the weight of the drill string and allow it to be raised and lowered during drilling operations.

11. Traveling Block

The traveling block is a movable assembly that is connected to the drill string. It works in conjunction with the crown block to raise and lower the drill string as needed.

12. Swivel

The swivel is a device that allows the drill string to rotate freely while drilling. It is connected to the top of the drill pipe and provides a connection point for the rotary table and the drill string.

13. Top Drive

A top drive is a motorized drilling assembly that replaces the traditional rotary table. It provides a means for rotating and hoisting the drill string, eliminating the need for a rotary table and improving drilling efficiency.

14. Mud Logger

A mud logger is a specialist who monitors and analyzes the drilling mud for signs of oil or gas. They collect samples of the mud and use various instruments to determine the composition of the underground formations.

15. Mud Engineer

A mud engineer is a specialist who is responsible for maintaining the drilling mud’s properties, ensuring that it meets the requirements for drilling operations. They analyze the mud and make adjustments to its composition as needed.

The Process of Oil Extraction

1. Drilling the Well

The process of oil extraction begins with drilling a well. A drilling rig is used to create a hole in the ground, called a wellbore, which extends deep into the Earth’s crust. The wellbore is usually lined with steel or cement to provide stability and prevent contamination of the surrounding ground and water sources.

2. Casing and Cementing

Once the well has been drilled, metal casing, usually made of steel, is inserted into the wellbore. The casing helps to maintain the structural integrity of the well and prevent the collapse of the walls. Cement is then pumped into the annular space between the casing and the wellbore walls, ensuring that the casing is securely held in place and creating a barrier to prevent the migration of oil, gas, or fluids to other areas.

3. Drill Bit and Mud Circulation

To extract oil from the reservoir rock formations, a drill bit attached to the bottom of the drilling string is used. The drill bit rotates and gradually cuts through the rock formations, creating a hole. During this process, drilling mud is continuously circulated down through the drill string, out of the drill bit, and back up to the surface. The drilling mud helps to cool the drill bit, remove cuttings from the hole, and maintain the stability of the well.

4. Reaching the Reservoir

As drilling progresses, the wellbore may encounter different layers of rock formations. The target for oil extraction is typically a porous and permeable rock formation known as the reservoir. Once the well reaches the reservoir, drilling may continue horizontally through the reservoir to increase the production rate.

5. Well Completion

After reaching the desired depth, the well is completed to prepare it for oil production. This involves the installation of production equipment such as casing, tubing, and wellhead components. The production equipment allows for the controlled extraction of oil from the reservoir to the surface.

6. Production and Extraction

Once the well is completed, oil production can begin. A pump or pressure from the reservoir may be used to bring the oil to the surface. The extracted oil is then transported through pipelines or tankers to refineries, where it undergoes further processing to refine it into various petroleum products.

7. Well Maintenance

Regular maintenance of the well is necessary to ensure its continued productivity. This includes monitoring the pressure and flow rate of the well, inspecting and repairing any equipment or infrastructure issues, and implementing measures to manage any potential environmental impacts.

8. Abandonment

Eventually, when the oil reserves in a well are depleted or it becomes no longer economically viable to produce from the well, it is abandoned. Proper abandonment procedures are carried out to ensure that the well is safely sealed and the surrounding environment is protected from any potential contamination.

Conclusion

The process of oil extraction involves a series of carefully planned steps to drill a well, reach the reservoir, and extract the oil. Well construction, drilling mud circulation, and proper well completion are crucial in ensuring the successful extraction of oil while minimizing environmental impacts.

Drilling Techniques and Methods

There are several drilling techniques and methods used in the oil drilling industry. These techniques are used to reach the oil reservoirs deep below the Earth’s surface and extract the oil. Each method has its own advantages and disadvantages, and the choice of technique depends on factors such as the geology of the area and the target depth.

1. Rotary Drilling

Rotary drilling is the most commonly used drilling technique in the oil industry. In this method, a drill bit attached to the end of a drill string is rotated to create a hole in the ground. As the drill bit rotates, it breaks the rock formations and creates a borehole. The drilling fluids, often called drilling mud, are pumped down through the drill string to cool and lubricate the drill bit, remove the drilling cuttings, and maintain pressure in the wellbore.

2. Directional Drilling

Directional drilling is used when the target reservoir is not directly below the drilling rig. It involves drilling at an angle or horizontally to reach the target. This technique is used to access oil or gas reservoirs that are located under obstacles such as mountains or bodies of water. Directional drilling requires advanced equipment and sensors to accurately navigate the drill bit.

3. Offshore Drilling

Offshore drilling is carried out in bodies of water, such as oceans or seas, to extract oil and gas deposits located beneath the seabed. Offshore drilling rigs are specially designed to withstand the harsh conditions of the marine environment. The drilling process in offshore drilling is similar to onshore drilling, but additional measures are taken to prevent oil spills and protect the marine ecosystem.

4. Hydraulic Fracturing

Hydraulic fracturing, or fracking, is a drilling technique used to extract oil and gas from unconventional reservoirs, such as shale formations. In this method, a mixture of water, sand, and chemicals is pumped down into the well at high pressure, causing the rock formations to fracture. This allows the oil or gas to flow more freely and be extracted from the reservoir.

5. Casing and Cementing

Casing and cementing are essential steps in the drilling process to ensure the integrity of the wellbore. Casing involves installing a series of steel pipes, called casing strings, to line the drilled hole and provide structural support. Cementing is the process of pumping cement slurry into the annular space between the casing and the wellbore wall to permanently seal the well and prevent the migration of fluids.

6. Well Completion

Well completion is the final stage of the drilling process, where the well is prepared for production. This includes installing production tubing, wellhead equipment, and downhole pumps, among other components. The well completion process varies depending on the type of reservoir and the desired production rate.

7. Well Stimulation

Well stimulation techniques, such as acidizing and hydraulic fracturing, are used to enhance the productivity of the well. Acidizing involves pumping acid into the wellbore to dissolve or loosen debris and improve the flow of oil or gas. Hydraulic fracturing, as mentioned earlier, fractures the rock formations to increase the permeability and release trapped hydrocarbons.

8. Well Abandonment and Decommissioning

Once a well is no longer productive or commercially viable, it needs to be properly abandoned and decommissioned. This involves permanently plugging the wellbore to prevent the escape of fluids, removing the drilling equipment, and restoring the site to its original condition. Well abandonment and decommissioning adhere to strict environmental regulations to minimize any impact on the surrounding environment.

Safety Measures in Oil Drilling

1. Rig Safety

Ensuring the safety of the drilling rig is crucial in oil drilling operations. Regular inspections and maintenance are conducted to identify and address any potential hazards or equipment failures.

- Well-trained Crew: The rig crew members undergo proper training to handle emergencies and operate the equipment safely.

- Personal Protective Equipment (PPE): All crew members are required to wear appropriate PPE, such as helmets, safety glasses, gloves, and safety shoes, to protect themselves from potential hazards.

- Fire Safety: Fire prevention and suppression systems are installed on the rig to quickly address any fire incidents.

2. Well Control

Well control refers to maintaining control over the pressure and flow of oil and gas from the well. Proper well control measures are essential to prevent blowouts and other dangerous situations.

- Blowout Preventer (BOP): BOPs are critical safety equipment that prevent uncontrolled release of oil or gas by sealing the wellbore in case of a blowout.

- Well Control Procedures: Strict procedures are followed during drilling, such as maintaining balanced drilling fluids, monitoring well pressure, and conducting regular well control drills.

3. Environmental Protection

Oil drilling operations must prioritize environmental protection to minimize the impact on ecosystems and surrounding communities.

- Spill Prevention and Response: Spill prevention measures, such as proper storage and handling of oil and chemicals, are implemented. Additionally, response plans and equipment for immediate spill containment and cleanup are in place.

- Waste Management: Proper disposal and treatment of drilling waste, such as drilling muds and cuttings, are carried out to prevent pollution of soil and water sources.

4. Safety Training and Communication

Continuous safety training and effective communication are essential to keep all personnel informed and prepared for any potential hazards.

- Safety Training Programs: Rig crews undergo regular safety training programs to enhance their knowledge and skills in handling emergency situations.

- Safety Meetings: Regular safety meetings are held to discuss safety procedures, address concerns, and reinforce the importance of following safety protocols.

5. Regulatory Compliance

Oil drilling operations must comply with regulatory standards and industry best practices to ensure the safety of personnel, the environment, and surrounding communities.

- Inspections and Audits: Regulatory authorities conduct inspections and audits to ensure compliance with safety regulations and identify any areas of improvement.

- Documentation and Reporting: Accurate and timely documentation and reporting of safety incidents, near misses, and corrective measures are essential for tracking and improving safety performance.

6. Emergency Response Planning

Developing robust emergency response plans and conducting drills are crucial to ensure prompt and efficient responses to unforeseen events.

- Emergency Response Team: A dedicated emergency response team is trained and equipped to handle various emergencies, such as well blowouts, fires, or spills.

- Mock Drills: Regular mock drills are conducted to test the effectiveness of emergency response plans and familiarize personnel with their roles and responsibilities.

- Coordination with Local Authorities: Oil drilling operations maintain close coordination with local authorities to ensure a coordinated and effective response in case of emergencies.

Conclusion

Implementing and maintaining comprehensive safety measures in oil drilling operations is crucial to protect the well-being of personnel, the environment, and surrounding communities. Rig safety, well control, environmental protection, safety training and communication, regulatory compliance, and emergency response planning are key elements in ensuring safe and responsible oil drilling operations.

Environmental Concerns in Oil Drilling

Oil drilling has a significant impact on the environment, causing various concerns related to pollution, habitat destruction, and climate change. Here are some of the main environmental concerns associated with oil drilling:

1. Pollution

Oil drilling operations can lead to various forms of pollution, including air pollution, water pollution, and soil contamination. The extraction process releases harmful gases, such as methane and volatile organic compounds, into the atmosphere. These gases contribute to air pollution and can have detrimental effects on human health. Additionally, oil spills during drilling can contaminate water bodies, causing harm to aquatic life and affecting the quality of drinking water sources.

2. Habitat Destruction

Oil drilling often requires the construction of large infrastructure, such as drilling platforms, pipelines, and storage tanks. These infrastructure developments can result in the destruction of natural habitats, particularly in sensitive ecosystems like wetlands and tropical rainforests. The destruction of habitats can lead to the loss of biodiversity, as it disrupts the natural balance of ecosystems and displaces wildlife species.

3. Climate Change

Oil drilling contributes to climate change through the release of greenhouse gases, primarily carbon dioxide (CO2). When fossil fuels are burned for energy or extracted through drilling, the release of CO2 into the atmosphere increases the concentration of greenhouse gases, trapping heat and causing the Earth’s average temperature to rise. This phenomenon, known as global warming, has various negative effects on the environment, including melting ice caps, rising sea levels, and extreme weather events.

4. Oil Spills

Oil spills are a major concern in oil drilling activities. Accidental spills during drilling, transportation, or storage can have severe consequences for marine ecosystems. Oil spills can coat the surfaces of water bodies, causing harm to marine organisms and disrupting their natural habitats. The long-term effects of oil spills can be devastating, leading to the death of marine species, reduced breeding success, and disruptions in the food chain.

5. Wastewater Disposal

During the drilling process, large volumes of wastewater are generated, known as produced water. This water contains various pollutants, including salts, metals, and chemicals used in the drilling process. Improper disposal of wastewater can contaminate freshwater sources, affecting the quality of drinking water and harming aquatic life. Treating and managing produced water properly is crucial to minimize environmental impacts.

6. Land Subsidence

In some cases, oil drilling can cause land subsidence, a phenomenon where the land sinks or collapses. The extraction of oil from underground reservoirs can result in the depletion of subsurface fluids, causing the surrounding rock and soil to compact or collapse. Land subsidence can lead to structural damage, impacts on infrastructure, and changes in the landscape, affecting ecosystems and human settlements.

To mitigate these environmental concerns, regulations and policies are in place to ensure responsible drilling practices. These include measures such as proper waste management, spill response plans, and the use of advanced drilling technologies to minimize environmental impacts. Ongoing efforts are being made to develop cleaner and more sustainable alternatives to oil drilling to reduce the environmental footprint of the oil industry.

The Economic Impact of Oil Drilling

Oil drilling has a significant economic impact on both the global and local economies. Below are some key aspects of the economic impact of oil drilling:

Job Creation

- Oil drilling creates a large number of jobs in various sectors such as engineering, construction, technical support services, and logistics

- These jobs provide employment opportunities for both skilled and unskilled workers

- Local communities near oil drilling sites often benefit from increased employment

Revenue Generation

- Oil drilling generates revenue through the sale of crude oil

- This revenue can be used by oil-producing countries to support various sectors such as healthcare, education, and infrastructure development

- In regions heavily reliant on oil production, the revenue generated can lead to economic growth and improved living standards

Industry Support

- The oil drilling industry supports a wide range of related sectors such as transportation, manufacturing, and finance

- These sectors benefit from the demand for equipment, materials, and services required for oil drilling operations

- Investments in infrastructure, such as pipelines and storage facilities, also contribute to economic growth

Trade Balance

- Countries that have significant oil reserves and engage in oil drilling activities often become major oil exporters

- Exporting oil can improve a country’s trade balance and increase its foreign currency reserves

- This allows countries to import goods and services from other countries, contributing to economic development

Market Influence

- Oil drilling has a significant influence on global oil markets

- Changes in oil production levels and supply can affect oil prices, which, in turn, impact global economies

- Countries with a strong presence in the oil drilling industry can exert influence over energy policies and global geopolitics

| Country | Production (barrels per day) |

|---|---|

| United States | 19,510,000 |

| Saudi Arabia | 11,800,000 |

| Russia | 11,490,000 |

| Canada | 5,295,000 |

| China | 4,893,000 |

It is evident that oil drilling plays a crucial role in the global economy, providing numerous economic benefits to countries and communities involved in the industry.

The Future of Oil Drilling

1. Introduction

The future of oil drilling holds many exciting possibilities and challenges as the world confronts the increasing demand for energy and the need to transition towards more sustainable sources. While the oil industry has been a critical component of the global economy for decades, its impact on the environment and finite supply make it essential to explore new technologies and practices for oil drilling.

2. Advancements in Technology

As technology continues to advance, so too does the oil drilling industry. Some of the key advancements that will shape the future of oil drilling include:

- Automated drilling rigs: These rigs will use artificial intelligence and robotics to operate with minimal human intervention, increasing efficiency and reducing safety risks.

- Drone technology: Drones will be utilized for aerial surveys, pipeline inspections, and monitoring environmental risks, providing real-time data to enhance safety and decision-making.

- Advanced data analytics: The use of big data and sophisticated algorithms will enable oil companies to optimize drilling processes, predict maintenance needs, and minimize downtime.

- Remote drilling: With advancements in communication technology, experts will be able to remotely monitor and control drilling operations from onshore facilities, reducing the need for offshore personnel.

3. Sustainable Practices

The future of oil drilling will also be shaped by the industry’s commitment to adopting more sustainable practices. Some of the key initiatives include:

- Reducing environmental impact: Oil companies are investing in technologies that reduce greenhouse gas emissions, such as carbon capture and storage, as well as implementing more efficient drilling methods.

- Exploring alternative energy sources: Many oil companies are diversifying their portfolios by investing in renewable energy sources like wind and solar power to supplement their traditional oil drilling operations.

- Enhancing safety measures: Improved safety protocols, equipment, and training will be paramount to minimizing accidents and spills, protecting both human lives and the environment.

4. Collaborations and Partnerships

The future of oil drilling will involve increased collaboration and partnerships among various stakeholders. This includes:

- Public-private partnerships: Governments and oil companies will work together to ensure responsible and sustainable exploration and drilling operations.

- Academic and research institutions: Collaborations with universities and research institutions will drive advancements in drilling technology, safety practices, and environmental preservation.

- International cooperation: Countries will collaborate to establish global standards, share best practices, and address transboundary environmental concerns associated with oil drilling.

5. Conclusion

The future of oil drilling holds great potential for innovation, sustainability, and collaboration. While the industry faces challenges in meeting the growing energy demands while minimizing environmental impact, advancements in technology, sustainable practices, and partnerships will shape a more responsible and efficient oil drilling industry.

FAQ:

What is an oil drill and how does it work?

An oil drill is a machine used to extract oil from beneath the Earth’s surface. It works by creating a hole in the ground, commonly known as a wellbore, and then using various techniques to reach and extract the oil.

What are the different types of oil drills?

There are several types of oil drills, including cable tool drills, rotary drills, and top drive drills. Cable tool drills use a weighted bit to penetrate the ground, rotary drills use a rotating drill bit to create the wellbore, and top drive drills are advanced drilling systems that use a motor to rotate the drill string.

How deep can an oil drill go?

The depth to which an oil drill can go depends on a few factors, including the type of drill being used and the location of the drilling operation. In some cases, oil drills can go as deep as several kilometers, reaching depths where oil reserves are likely to be present.

What are the main steps involved in the drilling process?

The drilling process typically involves several main steps. First, a location is chosen based on geologic data and analysis. Then, a shallow well is drilled to evaluate the formation. If it is determined to be suitable for oil extraction, a larger, more advanced drill is brought in to create the wellbore. Once the wellbore is drilled, casing and cementing are done to protect the well and maintain its integrity. Finally, the drilling rig is removed and production operations can begin.

What are the risks and challenges associated with oil drilling?

Oil drilling poses various risks and challenges. One of the main risks is the potential for oil spills, which can have devastating effects on the environment. There are also risks of equipment failures, well blowouts, and accidents causing harm to workers. Additionally, drilling in offshore locations can be especially challenging due to the harsh conditions and deep water depths.

Video: