Exploring the Versatility of a Drill Press: Endless Possibilities for Precision and Power

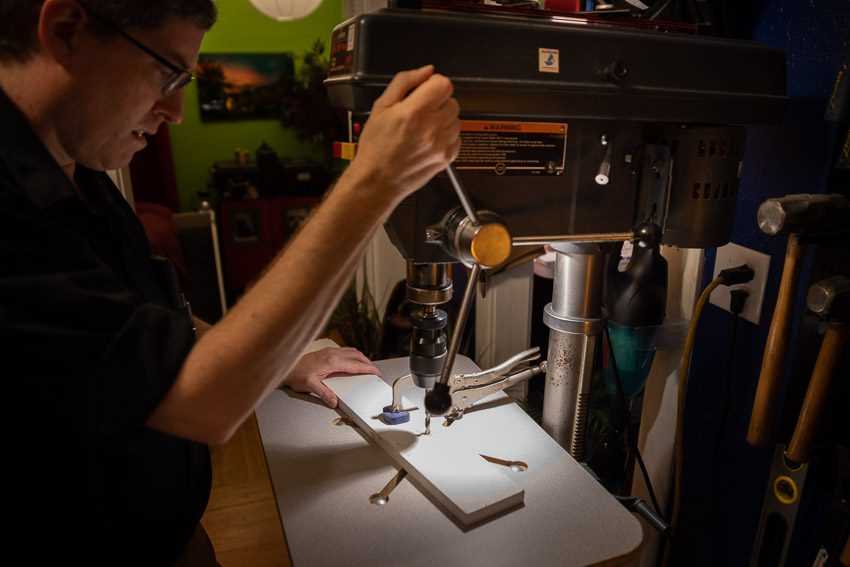

When it comes to power tools, a drill press is a must-have for any serious DIY enthusiast or professional craftsman. This versatile machine offers endless possibilities for precision and power, making it an essential tool for a wide range of projects. Whether you’re drilling holes in metal, woodworking, or even doing intricate detailing, the drill press has got you covered.

One of the key advantages of using a drill press is its unmatched level of accuracy. Unlike handheld drills, which rely on the user’s steadiness and precision, a drill press allows for controlled drilling with the utmost precision. With its adjustable depth stop and laser guides, you can easily achieve consistent and accurate holes every time, ensuring your project is completed to perfection.

But the versatility of a drill press doesn’t stop at drilling holes. With the right attachments and accessories, you can transform your drill press into a multi-purpose tool for a variety of tasks. From sanding and buffing to mortising and shaping, the drill press can handle it all. Its powerful motor and adjustable speed settings give you the control and flexibility needed to tackle different materials and achieve the desired results.

Whether you’re a hobbyist exploring new projects or a professional looking for a reliable and efficient tool, the drill press is a game-changer. Its precision, power, and versatility make it an indispensable addition to any workshop. So why limit yourself to traditional drilling when you can unlock a world of possibilities with a drill press?

Unleash Your Creativity

When it comes to a drill press, the possibilities for creativity are truly endless. Whether you are a DIY enthusiast or a professional craftsman, this versatile tool can help you bring your wildest ideas to life.

1. Woodworking Masterpieces

The drill press is a must-have tool for any woodworker. It allows you to create precise holes, shape and carve wood patterns, and even make intricate designs. Whether you are building custom furniture, crafting wooden toys, or making decorative items, the drill press will be your best friend in the workshop.

2. Metal Fabrication Projects

With the right attachments and accessories, the drill press can handle a variety of metalworking tasks. You can use it to drill holes in metal sheets, shape metal pieces, and even cut through thick steel. Whether you are working on a DIY metal sculpture or repairing a piece of machinery, the drill press will provide you with the power and precision you need.

3. Jewelry Making

If you are into jewelry making, the drill press can be a game-changer. It allows you to drill precise holes in gemstones, shape metal components, and polish your creations. Whether you are designing unique earrings, necklaces, or bracelets, the drill press will help you take your jewelry-making skills to the next level.

4. Glass Art

Believe it or not, a drill press can even be used for glass art projects. With the right diamond drill bits, you can drill holes in glass bottles, create stained glass patterns, and even etch intricate designs. Whether you are making glass sculptures or custom glassware, the drill press will help you achieve stunning results.

5. Precision Machining

The drill press is not just for creative projects. It is also an essential tool for precision machining. Whether you need to drill holes in metal parts, ream out a bore, or tap threads, the drill press will provide you with the accuracy and control you need for professional machining tasks.

6. Other DIY Projects

Aside from the more traditional uses, the drill press can be used in a wide range of other DIY projects. From making custom speaker enclosures to building birdhouses, the drill press can help you achieve precise and professional results in whatever project you take on.

So, unleash your creativity and explore the endless possibilities of the drill press! No matter what your project may be, this versatile tool will provide you with the precision and power you need to bring your ideas to life.

Enhance your Woodworking Projects

Woodworking is a timeless craft that allows for limitless creativity and the ability to craft functional and beautiful items. Whether you’re a seasoned woodworker or just starting out, using a drill press can greatly enhance your woodworking projects.

Precision Drilling

A drill press provides the accuracy and precision needed for drilling perfectly straight and consistent holes. This is especially important when working with intricate joinery or creating mortises and tenons. The drill press’s adjustable depth stop allows you to control the depth of the hole, ensuring uniformity throughout your project.

Efficient Sanding

In addition to drilling, a drill press can be used as a sanding station. By attaching a sanding drum or sanding disc to the chuck of the drill press, you can quickly and efficiently sand large or curved surfaces. The stability of the drill press helps prevent uneven sanding and provides a consistent finish.

Accurate Countersinking

When working with screws or bolts, countersinking is crucial to achieve a professional finish. A drill press allows for precise countersinking, ensuring the screw or bolt sits flush with the surface of your project. This not only enhances the appearance but also provides a secure and stable connection.

Custom Jigs and Fixtures

A drill press can also be used to create custom jigs and fixtures that aid in a variety of woodworking operations. From drilling repetitive holes to guiding cuts, jigs and fixtures provide consistency and improve accuracy. With a drill press, you can easily create these essential components, customizing them to suit your specific needs.

Conclusion

With its precision, power, and versatility, a drill press is a valuable tool for enhancing your woodworking projects. Whether you’re creating furniture, cabinetry, or small decorative items, incorporating a drill press into your workflow will help you achieve professional results and take your woodworking skills to the next level.

Maximize Efficiency in Metalworking

1. Choose the Right Drill Bits

In order to maximize efficiency in metalworking, it is important to choose the right drill bits for the job. Different types of metals require different types of bits, so it is crucial to select the appropriate ones. High-speed steel (HSS) bits are commonly used for general-purpose drilling, while cobalt bits are ideal for drilling through hard metals like stainless steel.

2. Use Coolants

When drilling through metal, heat can quickly build up, which can lead to poor performance and damage to the drill bit. Using coolants, such as cutting oil or water-soluble coolant, can help dissipate the heat and prolong the life of the drill bit. Apply the coolant directly to the drill bit and the surface being drilled for optimal results.

3. Maintain Proper Speed and Feed Rates

Another important factor in maximizing efficiency in metalworking is maintaining the proper speed and feed rates. Each type of metal requires different speeds and feeds to achieve the best results. Consult the manufacturer’s recommendations or reference charts to determine the appropriate settings for the specific metal being drilled. Running the drill press at the correct speed and feed rate will ensure efficient cutting and prevent overheating.

4. Secure the Workpiece

It is essential to secure the workpiece firmly to prevent movement during drilling. This will ensure accuracy and minimize the risk of accidents. Consider using clamps, vises, or other appropriate fixtures to hold the metal in place. Make sure the workpiece is positioned securely before starting the drilling process.

5. Perform Regular Maintenance

Regular maintenance of the drill press is crucial for maximizing efficiency in metalworking. Keep the drill press clean, free of debris, and well-lubricated. Check for any loose or damaged parts and replace them as necessary. Performing routine maintenance will help prevent breakdowns and extend the lifespan of the drill press.

6. Invest in Quality Tools

To achieve maximum efficiency in metalworking, it is worth investing in high-quality drill bits and accessories. Using superior tools will not only improve performance but also ensure greater precision and durability. Quality tools are less likely to break or wear out quickly, resulting in fewer interruptions and higher productivity.

7. Practice Safety Measures

Metalworking involves inherent risks, so it is essential to practice proper safety measures while using a drill press. Always wear appropriate personal protective equipment, such as safety glasses, gloves, and ear protection. Keep the work area clean and organized to minimize the risk of accidents. Familiarize yourself with the drill press’s safety features and follow all guidelines and precautions outlined in the user manual.

8. Seek Professional Training

If you are new to metalworking or unfamiliar with a drill press, it may be beneficial to seek professional training. Proper training will teach you the necessary techniques and safety procedures to ensure efficient and safe metal drilling. Learning from experienced professionals will give you the confidence and knowledge to maximize efficiency in your metalworking projects.

Conclusion

By following these tips and techniques, you can maximize efficiency in metalworking with a drill press. Choosing the right drill bits, using coolants, maintaining proper speed and feed rates, securing the workpiece, performing regular maintenance, investing in quality tools, practicing safety measures, and seeking professional training are all essential elements to achieve optimal results in your metalworking endeavors.

Experience the Accuracy in Jewelry Making

When it comes to jewelry making, precision is key. Every detail matters, and even the smallest mistake can affect the final result. That’s why having the right tools is crucial in this craft.

One tool that can greatly enhance your jewelry making skills is a drill press. This powerful machine has the ability to drill holes in various materials with precision and accuracy. Whether you’re working with metal, wood, or gemstones, a drill press can help you achieve perfectly sized and positioned holes every time.

Benefits of Using a Drill Press for Jewelry Making

- Consistent Depth: With a drill press, you can easily adjust the depth of the holes you’re drilling. This ensures that all your pieces have even and consistent depth, giving your jewelry a professional touch.

- Precise Positioning: Thanks to the sturdy base and adjustable table of a drill press, you can position your workpiece exactly where you want it. This is especially important when creating intricate designs or patterns in your jewelry.

- Various Speed Options: Different materials require different drilling speeds. A drill press allows you to choose from various speed settings, ensuring you’re using the right speed for the material you’re working with. This helps prevent damage and provides better control during the drilling process.

Types of Jewelry Projects You Can Create with a Drill Press

- Pendants: Use a drill press to create precise holes in pendants for attaching chains or jump rings.

- Beads: Drill consistent holes in beads of various sizes and materials to create beautiful necklaces, bracelets, or earrings.

- Bangles: Create unique bangle bracelets by drilling holes in metal or wooden blanks and adding decorative elements.

- Rings: Add intricate patterns or designs to rings by drilling precise holes in metal bands.

- Earrings: Drill holes in earrings to attach ear wires or create unique dangle earrings with drilled gemstones.

A drill press opens up endless possibilities for precision and accuracy in your jewelry making. With this powerful tool, you can take your creations to the next level and achieve professional-looking results. Start exploring the versatility of a drill press in jewelry making today!

Unleash the Power in Masonry Work

1. Introduction

When it comes to masonry work, precision and power are crucial. A drill press is a versatile tool that can assist in achieving professional results with ease and efficiency. Whether you are a professional mason or a DIY enthusiast, a drill press can help you unleash the true potential of your masonry projects.

2. Drilling into Masonry Surfaces

One of the primary uses of a drill press in masonry work is drilling into various surfaces such as bricks, concrete, and stone. With its powerful motor and stable drilling platform, a drill press can effortlessly penetrate even the toughest masonry materials. This ensures clean and precise holes for various applications, including installing anchors, attaching fixtures, or creating pathways for pipes and wires.

3. Masonry Sanding and Polishing

In addition to drilling, a drill press can also be used for sanding and polishing masonry surfaces. By attaching sanding discs or polishing wheels to the drill press, you can quickly and effectively smooth out rough edges, remove imperfections, and bring out the natural shine of the masonry. This saves time and effort compared to manual sanding and polishing methods.

4. Mortising and Chiseling

For more intricate masonry work, such as creating mortises or chiseling out designs, a drill press can be a game-changer. By attaching specialized mortising and chiseling attachments, you can achieve precise and consistent results every time. This is especially useful for creating decorative features on masonry structures or customizing bricks and stones for unique designs.

5. Masonry Cutting and Grinding

Another way to unleash the power of a drill press in masonry work is by using it for cutting and grinding tasks. With the right attachments, a drill press can cut through masonry materials like a hot knife through butter. Additionally, it can also be used for grinding down rough surfaces or removing excess material for a smooth and polished finish.

6. Conclusion

From drilling to sanding, polishing, mortising, chiseling, cutting, and grinding, a drill press offers endless possibilities for masonry work. Its precision and power make it an essential tool for professional masons and DIY enthusiasts alike. With a drill press by your side, you can unleash your creativity and achieve professional-quality results in your masonry projects.

Discover the Precision in Glass Drilling

Did you know that a drill press can be used to drill precise and clean holes in glass? With the right tools and techniques, you can transform a regular drill press into a powerful and accurate glass drilling machine. Whether you’re a professional glassworker or a DIY enthusiast, learning the art of glass drilling can open up a whole new world of possibilities.

Why Use a Drill Press for Glass Drilling?

Using a drill press for glass drilling offers several advantages over traditional methods. Here are a few reasons why you should consider using a drill press for your glass drilling needs:

- Precision: A drill press allows for precise control of drilling depth and speed, resulting in clean and accurate holes in glass.

- Safety: With a drill press, you can securely clamp your glass workpiece, preventing it from slipping or shattering during the drilling process.

- Efficiency: Compared to hand drilling, a drill press can save you time and effort by providing consistent and reliable drilling performance.

Tools and Techniques for Glass Drilling

Before you start drilling glass on a drill press, there are a few essential tools and techniques you should be familiar with:

- Diamond Drill Bits: To drill glass, you’ll need diamond-tipped drill bits specifically designed for glass drilling. These bits have a hard diamond coating that can cut through glass with ease.

- Lubrication: Lubricating the drill bit with water or cutting oil while drilling glass can help reduce friction and heat buildup, preventing the glass from cracking or chipping.

- Glass Support: When drilling glass, it’s essential to have proper support underneath to prevent cracking. Using a sacrificial material like plywood or plastic can help distribute the pressure evenly.

Tips for Successful Glass Drilling

Here are a few tips to help you achieve successful results when drilling glass on a drill press:

- Start Slowly: Begin drilling at a slow speed and gradually increase the speed to prevent the glass from cracking due to sudden pressure.

- Apply Even Pressure: Maintain a steady and even pressure on the drill press throughout the drilling process to prevent the glass from shattering.

- Use Cooling Methods: Keep the drill bit and glass cool by applying water or cutting oil to reduce heat buildup and increase the lifespan of the drill bit.

- Practice on Scrap Glass: If you’re new to glass drilling, it’s a good idea to practice on scrap pieces of glass before moving on to your actual project.

Conclusion

With the precision and power of a drill press, you can explore the endless possibilities of glass drilling. Whether you’re creating intricate designs or simply drilling holes for functional purposes, the drill press can help you achieve professional-grade results. Remember to always follow safety guidelines and practice proper techniques when working with glass and power tools.

Unlock Endless Applications in Electronics

When it comes to working with electronics, precision and power are of utmost importance. With a drill press, you can take your electronic projects to the next level and unlock endless possibilities.

1. Circuit Board Drilling

One of the most common applications of a drill press in electronics is drilling holes in circuit boards. Whether you’re prototyping or manufacturing electronic devices, a drill press ensures precise and uniform hole placement.

2. PCB Engraving

In addition to drilling holes, a drill press can be used for PCB (Printed Circuit Board) engraving. With the right attachments, you can create intricate designs and patterns on your circuit boards, adding a touch of personalization to your creations.

3. Component Assembly

A drill press can also be used for component assembly in electronics. By mounting specialized tools onto the drill press, you can easily and accurately insert components into circuit boards, saving time and improving efficiency.

4. Wire Stripping

Stripping wires is a common task in electronics, and a drill press can make it much easier. By attaching a wire stripping tool to the drill press, you can quickly and consistently strip the insulation off wires, ensuring a clean and reliable connection.

5. Heat Sink Drilling

When working with high-powered electronics, heat dissipation is crucial. A drill press can be used to drill precise holes in heat sinks, improving airflow and dissipating heat more effectively, ensuring the longevity and reliability of your electronic devices.

6. Custom Enclosure Modification

If you’re working on a project that requires a custom enclosure, a drill press can be a valuable tool for modifying enclosures to fit your specific needs. From drilling holes for connectors to cutting openings for displays, a drill press allows for precise and clean modifications.

7. 3D Printer Add-ons

For those involved in 3D printing, a drill press can be a powerful addition to your toolkit. With the right attachments, you can easily drill holes in 3D printed parts, adding functionality or allowing for better integration of electronic components.

8. Arduino and Raspberry Pi Projects

Arduino and Raspberry Pi projects often involve interfacing with electronic components. A drill press can help in mounting sensors, connectors, and other components onto the boards with precise alignment, ensuring a reliable and professional-looking final product.

9. Repairing Electronics

When it comes to repairing electronics, a drill press can be an invaluable tool. From removing stripped screws to drilling out broken components, a drill press provides the power and precision necessary for delicate and intricate repairs.

10. Can’t Stop Exploring

The versatility of a drill press in electronics is only limited by your imagination. From custom projects to repairs and modifications, there is always something new to explore and create with the power and precision of a drill press.

So, whether you’re an electronics enthusiast, a professional in the field, or someone looking to expand their creative horizons, don’t underestimate the possibilities that a drill press can unlock in the realm of electronics.

Elevate Your DIY Home Improvement Projects

Are you tired of spending a fortune on professional contractors for your home improvement projects? With a drill press, you can take matters into your own hands and achieve professional-grade results right from your own garage or workshop!

The Power of Precision

One of the most significant advantages of using a drill press for your DIY projects is the unparalleled precision it offers. Unlike handheld drills, a drill press allows you to make accurate, straight holes with consistent depth and angle. This precision is crucial for tasks such as installing hinges, creating joinery, or drilling dowel holes.

Versatile Applications

Whether you’re building furniture, installing cabinets, or working on intricate woodworking projects, a drill press can handle a wide range of tasks. With a variety of drill bits and attachments available, you can easily customize your drill press for specific applications. From drilling to sanding, buffing, and even polishing, a drill press opens up endless possibilities for your DIY projects.

Increased Safety

Using a drill press also enhances your safety while working on home improvement projects. The stable and secure work surface, along with the automatic drill depth control, reduces the risk of the drill slipping or causing any accidental injuries. Additionally, many drill press models come with built-in safety features such as emergency stop buttons and adjustable safety guards.

How to Choose the Right Drill Press

When shopping for a drill press, consider factors such as the power, speed options, and the size of the worktable. Opt for a drill press with a powerful motor and variable speed settings to accommodate different materials and applications. Also, ensure that the worktable is spacious and sturdy enough to support your projects.

TIP: Look for models with built-in laser guides or digital readouts for even more precise drilling.

Conclusion

Investing in a drill press can significantly elevate your DIY home improvement projects, allowing you to achieve professional-level results with precision and ease. From basic drilling tasks to more complex woodworking projects, a drill press opens up a whole new world of possibilities. So why wait? Take your projects to the next level and unleash your creativity with a drill press today!

FAQ:

What is a drill press and what is it used for?

A drill press is a machine tool used for drilling holes in various materials with precision and power. It consists of a rotating spindle that holds a cutting tool, which is lowered onto the workpiece to create holes of different sizes and depths.

What are the advantages of using a drill press over a handheld drill?

There are several advantages of using a drill press over a handheld drill. Firstly, a drill press provides greater precision and accuracy, as it allows you to control the depth and angle of the holes more easily. Additionally, it offers more power, making it suitable for drilling through tougher materials. Finally, a drill press is capable of performing repetitive drilling tasks without straining your hand or arm.

Can a drill press be used for other tasks besides drilling?

Yes, a drill press can be used for various tasks besides drilling. With the right attachments, it can be used for sanding, grinding, polishing, and even woodworking. Some drill presses also have a tapping function, which allows you to create threaded holes in metal. The versatility of a drill press makes it a valuable tool for any workshop.

What safety precautions should be taken when using a drill press?

When using a drill press, it is important to follow certain safety precautions to avoid accidents or injuries. Always wear safety glasses to protect your eyes from flying debris. Make sure the workpiece is securely clamped to the table or base to prevent it from moving. Keep your hands away from the rotating spindle and never attempt to adjust or remove the cutting tool while the machine is running. Finally, make sure the machine is turned off and unplugged when changing the drill bit or performing any maintenance tasks.

What are the different types of drill presses available in the market?

There are several types of drill presses available in the market, each with its own unique features and capabilities. Some common types include the benchtop drill press, floor-standing drill press, magnetic drill press, and radial arm drill press. Benchtop drill presses are compact and portable, making them suitable for small workshops or DIY projects. Floor-standing drill presses are larger and more powerful, making them suitable for heavy-duty tasks. Magnetic drill presses use magnets to secure the machine to metal surfaces, allowing for drilling in any position. Radial arm drill presses have an adjustable arm that can be moved to different positions, providing greater versatility.

What factors should be considered when choosing a drill press?

When choosing a drill press, there are several factors to consider. Firstly, consider the size and power of the machine, as this will determine its suitability for different tasks. Additionally, consider the maximum drilling capacity and the types of materials it can handle. Look for features such as adjustable speeds, depth stops, and laser guides, as these can enhance precision and ease of use. Finally, consider the brand and warranty, as well as customer reviews to ensure you are purchasing a reliable and durable machine.

Video: