Exploring the Fascinating Process of How Drill Bits are Made

Drill bits are an essential tool used in various industries, such as construction, manufacturing, and mining. These small but mighty tools are responsible for creating holes of different sizes and shapes in different materials. But have you ever wondered how drill bits are made? The process of manufacturing these precision tools is incredibly fascinating and involves several intricate steps.

Firstly, the manufacturing process begins with the selection of the raw materials. High-speed steel (HSS), cobalt steel, carbide, and diamond are commonly used materials for drill bits due to their durability and strength. Once the appropriate material is chosen, it is melted in a furnace and then poured into molds to create the desired shape of the drill bit.

After the molds are cooled and solidified, the drill bits are removed and sent to the grinding station. This is where the cutting edges of the drill bits are shaped and sharpened. A precision grinder is used to grind the flutes and angles of the drill bits, ensuring they have the necessary cutting properties. This step is critical in determining the performance and efficiency of the drill bit.

Once the grinding process is complete, the drill bits undergo a heat treatment process. This involves subjecting the drill bits to high temperatures to improve their hardness and toughness. The heat treatment process also helps to remove any stresses that may have occurred during the grinding process. After the heat treatment, the drill bits are cooled and then inspected for any defects or imperfections.

The Manufacturing Process of Drill Bits

1. Material Selection

Drill bits are typically made from high-speed steel (HSS) or carbide. HSS is a durable and cost-effective material, while carbide is harder and can withstand higher temperatures. The choice of material depends on the specific application and the type of material that will be drilled.

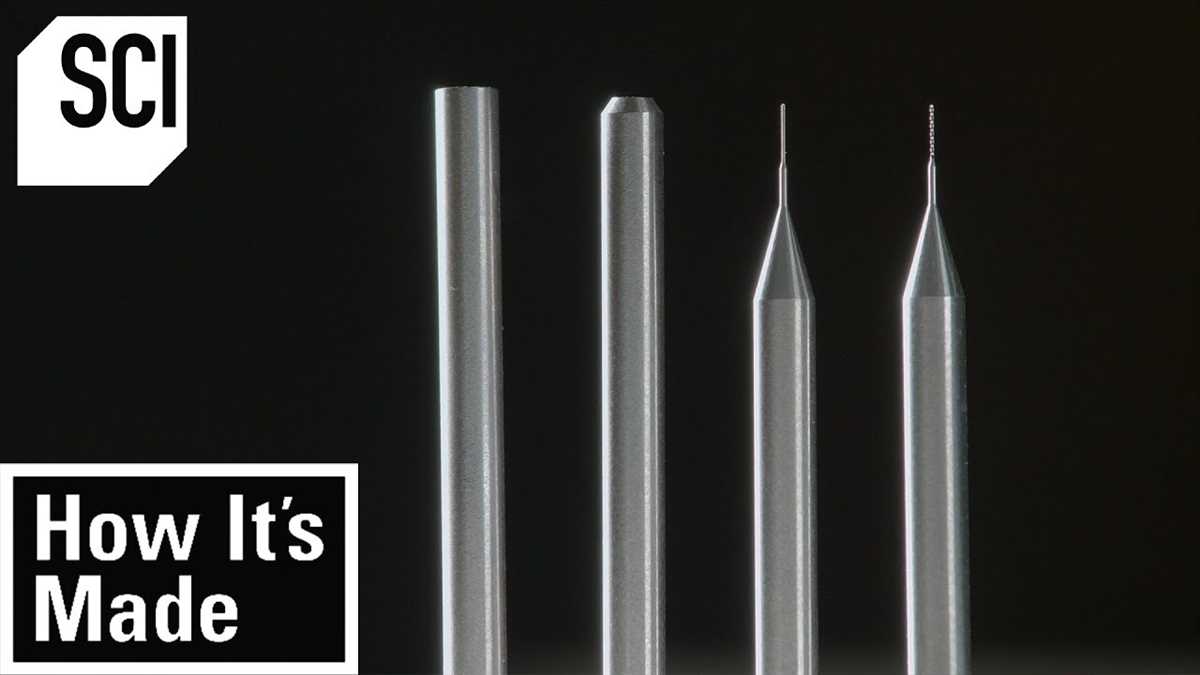

2. Forming the Blank

The manufacturing process begins with a metal rod, known as a blank, which is cut to the desired length. The blank is then heated to make it more pliable and easier to shape.

3. Shaping the Flutes

The blank is placed into a machine called a flute grinder. The flute grinder uses rotating wheels to create the spiral flutes that run along the length of the drill bit. The depth and pitch of the flutes determine the chip evacuation and cutting efficiency of the bit.

4. Grinding the Cutting Edges

After the flutes are formed, the next step is to grind the cutting edges. This process is done using a cutting machine that removes excess metal to create the sharp edges of the drill bit. The angle and geometry of the cutting edges affect the drilling performance and the type of material that can be drilled.

5. Heat Treatment

Once the cutting edges are formed, the drill bits undergo a heat treatment process to increase their hardness and durability. This involves heating the drill bits to a specific temperature and then rapidly cooling them to create a hardened surface.

6. Coating

In some cases, drill bits are coated with a thin layer of material to further enhance their performance and durability. Common coatings include titanium nitride (TiN) and black oxide. The coating helps reduce friction, increase chip evacuation, and prevent the drill bit from overheating.

7. Quality Control

Before the drill bits are packaged and sent for sale, they undergo rigorous quality control checks. This includes inspecting the dimensions, angles, and hardness of the drill bits to ensure they meet the specified standards and requirements.

8. Packaging

Finally, the drill bits are packaged in suitable containers or blister packs for easy storage and transportation. The packaging may include information about the drill bit’s size, type, and recommended applications.

Conclusion

The manufacturing process of drill bits involves a series of steps, from material selection to packaging. Each step is crucial in creating high-quality drill bits that can effectively drill through various materials. Understanding this process can help users appreciate the complexity and precision involved in producing these essential tools.

Material Selection for Drill Bits

The selection of materials for drill bits is a critical factor in their performance and longevity. Different materials offer varying levels of strength, hardness, and wear resistance, which are all important characteristics for drill bits.

High-Speed Steel (HSS)

- High-speed steel (HSS) is a commonly used material for drill bits due to its excellent combination of toughness, heat resistance, and wear resistance.

- HSS drill bits can be used for a wide range of materials, including wood, plastic, and most types of metal.

- They are typically made from a high-speed steel alloy containing elements such as tungsten, molybdenum, and chromium.

Cobalt Steel

- Cobalt steel is a type of high-speed steel that contains a higher percentage of cobalt.

- Drill bits made from cobalt steel have enhanced heat resistance and are capable of withstanding higher drilling temperatures.

- They are ideal for drilling hard materials such as stainless steel and cast iron.

Carbide

- Carbide drill bits are known for their exceptional hardness and resistance to wear.

- They are typically made from a combination of tungsten carbide and cobalt.

- Carbide drill bits are best suited for drilling through hard and abrasive materials such as concrete, brick, and tile.

Diamond

- Diamond drill bits are the hardest and most durable type of drill bits available.

- They are commonly used for drilling in extremely hard materials such as glass, ceramics, and stone.

- Diamond drill bits are made by bonding diamond particles to the tip of the bit using high-pressure and high-temperature techniques.

Coating

In addition to the base material, drill bits may also be coated with a thin layer of a different material to enhance their performance.

Conclusion

The selection of the appropriate material for drill bits depends on the type of material to be drilled and the specific requirements of the drilling operation. The right material choice can greatly improve the performance and durability of drill bits.

Designing the Drill Bit Geometry

The process of designing the drill bit geometry is a crucial step in creating an effective cutting tool. The geometry of the drill bit determines its performance in terms of drilling speed, precision, and stability. It also affects parameters such as chip evacuation and cooling efficiency. Here are the key factors involved in designing the drill bit geometry:

-

Point angle: The point angle is the angle formed at the center of the drill bit between the two cutting edges. It determines the ability of the drill bit to start cutting and maintain stability during the drilling process. The point angle is typically between 118 and 140 degrees for general-purpose drill bits.

-

Flute design: The flutes on the drill bit are the spiral-shaped grooves that help in chip evacuation. The number and helix angle of the flutes impact the chip removal efficiency and the cooling of the drill bit. A higher helix angle and more number of flutes provide better chip evacuation and cooling. However, a balance needs to be maintained to avoid compromising the stability of the drill bit.

-

Shank design: The shank is the portion of the drill bit that fits into the drill chuck. It should be designed to fit securely and prevent slippage during drilling. Common shank designs include straight shank, hex shank, and SDS shank.

-

Cutting edge design: The cutting edges are the sharp edges that actually cut into the workpiece. The design of the cutting edges depends on the material to be drilled. For example, drill bits used for drilling metal have different cutting edge designs compared to those used for drilling wood or masonry.

-

Coating: The drill bit may be coated with a thin layer of material to enhance its performance and durability. Common coatings include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and black oxide. These coatings reduce friction, increase hardness, and improve heat resistance.

Overall, the design of the drill bit geometry involves optimizing different parameters to maximize performance and quality in various drilling applications. Manufacturers use advanced computer-aided design (CAD) software and machining techniques to create drill bits with precise geometries that meet the requirements of different industries and materials.

Heat Treatment of Drill Bits

Heat treatment is a crucial step in the manufacturing process of drill bits. It involves subjecting the drill bits to controlled heating and cooling cycles to enhance their hardness, strength, and durability. The heat treatment process transforms the raw materials into high-performing drill bits capable of withstanding the demanding conditions of drilling operations.

Types of Heat Treatment

There are several types of heat treatment methods used in the production of drill bits. The most common ones include:

- Annealing: This process involves heating the drill bits to a specific temperature and then cooling them slowly. Annealing helps to relieve internal stresses, improve machinability, and increase toughness.

- Hardening: During hardening, the drill bits are heated to a high temperature and then rapidly cooled to create a hardened surface layer. This process enhances the drill bits’ wear resistance and strength.

- Tempering: Tempering involves reheating the hardened drill bits to a lower temperature and then cooling them gradually. This step reduces the brittleness caused by hardening and improves the drill bits’ toughness.

Benefits of Heat Treatment

The heat treatment process offers several benefits to drill bits:

- Improved Hardness: Heat treatment significantly increases the hardness of the drill bits, making them more resistant to wear, abrasion, and deformation.

- Enhanced Strength: By altering the microstructure of the drill bits, heat treatment improves their overall strength and toughness.

- Increased Durability: Heat-treated drill bits have a longer lifespan and can withstand rigorous drilling operations without easily succumbing to damage.

- Better Performance: The heat treatment process ensures that the drill bits maintain their cutting edges and sharpness for extended periods, resulting in improved drilling performance.

Quality Control

Heat treatment is a critical stage that requires careful monitoring to ensure the desired results. Quality control measures, such as hardness testing and microstructure examination, are performed to verify whether the drill bits have undergone the appropriate heat treatment process.

In conclusion

The heat treatment process plays a vital role in the production of high-quality drill bits. It enhances their hardness, strength, and durability, making them capable of withstanding the demands of drilling operations. Through annealing, hardening, and tempering, drill bits undergo transformations that result in improved performance and extended lifespan.

Machining the Flutes

Once the body of the drill bit has been formed and hardened, the next step in the manufacturing process is machining the flutes. The flutes are the spiral-shaped channels that run along the length of the bit and help to remove the material as the bit cuts into it. These flutes play a crucial role in the overall performance of the drill bit, as they help to ensure efficient material removal and prevent clogging or overheating.

Machining the flutes involves the use of specialized cutting tools that are designed to create the precise spiral shape. The cutting tools typically consist of multiple flutes themselves, each with a specific shape and angle to create the desired flute geometry. The cutting tools are mounted on a machine called a CNC grinder, which uses computer-controlled movements to accurately shape the flutes with high precision.

During the machining process, the drill bit is clamped into the CNC grinder, and the cutting tools are brought into contact with the surface of the bit. The grinder spins the bit at a high speed while the cutting tools move along the length of the bit, gradually creating the spiral-shaped flutes. The depth, pitch, and shape of the flutes are carefully controlled to ensure optimal performance.

The machining process for the flutes requires careful attention to detail, as any inaccuracies or deviations from the desired flute geometry can negatively impact the performance of the drill bit. The cutting tools used in the process are made from high-speed steel or carbide, which allows them to withstand the high temperatures and forces involved in cutting through various materials.

Once the flutes have been machined, the drill bit undergoes further finishing processes, such as grinding or polishing, to ensure a smooth surface and sharp cutting edges. The finished drill bit is then inspected for quality and undergoes rigorous testing before it is deemed ready for use.

Coating Drill Bits for Increased Performance

Introduction

Drill bits are an essential tool used in various industries, from construction to metalworking. To improve their performance and durability, drill bits are often coated with special materials. These coatings provide added strength, reduce friction, and enhance the cutting ability of the drill bit. In this article, we will explore the different types of coatings used for drill bits and how they can increase their overall performance.

Types of Drill Bit Coatings

There are several types of coatings that can be applied to drill bits, each with its unique properties and advantages. Some of the commonly used drill bit coatings include:

- Titanium Nitride (TiN) Coating: TiN coating is one of the most popular and widely used coatings for drill bits. It provides excellent wear resistance, reduces friction, and increases the hardness of the drill bit. TiN-coated drill bits can effectively drill through a wide range of materials, including steel, wood, and plastic.

- Titanium Aluminum Nitride (TiAlN) Coating: TiAlN coating is an advanced coating that offers superior hardness and heat resistance compared to TiN. It is ideal for high-speed drilling and can handle more demanding tasks. TiAlN-coated drill bits are often used in aerospace and automotive industries.

- Black Oxide Coating: Black oxide coating is a low-cost option that provides moderate wear resistance and corrosion protection. It also helps in reducing friction and heat buildup during drilling. Black oxide-coated drill bits are commonly used for general-purpose drilling in softer materials.

- Diamond Coating: Diamond coating is the hardest and most durable coating available for drill bits. It is commonly used for drilling in extremely abrasive materials such as glass, ceramics, and composites. Diamond-coated drill bits offer exceptional performance and can last significantly longer than other coatings.

Benefits of Coated Drill Bits

Coating drill bits with these special materials can offer several benefits, including:

- Improved Hardness: The coatings significantly increase the hardness of the drill bit, making it more resistant to wear and extending its lifespan.

- Reduced Friction: The coatings act as a lubricant, reducing friction between the drill bit and the material being drilled. This reduces heat buildup and prevents the drill bit from overheating, allowing for smoother drilling.

- Better Chip Evacuation: Coated drill bits have enhanced chip evacuation properties, allowing them to remove material more efficiently. This reduces the risk of clogging and improves drilling speed.

- Enhanced Cutting Ability: The coatings improve the cutting ability of the drill bit, allowing it to cut through materials more easily and with less effort.

Conclusion

Coating drill bits with special materials is a crucial process that enhances their performance and durability. Each type of coating offers its unique benefits and is suitable for specific drilling applications. By selecting the right coated drill bits for a particular task, professionals can achieve better drilling results, increased productivity, and improved longevity of their drill bits.

Inspection and Quality Control of Drill Bits

Inspection and quality control of drill bits play a crucial role in ensuring their performance and reliability. Various tests and examinations are conducted throughout the manufacturing process to ensure that the drill bits meet the required standards and specifications. This article explores some of the common inspection and quality control procedures employed in the production of drill bits.

Visual Inspection

The first step in the inspection process is a visual examination of the drill bits. Skilled inspectors carefully examine the external surfaces of the drill bits to detect any visible defects such as cracks, chips, or deformities. Any irregularities found during this inspection are recorded, and the affected drill bits are rejected or repaired, depending on the severity of the issue.

Dimensional Measurement

To ensure accuracy, the dimensions of the drill bits are measured using precision tools such as micrometers and calipers. Critical dimensions such as the diameter, length, and flute depth are carefully measured and compared against the specified tolerances. Any deviations outside the tolerances are flagged for further evaluation and corrective action.

Hardness Testing

Drill bits need to possess a specific level of hardness to withstand the demanding drilling tasks they are designed for. Hardness testing is performed using a specialized hardness tester to determine the Rockwell hardness of the drill bits. The results are compared to the required hardness range, and any drill bits falling outside this range are rejected.

Magnetic Particle Inspection

Magnetic particle inspection is commonly used to detect surface and near-surface defects in the drill bits. The process involves magnetizing the drill bits and applying magnetic particles to the surface. If there are any defects present, the magnetic particles will accumulate at the defect sites, making them visible to the inspector. This inspection method is particularly effective in detecting cracks, porosity, and other similar defects.

Performance Testing

To ensure the functionality and performance of the drill bits, performance testing is conducted. Drill bits are subjected to various drilling tests using different materials and drilling conditions. The performance parameters evaluated include drilling speed, drilling efficiency, torque requirements, and overall durability. The test results help determine if the drill bits meet the performance standards and if any adjustments or improvements are necessary.

Final Inspection and Packaging

Once all the required tests and inspections have been completed, the drill bits undergo a final inspection to ensure they are free from any defects or deviations. If the drill bits pass the final inspection, they are cleaned, packaged, and prepared for shipment or distribution to the customers.

In conclusion, inspection and quality control are integral aspects of the drill bit manufacturing process. By conducting visual inspections, dimensional measurements, hardness testing, magnetic particle inspections, and performance testing, manufacturers can ensure the production of high-quality, reliable drill bits that meet the required standards and specifications.

Packaging and Distribution of Drill Bits

After the drill bits are manufactured, they go through a packaging and distribution process before they reach the end users. This process involves careful packaging, labeling, and shipping to ensure that the drill bits are delivered in optimal condition.

Packaging: Drill bits are typically packaged in protective cases or boxes to prevent damage during transportation. The packaging is designed to keep the drill bits secure and organized, as well as provide information about the product.

Labeling: Each package is labeled with essential details about the drill bits, such as the size, type, and material. This information helps users easily identify the right drill bits for their specific needs.

Shipping: Once packaged and labeled, the drill bits are ready to be shipped to distributors, retailers, or directly to customers. The shipping process involves arranging transportation, ensuring proper handling, and tracking the delivery to ensure it reaches the intended destination.

Distribution: Distributors play a crucial role in the distribution of drill bits. They act as intermediaries between manufacturers and retailers, ensuring that the products are efficiently distributed to the intended markets. They may utilize various distribution channels, including online platforms, hardware stores, or industrial supply chains.

Retail: Drill bits are available for purchase in retail stores, both physical and online. In physical stores, drill bits are typically displayed on racks or shelves, organized by type and size. Online retailers often provide detailed product descriptions, customer reviews, and comparison tools to assist customers in making informed purchasing decisions.

End User: Finally, the end users, such as professionals or DIY enthusiasts, purchase the drill bits for their specific drilling needs. Once in the hands of the end users, the drill bits are used in various applications, ranging from woodworking to metal fabrication.

In conclusion, the packaging and distribution of drill bits involve careful packaging, labeling, and shipping to ensure that the products reach the end users in optimal condition. Distributors play a crucial role in efficiently distributing the drill bits to the intended markets, while retailers provide convenient access for customers to purchase the drill bits for their specific drilling needs.

FAQ:

What material are drill bits made of?

Drill bits are typically made of high-speed steel (HSS), cobalt steel, carbide, or diamond.

How are drill bits manufactured?

Drill bits are manufactured through various processes such as forging, rolling, heat treating, grinding, and coating.

What is the purpose of the grinding process in drill bit manufacturing?

The grinding process in drill bit manufacturing helps to shape and sharpen the cutting edges of the bit, ensuring clean and efficient drilling.

Can you explain the steps involved in the manufacturing of a drill bit?

Sure! The manufacturing process of a drill bit typically includes steps such as material selection, shaping the bit, heat treating, grinding, and coating.

What are the advantages of using carbide drill bits compared to HSS drill bits?

Carbide drill bits are known for their high hardness and resistance to wear, making them ideal for drilling through hard materials such as metal and concrete. They also tend to have a longer lifespan compared to HSS drill bits.

Are there any specific safety precautions to consider when using drill bits?

Yes, when using drill bits, it is important to wear protective eyewear and gloves, as well as ensuring a secure grip on the drill. It is also important to follow the manufacturer’s instructions and guidelines for safe and proper usage.

What are some common types of drill bits?

Some common types of drill bits include twist drill bits, spade drill bits, masonry drill bits, auger drill bits, and step drill bits.

Video: