Effective Techniques for Marking Drill Locations in Blind Holes

When it comes to drilling in blind holes, accuracy is crucial. Blind holes are holes that do not pass through the entire material, and drilling in the wrong location can be costly and time-consuming to correct. To ensure precise drilling, it is essential to have effective techniques for marking drill locations in blind holes.

One technique that proves to be useful is the use of strong and visible markers. These markers can be in the form of permanent markers or colored tape. By marking the exact location where the drill needs to go, it eliminates any confusion and minimizes the chances of drilling in the wrong spot. The chosen marker should be resistant to smudging or fading as it may come into contact with cutting fluids or other substances during the drilling process.

Another effective technique is the use of templates or jigs. These are specific tools designed to guide the drill accurately to the desired location. Templates can be made from materials such as plastic or metal and have pre-drilled holes that align with the intended drill locations. Jigs, on the other hand, are devices that securely hold the material in place while also guiding the drill. Both templates and jigs provide a reliable and repeatable method for marking drill locations in blind holes.

Creating a pilot hole is also a valuable technique for marking drill locations in blind holes. A pilot hole is a small guide hole that is drilled prior to the actual hole. This pilot hole serves as a reference point for the drill and ensures that the drill bit stays on track. By starting with a pilot hole, it becomes easier to mark the exact location for the blind hole, reducing the chances of error.

In conclusion, marking drill locations in blind holes requires effective techniques to ensure accuracy and efficiency. Using visible markers, templates or jigs, and creating pilot holes are all valuable methods for accurately marking drill locations. Employing these techniques will help avoid costly mistakes and ensure precise drilling in blind holes.

Techniques for Accurate Drilling

1. Preparing the Drill Bit

Before drilling blind holes, it is essential to ensure that the drill bit is properly prepared. This involves checking the sharpness of the bit and removing any debris or burrs that may affect its performance. Using a drill bit sharpener or a file, carefully sharpen the bit to ensure clean and precise drilling.

2. Securing the Workpiece

Properly securing the workpiece is crucial for accurate drilling. If the workpiece is not held securely in place, it may move or shift during drilling, leading to misaligned holes. Depending on the size and shape of the workpiece, various methods can be used for securing, such as clamps, vices, or a dedicated drilling jig.

3. Marking Drill Locations

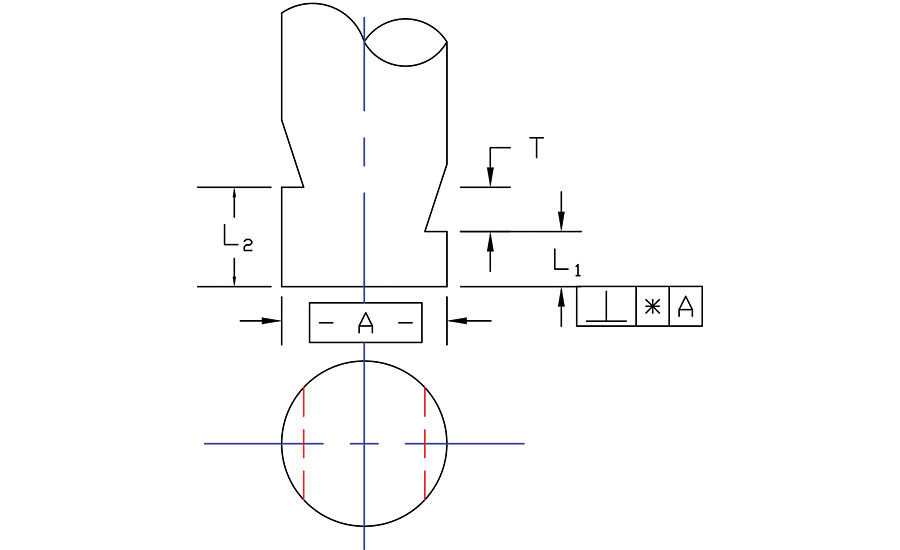

Accurate markings are essential for drilling blind holes. Start by measuring and marking the desired drill locations on the workpiece using a ruler or measuring tape. To ensure precision, use a center punch to make small indents at the marked locations. These indents will act as a guide for the drill bit, ensuring accurate positioning.

4. Using Depth Stops

Depth stops are useful tools for drilling blind holes to a specific depth. These stops can be attached to the drill bit or the drill itself, limiting the drilling depth and preventing over-drilling. Adjust the depth stop according to the required depth and ensure that it is securely in place before starting the drilling process.

5. Using Proper Speed and Pressure

The speed and pressure applied during drilling can significantly affect the accuracy of the holes. Using a drill with adjustable speed settings, choose an appropriate speed for the material being drilled. Too high of a speed can cause the drill bit to wander, while too low of a speed can lead to inefficient drilling. Apply consistent pressure while drilling, maintaining control over the drill.

6. Clearing Chips and Debris

During drilling, chips and debris can accumulate in the blind hole, obstructing visibility and affecting accuracy. To ensure accurate drilling, periodically remove the chips and debris using a brush or compressed air. This will help maintain clear visibility of the drill location and prevent any interference with the drilling process.

7. Checking Accuracy

After drilling blind holes, it is crucial to check their accuracy to verify that they are aligned correctly. Use a depth gauge or a measuring tool to measure the depth of the hole. Additionally, use a straight edge or a square to check the alignment of the hole with the surface of the workpiece. If any inaccuracies are found, adjustments can be made accordingly.

8. Practicing Proper Technique

Accurate drilling requires practice and proper technique. Take the time to familiarize yourself with the drilling equipment and practice on scrap materials before working on a final project. This will help develop the necessary skills and ensure accurate and precise drilling in blind holes.

| Technique | Description |

|---|---|

| Preparing the Drill Bit | Checking and sharpening the drill bit before drilling. |

| Securing the Workpiece | Using clamps, vices, or jigs to hold the workpiece firmly. |

| Marking Drill Locations | Measuring and marking the drill locations accurately. |

| Using Depth Stops | Attaching depth stops to limit drilling depth. |

| Using Proper Speed and Pressure | Adjusting drill speed and applying consistent pressure. |

| Clearing Chips and Debris | Removing chips and debris from the blind hole. |

| Checking Accuracy | Verifying the accuracy of the drilled blind holes. |

| Practicing Proper Technique | Developing skills and practicing accurate drilling. |

Importance of Marking Drill Locations

Marking drill locations is a crucial step in any drilling process, especially when dealing with blind holes. Blind holes are holes that do not fully penetrate through the material, and therefore, require precise marking to ensure that the drill is placed correctly.

There are several reasons why marking drill locations is important:

- Accuracy: By marking drill locations, the accuracy of the drilling process is greatly improved. It allows the operator to visually verify the position of the drill before initiating the drilling process. This helps in reducing the chances of errors and ensures that the hole is placed in the desired location.

- Safety: Marking drill locations also improves safety by making it easier for the operator to locate the exact point where the drill needs to be placed. This helps in preventing accidental drilling in the wrong location, which can lead to damage to the material, tools, or even injury to the operator.

- Consistency: Consistency is crucial in many drilling processes, especially when multiple holes need to be drilled in a precise pattern. Marking drill locations ensures that the same position is maintained for each hole, resulting in consistent and accurate drilling.

- Efficiency: By marking drill locations, the overall efficiency of the drilling process is improved. It eliminates the need for guesswork or trial and error, allowing the operator to quickly and efficiently position the drill in the correct location.

There are various methods for marking drill locations, ranging from simple techniques such as using a marker or scribe to more advanced methods such as using laser alignment tools or templates. The choice of method depends on the specific requirements of the drilling process and the precision needed.

In conclusion, marking drill locations is an important step in ensuring accuracy, safety, consistency, and efficiency in the drilling process. It should not be overlooked or underestimated, especially when dealing with blind holes or complex drilling patterns.

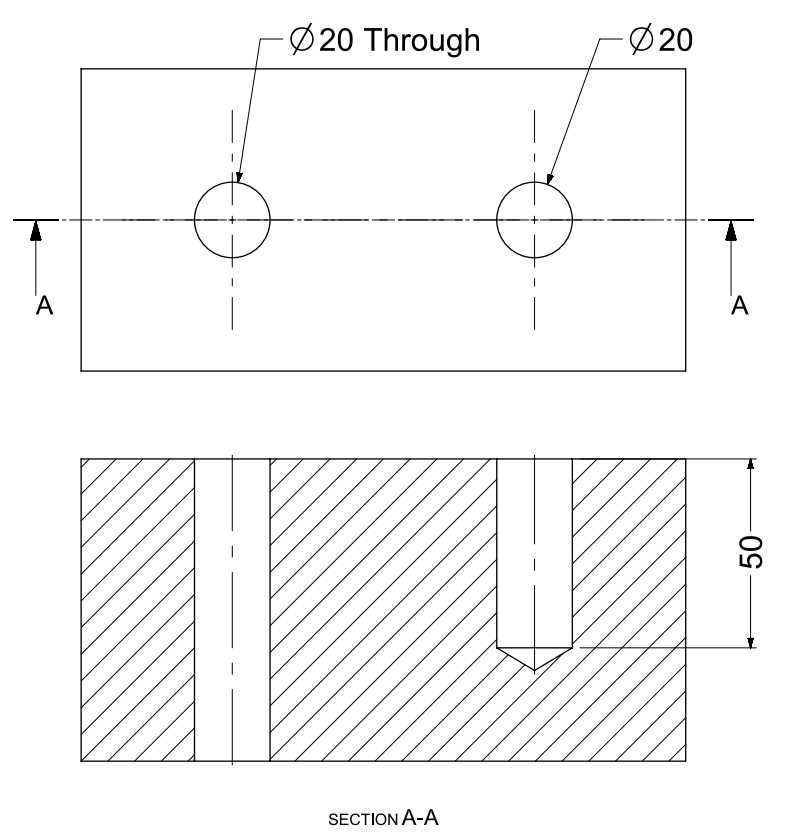

Understanding Blind Holes

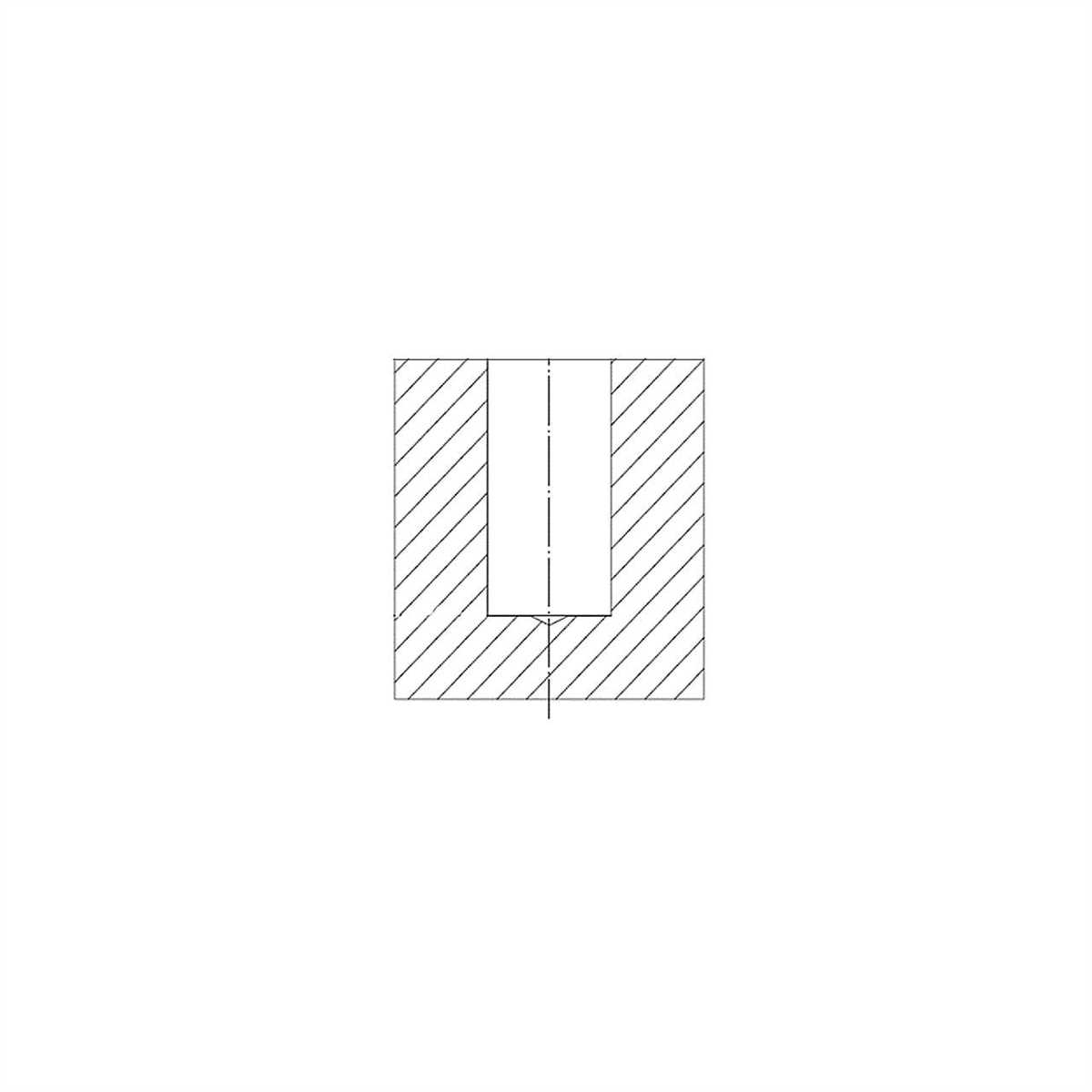

In machining processes, blind holes refer to holes that do not pass entirely through a workpiece. These holes are usually drilled to a specific depth and are commonly used for various purposes such as creating threaded connections, counterboring, or creating depth stops.

Key Characteristics

- Depth: Blind holes are drilled to a specific depth that does not pass through the entire workpiece. This depth is determined by the specific requirements of the application.

- No exit point: Unlike through holes, blind holes do not have an exit point on the opposite side of the workpiece.

- Orientation: Blind holes can be drilled vertically or at an angle, depending on the specific requirements of the application.

- Functionality: Blind holes can serve multiple purposes, such as providing a threaded connection for screws or bolts, creating a recess for a component to fit into, or establishing a depth stop for drilling or boring operations.

Drilling Blind Holes

Drilling blind holes requires careful planning and execution to ensure accurate positioning and appropriate depth. The following steps are typically involved in drilling blind holes:

- Workpiece preparation: The workpiece must be properly secured in a vice or fixture to prevent movement during the drilling process.

- Marking the hole location: Accurate marking of the hole location is crucial to ensure precise drilling. This can be done using center punches or scribing tools.

- Selecting the appropriate drill bit: The drill bit size and type should be chosen based on the desired hole diameter and the material being drilled.

- Setting the drilling depth: The drilling depth should be set based on the requirements of the application. This can be done using depth stop collars or depth gauges.

- Drilling the hole: The hole can be drilled using a drilling machine or a drill press. Care should be taken to ensure the drill bit does not exceed the desired depth.

- Cleaning and deburring: After drilling, the hole should be cleaned and any burrs or sharp edges should be removed.

Conclusion

Understanding blind holes is crucial for effective machining processes. By accurately marking the hole location and following the appropriate drilling steps, blind holes can be created with precision and reliability, ensuring successful assembly and functionality of the workpiece.

Choosing the Right Marking Tools

When it comes to marking drill locations in blind holes, choosing the right marking tools is crucial for accuracy and efficiency. The right tools can help ensure that your holes are properly marked and drilled, resulting in a successful project.

Considerations when choosing marking tools:

- Visibility: Select marking tools that offer good visibility in the specific material you are working with. For example, if you are marking holes in a dark-colored material, choose a marking tool that will be easily visible on that surface.

- Ease of use: Look for marking tools that are easy to handle and use. This will help minimize errors and improve overall efficiency.

- Precision: Accuracy is key when marking drill locations. Choose marking tools that allow for precise marking, such as fine-tipped markers or center punches.

- Durability: It is important to choose markers that are durable and long-lasting. This will ensure that the marking tool can withstand the demands of drilling and provide consistent markings throughout the project.

Types of marking tools:

There are various types of marking tools available for marking drill locations in blind holes. Here are some commonly used tools:

- Center punches: These tools have a pointed tip that can be used to make an indentation in the material, providing a precise starting point for drilling.

- Drill bits: Using the actual drill bits can be a convenient way to mark the drill location, especially when working with soft materials.

- Markers: Fine-tipped markers or paint pens can be used to make visible marks on the material’s surface. Choose markers that are suitable for the specific material you are working with.

- Templates: Templates are pre-made guides that can be placed on the material to mark the drill locations accurately. They can be made of plastic, paper, or metal.

Choosing the right marking tools for your project:

| Material | Recommended Marking Tools |

|---|---|

| Wood | Center punches, drill bits |

| Metal | Center punches, markers, templates |

| Plastic | Markers, templates |

| Stone | Markers, templates |

Choosing the right marking tools greatly depends on the specific material you are working with. Consider the characteristics of the material and the requirements of your project to determine the most suitable marking tools to use. Remember to prioritize visibility, ease of use, precision, and durability when making your selection.

By selecting the appropriate marking tools, you can ensure accurate and efficient marking of drill locations in blind holes, leading to successful drilling and overall project success.

Proper Preparation for Marking Drill Locations

Before marking drill locations in blind holes, it is important to properly prepare your work area and gather the necessary tools and supplies. By taking the time to prepare, you can ensure accurate and efficient marking, minimizing the risk of errors and damage.

Gather the Necessary Tools and Supplies

Before you begin marking drill locations, gather the following tools and supplies:

- Measuring tape or ruler

- Marker or pencil

- Masking tape

- Drill

- Drill bits of appropriate size

- Protective goggles

- Work gloves

Clean and Prepare the Work Area

Ensure that your work area is clean and free of any debris or obstructions. This will allow for easier and more accurate marking. Use a damp cloth or cleaning solution to wipe down the surface if necessary.

Inspect the Blind Holes

Take a moment to inspect the blind holes where the drill locations will be marked. Look for any irregularities or obstructions that may affect the drilling process. Make sure the blind holes are clear and accessible.

Measure and Mark the Drill Locations

Using the measuring tape or ruler, carefully measure the desired distance from the edge or reference point to the drill location. Mark the spot with a marker or pencil. Applying a small piece of masking tape over the mark can help prevent the drill bit from slipping during drilling.

Double-Check the Measurements

Before proceeding with drilling, double-check the measurements to ensure accuracy. It is better to spend a few extra moments verifying the locations than to make mistakes that can be costly to fix.

Proceed with Drilling

Once you have properly prepared and marked the drill locations, you can proceed with drilling. Follow proper drilling techniques, such as applying steady pressure and using the appropriate drill bit for the material being drilled.

By following these steps and properly preparing for marking drill locations in blind holes, you can ensure accurate and efficient drilling, leading to successful outcomes in your projects.

Key Factors for Accurate Marking

- Proper lighting: Adequate lighting is essential for accurate marking in blind holes. Insufficient lighting can lead to inaccuracies and mistakes in marking. It is important to ensure that the drill hole is well-lit and clear of any shadows or obstructions.

- High-quality marking tools: Using high-quality and precise marking tools can greatly enhance the accuracy of the marking process. It is recommended to invest in quality markers that provide clear and visible markings on different surfaces.

- Correct positioning: Proper positioning of the marking tool is vital for accurate marking. The marker should be aligned perpendicular to the surface of the blind hole to ensure precise marking. It is important to maintain a steady hand while marking to avoid any errors.

- Clear visibility: The marking area should be free from any dust, debris, or obstructions that may interfere with visibility. Cleaning the blind hole thoroughly before marking is necessary to ensure clear visibility and accurate marking.

- Consistent pressure: Applying consistent pressure while marking helps to ensure uniform and accurate markings. Too much pressure can result in deep and uneven marks, while too little pressure may make the marking faint or unclear. Maintaining a steady and controlled pressure is necessary for accurate marking.

- Verification and double-checking: After marking a blind hole, it is important to verify and double-check the markings for accuracy. This can be done by comparing the marking with the desired position or by using measurement tools to confirm the accuracy. Double-checking ensures that any mistakes or discrepancies are identified and rectified before proceeding.

By considering these key factors for accurate marking in blind holes, you can achieve precise and reliable results in your drilling operations.

Techniques for Marking Blind Drill Locations

Drilling blind holes can be a challenging task, especially when it comes to marking the locations accurately. Blind holes are holes that do not go all the way through the material, and they require special techniques for marking because you cannot see through them. Here are some effective techniques for marking blind drill locations:

1. Tape and Drill Bit Method

One simple technique is to use tape and a drill bit to mark the drill location. Start by applying a piece of tape over the intended drilling spot. Then, insert the tip of the drill bit through the tape, ensuring it is centered on the desired location. Press the tape firmly against the material to ensure it doesn’t move. The tape will act as a guide for drilling.

2. Center Punch Method

Using a center punch is another effective technique for marking blind drill locations. A center punch is a tool with a pointed tip that creates a small dent in the material. Place the center punch on the spot where you want to drill and strike it with a hammer to create a mark. The dent will serve as a guide for the drill bit.

3. Laser Guide Method

If precision is crucial, you can use a laser guide to mark blind drill locations. These guides project a laser beam onto the material, showing exactly where the drill bit will penetrate. Align the laser guide with the desired spot and mark the location. This method is especially useful when drilling multiple blind holes that need to be evenly spaced.

4. Template Method

Creating a template can greatly simplify the process of marking blind drill locations, especially for repetitive tasks. Make a template out of a piece of plywood or cardboard by drilling holes in the desired locations. Place the template over the material, align it properly, and mark the drill locations through the holes in the template. This technique ensures consistent and accurate drill hole placement.

5. Use Drill Depth Stop Collars

Drill depth stop collars are small metal rings that can be attached to the drill bit to control the depth of the hole. By setting the depth stop collar to the desired depth, you can ensure that the blind hole will be drilled to the correct depth. This technique eliminates the need for marking the drill location and allows for precise drilling every time.

These techniques can help you accurately mark blind drill locations and make the process of drilling blind holes much easier. Experiment with different methods to find the one that works best for your specific needs.

Common Mistakes to Avoid

- Not using a center punch: One of the most common mistakes is not using a center punch before drilling blind holes. This can lead to misalignment and inaccuracies in the hole position. Always make sure to use a center punch to create a small indentation in the material, which will help guide the drill bit and ensure accurate hole placement.

- Using the wrong drill bit: Using the wrong type or size of drill bit can cause issues when marking drill locations in blind holes. It is important to use the correct drill bit for the material you are working with and ensure it is the appropriate size for the hole you need to drill. Using the wrong drill bit can result in a hole that is too large or too small, or can cause damage to the material.

- Not cleaning the hole before marking: Another common mistake is not properly cleaning the hole before marking. Dust, debris, or residue left in the hole can affect the accuracy of the marking. Make sure to thoroughly clean the hole before marking to ensure accurate placement.

- Marking too close to the edge: Placing the drill mark too close to the edge of the material can result in drilling into an unintended area or causing the material to crack or splinter. Always measure and mark the hole location a safe distance away from the edge to avoid these issues.

- Not double-checking measurements: Failing to double-check measurements before marking drill locations can lead to costly mistakes. Always double-check your measurements and ensure they are accurate before marking the holes.

- Not using a drill stop: When drilling blind holes, it is important to use a drill stop to prevent over-drilling. Not using a drill stop can result in drilling too deep and damaging the material or going through the other side of the material. Always use a drill stop to control the depth of the hole.

By avoiding these common mistakes, you can improve the accuracy and efficiency of marking drill locations in blind holes. Taking the time to properly prepare the material, use the correct tools and techniques, and double-check measurements will help ensure successful drilling and prevent costly errors.

Final Tips for Successful Marking

1. Double-check your measurements

Before marking the drill locations, it is essential to double-check the measurements to ensure accuracy. Use a high-quality measuring tool and take multiple measurements to confirm consistency.

2. Clean the hole before marking

Blind holes can accumulate debris and dust, which can interfere with the marking process. Clean the hole thoroughly using compressed air or a brush to ensure a clear surface for marking.

3. Use a bright and visible marking tool

When marking drill locations in blind holes, it is crucial to use a marking tool that is bright and easily visible. This will help prevent any confusion or misalignment during the drilling process. Consider using a sharpie or a bright colored pencil for this purpose.

4. Mark multiple points of reference

To ensure accurate drilling, it is recommended to mark multiple points of reference in the blind hole. This can include marking the center point as well as other relevant measurements or indicators. Having multiple points of reference will help you align the drill accurately.

5. Consider using templates or jigs

If you have multiple blind holes to mark, it may be helpful to create templates or jigs that can be used as guides. These tools can be easily aligned with the hole and will ensure consistent and precise marking.

6. Test your marking technique

Before marking the actual blind hole, it is always a good idea to test your marking technique on a scrap or test piece. This will help you identify any issues or errors in your marking process and make necessary adjustments before working on the actual workpiece.

7. Work in a well-lit area

Working in a well-lit area is crucial to accurately mark drill locations in blind holes. Ensure that the workspace is well-lit and positions the workpiece in a way that allows you to clearly see the drill markings.

8. Take your time

Accuracy is key when marking drill locations in blind holes. Take your time and work patiently to ensure precise marking. Rushing through the process can lead to errors and misalignment.

9. Check for alignment before drilling

Before proceeding with drilling, double-check the alignment of the drill markings. Use measuring tools or visual checks to ensure that the marks are accurate and in the desired position. Making corrections at this stage will help prevent costly mistakes.

10. Follow safety precautions

Lastly, always prioritize safety when working with drill marking in blind holes. Wear appropriate protective gear such as goggles and gloves, and follow safety guidelines to prevent accidents or injuries.

- Double-check your measurements

- Clean the hole before marking

- Use a bright and visible marking tool

- Mark multiple points of reference

- Consider using templates or jigs

- Test your marking technique

- Work in a well-lit area

- Take your time

- Check for alignment before drilling

- Follow safety precautions

FAQ:

What are blind holes?

Blind holes are those holes that are drilled partially or entirely through a material, but do not pass through it completely.

Why is it important to mark drill locations in blind holes effectively?

It is important to mark drill locations in blind holes effectively because without proper markings, it can be difficult to accurately drill the hole in the desired location. Effective markings ensure precision and reduce the chances of errors during drilling.

What are some common challenges faced while marking drill locations in blind holes?

Some common challenges faced while marking drill locations in blind holes include limited visibility, cramped working spaces, and the need for precision. These factors make it crucial to use effective techniques for marking, such as using high-contrast markers or using additional tools like depth stops.

What are some effective techniques for marking drill locations in blind holes?

Some effective techniques for marking drill locations in blind holes include using center punches, depth stops, high-contrast markers, or even utilizing laser measurement tools. These techniques ensure accuracy and precision in drilling.

Are there any specific tools or equipment that can assist in marking drill locations in blind holes?

Yes, there are specific tools and equipment that can assist in marking drill locations in blind holes. These include center punches, depth stops, laser measurement tools, and high-contrast markers. These tools help in achieving accurate and precise markings for drilling.

Can you provide some tips for effectively marking drill locations in blind holes?

Some tips for effectively marking drill locations in blind holes include ensuring good lighting in the working area, using sharp center punches for creating clear indentations, double-checking the accuracy of markings before drilling, and using additional tools like depth stops for better precision. It is also important to take your time and be patient while marking the locations.

Are there any alternative methods for marking drill locations in blind holes?

Yes, there are alternative methods for marking drill locations in blind holes. Some people prefer using masking tape or adhesive templates to mark the drill locations. These methods can provide more flexibility and make it easier to achieve accurate markings in certain situations.

Video: