Easy Ways to Fill Drill Holes in Concrete

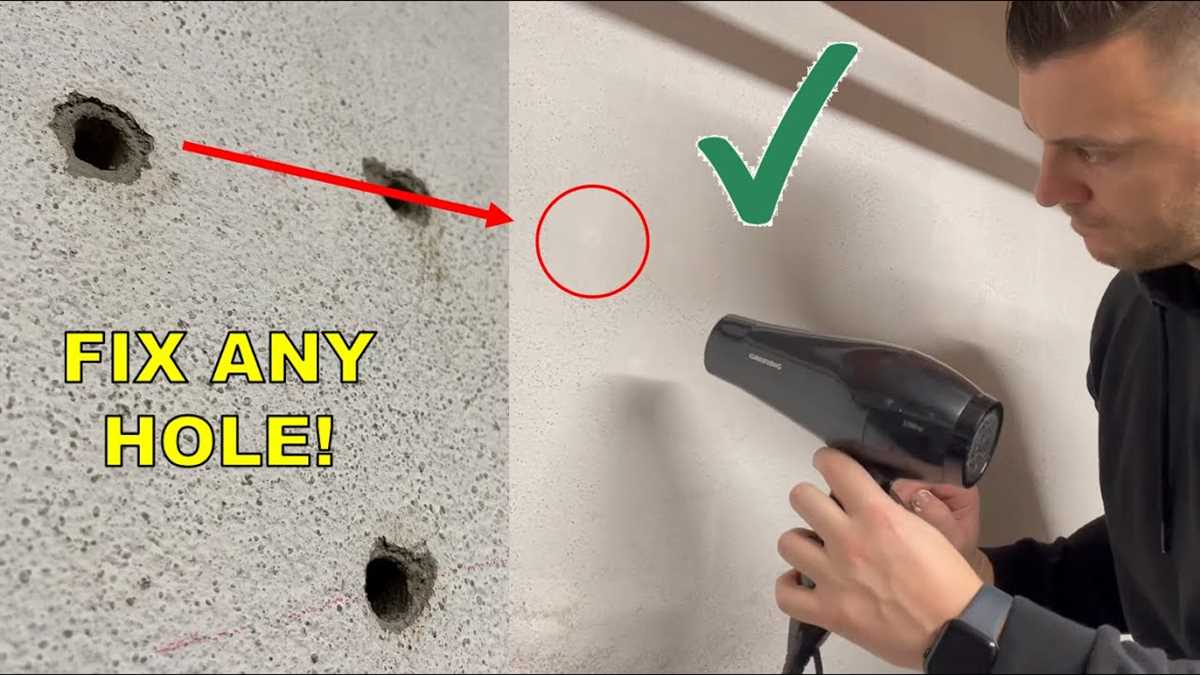

Drilling holes in concrete can be a necessary step when you’re working on a DIY project or undertaking a home improvement task. However, once the project is complete, you may find yourself left with unsightly drill holes in the concrete. Fortunately, there are several easy and effective ways to fill these holes and restore the appearance of your concrete surface.

One common method for filling drill holes in concrete is to use a concrete patching compound. These compounds are available in various forms, such as pre-mixed paste or powder that can be mixed with water. Simply apply the compound to the hole with a putty knife or trowel, making sure to fill it completely. Smooth the surface of the compound with the tool, and allow it to dry according to the manufacturer’s instructions. Once dried, the compound will harden and blend in with the surrounding concrete.

Another option is to use a quick-setting cement. This type of cement is designed to dry rapidly, allowing you to complete your project more quickly. To fill a drill hole with quick-setting cement, mix the cement with water according to the package instructions and pour it into the hole. Make sure the cement fills the hole completely and level the surface with a trowel. Within a few hours, the cement will harden and can be sanded down to achieve a smooth finish.

If you’re looking for a more natural and eco-friendly solution, you can also fill drill holes in concrete with a mixture of sand and Portland cement. Start by cleaning the hole and wetting it with water. Then, mix sand and Portland cement in equal parts and add water to create a thick paste. Use a putty knife or trowel to fill the hole with the mixture, making sure to press it down firmly. Once the paste has dried and hardened, it can be sanded down to create a seamless surface.

In conclusion, filling drill holes in concrete doesn’t have to be a difficult or time-consuming task. Whether you choose to use a concrete patching compound, quick-setting cement, or a mixture of sand and Portland cement, these methods can help you achieve a professional-looking result. With just a few simple steps, you can restore the appearance of your concrete surface and enjoy the satisfaction of a job well done.

Why Fill Drill Holes in Concrete?

When working with concrete, it is common to create drill holes for various purposes, such as installing anchors, mounting fixtures, or routing cables. However, these drill holes can leave unsightly gaps in the concrete surface and compromise its structural integrity. Filling these drill holes is not just a cosmetic concern but also an essential step to maintain the durability and strength of the concrete.

Filling drill holes in concrete offers several benefits:

- Maintains Aesthetics: Filling the drill holes prevents the formation of visible gaps or depressions on the concrete surface, ensuring a smooth and uniform appearance.

- Prevents Moisture Penetration: Unfilled drill holes can allow moisture to seep into the concrete, leading to potential issues like mold growth, corrosion of embedded metal, and degradation of concrete over time.

- Enhances Structural Integrity: The filled holes add strength and stability to the concrete structure, reducing the risk of cracks, spalling, or other forms of damage.

- Improves Safety: Unfilled drill holes can create tripping hazards or pose a risk of injury, especially in high-traffic areas. Filling the holes ensures a safe and even surface.

- Increases Lifespan: By filling drill holes promptly, you can prevent further deterioration of the concrete, prolonging its lifespan and reducing the need for costly repairs or replacements.

Overall, filling drill holes in concrete is crucial for maintaining the visual appeal, structural integrity, and longevity of the concrete surface. It is a simple and cost-effective solution that can prevent potential problems and ensure the concrete remains strong and durable for years to come.

Importance of Filling Drill Holes

When drilling holes in concrete, it is important to fill them properly for several reasons. Failing to fill drill holes can lead to various issues and problems, ranging from aesthetic concerns to structural damage. Here are some reasons why filling drill holes in concrete is crucial:

1. Aesthetics

Unfilled drill holes can be unsightly, especially if they are visible on a finished concrete surface. Whether it’s a wall, floor, or countertop, leaving drill holes unfilled can create an uneven and unprofessional look, which can detract from the overall appearance of the space.

2. Protection

Filling drill holes helps to protect the concrete from damage caused by moisture, debris, and other elements that can seep into the holes over time. Moisture can lead to the growth of mold and mildew, while debris can cause cracks and weakening of the concrete. By filling the drill holes, you provide a barrier that prevents these issues from occurring.

3. Structural Integrity

Filling drill holes is essential for maintaining the structural integrity of the concrete. Unfilled holes can create weak points in the concrete, making it more susceptible to cracking and breaking. This is particularly important in load-bearing structures, where the strength of the concrete is crucial for ensuring the safety and stability of the building or structure.

4. Longevity

By filling drill holes, you can extend the lifespan of the concrete. Unfilled holes can lead to further deterioration of the concrete over time, compromising its overall durability and longevity. Properly filling drill holes helps to preserve the integrity of the concrete and ensure that it will last for many years to come.

5. Professionalism

Finally, filling drill holes demonstrates professionalism and attention to detail. Whether you are working on a DIY project or managing a construction site, properly filling drill holes shows that you take pride in your work and understand the importance of completing tasks thoroughly and correctly.

In conclusion, filling drill holes in concrete is crucial for various reasons, including aesthetics, protection, structural integrity, longevity, and professionalism. Taking the time to properly fill drill holes will not only enhance the appearance of the concrete but also contribute to its overall strength and durability.

Materials Needed to Fill Drill Holes

When it comes to filling drill holes in concrete, you will need a few materials to ensure a successful repair. Here are the essential materials you will need:

- Epoxy filler: Epoxy filler is a versatile and durable material that is commonly used for filling drill holes in concrete. It is available in two parts – epoxy resin and hardener, which need to be mixed together according to the manufacturer’s instructions.

- Putty knife: A putty knife is needed to apply the epoxy filler into the drill holes. It is a flat-bladed tool that helps spread the filler evenly and smoothly.

- Wire brush: A wire brush is essential for cleaning the drill holes before filling them. It helps remove any loose debris, dust, or old filler, ensuring a clean and secure bond for the new filler.

- Caulking gun: A caulking gun is necessary to dispense the epoxy filler from the tubes. It provides a controlled flow and allows for precise application of the filler into the drill holes.

- Gloves and safety glasses: As with any DIY project, it is important to protect yourself by wearing gloves and safety glasses. These will help prevent skin contact with the epoxy filler and any accidental eye injuries.

It is important to note that the specific materials required may vary depending on the size of the drill holes and the specific epoxy filler being used. Always refer to the manufacturer’s instructions for the recommended materials and application techniques.

Easy Steps to Fill Drill Holes

Step 1: Gather Materials

Before you begin filling the drill holes in concrete, make sure you have all the necessary materials on hand. You will need:

- A drill hole cleaning tool or brush

- Epoxy adhesive or concrete filler

- A putty knife or trowel

- Sandpaper

- A damp cloth or sponge

Step 2: Clean the Drill Holes

Use a drill hole cleaning tool or brush to remove any loose debris or dust from the drill holes. This will ensure that the filler adheres properly. You can also use a vacuum to remove any remaining particles.

Step 3: Mix the Filler

If you are using epoxy adhesive, follow the instructions on the packaging to mix it properly. If you are using concrete filler, mix it according to the manufacturer’s instructions.

Step 4: Fill the Holes

- Using a putty knife or trowel, apply the mixed filler into the drill holes. Make sure to completely fill the holes, leaving no gaps or air pockets.

- Smooth the surface of the filler with the putty knife or trowel, ensuring it is level with the surrounding concrete.

Step 5: Allow the Filler to Dry

Check the drying time specified by the manufacturer of the filler you used. Leave the filled drill holes undisturbed for the recommended period to allow the filler to fully dry and harden.

Step 6: Sand and Clean

Once the filler has dried, use sandpaper to smooth the surface until it is flush with the surrounding concrete. Clean the area with a damp cloth or sponge to remove any remaining dust or debris.

Step 7: Inspect and Touch Up

Inspect the filled drill holes for any imperfections or unevenness. If necessary, apply additional filler and repeat the smoothing and drying process.

Step 8: Final Touches

After the filler has completely dried and any necessary touch-ups have been made, the drill holes are now filled and ready for any desired finishing touches, such as painting or sealing.

Step 9: Maintain and Monitor

Regularly inspect the filled drill holes for any signs of cracking or deterioration. If any issues arise, promptly address them to ensure the integrity and longevity of the filled holes.

Step 10: Safety Precautions

When working with epoxy adhesive or concrete filler, make sure to follow all safety precautions specified by the manufacturer. This may include wearing gloves, goggles, or a mask to protect yourself from any potential hazards.

Tips for Successful Hole Filling

1. Prepare the Surface

Before filling the drill holes in concrete, it is important to prepare the surface properly. Remove any loose debris or dust from the hole using a brush or vacuum. Clean the area surrounding the hole as well to ensure a clean and smooth surface.

2. Choose the Right Filling Material

Selecting the appropriate filling material is crucial for successful hole filling. There are several options available, including epoxy fillers, cementitious fillers, or hydraulic cement. Consider the size and depth of the hole, as well as the desired finish and durability, when choosing the filling material.

3. Mix the Filler According to Instructions

If you are using a cementitious or hydraulic cement filler, follow the mixing instructions provided by the manufacturer. Ensure that the filler is mixed thoroughly to achieve a consistent and workable texture. Use a mixing paddle and a drill to make the process easier.

4. Apply the Filler to the Hole

Using a putty knife or trowel, fill the hole with the prepared filler. Press the filler firmly into the hole to ensure proper adhesion. Fill the hole slightly above the surface level to account for any shrinkage that may occur during the drying process.

5. Smooth and Level the Filler

After filling the hole, use a trowel or putty knife to smoothen the surface of the filler. Ensure that the filler is level with the surrounding concrete to create a seamless finish. Remove any excess filler and clean the tools immediately to prevent the filler from hardening on them.

6. Allow Sufficient Drying Time

Give the filler ample time to dry and cure before subjecting it to any heavy loads or pressure. Follow the drying instructions provided by the manufacturer. Keep in mind that drying times may vary depending on the type of filler used and the ambient temperature and humidity.

7. Sand and Finish the Filled Hole

If necessary, sand the filled hole to achieve a smooth and even surface. Use sandpaper or a sanding block to carefully sand away any uneven edges or excess filler. Once the surface is smooth, you can apply a concrete sealer or paint to match the surrounding area.

8. Regular Maintenance

After successfully filling the drill holes, it is important to maintain the repaired area properly. Regularly clean the filled holes and inspect them for any signs of damage or deterioration. Promptly address any issues to prevent further damage and maintain the overall integrity of the concrete.

Alternative Methods to Fill Drill Holes

While using an epoxy-based filler or concrete patching mix is the most common method to fill drill holes in concrete, there are alternative methods you can try if those materials are not available or suitable for your project. These alternative methods can provide a temporary solution or can be used as a budget-friendly option.

1. Cement and Sand Mixture

If you have cement and sand available, you can create a simple mixture to fill the drill holes. Start by mixing one part cement with two parts sand in a bucket or mixing container. Gradually add water and mix until you achieve a thick paste-like consistency. Use a putty knife or a trowel to fill the drill holes with the mixture, ensuring that it is packed tightly. Allow it to dry completely before smoothing the surface.

2. Grout

Grout is another alternative material that you can use to fill drill holes in concrete. Prepare the grout according to the manufacturer’s instructions, ensuring that it is in a thick consistency. Use a putty knife or a grout float to push the grout into the drill holes, ensuring that they are completely filled. Wipe off any excess grout on the surface using a damp sponge. Allow the grout to dry and harden before smoothing the surface.

3. Concrete Slurry

If you have access to concrete dust or small amounts of concrete, you can create a concrete slurry to fill the drill holes. Mix the concrete dust or small amounts of concrete with water to create a thick paste-like consistency. Use a putty knife or a trowel to fill the drill holes with the slurry, ensuring that it is packed tightly. Allow it to dry completely before smoothing the surface.

4. Expansion Foam

Expansion foam is a foam-based material that expands when applied and hardens to fill gaps and voids. While not specifically designed for filling drill holes, it can be used as a temporary solution. Apply the expansion foam carefully into the drill holes, ensuring that it expands to fill the void completely. Trim off any excess foam using a sharp knife. Keep in mind that this method is not suitable for long-term use and may need to be replaced or reinforced over time.

Remember, while these alternative methods can provide a temporary solution or be used in certain circumstances, epoxy-based fillers or concrete patching mixes are generally the best options for filling drill holes in concrete. They offer durability, longevity, and a finished appearance that can blend seamlessly with the surrounding surface.

Tools and Equipment for Hole Filling

When it comes to filling drill holes in concrete, there are several tools and equipment that can make the process easier and more efficient. Here are some of the most commonly used tools:

1. Putty Knife

A putty knife is a versatile tool that can be used for various applications, including hole filling. Its flat, wide blade allows for smooth spreading and shaping of the filler material.

2. Wire Brush

A wire brush is used to clean the surface of the hole before filling it. This helps remove any loose debris or dust, ensuring proper adhesion of the filler material.

3. Vacuum Cleaner

A vacuum cleaner can be used to remove any remaining dust or debris from the hole after using a wire brush. This ensures a clean surface for the filler material to adhere to.

4. Mixing Tools

Depending on the type of filler material being used, you may need mixing tools such as a drill with a mixing attachment or a hand-held mixer. These tools help in thoroughly mixing the filler material, ensuring a homogenous mixture.

5. Caulking Gun

If you’re using a caulk or sealant to fill the hole, a caulking gun is essential. It allows for controlled and precise application of the filler material, ensuring a clean and professional finish.

6. Filler Material

The type of filler material you choose will depend on the size and depth of the hole, as well as the desired finish. Common options include concrete patching compound, epoxy filler, spackling paste, or hydraulic cement.

7. Sandpaper or Sanding Block

After the filler material has dried, sandpaper or a sanding block can be used to smooth out any rough edges or uneven surfaces, providing a finished and seamless look.

Having these tools and equipment on hand will make the process of filling drill holes in concrete much easier and ensure a professional-looking result.

FAQ:

What are some easy ways to fill drill holes in concrete?

There are several easy ways to fill drill holes in concrete. One method is to use a concrete patching compound, which can be mixed and applied directly into the hole. Another option is to use a quick-setting cement, which can be mixed with water and poured into the hole. Another easy way to fill drill holes in concrete is to use epoxy resin, which can be mixed and poured into the hole. These methods are all relatively simple and can be done by DIYers with basic tools.

Can I use regular concrete to fill drill holes in concrete?

Regular concrete can be used to fill drill holes in concrete, but it may not provide the best results. Regular concrete can be difficult to mix and pour into small drill holes, and it may not adhere well to the sides of the hole. Additionally, it may take a long time for regular concrete to fully cure and harden, which can be inconvenient. It is generally better to use a specialized concrete patching compound or quick-setting cement for filling drill holes, as these materials are specifically designed for this purpose.

How long does it take for the fill material to set and harden?

The time it takes for the fill material to set and harden can vary depending on the specific product used. Concrete patching compounds and quick-setting cements typically set within a few hours and fully harden within 24 hours. Epoxy resin, on the other hand, can take longer to set and harden, often requiring 24-48 hours or more. It is important to follow the manufacturer’s instructions for the specific product being used to ensure proper setting and hardening.

Do I need any special tools to fill drill holes in concrete?

No, you do not necessarily need any special tools to fill drill holes in concrete. However, there are some basic tools that can make the process easier. These include a drill for making the holes, a mixing container for mixing the fill material, a mixing paddle or stirring stick for mixing the material, a trowel or putty knife for applying the fill material into the hole, and a level or straight edge for smoothing the surface of the fill material. These tools can usually be found at a local hardware store or home improvement store.

Is it possible to fill drill holes in concrete without professional help?

Yes, it is definitely possible to fill drill holes in concrete without professional help. The methods for filling drill holes, such as using a concrete patching compound or quick-setting cement, are relatively simple and can be done by DIYers with basic tools. However, it is important to follow the manufacturer’s instructions for the specific product being used and take proper safety precautions. If you are unsure or uncomfortable with the process, it may be best to consult a professional.

Can the filled drill holes in concrete be painted over?

Yes, the filled drill holes in concrete can be painted over. Once the fill material has fully set and hardened, it can be painted using a suitable concrete paint or coating. Before painting, it is important to clean the surface of the fill material to remove any dust or debris. It may also be necessary to apply a primer or sealant before painting to ensure proper adhesion and durability. The specific steps and materials required for painting over filled drill holes may vary depending on the type of paint or coating being used.

Video: