Easy Steps to Drill through Metal with a Hand Drill

Drilling through metal may seem like a daunting task, but with a few simple steps and the right tools, it can be a straightforward process. Whether you’re a DIY enthusiast or a professional, knowing how to drill through metal can come in handy for various projects, such as installing shelves or hanging decorations.

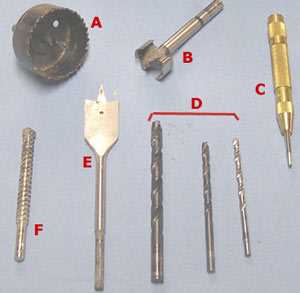

First and foremost, it’s essential to choose the correct drill bit for the metal you’ll be drilling. Different types of metal require different drill bits. For softer metals, such as aluminum or brass, a high-speed steel (HSS) drill bit will suffice. However, for harder metals like stainless steel or cast iron, you’ll need a cobalt drill bit, as it is designed to withstand high temperatures and is more durable.

Once you’ve selected the right drill bit, it’s time to prepare the metal surface for drilling. It’s crucial to secure the metal firmly in place using clamps or a vise grip to prevent it from moving during the drilling process. This will ensure accuracy and safety while drilling.

Next, mark the spot where you want to drill using a center punch. This will create a small indentation on the metal surface, allowing the drill bit to stay in place and prevent it from slipping when you start drilling. Make sure to position the center punch precisely where you want the hole to be.

With your metal secured and the center punch mark in place, it’s time to start drilling. Start at a slow speed and apply constant pressure to the drill. Let the drill bit do the work and avoid excessive force, as it can cause the drill bit to break or the metal to warp. As you drill through the metal, periodically release the pressure to remove any metal shavings and cool down the drill bit. This will help prevent overheating and prolong the life of your drill bit.

Drilling through metal with a hand drill doesn’t have to be complicated. By following these easy steps and taking the necessary precautions, you’ll be able to drill through metal like a pro in no time.

Choose the Right Drill Bit

Choosing the right drill bit is crucial for effectively drilling through metal with a hand drill. Here are some factors to consider when selecting the appropriate drill bit for your project:

1. Material

The type of material you are drilling through will determine the type of drill bit you should use. Common drill bit materials for metal drilling include high-speed steel (HSS) and cobalt steel. HSS drill bits are suitable for drilling through softer metals, while cobalt steel drill bits are better for drilling through harder metals.

2. Size

The size of the hole you need to drill will determine the size of the drill bit required. Drill bits come in various sizes, usually measured in inches or millimeters. Ensure that the size of the drill bit matches the desired hole size.

3. Point Angle

The point angle of the drill bit refers to the angle at the tip of the bit. For drilling through metal, a drill bit with a point angle between 118 degrees and 135 degrees is typically recommended. This angle helps to create an effective cutting edge for metal drilling.

4. Coating

Some drill bits come with special coatings to increase their durability and performance. Titanium nitride (TiN) coating, for example, provides enhanced hardness and reduces friction during drilling. Consider using coated drill bits for better results.

5. Shank

The shank of the drill bit is the section that is inserted into the drill’s chuck. Ensure that the shank size matches the chuck size of your hand drill. Common shank sizes include 1/4-inch, 3/8-inch, and 1/2-inch.

6. Brand and Quality

Choosing drill bits from reputable brands known for their quality can ensure better performance and durability. Brands like Bosch, Dewalt, and Irwin are often recommended for metal drilling.

By considering these factors and choosing the right drill bit, you can achieve accurate and efficient drilling through metal with a hand drill.

Mark the Spot

Before you start drilling into metal, it’s important to mark the spot where you want to drill. This will ensure that you are drilling in the right spot and help you avoid any mistakes. Here are a few steps to follow when marking the spot:

- Clean the surface: Use a clean cloth or paper towel to wipe away any dirt or debris from the area where you plan to drill. This will give you a clear view and make it easier to mark the spot.

- Measure and mark: Use a measuring tape or ruler to determine the exact location where you want to drill. Use a pencil or marker to make a small dot or mark on the surface. Make sure the mark is clear and visible.

- Double-check: Take a moment to step back and double-check your mark. Make sure it is in the right place and aligned correctly. This will help you avoid any drilling errors.

- Protect the surface: If you are drilling into a delicate or finished surface, consider using a piece of scrap wood or a drilling guide to protect it. This will prevent any damage to the surface.

By following these steps, you can ensure that you are accurately marking the spot and drilling in the right place. Taking the time to mark the spot properly will help you achieve better results and avoid any unnecessary mistakes.

Secure the Workpiece

Before you begin drilling through metal, it is important to secure the workpiece in place. This will prevent it from moving or slipping while you are drilling. There are several methods you can use to secure the workpiece:

- Clamps: Use clamps to secure the workpiece to a stable surface, such as a workbench. Make sure the clamps are tight enough to hold the workpiece securely in place.

- Vise: If you have access to a vise, you can use it to hold the workpiece. Place the workpiece between the jaws of the vise and tighten them until the workpiece is held firmly.

- Magnetic base: If the workpiece is made of magnetic material, you can use a magnetic base to secure it. Place the magnetic base on a stable surface and position the workpiece on top of it. The magnetic force will hold the workpiece securely.

- Workbench pegs: Some workbenches have pegs that can be used to secure the workpiece. Simply position the workpiece against the pegs and make sure it is held firmly in place.

Regardless of the method you choose, it is important to ensure that the workpiece is properly secured before you start drilling. This will help to ensure your safety and the accuracy of your drilling.

Apply Lubricant

Applying a lubricant is an important step when drilling through metal with a hand drill. Lubricants help reduce friction and heat buildup, making the drilling process smoother and preventing damage to the drill bit and the metal surface.

There are various types of lubricants that can be used for drilling through metal, including cutting oil, tapping fluid, or even simple household lubricants such as WD-40. Choose a lubricant that is suitable for metal drilling and readily available to you.

Step 1: Prepare the Surface

Before applying the lubricant, make sure the metal surface is clean and free from any debris or rust. Use a cleaning solvent or a wire brush to remove any dirt or rust particles. This will ensure that the lubricant can penetrate the metal surface effectively.

Step 2: Apply the Lubricant

Once the metal surface is clean, apply a small amount of lubricant to the drilling area. You can use a brush or a rag to spread the lubricant evenly. Make sure to cover the entire drilling area and apply a sufficient amount of lubricant. Too much lubricant is better than too little, as it will help keep the drill bit cool and prevent it from overheating.

Step 3: Begin Drilling

After applying the lubricant, you can start drilling. Make sure to use the appropriate drill bit for metal drilling and set your hand drill to the correct speed. The lubricant will help reduce friction, allowing the drill bit to move smoothly through the metal surface. Take breaks every few seconds to reapply the lubricant, especially if you notice any increased resistance or heat buildup.

Remember to always wear protective gear, such as safety glasses and gloves, when drilling through metal. This will help prevent injuries from metal shavings or splinters.

Start Drilling Slowly

When you’re ready to start drilling through the metal, it’s important to begin at a slow speed. This will help you maintain control and prevent the drill bit from slipping or wandering off course. Follow these steps to start drilling slowly:

- Select the appropriate drill bit: Choose a drill bit that is suitable for drilling through metal. The size and type of metal will determine the best bit to use. A high-speed steel (HSS) bit or a cobalt bit are commonly recommended for drilling through metal.

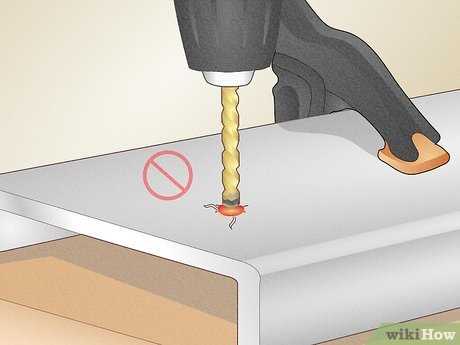

- Secure the metal: Use clamps or a vise to securely hold the metal in place. This will prevent it from moving or vibrating while you drill.

- Mark the drilling spot: Use a marker or center punch to create a small indentation on the metal where you want to drill. This will serve as a guide for the drill bit.

- Position the drill: Hold the drill with both hands and align the bit with the marked spot on the metal.

- Apply steady pressure: Gently apply pressure to the drill and start the motor. Begin drilling at a slow speed, allowing the bit to bite into the metal.

Drilling slowly at the beginning will help you establish a stable drilling path and reduce the risk of damaging the metal or the drill bit. As you gain more experience and confidence, you can gradually increase the drilling speed.

Keep the Drill Steady

Keeping the drill steady is crucial for achieving accurate and clean holes in metal. Here are some tips to help you maintain control and stability while drilling:

- Select the proper drill bit: Choose a drill bit that is suitable for drilling through metal. Using the correct type of bit will facilitate easier drilling and reduce the chances of the drill bit slipping or wandering.

- Secure the workpiece: Clamp or fix the metal piece securely before drilling. This will prevent it from moving or vibrating during the drilling process.

- Mark the drilling spot: Use a marker or punch to mark the exact spot where you want to drill the hole. This will help you guide the drill and keep it on track.

- Apply steady pressure: Apply firm and consistent pressure on the drill while drilling. Avoid pushing too hard or too lightly. Maintaining the right amount of pressure will prevent the drill from slipping and ensure a smoother drilling process.

- Use a low drilling speed: When drilling through metal, it is recommended to use a slower drilling speed. This will give you more control over the drill and minimize the chances of the metal overheating or the drill bit breaking.

- Make pilot holes: For larger holes, it is advisable to start with a smaller pilot hole. This will help guide the drill and prevent it from wandering off track. Once the pilot hole is made, you can then use a larger drill bit to widen the hole.

- Keep the drill perpendicular: Ensure that the drill is held at a 90-degree angle to the surface of the metal. This will help maintain the accuracy of the hole and prevent it from being skewed or angled.

By following these steps and keeping the drill steady, you will be able to drill through metal with ease and precision.

Watch for Metal Chips

When drilling through metal, it is important to watch for metal chips that may be generated during the drilling process. These metal chips can be sharp and can pose a safety hazard if not properly managed.

Here are some tips for handling metal chips:

- Wear safety goggles to protect your eyes from flying metal chips.

- Use a sturdy workbench or surface to drill on, and ensure that it is clear of any flammable materials that can be ignited by hot metal chips.

- Place a piece of scrap wood or a metal working mat underneath the metal being drilled to catch and collect the metal chips.

- If drilling overhead, use a drop cloth or tarp to catch the metal chips and prevent them from falling onto you or your workspace.

- Periodically stop drilling to remove the metal chips from the drill bit. This will help prevent the chips from building up and affecting the drilling performance.

Remember to always prioritize safety when working with metal and take the necessary precautions to prevent injuries caused by metal chips.

Use Safety Precautions

- Wear safety glasses to protect your eyes from flying metal chips.

- Wear a pair of gloves to prevent cuts and burns on your hands.

- Wear ear protection if you are drilling through thick or hard metals, as the process can be noisy.

- Ensure that your work area is well-ventilated to avoid inhaling any metal dust or fumes.

Before drilling:

- Secure the metal firmly in a vise or clamp to prevent it from moving during drilling.

- Double-check the speed settings on your drill to ensure it is appropriate for the type of metal you are drilling through.

During drilling:

- Start drilling at a slow speed, gradually increasing the speed as you penetrate the metal.

- Apply steady and even pressure while drilling to prevent the bit from binding or slipping.

- Periodically withdraw the drill bit to remove metal chips and prevent overheating.

After drilling:

- Carefully inspect the drilled hole to make sure it is clean and free of burrs or sharp edges.

- Remove the metal from the vise or clamp once you have finished drilling.

- Store your tools in a safe and secure location to prevent accidents or damage.

FAQ:

What is a hand drill?

A hand drill is a simple manual tool used to create holes in various materials, including metal.

Is it difficult to drill through metal using a hand drill?

Drilling through metal with a hand drill can be a bit challenging, especially if you don’t have the right technique and tools. However, with the right steps, it can be done easily.

What are the necessary tools and materials needed to drill through metal with a hand drill?

To drill through metal with a hand drill, you will need a hand drill, drill bits suitable for metal, a center punch, a hammer, lubricant (like oil or cutting fluid), clamps (if necessary), and safety goggles.

Can I use a hand drill to drill through thick metal?

Yes, you can use a hand drill to drill through thick metal, but it may require more effort and time. It’s important to choose the appropriate drill bits designed for drilling through thick metal, use a lower speed, and apply sufficient pressure while drilling.