Drilling Techniques for Polycarbonate Sheets

Polycarbonate sheets are widely used in various industries and applications due to their exceptional strength, durability, and transparency. However, drilling holes in polycarbonate can be a tricky task if not done correctly. This article will provide you with essential tips and techniques for drilling holes in polycarbonate sheets.

Firstly, it is important to choose the right type of drill bit for your project. For polycarbonate sheets, it is recommended to use a drill bit specifically designed for plastics. These drill bits have a sharp, pointed tip and fluted edges that allow for smooth and clean cuts. Avoid using standard drill bits, as they can cause cracking, chipping, or melting of the polycarbonate.

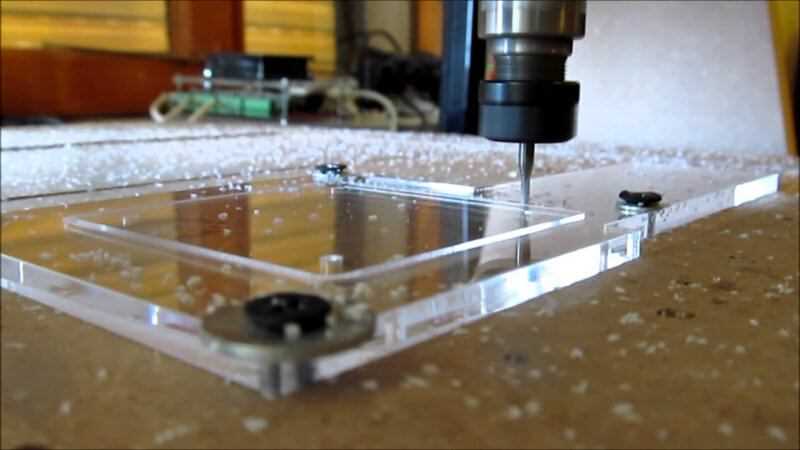

Secondly, it is crucial to secure the polycarbonate sheet firmly before drilling. Use clamps or a vise to hold the sheet in place to prevent it from moving or vibrating during the drilling process. This will help maintain the integrity of the sheet and minimize the risk of cracks or damages.

Next, it is important to start drilling at a low speed to avoid overheating the polycarbonate. Slowly increase the speed as you progress, but be cautious not to apply too much pressure. Applying excessive force can cause the polycarbonate to crack or chip. Instead, let the sharp drill bit do the work while you maintain a steady and controlled drilling motion.

In conclusion, drilling holes in polycarbonate sheets requires careful preparation and execution. By using the right drill bit, securing the sheet firmly, and drilling at a slow and steady pace, you can achieve clean and precise holes without compromising the integrity of the polycarbonate.

What is Polycarbonate?

Polycarbonate is a type of thermoplastic polymer that is known for its durability and impact resistance. It is made from a combination of carbon atoms and oxygen atoms, giving it its unique properties. Polycarbonate sheets are commonly used in various applications, including construction, automotive, and electronics industries.

Polycarbonate has many advantages over other materials. It is lightweight, making it easy to transport and install. It is also highly transparent, allowing for maximum light transmission. In addition, polycarbonate is extremely strong and can withstand high levels of impact without breaking or shattering.

Polycarbonate sheets can be found in a wide range of thicknesses, colors, and textures, making them suitable for various uses. They can be clear, translucent, or opaque, depending on the desired application. Polycarbonate sheets are also available in different finishes, such as smooth, matte, or textured.

One of the key properties of polycarbonate is its ability to be easily drilled. This makes it an ideal material for projects that require holes to be made for fasteners, wiring, or other purposes. Additionally, drilling polycarbonate sheets can be done using several different techniques, depending on the desired results and the equipment available.

Why Use Polycarbonate Sheets?

Polycarbonate sheets have become a popular choice for a wide range of applications due to their unique properties and advantages. Here are some reasons why you should consider using polycarbonate sheets:

Durability and Strength

Polycarbonate sheets are extremely strong and durable, making them an ideal choice for applications that require high impact resistance. They are virtually unbreakable and can withstand extreme weather conditions, making them suitable for outdoor use.

Lightweight

Despite their strength, polycarbonate sheets are lightweight, making them easy to handle and transport. This makes them a convenient option for projects that require materials to be moved frequently.

Transparency

Polycarbonate sheets are highly transparent, allowing for excellent light transmission. This makes them suitable for applications where visibility is important, such as windows, skylights, and greenhouses. Additionally, they have excellent clarity and do not yellow or become cloudy over time.

Thermal Insulation

Polycarbonate sheets have good thermal insulation properties, helping to regulate the temperature and reduce heat loss. This makes them energy-efficient and can contribute to cost savings in heating and cooling.

Versatility

Polycarbonate sheets can be easily shaped, bent, and formed to fit various applications. They can be cut to size, drilled, and joined together using adhesives or fasteners, offering flexibility in design and installation.

UV Protection

Polycarbonate sheets are UV-resistant, protecting against harmful UV rays. This makes them ideal for outdoor applications, as they can withstand prolonged exposure to sunlight without degrading or yellowing.

| Advantages of Polycarbonate Sheets |

|---|

| High impact resistance |

| Lightweight |

| Excellent transparency |

| Good thermal insulation |

| Versatility in design and installation |

| UV protection |

Overall, polycarbonate sheets offer a combination of durability, transparency, insulation, and versatility, making them a reliable choice for various applications. Whether you need to enhance the aesthetics of your space, improve energy efficiency, or ensure safety and security, polycarbonate sheets can meet your requirements.

Importance of Proper Drilling Techniques

When working with polycarbonate sheets, it is important to use proper drilling techniques to ensure accurate and secure installations. Using the wrong drilling techniques can lead to cracking, chipping, and other damage to the material, which can compromise the structural integrity of the project.

1. Preventing Cracks and Chips

One of the main reasons why proper drilling techniques are important when working with polycarbonate sheets is to prevent cracks and chips. Polycarbonate is a brittle material, and drilling without the proper precautions can cause stress concentrations that lead to cracking. By using the correct drilling techniques, you can reduce the risk of cracks and chips, ensuring a clean and smooth installation.

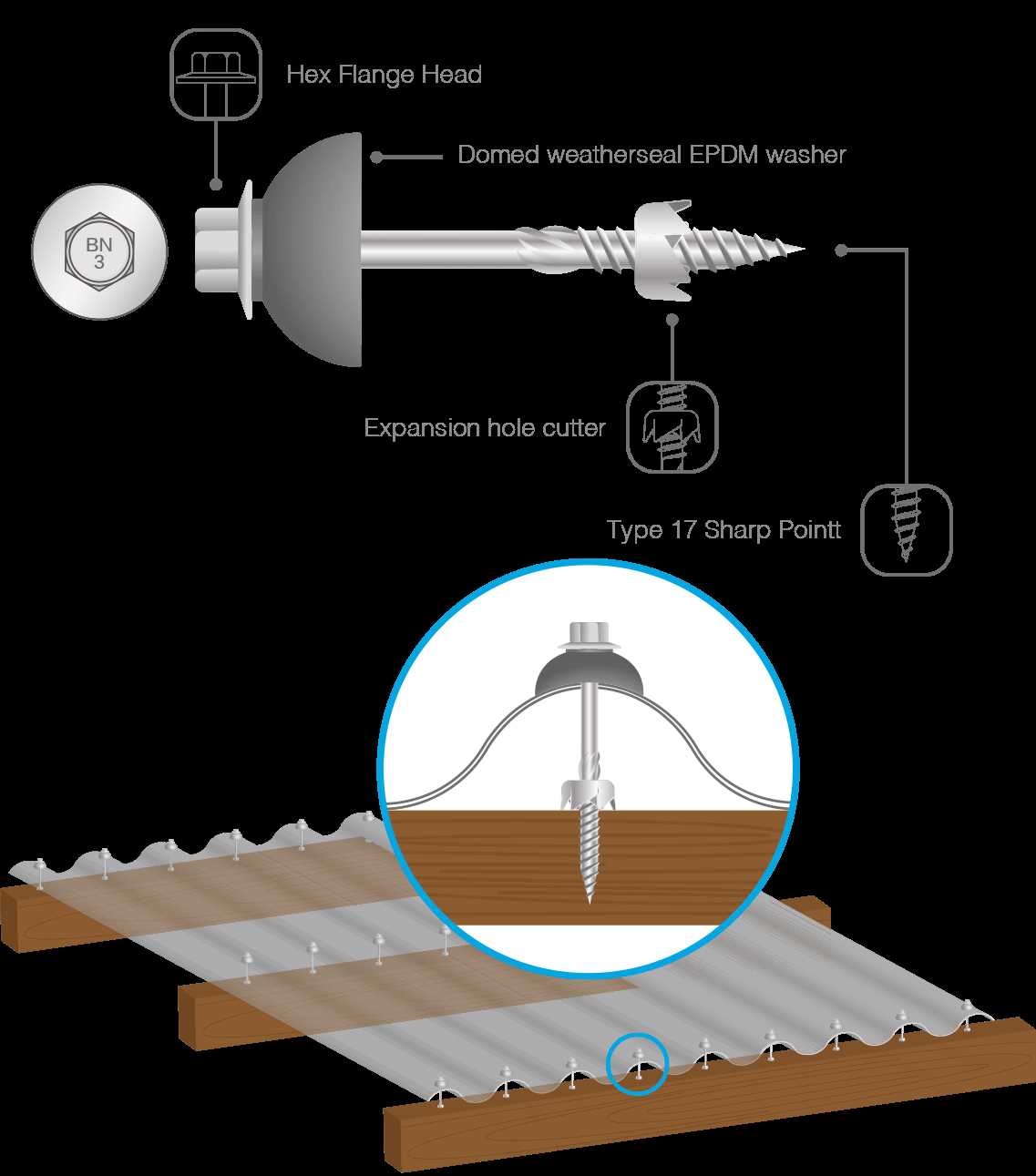

2. Ensuring Secure Installations

In addition to preventing damage to the polycarbonate, proper drilling techniques also help ensure secure installations. Polycarbonate sheets are often used in applications where they need to be securely fastened, such as in construction or signage. Using the correct drilling techniques, including the appropriate drill bit size and speed, can help create the necessary holes for secure fastening.

3. Maintaining Aesthetic Appeal

Proper drilling techniques also help maintain the aesthetic appeal of the polycarbonate installation. When drilling into the material, it is important to avoid leaving visible blemishes or marks. By using the right drill bit and drilling technique, you can create clean and precise holes that do not detract from the overall appearance of the project.

4. Minimizing Material Waste

Using proper drilling techniques can also help minimize material waste. When drilling incorrectly, you may end up with damaged or unusable pieces of polycarbonate. By following the correct drilling techniques, you can reduce the likelihood of waste and maximize the efficiency of your project.

5. Safety Considerations

Lastly, using proper drilling techniques is essential for safety. Polycarbonate sheets can shatter or break if drilled incorrectly, creating sharp edges or flying debris. By using the right techniques and taking the necessary safety precautions, such as wearing protective eyewear and gloves, you can minimize the risk of accidents or injuries.

In conclusion, proper drilling techniques are crucial when working with polycarbonate sheets. They help prevent cracks and chips, ensure secure installations, maintain aesthetic appeal, minimize material waste, and promote safety. By taking the time to learn and apply the correct drilling techniques, you can achieve successful and durable polycarbonate installations.

Preparation

Before drilling polycarbonate sheets, it is important to properly prepare the area and gather the necessary tools and materials. This will help ensure a successful and accurate drilling process. The following steps can be followed to prepare for drilling:

1. Gather the necessary tools and materials:

- Power drill

- Drill bits (specifically designed for plastic or polycarbonate)

- Masking tape

- Ruler or measuring tape

- Marker or pencil

- Clamps or a vice

- Safety glasses

- Dust mask

2. Measure and mark the drilling points:

- Using a ruler or measuring tape, measure and mark the desired drilling points on the polycarbonate sheet. Ensure that the measurements are accurate and evenly spaced.

- For multiple drilling points, it can be helpful to create a template using paper or cardboard to ensure consistency.

- Mark the drilling points with a marker or pencil, making sure the marks are easily visible.

3. Secure the polycarbonate sheet:

- If possible, secure the polycarbonate sheet to a stable work surface using clamps or a vice. This will prevent the sheet from moving during the drilling process and ensure accuracy.

- Alternatively, the sheet can be held firmly by hand, but caution should be taken to avoid any slippage or movement during drilling.

4. Apply masking tape:

- Place a strip of masking tape over the marked drilling points. This will help prevent any cracking or chipping of the polycarbonate during drilling.

- Ensure that the tape is securely adhered to the sheet and covers the entire drilling point.

5. Put on safety gear:

- Before drilling, put on safety glasses to protect your eyes from any debris that may be generated during drilling.

- Consider wearing a dust mask to prevent inhalation of any dust or particles.

Following these preparation steps will help ensure that the drilling process for polycarbonate sheets is successful and results in clean and accurate holes. It is important to take the time to prepare properly to avoid any potential damage or issues.

Using the Right Drill Bit

When drilling holes in polycarbonate sheets, it is essential to use the right drill bit to prevent cracking or damaging the material. Polycarbonate is a durable and flexible plastic, but it can be prone to chipping or splintering if not drilled properly.

There are several types of drill bits available, but not all of them are suitable for drilling polycarbonate sheets. Here are some important factors to consider when choosing the right drill bit:

1. Material

The drill bit should be made of a material that is suitable for drilling plastics. High-speed steel (HSS) or carbide drill bits are recommended for drilling polycarbonate. These materials are harder and more durable than regular steel, and they can withstand the heat generated during the drilling process.

2. Point Angle

The point angle of the drill bit is also important. A drill bit with a 60-degree point angle is usually best for drilling polycarbonate sheets. This point angle helps to reduce the friction and heat generated during drilling, minimizing the risk of cracking or melting the plastic.

3. Flute Design

The flute design of the drill bit determines how it removes the material while drilling. For polycarbonate sheets, a drill bit with a spiral or straight flute design is recommended. These flute designs help to remove the plastic chips efficiently without clogging the bit.

4. Size

The size of the drill bit should match the size of the hole you want to drill. It’s essential to use the appropriate size to ensure accuracy and prevent unnecessary stress on the material. Using a bit that is too large may result in a weakened or cracked hole.

5. Speed and Pressure

When drilling polycarbonate sheets, it’s important to use a slow speed and gentle pressure. Excessive speed or pressure can generate heat and cause the plastic to melt or crack. Take your time and let the drill bit do the work, applying only enough pressure to ensure a smooth and controlled drilling process.

By using the right drill bit and employing proper drilling techniques, you can achieve clean and precise holes in polycarbonate sheets without damaging the material.

Drilling Process

When it comes to drilling polycarbonate sheets, there are a few important considerations to keep in mind. Polycarbonate is a durable and lightweight material, but it can also be quite brittle. This means that proper drilling techniques are essential to prevent cracking or damaging the sheet.

1. Select the right drill bit

Choosing the correct drill bit is crucial for drilling polycarbonate sheets. It is recommended to use a drill bit specifically designed for plastic or a high-speed steel (HSS) drill bit. These types of drill bits are sharp and have a higher speed rating, which helps to reduce the chances of chipping or cracking the material.

2. Secure the sheet

Before drilling, it is important to securely hold the polycarbonate sheet in place to prevent it from moving or vibrating during the drilling process. This can be done by clamping the sheet to a workbench or using a jig to ensure stability.

3. Mark the drilling locations

Using a pencil or marker, mark the drilling locations on the polycarbonate sheet. This will help guide you during the drilling process and ensure accurate placement of the holes.

4. Use low speed and light pressure

When drilling the polycarbonate sheet, it is important to use a low speed setting on your drill and apply light pressure. Excessive speed or pressure can cause the sheet to crack or shatter. Start the drill at a slow speed and gradually increase as needed.

5. Lubricate the drill bit

To reduce heat and friction, it is recommended to lubricate the drill bit with a small amount of cutting oil or water. This will help prevent the drill bit from overheating and reduce the chances of the polycarbonate sheet melting or becoming damaged.

6. Drill in a pecking motion

Instead of drilling continuously, it is best to use a pecking motion when drilling polycarbonate sheets. This involves drilling for a short period, then lifting the drill bit slightly to remove any plastic chips or debris. This technique helps prevent the build-up of heat and reduces the chances of the material cracking.

7. Clean the holes

After drilling, be sure to clean out any plastic chips or debris from the holes. This can be done using a brush or compressed air. Cleaning the holes will ensure a proper fit when installing any screws or fasteners.

By following these drilling techniques, you can successfully drill polycarbonate sheets without causing any damage or cracking. Remember to work slowly and carefully, as the material can be quite delicate. Take your time and ensure the proper tools and techniques are used for a successful drilling process.

Additional Tips and Considerations

1. Choosing the Right Drill Bit

When drilling polycarbonate sheets, it is important to choose the right type of drill bit. A drill bit made of high-speed steel (HSS) or a carbide-tipped one would work best. These types of drill bits are designed to handle the high-speed rotation required for drilling through hard materials like polycarbonate.

2. Smoothing Edges

After drilling holes in a polycarbonate sheet, it is recommended to smooth the edges to prevent any sharp edges that could potentially cause injury. This can be done using sandpaper or a deburring tool. Taking the time to smooth the edges will ensure a safe and professional finish.

3. Work Surface Support

When drilling polycarbonate sheets, it is important to provide proper support to the work surface to prevent cracking or chipping. Placing a sacrificial backing underneath the sheet, such as a scrap piece of wood or a plastic cutting board, will help distribute the drilling force and reduce the risk of damage to the sheet.

4. Proper Clamping

Before drilling, ensure that the polycarbonate sheet is securely clamped to prevent it from moving or vibrating during the drilling process. This will help create clean and accurate holes without any potential slippage. Using clamps or a vice grip can help keep the sheet in place.

5. Start with a Pilot Hole

Starting with a small pilot hole before drilling the final hole size will help reduce the risk of cracking or splitting the polycarbonate sheet. A pilot hole allows for more control and prevents the drill bit from grabbing and causing damage to the sheet. Once the pilot hole is drilled, gradually increase the drill bit size to achieve the desired hole size.

6. Cooling the Drill Bit

During the drilling process, the heat generated can melt the polycarbonate and cause it to stick to the drill bit. To prevent this, it is important to keep the drill bit cool. This can be done by periodically dipping the drill bit in cool water or using a lubricant specifically designed for drilling.

7. Practice on Scrap Material

If you are not familiar with drilling polycarbonate, it is a good idea to practice on a scrap piece of material first. This will allow you to get a feel for the drilling process and make any necessary adjustments before working on the final product.

8. Safety Precautions

Always remember to wear safety glasses or goggles when drilling polycarbonate sheets to protect your eyes from any potential flying debris. Additionally, using a dust mask is highly recommended to avoid inhalation of any small particles that may be produced during the drilling process.

By following these additional tips and considerations, you can ensure a successful drilling process and achieve the desired results when working with polycarbonate sheets.

FAQ:

What are the different drilling techniques for polycarbonate sheets?

There are several drilling techniques for polycarbonate sheets, including standard drilling, step drilling, and pilot hole drilling. Standard drilling involves using a regular drill bit to create a hole directly through the sheet. Step drilling involves using a series of drill bits with increasing diameters to gradually create a larger hole. Pilot hole drilling is when a small hole is first drilled, and then a larger drill bit is used to enlarge the hole to the desired size.

Which drilling technique is best for polycarbonate sheets?

The best drilling technique for polycarbonate sheets depends on the specific application and the desired hole size. In general, standard drilling is the most common method and suitable for most applications. However, for larger holes or when drilling thicker sheets, step drilling or pilot hole drilling may be preferred.

What types of drill bits are recommended for drilling polycarbonate sheets?

When drilling polycarbonate sheets, it is recommended to use drill bits specifically designed for plastics or those with a high-speed steel construction. These types of drill bits are less likely to crack or chip the sheet and provide a clean, smooth hole.

Is it necessary to use lubrication when drilling polycarbonate sheets?

Using lubrication when drilling polycarbonate sheets is not typically necessary. However, if you are drilling through a particularly thick sheet or you are concerned about heat buildup, you can use a small amount of coolant or water as lubrication to keep the drill bit and the sheet cool during the drilling process.

What safety precautions should be taken when drilling polycarbonate sheets?

When drilling polycarbonate sheets, it is important to wear safety goggles or protective eyewear to protect your eyes from flying debris. Additionally, it is recommended to secure the sheet firmly in place to prevent slipping or movement during drilling. Always use proper drilling techniques and take your time to ensure a clean and accurate hole.

Can polycarbonate sheets be drilled without cracking or chipping?

Yes, it is possible to drill polycarbonate sheets without cracking or chipping if you use the proper drilling techniques and tools. Using a drill bit specifically designed for plastics, drilling at a slow speed, and applying consistent pressure will help minimize the risk of cracking or chipping.

What are some common applications for polycarbonate sheets?

Polycarbonate sheets are commonly used in applications such as architectural glazing, greenhouse construction, safety barriers, protective covers, and signage. They are valued for their high impact resistance, excellent optical properties, and versatility.

Video: