Drilling Holes in Sheet Metal: An Easy Step-by-Step Guide

Sheet metal is a versatile material that is commonly used in a variety of projects, from HVAC systems to automotive parts. One of the most common tasks when working with sheet metal is drilling holes. Whether you’re a seasoned professional or a DIY enthusiast, it’s important to know the proper technique for drilling holes in sheet metal to ensure a clean and accurate result.

In this step-by-step guide, we will walk you through the process of drilling holes in sheet metal. We will cover everything from choosing the right drill bit, to marking the hole location, to drilling the hole itself. By following these simple steps, you’ll be able to successfully drill holes in sheet metal and achieve professional-looking results.

First and foremost, it’s essential to choose the right drill bit for the job. When drilling holes in sheet metal, it’s best to use a high-speed steel (HSS) twist drill bit. These bits are specifically designed for drilling through metal and can handle the high speeds and pressures associated with the task. Additionally, it’s important to select a drill bit size that matches the diameter of the hole you want to create.

Once you have the appropriate drill bit, you can begin the process of marking the hole location on the sheet metal. This can be done using a center punch or a sharpie marker. It’s important to mark the spot accurately to ensure that the hole is drilled in the right place. After marking the hole location, you can secure the sheet metal in place using clamps or a vise. This will prevent it from moving or vibrating during the drilling process.

Now it’s time to drill the hole. Start by setting the drill to a low speed and apply light pressure to the sheet metal. This will prevent the drill from slipping and ensure a clean and accurate hole. As you drill, it’s important to keep the drill bit perpendicular to the sheet metal to avoid creating an angled or off-center hole. Gradually increase the drill speed as you progress, but be careful not to go too fast, as this can cause the drill bit to overheat and dull prematurely.

By following these simple steps, drilling holes in sheet metal can be a straightforward and successful task. Remember to choose the right drill bit, accurately mark the hole location, and drill with care and precision. With practice and proper technique, you’ll be able to achieve clean and accurate holes in sheet metal for all your projects.

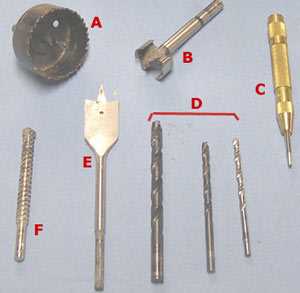

Choose the Right Drill Bit

One of the most important factors to consider when drilling holes in sheet metal is the choice of drill bit. It is crucial to select the right drill bit for the job to ensure clean and precise holes. Here are some factors to consider when choosing a drill bit:

Material

The material of the sheet metal will determine the type of drill bit suitable for the job. For softer metals such as aluminum and copper, high-speed steel (HSS) drill bits are recommended. However, for harder metals like stainless steel or titanium, cobalt or carbide drill bits are preferred as they can withstand the heat generated during drilling.

Size

The size of the hole you need will determine the size of the drill bit to choose. Drill bits are available in various sizes, and it is important to select the right size to achieve the desired hole diameter. Using a drill bit that is too small may result in a hole that is too small, while using a drill bit that is too large can damage the sheet metal or create an imprecise hole.

Flutes

The number of flutes on a drill bit is another factor to consider. Flutes are the spiral grooves on the surface of the drill bit that help remove chips and debris from the hole. Drill bits with more flutes generally provide better chip evacuation and result in cleaner holes, making them suitable for sheet metal drilling.

Coating

Some drill bits come with a coating to enhance their performance and prolong their lifespan. Titanium nitride (TiN) coating, for example, improves the hardness and lubricity of the drill bit, reducing friction and heat buildup. This coating can be beneficial when drilling through tough metals.

In summary, choosing the right drill bit for drilling holes in sheet metal is crucial for achieving clean and precise results. Consider factors such as the material, size, flutes, and coating of the drill bit to ensure optimal performance and longevity.

Mark the Hole Location

Before drilling any holes in the sheet metal, you need to mark the hole location. This step is important to ensure accuracy and avoid mistakes. Here are the steps to follow:

- Carefully measure and mark the desired location for the hole using a measuring tape or ruler. Use a pencil or a marker that can be easily seen on the sheet metal.

- If you are drilling multiple holes, it is a good idea to create a template or marking guide. This can be done by creating a cardboard or paper cutout of the hole pattern or by using a pre-made template.

- Place the template or marking guide on the sheet metal at the desired location. Use clamps or tape to secure it in place.

- Double-check the alignment and position of the template or marking guide to ensure it is exactly where you want the hole to be drilled.

- Use a punch or center punch to create a small indentation in the sheet metal at the center of the marked hole location. This indentation will serve as a guide for drilling and help to prevent the drill bit from wandering.

Once you have marked the hole location and created the indentation, you are ready to proceed with drilling the hole in the sheet metal.

Secure the Sheet Metal

Before you begin drilling holes in the sheet metal, it is important to secure it in place. This will ensure that the metal does not move or shift while you are drilling, which can lead to inaccurate holes or damage to the metal.

There are several methods you can use to secure the sheet metal, depending on the size and shape of the piece. Here are a few options:

- Clamps: If you are working with a small piece of sheet metal, you can use clamps to hold it down. Place the clamps around the edges of the metal, ensuring that it is firmly held in place.

- Vise: For larger pieces of sheet metal, a vise can be used to secure the metal. Place the metal between the jaws of the vise and tighten it to hold the metal in place.

- Tape: Another option is to use double-sided tape or masking tape to hold the metal down. Apply the tape along the edges or corners of the metal, pressing it firmly to create a secure bond.

- Magnetic sheet holders: If your sheet metal is magnetic, you can use magnetic sheet holders to secure it. These holders have magnets built into them, which will hold the metal in place.

Once you have secured the sheet metal, double-check that it is firmly held in place. Make sure there is no movement or wobbling before proceeding with drilling the holes.

Start Drilling

Once you have marked the spot where you want to drill the hole, it’s time to start drilling. Make sure you have the correct drill bit for the size of hole you want to create. Using the wrong drill bit can result in a poor-quality hole or damage to the sheet metal.

Step 1: Put on safety goggles and gloves to protect yourself from any flying debris or sharp edges.

Step 2: Secure the sheet metal in a vice or clamp it down securely to a work surface. This will prevent the metal from moving and help you maintain control over the drilling process.

Step 3: Position the drill bit at a 90-degree angle to the sheet metal surface. This will ensure that the hole is drilled straight and does not become distorted.

Step 4: Apply light pressure to the drill and start drilling at a slow speed. Gradually increase the speed as the drill bit penetrates the metal. Too much pressure or a high speed can cause the drill bit to break or the metal to warp.

Step 5: Keep a steady hand and maintain control over the drill as you continue to drill through the sheet metal. Take breaks if needed to prevent overheating of the drill bit or the metal.

Step 6: Once the drill bit has completely penetrated the metal, retract it slowly and carefully to avoid any damage to the hole or the surrounding area.

Step 7: Inspect the hole to ensure it is clean and smooth. If there are any rough edges or burrs, you can use a deburring tool or sandpaper to smooth them out.

Step 8: Repeat the process for any additional holes you need to drill in the sheet metal.

Remember to always follow safety precautions when drilling in sheet metal and take your time to ensure accurate and clean holes.

Use Proper Technique

When drilling holes in sheet metal, it’s important to use the proper technique to ensure accurate and clean holes. By following these steps, you can achieve professional-looking results:

Materials and Tools Needed

- Sheet metal

- Drill

- Drill bits (appropriate size for the desired hole diameter)

- Clamps or vice

- Center punch

- Ruler or measuring tape

- Protective eyewear and gloves

Step-by-Step Process

- Secure the sheet metal: Clamp the sheet metal securely to a workbench or use a vice to hold it in place. This will prevent it from moving during the drilling process and ensure accuracy.

- Mark the hole location: Use a ruler or measuring tape to mark the exact location where you want to drill the hole. This will help guide your drill bit and ensure proper alignment.

- Create a pilot hole: Before drilling the final hole, it’s a good idea to create a pilot hole using a smaller drill bit. This will help guide the larger drill bit and prevent the sheet metal from being damaged or warped.

- Center punch: Once the pilot hole is created, use a center punch to make a small indentation at the center of the marked hole location. This will provide a starting point for the drill bit and help prevent it from slipping.

- Select the appropriate drill bit: Choose a drill bit that is suitable for the material and desired hole diameter. It’s important to use the proper drill bit to ensure clean and precise holes without damaging the sheet metal.

- Drill the hole: Attach the appropriate drill bit to your drill and position it over the center punch indentation. Apply steady pressure and begin drilling the hole. Take care to maintain a consistent speed and avoid applying excessive force, as this can cause the drill bit to overheat or break.

- Deburr the edges: After drilling the hole, you may notice sharp or jagged edges. To prevent injury and ensure a professional finish, use a deburring tool or a file to smooth out the edges of the hole.

Tips and Precautions

- Wear protective eyewear and gloves to protect yourself from metal chips and sharp edges.

- Always use the appropriate drill bit and ensure it is sharp and in good condition.

- Work slowly and steadily to maintain control and prevent damage to the sheet metal.

- If drilling multiple holes, use a drilling guide or template to ensure consistent spacing and alignment.

- Regularly clean the drill bit to remove metal shavings and prevent clogging or overheating.

By using proper technique and following these guidelines, you can confidently drill holes in sheet metal and achieve professional results. Remember to always prioritize safety and take necessary precautions when working with tools and sharp objects.

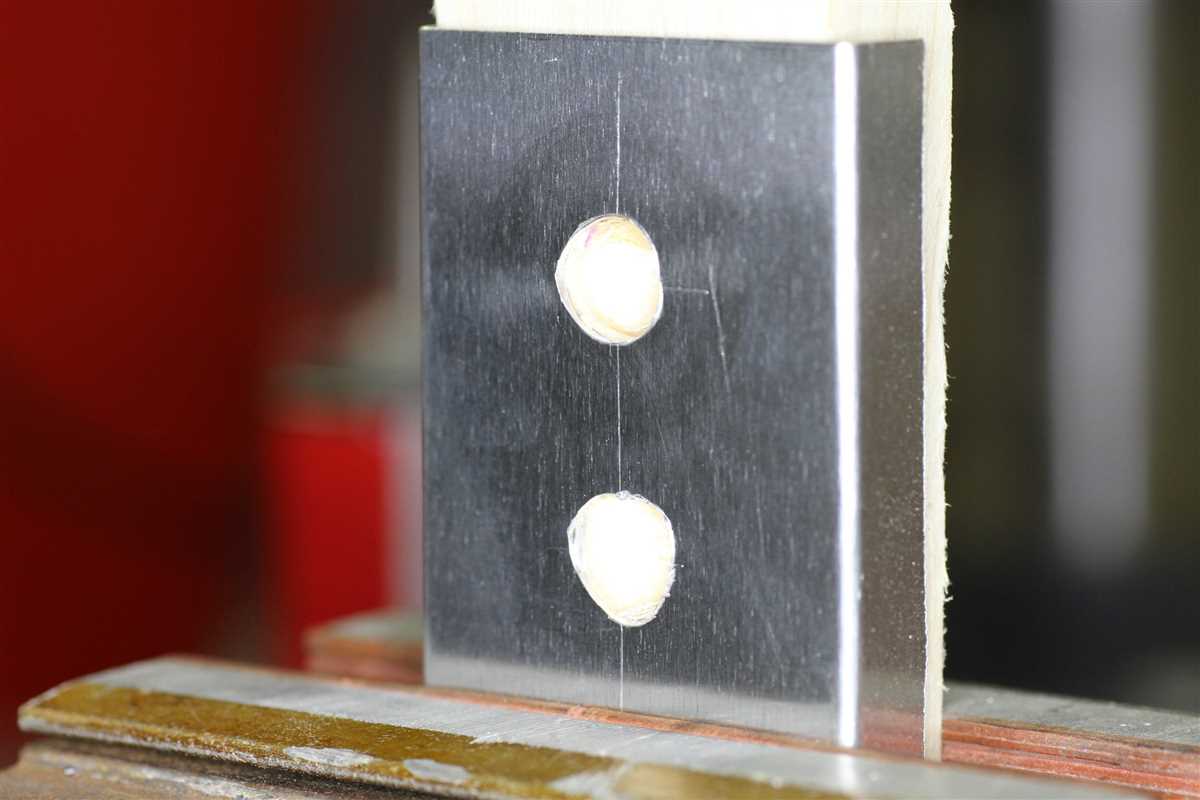

Clean Up the Hole

After drilling the hole, it’s important to clean up any rough edges or burrs that may be left behind. This will not only improve the appearance of the hole but also prevent any injuries or damage to the surrounding material.

Materials needed:

- Deburring tool

- Sandpaper or file

- Safety goggles

- Put on safety goggles to protect your eyes.

- Inspect the drilled hole for any rough edges or burrs.

- If visible, use a deburring tool to remove any burrs. Simply insert the deburring tool into the hole and rotate it in a circular motion to smooth out the edges.

- If the hole still has rough edges, gently sand it with sandpaper or file until it becomes smooth.

- Once you are satisfied with the smoothness of the hole, clean up any debris or metal shavings that may be left behind.

- Inspect the hole once again to ensure that it is clean and free from any burrs or rough edges.

- Material Type: Before drilling holes in sheet metal, it is important to consider the type of material you are working with. Different materials have different levels of hardness and thickness, which can affect the drilling process. For example, drilling through aluminum sheet metal may require a different approach compared to drilling through stainless steel sheet metal. Make sure to use the appropriate tools and techniques for the specific type of material you are working with.

- Drill Bit Selection: The choice of drill bit is crucial when drilling holes in sheet metal. It is recommended to use a drill bit specifically designed for sheet metal, such as a cobalt drill bit or a step drill bit. These types of drill bits are designed to cut through metal efficiently and prevent the metal from becoming too hot. Avoid using regular twist drill bits, as they may not perform as well and can easily break or dull.

- Drill Speed: The speed at which you run the drill can have a big impact on the drilling process. When drilling through sheet metal, it is generally recommended to use a slower drill speed. This helps to prevent the metal from heating up too quickly, which can cause it to warp or distort. Start with a lower drill speed and gradually increase if necessary, while always monitoring the temperature of the metal.

- Pilot Holes: For larger holes or thicker sheet metal, it can be helpful to create pilot holes before drilling the final hole. A pilot hole is a smaller hole that serves as a guide for the drill bit. This helps to prevent the drill bit from slipping and provides more stability during the drilling process. It is important to use an appropriate-sized drill bit for the pilot hole, as using a drill bit that is too small or too large can lead to issues.

- Clamping: To ensure accuracy and safety, it is recommended to clamp the sheet metal securely before drilling. This helps to prevent the sheet metal from moving or vibrating during the drilling process, which can cause the drill bit to wander or damage the metal. Use a suitable clamp or vise to hold the sheet metal firmly in place before drilling.

- Deburring: After drilling the holes in the sheet metal, it is important to remove any burrs or sharp edges that may have been created. Burrs can be sharp and can pose a safety hazard, as well as affect the overall appearance of the finished project. Use a deburring tool or a file to smooth out the edges and ensure a clean finish.

- Safety Precautions: Always prioritize safety when working with sheet metal and power tools. Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself from metal shavings and other potential hazards. Additionally, make sure to work in a well-ventilated area to avoid inhaling any harmful fumes that may be produced during the drilling process.

Instructions:

Note: It is important to be cautious and wear safety goggles throughout the cleaning process to protect your eyes from any flying debris. Additionally, make sure to use the appropriate tools and techniques for cleaning up the hole, depending on the type of sheet metal and the size of the hole.

Additional Considerations

By taking these additional considerations into account, you can ensure a successful and efficient drilling process when working with sheet metal.

FAQ:

What tools do I need for drilling holes in sheet metal?

You will need a drill, drill bits suitable for metal, a center punch, and safety equipment like ear protection and safety glasses.

What is the best way to mark the holes on the sheet metal before drilling?

The best way is to use a center punch to create a small indentation at the center of the hole, which will help guide the drill bit.

How do I choose the right size drill bit for the hole I want to drill?

To choose the right size drill bit, you should measure the diameter of the hole you want to drill and select a drill bit that matches or is slightly larger than that size.

Can I use a regular drill for drilling holes in sheet metal?

Yes, you can use a regular drill for drilling holes in sheet metal. However, it is important to use the appropriate drill bits for metal and adjust the drill speed accordingly to avoid damaging the metal.

Do I need to use lubrication when drilling holes in sheet metal?

Using lubrication can help reduce friction and heat buildup while drilling. It is recommended to use a cutting fluid or drilling oil to ensure smooth and efficient drilling.

Video: