Drilling for Oil: A Comprehensive Guide

Drilling for oil is a complex and essential process that involves extracting crude oil from the Earth’s surface. This comprehensive guide will provide you with an in-depth understanding of the drilling process, from the initial exploration to the extraction of oil reserves.

Exploration

The first step in drilling for oil is exploration. Geologists and engineers analyze various data, such as seismic surveys and well logs, to identify potential oil reservoirs. Once a suitable location is identified, the drilling process begins.

Well Construction

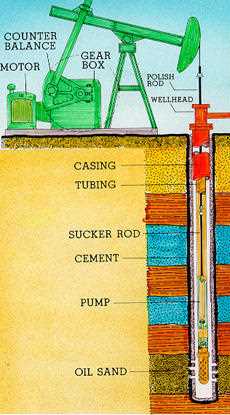

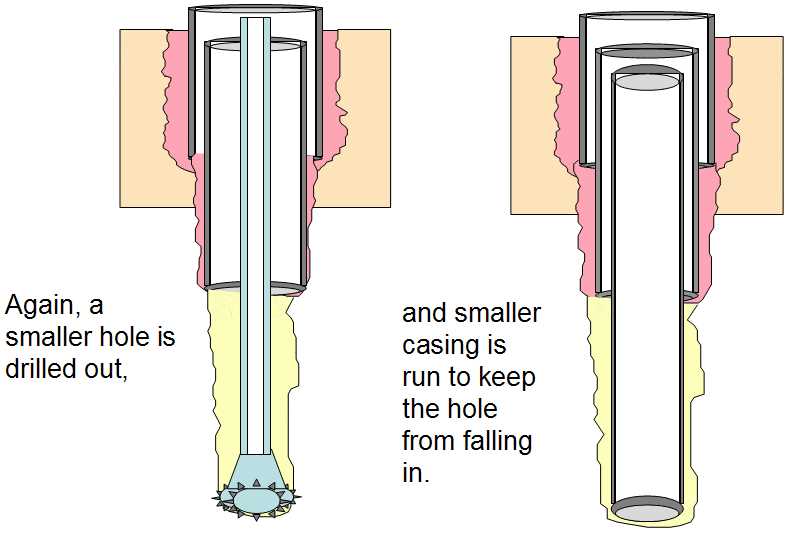

Well construction involves drilling a hole into the ground using a drill bit attached to a drilling rig. The drill bit is equipped with cutting teeth that break through rocks, allowing for deeper penetration. As the drill goes deeper, pipe sections, known as casing, are inserted and cemented into the wellbore to prevent collapse and maintain well integrity.

The drilling process is a combination of art and science. It requires skilled operators and sophisticated equipment to ensure safe and efficient drilling operations.

The Importance of Drilling for Oil

Drilling for oil plays a crucial role in meeting the world’s energy demands. Oil is a vital resource that fuels transportation, powers industries, and provides the raw materials needed for many everyday products. Without oil, the global economy would grind to a halt, as it is a primary source of energy for various sectors.

1. Energy Production

Oil drilling is an essential activity to extract crude oil, which serves as a major fuel source for electricity generation. Power plants use oil to generate electricity, especially in regions where alternative energy sources are limited or not yet fully developed. Oil-based energy production ensures a stable power supply and supports economic growth.

2. Transportation

Transportation heavily relies on oil as a fuel source. Cars, buses, trucks, and airplanes all require oil-based fuels, such as gasoline and jet fuel, to operate efficiently. Drilling for oil ensures the availability of these fuels, keeping transportation systems functional and enabling the movement of goods and people worldwide.

3. Industrial Applications

Oil is used as a raw material in various industrial processes. It serves as a feedstock for petrochemicals, which are essential in the production of plastics, synthetic fibers, detergents, and pharmaceuticals. Drilling for oil ensures a steady supply of these raw materials, supporting manufacturing industries and providing crucial components for many consumer products.

4. Economic Impact

The oil industry has a significant economic impact, generating job opportunities, tax revenue, and foreign exchange earnings. Drilling for oil creates employment in exploration, extraction, refining, and distribution sectors. Additionally, oil exports contribute to a country’s revenue and help in maintaining a favorable trade balance.

5. Energy Security

With oil being a globally traded commodity, drilling for oil enhances a country’s energy security. It reduces dependence on foreign oil imports and minimizes vulnerability to supply disruptions. By developing domestic oil resources, countries can ensure a stable energy supply, reducing the risk of economic instability caused by fluctuations in oil prices or geopolitical tensions.

Conclusion

Drilling for oil is of utmost importance due to its role in energy production, transportation, industrial applications, economic impact, and energy security. It fuels our world and supports economic growth while playing a significant role in maintaining a stable and prosperous global society.

Exploring Oil Reserves

Exploring oil reserves is a crucial step in the process of drilling for oil. It involves various techniques and technologies to identify potential oil deposits underground. This exploration phase helps oil companies determine whether a site is worth drilling and investing in.

1. Seismic Surveys

One of the most common methods used in exploring oil reserves is seismic surveys. This technique involves sending sound waves into the ground and measuring the reflections to create a detailed image of the subsurface geology. By analyzing these images, geophysicists can identify potential oil-bearing formations.

2. Gravity and Magnetic Surveys

Gravity and magnetic surveys are another type of exploration method used to locate oil reserves. These surveys measure variations in gravity and magnetic fields to identify areas where oil may be present. Oil reservoirs often have distinctive gravitational and magnetic anomalies due to the density of the rock formations and the presence of hydrocarbons.

3. Geochemical Analysis

Geochemical analysis involves collecting and analyzing surface samples, such as soil, rock, and water, to detect traces of hydrocarbons. This method can help determine the existence of oil reservoirs in a particular area based on the presence of certain chemical compounds associated with oil and gas deposits.

4. Remote Sensing

Remote sensing techniques, such as satellite imagery and aerial surveys, are used to gather data about the Earth’s surface without physical contact. These methods can help identify potential oil reserves by detecting surface features associated with petroleum formations, such as oil seepages or structural indicators.

5. Well Logging

Well logging is a technique that involves lowering instruments into a drilled well to measure various parameters, such as rock properties, fluid content, and pressure. These measurements can provide valuable information about the presence and characteristics of oil reservoirs, helping oil companies assess the potential productivity of a well.

6. Exploratory Drilling

Once potential oil reserves have been identified through the exploration phase, exploratory drilling is conducted. This involves drilling a test well to confirm the presence of oil and evaluate the reservoir’s size and productivity. If the results are promising, additional drilling may be pursued to fully exploit the oil reserves.

Overall, exploring oil reserves requires a comprehensive approach that combines different techniques and technologies. The data gathered during the exploration phase plays a vital role in the decision-making process for oil companies, helping them determine whether to invest in drilling operations and potentially extract valuable oil resources.

The Drilling Process: Preparations and Equipment

1. Preparations

Prior to starting the drilling process, thorough preparations must be made to ensure a safe and efficient operation. These preparations typically include:

- Site Survey: A comprehensive survey of the drilling location is conducted to assess potential hazards, geological formations, and other important factors. This information helps in determining the drilling technique and equipment required.

- Permitting: Obtaining the necessary permits from regulatory bodies is a crucial step before commencing drilling operations. Failing to do so can result in legal and financial penalties.

- Clearing the Area: The drilling site needs to be cleared of any structures, obstacles, or vegetation that may hinder the drilling process. Additionally, adequate space should be available for setting up drilling rigs and equipment.

- Erosion Control: Measures are put in place to prevent soil erosion from occurring during the drilling process. This may involve using erosion control methods such as gravel or geotextile fabrics.

- Environmental Protection: Precautions are taken to minimize the impact of drilling on the environment. This includes setting up containment measures to collect any potential spills or leaks.

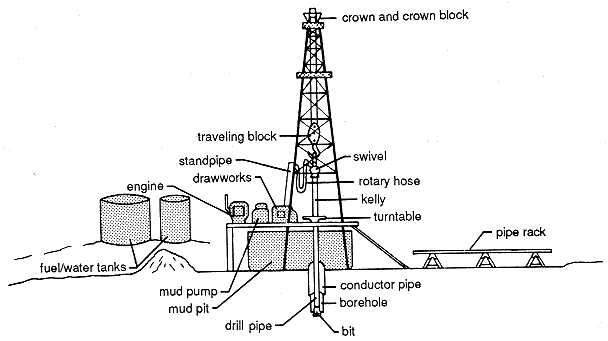

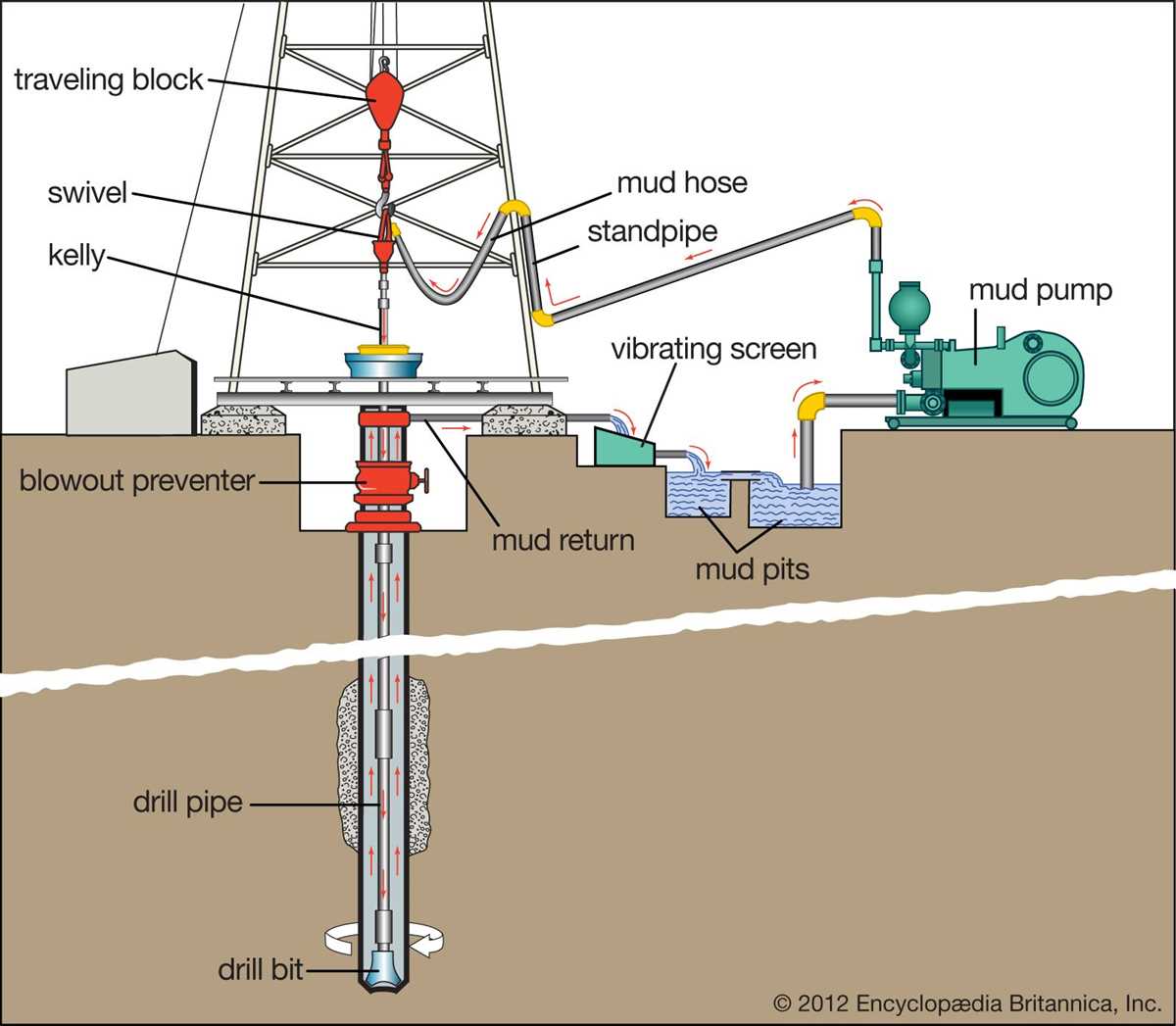

2. Equipment

The drilling process requires specialized equipment to enable effective and safe drilling. Some of the key equipment used in drilling operations are:

- Drilling Rigs: These are large machines used to create boreholes in the earth’s surface. They provide the necessary power and stability to drill into the ground.

- Drill Bits: These are the cutting tools attached to the end of the drill string. They come in various designs and materials, depending on the type of rock or formation being drilled.

- Mud Pump: The mud pump circulates drilling fluid (commonly referred to as “mud”) through the drill pipe and bit. This helps cool the bit, remove cuttings, and provide pressure to control formation pressures.

- BOP (Blowout Preventer): A BOP is a critical safety device used to control the wellbore pressure and prevent blowouts during the drilling process. It consists of several valves and rams that isolate the well in case of emergencies.

- Rotary Table: The rotary table is responsible for rotating the drill string, thus facilitating the drilling process. It is controlled by the drilling crew and enables the drill bit to penetrate the rock.

- Wellhead: The wellhead is installed at the surface of the well and serves as the main point of control for the flow of oil or gas. It includes valves, fittings, and other components necessary for managing the well.

These are just a few examples of the equipment used in the drilling process. The specific equipment required may vary depending on the location, depth, and purpose of the drilling operation.

Offshore vs Onshore Drilling: Pros and Cons

Offshore Drilling

- Pros:

- Access to larger oil reserves: Offshore drilling allows access to oil reserves that are not available on land. This can potentially lead to larger yields and increased energy production.

- Reduced environmental impact on land: Since drilling takes place away from populated areas, offshore drilling can help prevent the disruption of ecosystems and minimize the impact on wildlife compared to onshore drilling.

- Job creation and economic benefits: Offshore drilling projects require a significant workforce, which can stimulate employment opportunities in coastal regions and contribute to local economies.

- Technological advancements: Offshore drilling pushes for technological advancements in drilling equipment and techniques, leading to improved safety measures and more efficient extraction methods.

- Cons:

- Environmental risks: Offshore drilling poses risks to marine life and coastal habitats. Spills, leaks, and accidents can lead to oil pollution, which can be challenging to contain and clean up.

- High initial costs: Offshore drilling projects are generally costlier to develop due to the need for specialized equipment, infrastructure, and logistics.

- Harsh working conditions: Working offshore can be physically demanding and hazardous. Employees must endure long shifts, rough seas, and challenging weather conditions.

Onshore Drilling

- Pros:

- Lower development costs: Onshore drilling projects generally have lower initial costs as they do not require offshore-specific infrastructure and equipment.

- Easier access to equipment and manpower: Onshore drilling is more accessible, making it easier to transport equipment and materials and hire additional manpower if needed.

- Reduced risks to marine life: Onshore drilling reduces the immediate risks to marine life and ecosystems compared to offshore drilling.

- Local job creation and economic benefits: Onshore drilling can create employment opportunities and contribute to local economies, especially in regions with existing oilfields.

- Cons:

- Land and environmental disruption: Onshore drilling can lead to disruption of land, habitats, and ecosystems. It may require clearing vegetation, building access roads, and installing pipelines, potentially affecting wildlife and natural resources.

- Population and infrastructure challenges: Onshore drilling near populated areas can result in increased noise, traffic, and temporary population influxes, straining local infrastructure and resources.

- Potential groundwater pollution: Onshore drilling activities carry the risk of groundwater contamination if proper precautions are not taken to prevent the leakage or spills of drilling fluids.

Conclusion

Both offshore and onshore drilling have their advantages and disadvantages. Offshore drilling offers access to larger oil reserves and reduced environmental impact on land, but it carries the risk of environmental disasters and higher costs. On the other hand, onshore drilling has lower development costs and reduced risks to marine life but can disrupt land and local communities.

The choice between offshore and onshore drilling ultimately depends on various factors, including environmental considerations, the potential size of oil reserves, available infrastructure, and the economic viability of the project.

Environmental Impact of Drilling Operations

1. Air Pollution

Drilling operations can release various air pollutants, including volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. These pollutants can contribute to air pollution and have adverse effects on human health and the environment.

2. Water Contamination

Drilling activities can lead to water contamination through the leakage or accidental release of drilling fluids, hydraulic fracturing fluids, and produced water. These fluids can contain chemicals, heavy metals, and naturally occurring radioactive materials, which can contaminate groundwater and surface water sources.

3. Noise Pollution

Drilling operations can generate significant noise levels, which can have adverse effects on nearby communities and wildlife. Prolonged exposure to high levels of noise can disrupt wildlife habitats, interfere with communication and mating patterns, and negatively impact the well-being of humans living or working in the vicinity.

4. Habitat Destruction

Drilling operations often require clearing vegetation and leveling the land, which can result in habitat destruction. This can lead to the displacement or loss of wildlife species, disruption of ecosystems, and reduced biodiversity in the affected areas.

5. Spills and Accidents

Drilling operations carry the risk of spills and accidents, which can result in the release of oil, drilling fluids, or other hazardous substances into the environment. Such incidents can cause immediate and long-term harm to ecosystems, wildlife, and surrounding communities.

6. Induced Seismicity

Certain drilling techniques, such as hydraulic fracturing, can induce earthquakes or increase seismic activity in the vicinity of the drilling site. These man-made earthquakes can pose risks to infrastructure, water sources, and the stability of the surrounding areas.

7. Greenhouse Gas Emissions

Drilling operations contribute to greenhouse gas emissions, primarily through the release of methane, a potent greenhouse gas, during the extraction and transport of natural gas. Methane leaks can occur during drilling, well completion, and infrastructure operations, exacerbating climate change.

8. Land Disturbance

Drilling activities require the construction of well pads, access roads, and other infrastructure, resulting in land disturbance and fragmentation. This can lead to the loss of prime agricultural land, disruption of natural landscapes, and degradation of soil quality.

9. Wildlife Impacts

Drilling operations can disrupt wildlife migration patterns, breeding habits, and overall populations. Noise pollution, habitat destruction, and the introduction of hazardous substances can have detrimental effects on wildlife species, leading to declines in populations and ecological imbalances.

10. Cumulative Impacts

The cumulative impacts of multiple drilling operations in a region can have compounding effects on the environment. This includes increased air and water pollution, habitat fragmentation, and the degradation of natural resources, making it crucial to consider the cumulative effects when assessing the overall environmental impact of drilling operations.

In conclusion, drilling operations have various environmental impacts, including air and water pollution, noise pollution, habitat destruction, spills and accidents, induced seismicity, greenhouse gas emissions, land disturbance, wildlife impacts, and cumulative effects. It is important for the industry to adopt best practices and technologies to minimize these impacts and promote sustainable drilling practices.

Safety Measures in Oil Drilling

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is crucial in oil drilling to protect workers from potential hazards. PPE includes hard hats, safety glasses, gloves, and steel-toed boots. These items help prevent head injuries from falling objects, eye injuries from flying debris, hand injuries from sharp objects, and foot injuries from heavy equipment or chemical spills.

Well Control

Ensuring well control is a critical safety measure in oil drilling. Well control refers to the methods and equipment used to prevent the uncontrolled release of oil or gas from a well. This involves maintaining proper drilling fluid pressure and controlling the flow of reservoir fluids to prevent blowouts. Regular testing and maintenance of well control equipment are essential to prevent accidents and protect the well and surrounding environment.

Fire Safety

Fire safety is of utmost importance in oil drilling operations. Fires can occur due to equipment malfunctions, electrical issues, or the ignition of flammable materials. The installation and maintenance of fire prevention and suppression systems, such as fire extinguishers and sprinkler systems, are essential. Adequate training for workers on fire safety protocols and emergency evacuation procedures is also crucial.

Fall Protection

Fall protection measures are essential to prevent workers from falling from elevated platforms or into excavations during oil drilling activities. Safety harnesses, guardrails, safety nets, and personal fall arrest systems are commonly used fall protection equipment. Regular inspection and maintenance of these systems are necessary to ensure their effectiveness.

Hazard Communication

Clear and effective communication regarding potential hazards in the workplace is vital for maintaining safety in oil drilling operations. Hazard communication programs should be in place, including labeling of hazardous materials, safety data sheets, and training on the proper handling and storage of hazardous substances. Workers should also have access to information on emergency response procedures in case of an incident.

Noise Control

The drilling process can produce significant noise levels that can cause hearing damage to workers. Implementing noise control measures, such as the use of earplugs or earmuffs, can help protect workers from excessive noise exposure. Regular monitoring of noise levels and providing appropriate hearing protection devices are vital to prevent long-term hearing loss.

Regular Safety Training

Oil drilling workers should receive regular safety training to stay updated on industry best practices and safety protocols. Training programs should cover topics such as hazard identification and mitigation, emergency response procedures, first aid, and the proper use of safety equipment. Regular safety drills and exercises should also be conducted to ensure workers are prepared for potential emergencies.

Emergency Response Plans

Oil drilling operations should have comprehensive emergency response plans in place to address potential incidents. These plans should include evacuation procedures, communication strategies, medical assistance protocols, and coordination with local emergency services. Regular drills and simulations should be conducted to test the effectiveness of the emergency response plans and identify areas for improvement.

Safety Inspections

Regular safety inspections should be conducted at oil drilling sites to identify potential hazards and ensure compliance with safety regulations. These inspections should cover equipment inspections, hazard identification, and adherence to safety protocols. Findings from safety inspections should be promptly addressed to prevent accidents and promote a safe working environment.

Continuous Improvement and Learning Culture

Creating a culture of continuous improvement and learning is crucial for maintaining safety in oil drilling operations. Encouraging workers to report near misses, incidents, and potential hazards helps identify areas for improvement and prevent future accidents. Regular safety meetings, feedback sessions, and training programs can foster a proactive approach to safety and create a positive safety culture in the workplace.

Drilling Techniques: Rotary vs Wireline Drilling

When it comes to drilling for oil, two main techniques are commonly used: rotary drilling and wireline drilling. Each technique has its own advantages and disadvantages, and understanding the differences between them is essential for successful drilling operations.

Rotary Drilling

Rotary drilling is the most common drilling technique used in the oil and gas industry. It involves the use of a rotating drill bit to create a hole in the earth’s surface. The drill bit is powered by a rotary table which is turned by a drilling rig. This rotation generates the necessary force to penetrate the ground and extract the oil or gas.

- Advantages of rotary drilling:

- Efficiency: Rotary drilling is a fast and efficient method of drilling. It allows for rapid penetration of the ground, enabling operators to reach the target depth quickly.

- Versatility: Rotary drilling can be used in a variety of geological formations, making it a versatile technique for oil and gas exploration.

- Cost-effective: Rotary drilling is generally less expensive than other drilling techniques, making it an attractive option for operators on a tight budget.

- Disadvantages of rotary drilling:

- Environmental impact: The use of rotary drilling can cause environmental damage, including habitat disruption and water pollution.

- Drilling fluid management: Proper management of drilling fluids is crucial in rotary drilling to prevent contamination and ensure smooth operation.

Wireline Drilling

Wireline drilling is a more specialized technique used for specific drilling applications. It involves the use of a steel cable, or wireline, to lower a drilling tool into the borehole. Unlike rotary drilling, the drill bit does not rotate, but rather relies on mechanical or hydraulic force to penetrate the ground.

- Advantages of wireline drilling:

- Precision: Wireline drilling allows for precise control of the drilling tool, making it ideal for applications that require accurate measurements and sampling.

- Efficiency in deep drilling: Wireline drilling is often used for deep drilling projects where conventional rotary drilling is not feasible.

- Disadvantages of wireline drilling:

- Limited speed: Wireline drilling is generally slower compared to rotary drilling, which can impact drilling productivity.

- Higher costs: Wireline drilling can be more expensive due to the specialized equipment and expertise required.

Both rotary drilling and wireline drilling have their place in the oil and gas industry. The choice of technique depends on various factors such as the geological formation, project requirements, and budget constraints. By understanding the differences between these drilling techniques, operators can make informed decisions and optimize drilling operations for maximum productivity and efficiency.

Extracting and Refining Crude Oil

Introduction

Crude oil, also known as petroleum, is a natural resource that is formed over millions of years from the remains of plants and animals. It is a complex mixture of hydrocarbons, which makes it the primary source of energy for many industries and transportation systems.

Exploration and Extraction

The process of extracting crude oil begins with exploration, which involves searching for potential oil reserves using seismic surveys and drilling wells. Once a promising site is identified, drilling rigs are used to penetrate the earth’s surface, reaching the oil reservoirs deep underground.

There are two main methods for extracting crude oil: onshore drilling and offshore drilling. Onshore drilling involves drilling wells on land, while offshore drilling involves drilling wells in bodies of water, such as oceans or lakes. Offshore drilling is often more challenging and expensive due to the additional logistics required.

Production and Transportation

Once the crude oil is extracted from the reservoir, it needs to be processed before it can be used. This involves removing impurities and separating it into different components such as gasoline, diesel, and jet fuel.

The transportation of crude oil is crucial to supply the global demand. It is typically transported through pipelines, ships, or trains, depending on the location and quantity of oil. Pipelines are the most common method of transportation, as they are cost-effective and can transport large volumes of oil over long distances.

Refining and Petrochemicals

Refining is the process of converting crude oil into various petroleum products through distillation and other refining techniques. The crude oil is heated and separated into different fractions based on their boiling points. These fractions are then processed further to create gasoline, diesel, jet fuel, lubricants, and other petroleum products.

Besides fuel production, crude oil is also an essential feedstock for the petrochemical industry. Petrochemicals are used to produce various chemicals, plastics, fertilizers, and synthetic materials that are integral to various industries and consumer products.

Environmental Impact

The extraction and refining of crude oil have significant environmental impacts. Drilling operations can result in habitat destruction, water pollution, and the release of greenhouse gases. The burning of petroleum products also contributes to air pollution and climate change.

To mitigate these impacts, regulations and technologies are continuously being developed to minimize emissions, reduce the environmental footprint, and promote more sustainable practices in the oil industry.

Future Trends in Oil Drilling Technologies

1. Automated Drilling Systems

One of the future trends in oil drilling technologies is the development of automated drilling systems. These systems use advanced sensors and artificial intelligence to control and optimize drilling operations. Automated drilling systems can improve efficiency and safety by reducing the need for human intervention and by optimizing drilling parameters in real time.

2. Extended Reach Drilling

Extended reach drilling (ERD) is another emerging trend in oil drilling technologies. ERD involves drilling wells with longer horizontal sections, allowing for access to more reservoirs from a single drilling platform. This technique can increase productivity and reduce costs by minimizing the number of drilling platforms required.

3. Directional Drilling

Directional drilling is another future trend in oil drilling technologies. This technique involves drilling wells at angles or curves, allowing for better access to the reservoir and maximized oil recovery. Directional drilling can increase the overall productivity of an oil field by reaching reservoirs that cannot be accessed with vertical drilling techniques.

4. Managed Pressure Drilling

Managed pressure drilling (MPD) is an innovative technology that enables precise control of wellbore pressure during drilling operations. This technique allows for drilling in challenging environments, such as high-pressure reservoirs, without the risk of wellbore instability. MPD can improve safety and efficiency by reducing non-productive time and minimizing well control issues.

5. Intelligent Completion Systems

Intelligent completion systems involve the installation of sensors and control devices in the completion assembly of a well. These systems provide real-time monitoring and control of well production, allowing for optimization of production rates and reservoir management. Intelligent completion systems can increase oil recovery and reduce maintenance costs.

6. Environmentally Friendly Drilling

In the future, there will be an increasing emphasis on environmentally friendly drilling technologies. This includes the use of advanced drilling fluids that are less harmful to the environment, as well as the implementation of technologies to reduce emissions and waste generated during drilling operations. Environmentally friendly drilling technologies aim to reduce the impact of oil drilling on the environment.

7. Data Analytics and Machine Learning

Data analytics and machine learning technologies will play a significant role in the future of oil drilling. These technologies can analyze large volumes of drilling data to identify patterns and optimize drilling operations. By using machine learning algorithms, drilling engineers can make more informed decisions that can improve drilling efficiency and reduce costs.

8. Remote Monitoring and Control

Remote monitoring and control technologies will become increasingly important in the future of oil drilling. These systems allow for real-time monitoring and control of drilling operations from a remote location. This can improve safety and efficiency by reducing the need for personnel on site and allowing for prompt response to drilling issues.

9. Advanced Drill Bits and Tools

Advancements in drill bit and drilling tool technologies are anticipated in the future. These advancements can include the development of more durable and efficient drill bits, as well as the introduction of new technologies, such as electromagnetic drilling. Improvements in drill bits and tools can enhance drilling performance and reduce equipment failure.

10. Deepwater and Arctic Drilling

As oil reserves in conventional onshore locations diminish, there will be a greater focus on deepwater and arctic drilling. These environments present unique challenges, such as extreme temperatures and high pressures. Future trends in oil drilling technologies will include the development of specialized equipment and techniques to overcome these challenges.

FAQ:

What is oil drilling?

Oil drilling is the process of extracting crude oil from underground reservoirs.

How is oil drilling done?

Oil drilling is done by creating a wellbore in the ground and then using various methods and equipment to extract the oil from the reservoir.

What are the different types of oil drilling?

There are several types of oil drilling, including onshore drilling, offshore drilling, and directional drilling.

What are the environmental impacts of oil drilling?

Oil drilling can have significant environmental impacts, such as the potential for oil spills, air and water pollution, and habitat destruction.

Video: