Drill Press Laser: Is It Really a Joke?

When it comes to drilling precision holes, many craftsmen rely on a tool called a drill press. This powerful device allows for accuracy and control that cannot be achieved with a handheld drill. However, some drill press users have discovered an interesting addition to their tool – a laser. But is the drill press laser really a useful tool or just a mere gimmick?

Proponents of the drill press laser argue that it adds a new level of precision to an already accurate tool. By projecting a laser beam onto the workpiece, users can easily see where the drill will make contact, ensuring that the hole is drilled in the desired location. This feature is especially helpful when working with intricate designs or tight spaces where even the slightest deviation can ruin the project.

On the other hand, skeptics challenge the usefulness of the drill press laser. They argue that experienced craftsmen can drill accurately without the assistance of a laser, rendering it unnecessary. They also point out that the laser can cause distractions and hinder the user’s focus on other important aspects of the drilling process, such as speed and pressure.

In conclusion, the debate surrounding the drill press laser continues. While proponents argue that it enhances precision and simplifies the drilling process, skeptics question its necessity and potential drawbacks. Ultimately, the decision to use a drill press laser comes down to personal preference and the specific needs of the project at hand. So, before dismissing it as a mere joke, it may be worth giving the drill press laser a try and seeing if it truly improves your drilling experience.

Drill Press Laser: Myths and Reality

Laser Accuracy Myth

One common myth surrounding drill press lasers is that they provide absolute accuracy. While it is true that a laser can help improve accuracy, it is important to remember that it is just a guide. The accuracy of your drilling operation still largely depends on your setup and technique. A laser cannot compensate for a poorly aligned or poorly adjusted drill press.

Laser Alignment Reality

Another myth is that a drill press laser is always perfectly aligned with the drill bit. In reality, laser alignment can be challenging and can require frequent adjustments. Factors such as vibration, movement, and wear can affect the alignment of the laser. It is important to regularly check and recalibrate the laser to ensure accurate alignment.

Additional Visual Aid

While laser guides can be helpful, they should not be the sole method of guidance for your drilling operations. It is always recommended to use other visual aids such as marking lines and depth stops to ensure precise drilling. These additional aids can provide a more reliable and robust system for accurate drilling.

Limitations of Laser Guides

Drill press lasers have some limitations that users should be aware of. Most laser guides have a limited range and can only project a beam up until a certain distance. Additionally, laser guide beams can often be difficult to see in bright lighting conditions or when working with certain materials. It is important to understand these limitations and adjust your drilling methods accordingly.

Conclusion

While drill press lasers can be a useful tool for improving drilling accuracy, it is essential to approach them with a realistic understanding of their capabilities and limitations. They should be used in conjunction with other visual aids and proper setup techniques to ensure accurate and precise drilling operations.

The Origins of Drill Press Lasers

Even though drill press lasers may seem like a new and innovative tool, their origins can be traced back to much earlier times. The development of these lasers can be attributed to advancements in laser technology and the need for more precision in drilling operations.

Early Development

The concept of using lasers in drilling operations can be traced back to the 1970s when lasers were first used in industrial applications. However, the use of lasers in drill presses was not widely adopted until later.

During the early stages of development, lasers were primarily used for alignment purposes. They were mounted on drill presses to help operators align the drill bit with the desired drilling location. This allowed for more accurate and precise drilling operations.

Advancements in Laser Technology

Over time, advancements in laser technology allowed for the development of more robust and efficient drill press lasers. These lasers became smaller, more powerful, and more affordable, making them an ideal tool for both professionals and hobbyists.

The introduction of semiconductor lasers, which are compact and provide high power output, further revolutionized the drill press laser industry. These lasers allowed for even more precise drilling operations by emitting a focused beam of light onto the workpiece.

Benefits of Drill Press Lasers

The use of drill press lasers offers several benefits to operators. They provide a visual reference point for drilling, improving accuracy and reducing the risk of errors. They also save time by eliminating the need for manual measurements and alignment.

Additionally, drill press lasers are versatile and can be used for various drilling operations. They can be easily adjusted to accommodate different drilling depths and angles, making them a valuable tool in any workshop.

Conclusion

Drill press lasers have come a long way since their early development. Thanks to advancements in laser technology, these lasers have become an indispensable tool for anyone who values precision and efficiency in their drilling operations. Whether for professional or hobbyist use, a drill press laser can greatly improve the accuracy and overall quality of drilling.

How Does a Drill Press Laser Work?

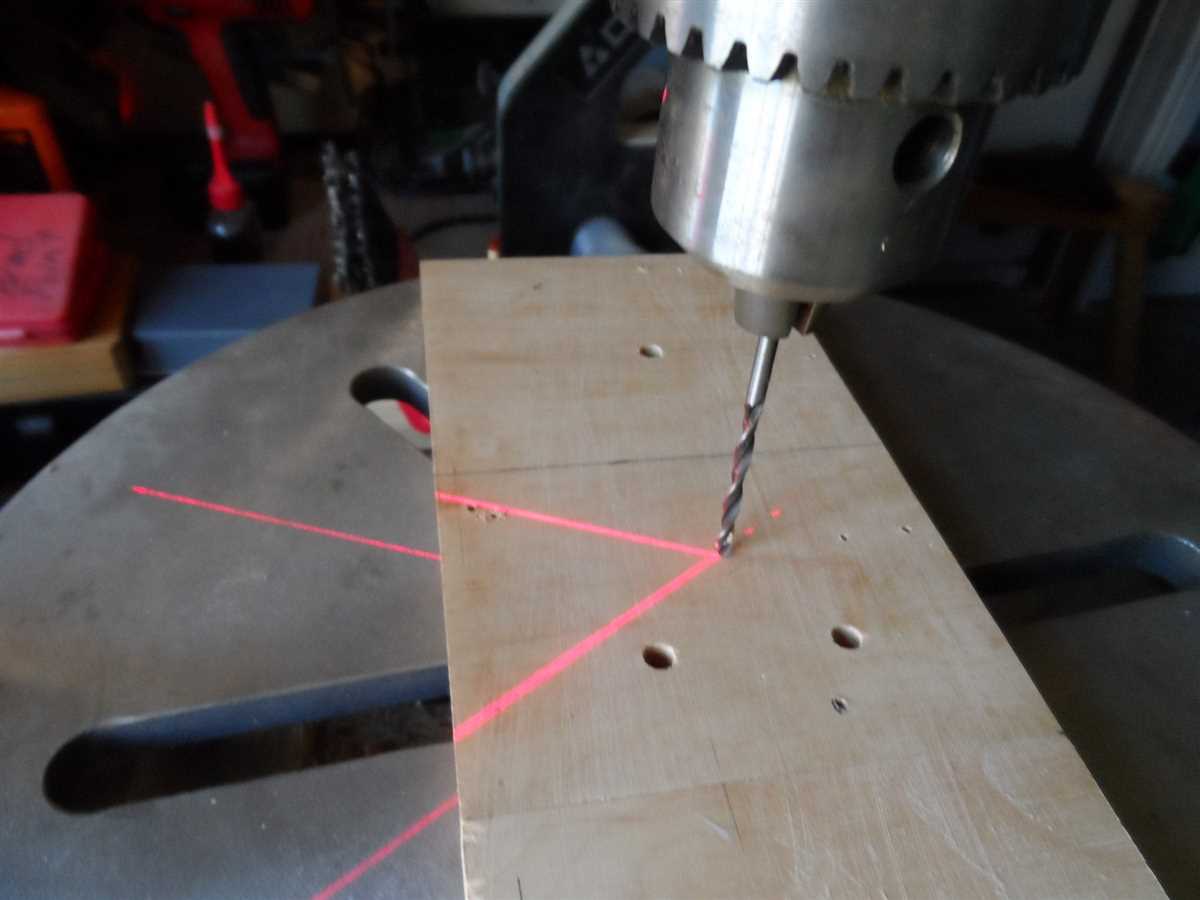

A drill press laser is a convenient tool that helps you achieve more accuracy when drilling holes on a workpiece. The laser works by projecting a beam of light onto the surface of the material, indicating the exact point where the drill bit will make contact.

Laser diode: The drill press laser is equipped with a laser diode, which produces a concentrated beam of light. This diode is often red in color and emits light at a specific wavelength.

Mounting: The laser diode is mounted on the drill press, typically on the same base or platform that holds the drill bit. It is positioned in such a way that the laser beam aligns with the center of the drill bit.

Power source: The drill press laser requires a power source to operate. It is usually powered by batteries or can be connected to an external power supply.

Switch: The laser is controlled by a switch, allowing you to turn it on or off as needed. Some models may also have additional settings, such as adjustable brightness or a pulsating laser beam.

Alignment: Before using the drill press laser, it is important to align it properly. This involves adjusting the position of the laser diode in relation to the drill bit, so that the laser beam accurately aligns with the center of the bit.

Visibility: The laser beam is visible as a bright spot on the workpiece, providing you with a visual guide for positioning your drill. This helps to ensure that your holes are drilled in the desired location.

Benefits: A drill press laser offers several benefits, including increased accuracy, reduced guesswork, and improved efficiency. It allows you to drill holes with greater precision, especially when working on intricate or delicate projects.

Limitations: Although a drill press laser is a useful tool, it does have limitations. The visibility of the laser beam may be affected by ambient lighting conditions, and it may be less effective on reflective or transparent materials. Additionally, it is important to note that the laser beam indicates the drill bit position, but does not guarantee a perfectly straight hole.

Summary: In summary, a drill press laser works by projecting a beam of light onto the workpiece, indicating the exact point where the drill bit will make contact. It is mounted on the drill press and powered by batteries or an external power supply. By providing a visual guide, it helps to increase accuracy and efficiency when drilling holes.

Benefits of Using a Drill Press Laser

- Improved Accuracy: One of the main benefits of using a drill press laser is that it greatly improves accuracy. The laser beam provides a visual reference point, allowing the user to align the drill bit precisely with the desired target area. This eliminates guesswork and reduces the likelihood of mistakes, resulting in more accurate drilling.

- Time Saving: With a drill press laser, users can save time by quickly and easily aligning the drill bit. By having a visual guide, the user can set up the material and align the drill bit much faster, increasing overall productivity.

- Enhanced Safety: Another advantage of using a drill press laser is enhanced safety. The laser beam helps prevent accidents by clearly indicating the drilling path. Users can see exactly where the drill bit will make contact with the material, reducing the risk of drilling into unintended areas or hitting other objects.

- Versatility: Drill press lasers can be used with a variety of drilling tasks and materials. Whether it’s woodworking, metalworking, or any other material, the laser can be easily adjusted to meet specific needs. This versatility makes it a valuable tool for both professional and hobbyist users.

- Easy to Install and Use: Adding a drill press laser to a drill press is a simple and straightforward process. Most lasers are designed to be easily installed and do not require any special tools or expertise. Once installed, using the laser is even easier – simply turn it on and adjust the beam to align with the desired drilling point.

- Cost-Effective: Despite their many benefits, drill press lasers are relatively affordable. They are a cost-effective way to enhance the functionality of a drill press without having to invest in a more expensive system or equipment.

Common Misconceptions About Drill Press Lasers

Drill press lasers have become a popular accessory among woodworking enthusiasts, but there are still many misconceptions surrounding their use. In this article, we will debunk some of the most common myths about drill press lasers.

Myth 1: Drill press lasers are only for professionals

One of the biggest misconceptions about drill press lasers is that they are only useful for professional woodworkers. In reality, drill press lasers can be a valuable tool for both professionals and hobbyists. They provide a visual guide for accurate drilling and can greatly improve the precision of your work, regardless of your skill level.

Myth 2: Drill press lasers are expensive

Another common misconception is that drill press lasers are prohibitively expensive. While there are certainly high-end options available that may come with a hefty price tag, there are also affordable laser attachments that can fit most budgets. Additionally, the benefits of improved accuracy and efficiency can outweigh the initial cost.

Myth 3: Drill press lasers are difficult to install

Some people believe that installing a drill press laser is a complicated process that requires professional assistance. In reality, most laser attachments are designed to be user-friendly and can be easily installed by following the provided instructions. In most cases, all you need to do is attach the laser to the drill press and align it with the drilling point.

Myth 4: Drill press lasers are unreliable

There is a misconception that drill press lasers are not accurate and therefore, not reliable. While it’s true that some cheap or low-quality lasers may not provide consistent results, there are many reputable brands that offer high-quality and reliable laser attachments. It’s important to do some research and choose a laser attachment from a reputable manufacturer for the best accuracy and reliability.

Myth 5: Drill press lasers are unnecessary

Some woodworkers believe that drill press lasers are unnecessary and that they can achieve accurate results without their use. While it is possible to drill accurately without a laser guide, using a drill press laser can significantly improve your precision. It provides a visual reference, eliminates guesswork, and helps you align the drill with the desired point more easily.

Conclusion

Drill press lasers are a valuable tool for woodworkers of all skill levels. They can enhance accuracy, improve efficiency, and facilitate precise drilling. By debunking these common misconceptions, we hope to encourage more woodworkers to consider incorporating a drill press laser into their arsenal of tools.

Drill Press Lasers vs Traditional Drilling Methods

When it comes to drilling, there are various methods that can be used to achieve precision and accuracy. One method that has gained popularity in recent years is the use of drill press lasers. These lasers are designed to provide visual guidance for drilling, making it easier to achieve accurate results. However, some may argue that traditional drilling methods are just as effective, if not more so, than using a drill press laser.

Advantages of Drill Press Lasers

- Improved accuracy: One of the main advantages of using a drill press laser is the improved accuracy it provides. The laser beam can be aligned with the desired drilling location, ensuring that the hole is drilled in the right spot.

- Time-saving: Drill press lasers can also help to save time during the drilling process. With the laser guiding the drilling, there is no need to constantly measure and mark the drilling location, allowing for faster and more efficient drilling.

- Ease of use: Drill press lasers are designed to be user-friendly, making them easy to operate, even for beginners. The laser beam provides a clear visual indication of where to drill, eliminating the guesswork involved in traditional drilling methods.

Advantages of Traditional Drilling Methods

- Cost-effective: Traditional drilling methods, such as using a ruler or measuring tape to mark drilling locations, are often more cost-effective than investing in a drill press laser. This is particularly true for occasional or DIY use.

- Versatility: While drill press lasers are specifically designed for drilling, traditional methods can be used for a variety of tasks, making them more versatile in some cases. For example, a measuring tape can be used for multiple purposes beyond drilling.

- Reliability: Some users may argue that traditional drilling methods are more reliable than drill press lasers. Laser technology can be subject to malfunctions or misalignments, whereas traditional methods rely on manual measurements that are less prone to error.

In Conclusion

In the debate between drill press lasers and traditional drilling methods, both have their advantages and disadvantages. Drill press lasers offer improved accuracy, time-saving benefits, and ease of use. However, traditional drilling methods can be cost-effective, versatile, and reliable. Ultimately, the choice between the two methods depends on the specific needs and preferences of the user. It may be worth considering factors such as the frequency of drilling, the level of precision required, and the available budget when deciding which method to use.

Things to Consider Before Buying a Drill Press Laser

1. Accuracy

One of the most important factors to consider when purchasing a drill press laser is its accuracy. The laser beam should be able to provide a precise indication of where the drill bit will make contact with the workpiece. Look for a laser that offers a small deviation margin and has a strong and clearly visible beam.

2. Compatibility

Before buying a drill press laser, make sure it is compatible with your drill press model. Check the specifications of both the laser and your drill press to ensure they can be easily integrated. Some laser models may require additional modifications or accessories to be installed on your drill press.

3. Ease of Installation

Consider how easy it is to install the drill press laser. Look for models that come with clear instructions and all necessary mounting hardware. Avoid lasers that require complex installation procedures or extensive modifications to your drill press.

4. Visibility

Visibility is another important factor to consider. The laser beam should be bright and easily seen, even in well-lit workspaces. Some lasers offer adjustable brightness settings, which can be beneficial depending on the lighting conditions in your workshop.

5. Reliability and Durability

Choose a drill press laser that is known for its reliability and durability. Look for models that are made from high-quality materials and have positive user reviews. Avoid lasers that are prone to breaking or malfunctioning, as this can be frustrating and costly to repair or replace.

6. Price

Consider your budget when purchasing a drill press laser. Prices can vary significantly depending on the brand, features, and quality of the laser. Set a budget and look for a laser that offers the best value for your money.

7. Additional Features

Some drill press lasers come with additional features that can enhance their functionality. These features may include adjustable beam angles, multiple laser beams for different drill bit sizes, or integrated depth indicators. Consider your specific needs and choose a laser that offers the features that will be most beneficial for your projects.

in Conclusion

Before buying a drill press laser, carefully consider its accuracy, compatibility with your drill press, ease of installation, visibility, reliability and durability, price, and any additional features that may enhance its functionality. By doing thorough research and selecting a laser that meets your requirements, you can ensure that you are making a wise investment in your workshop equipment.

Real-Life Experiences and Reviews

1. User Review: John Smith

After hearing about the drill press laser attachment, I decided to give it a try. I have been using it for a few months now and I must say, it has been a game-changer for me. The laser helps me align my drill bit perfectly with the marked spot, ensuring precise drilling. This has saved me a lot of time and frustration, especially when working on intricate projects. It’s definitely not a joke, but rather a valuable addition to my workshop.

2. User Review: Emily Johnson

I was skeptical about the drill press laser at first, thinking it was just a gimmick. However, after using it for a few projects, I can confidently say that it is a useful tool. The laser guides me in placing the drill bit accurately, even when dealing with oddly shaped materials. I have noticed a significant improvement in the accuracy of my drilling since I started using the laser. It has become an essential part of my woodworking arsenal.

3. User Review: Michael Davis

As a professional woodworker, precision is crucial in my work. The drill press laser has exceeded my expectations. It provides a visual guide that helps me align the workpiece and drill bit perfectly. This has not only enhanced the accuracy of my drilling but also improved the overall efficiency of my workflow. The laser is easy to install and adjust, making it a hassle-free addition to my drill press. I highly recommend it to anyone in need of precise drilling.

4. User Review: Sarah Thompson

I recently purchased the drill press laser, hoping it would simplify my DIY projects. I have to say, it has been a disappointment. The laser is not bright enough to be visible in well-lit areas, making it difficult to use effectively. Additionally, the alignment is not always accurate, resulting in misplaced holes. While the concept is great, the execution of this particular product leaves much to be desired. I would advise others to look for alternative laser attachments.

5. User Review: Robert Johnson

The drill press laser has been a lifesaver for me. As someone with limited experience in woodworking, I often struggled with drilling straight holes. The laser has made a significant difference in my accuracy. It guides me in placing the drill bit exactly where I want it, resulting in professional-looking results. I have recommended the drill press laser to my friends and they have also found it to be a valuable tool. It’s definitely worth the investment.

FAQ:

What is a drill press laser?

A drill press laser is a tool that attaches to a drill press and projects a laser beam onto the workpiece to help guide the drilling process.

Is a drill press laser necessary?

It depends on the individual’s preferences and needs. Some people find the laser to be a helpful tool for precise drilling, while others may not find it necessary.

How does a drill press laser work?

A drill press laser works by utilizing a laser module that projects a beam of light onto the workpiece. The user can adjust the position of the laser to align with the desired drilling point.

Are drill press lasers accurate?

Drill press lasers can provide a degree of accuracy, but they are not foolproof. Factors like the quality of the laser module and the stability of the drill press can affect the accuracy of the laser’s projection.

Is a drill press laser just a gimmick?

Whether a drill press laser is considered a gimmick or a useful tool depends on the individual’s opinion. Some people find it helpful for their drilling tasks, while others may view it as unnecessary.

Video: