Choosing the Right Size Drill Press for an 80% Lower

When it comes to completing an 80% lower receiver, one of the most important tools you’ll need is a drill press. A drill press allows for precise and accurate drilling, ensuring that all holes are properly aligned and clean. But choosing the right size drill press can be a bit overwhelming, especially for beginners.

The size of the drill press refers to the distance between the center of the chuck and the support column. This measurement determines the maximum width of material that the drill press can accommodate. The most common sizes for drill presses are 8-inch, 10-inch, 12-inch, and 15-inch. Each size has its own advantages and limitations.

A smaller 8-inch drill press is suitable for small projects and lighter materials, such as aluminum or polymer lowers. It’s compact and portable, making it ideal for hobbyists or those with limited space. However, it may not have enough power for drilling through tougher metals or larger projects.

A larger 15-inch drill press, on the other hand, provides more power and stability. It can handle heavy-duty drilling and is capable of drilling through steel and other hard materials. This makes it a great choice for those planning to work on multiple lowers or larger projects.

Ultimately, the size of the drill press you choose depends on your specific needs and the type of projects you’ll be working on. It’s important to consider the size and weight of the lowers you’ll be completing, as well as the materials you’ll be drilling through. If you’re unsure, it’s always a good idea to consult with an expert or do some research to ensure you’re making the right choice.

Understanding the Basics of an 80% Lower

An 80% lower refers to a firearm lower receiver that is not yet considered a firearm by the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). It is called “80%” because it is only 80% complete, with the remaining 20% left for the user to finish. This allows individuals to purchase and complete the lower receiver without the need for a background check or other restrictions that apply to fully finished firearms.

The lower receiver is a critical component of a firearm, as it houses the trigger mechanism, magazine well, and the buffer tube where the stock attaches. It is typically made of aluminum and acts as the foundation upon which the rest of the firearm is built. By purchasing an 80% lower, enthusiasts can legally build their own firearms from scratch, customizing them to their own preferences.

Advantages of Using an 80% Lower

- Legal Flexibility: Since an 80% lower is not considered a firearm, it can be purchased and shipped directly to your doorstep without the need for an FFL transfer.

- Privacy: Building your own firearm using an 80% lower allows you to maintain your privacy as it does not require any background checks or documentation.

- Customization: With an 80% lower, you have the freedom to fully customize your firearm by choosing the components, finishes, and accessories that suit your personal preferences.

- Learning Experience: Building a firearm from an 80% lower can be a rewarding learning experience that allows you to understand the intricacies of firearm assembly and operation.

Finishing an 80% Lower

In order to complete an 80% lower, you will need a few specialized tools and some basic knowledge of machining. The process involves using a drill press or a milling machine to remove the excess material and mill out the fire control group pocket, trigger slot, and other necessary areas. This process requires precision and attention to detail to ensure the firearm is properly functioning and safe to use.

It’s important to note that although an 80% lower can legally be completed by an individual, there may be specific laws and regulations that govern the manufacturing and use of firearms in your jurisdiction. It is always recommended to familiarize yourself with your local laws and regulations before undertaking any firearms-related projects.

Conclusion

An 80% lower provides firearms enthusiasts with the opportunity to legally build their own custom firearms while enjoying legal flexibility and privacy. Understanding the basics of an 80% lower, along with the required tools and laws in your area, is essential before starting any DIY firearm project.

Considerations for Selecting a Drill Press Size

Choosing the right size drill press is an important decision when working with an 80% lower. There are a few key considerations to keep in mind:

Workspace Limitations

- Before purchasing a drill press, it’s essential to consider the available workspace. Measure the space where the drill press will be placed to ensure that the selected size will fit.

- It’s important to account for the height of the drill press as well, as some models may be too tall for certain workspaces.

Projected Use

- Consider the types of projects you plan to undertake with the drill press. Different sizes and capacities are better suited for specific tasks.

- If you primarily work on smaller projects, such as woodworking or crafting, a compact drill press with a lower horsepower may be sufficient.

- For larger projects or heavy-duty applications, a bigger drill press with more power and a larger spindle travel may be necessary.

Budget

- Like any tool, drill presses come in a range of prices. Consider your budget and how much you are willing to invest in a drill press.

- Remember that higher-priced models often come with more features and better build quality, which can enhance performance and durability.

Features and Accessories

- Consider the features and accessories that are important to you. Some drill presses offer variable speed control, depth stops, laser guides, and other helpful features.

- Depending on the type of project and material you work with, you may need additional accessories such as drill press vices, clamps, or specialty bits.

Safety

- Always prioritize safety when selecting a drill press. Look for models with built-in safety features, such as safety switches, guards, and adjustable depth stops.

- Consider your level of experience with drill presses and choose a size and configuration that you are comfortable operating.

By considering these factors, you can select the right drill press size for your specific needs and ensure a successful project with your 80% lower.

Why Size Matters in Drill Press Selection

When it comes to choosing the right drill press for an 80% lower, size matters. The size of the drill press refers to the distance between the center of the chuck and the front of the column, also known as the swing. This measurement is important because it determines the largest diameter of workpiece that can be drilled.

Increased Versatility

One of the main reasons why size matters in drill press selection is because a larger drill press offers increased versatility. With a larger swing, you can drill larger diameter holes and work with larger pieces of material. This is especially important when working with an 80% lower, as it may require drilling larger holes for various components.

A larger drill press also allows for more flexibility in terms of the types of projects you can complete. Whether you are working on small-scale hobby projects or larger woodworking tasks, a larger drill press will provide the capability to tackle a wide range of projects.

More Stability and Power

Another reason why size matters is that a larger drill press typically offers more stability and power. The larger size and weight of the drill press helps to reduce vibration, providing a more stable drilling experience. This is especially important when drilling into harder materials, as it helps to prevent the drill bit from wandering or causing damage.

In addition to stability, a larger drill press often offers more power. This means you can drill through tougher materials with ease, ensuring clean and precise cuts. Whether you are drilling into metal, wood, or plastic, a larger drill press will have the power to handle the task.

Overall Efficiency

The size of the drill press also plays a role in overall efficiency. With a larger drill press, you can complete tasks more quickly and efficiently. The increased size allows for faster drilling, reducing the time and effort required to complete your project.

A larger drill press also typically has a larger worktable, providing ample space to work with your 80% lower and other materials. This makes it easier to position and secure your workpiece, ensuring accuracy and precision during the drilling process.

| Drill Press Size | Swing | Recommended Use |

|---|---|---|

| 8-inch | 8 inches | Small-scale projects |

| 12-inch | 12 inches | Medium-sized projects |

| 15-inch | 15 inches | Large-scale projects |

Choosing the right size drill press for your 80% lower is essential for a successful and efficient drilling process. By considering the size and swing of the drill press, you can ensure that it meets your specific project needs and provides the versatility, stability, and power required for accurate and precise drilling.

Determining the Ideal Size for Your Project

Consider the Material

The first factor to consider when determining the ideal size for your project is the type of material you will be working with. Different materials require different drill press sizes to ensure optimal performance and accuracy.

Soft materials: If you primarily work with soft materials like wood or plastic, a smaller drill press with lower power may be sufficient for your needs. These materials are easier to drill through and do not require as much force.

Hard materials: On the other hand, if you frequently work with harder materials like metal or granite, a larger drill press with higher power is recommended. Hard materials require more force to drill through, and a larger drill press can provide the necessary power and stability.

Consider the Size of Your Workpieces

Another important factor to consider is the size of your workpieces. The size of your drill press should be able to accommodate the dimensions of your workpieces.

Measure the largest workpiece you typically work with, including its length, width, and height. Make sure that the drill press you choose has a large enough table and enough throat depth to comfortably accommodate your workpieces. This will ensure that you can properly position and secure your workpieces during drilling.

Consider the Type of Projects You Do

Consider the type of projects you typically do or plan to do in the future. Are you a DIY enthusiast who primarily works on small-scale projects, or are you a professional woodworker who frequently handles large projects?

If you mainly work on small-scale projects, a benchtop or a compact floor drill press may be suitable for your needs. These models are smaller in size and are generally more affordable.

However, if you frequently work on large-scale or commercial projects, a floor drill press with a larger motor and drilling capacity may be necessary. These larger models offer more power and stability, allowing you to handle heavy-duty projects with ease.

Consider Your Workspace

Lastly, consider the available space in your workshop or garage. Measure the area where you plan to place the drill press to ensure that it will fit comfortably without obstructing your workflow.

Additionally, take into account the ceiling height of your workspace. Some floor drill presses are taller and may require higher clearance to operate safely.

It is also important to ensure that your workspace has sufficient electrical power to support the drill press you choose. Check the voltage and amperage requirements of the drill press and ensure that they align with your electrical capabilities.

Overall, by considering the material, size of your workpieces, type of projects, and available workspace, you can determine the ideal size for your drill press that will meet your needs and ensure successful outcomes for your projects.

Key Factors to Keep in Mind

- Size of the 80% Lower: One of the most important factors to consider when choosing the right size drill press for an 80% lower is the size of the lower itself. Different manufacturers may produce lower receivers that vary slightly in dimensions, so it is crucial to measure the size of your specific lower before purchasing a drill press.

- Drill Press Capacity: Another critical factor is the capacity of the drill press. The drill press should have a large enough throat depth and spindle travel to accommodate the dimensions of the lower and ensure that it can be drilled properly.

- Motor Power: The motor power of the drill press is also an essential consideration. The motor should have sufficient power to drill through the material of the lower without straining or overheating.

- Speed Settings: Different drill presses offer different speed settings. It is recommended to choose a drill press that has adjustable speed settings to allow for versatility in drilling various materials and sizes of holes.

- Table Size and Stability: The size and stability of the drill press table are important factors to consider. The table should be large enough to support the size of the lower and should have a stable base to ensure accurate drilling.

- Adjustability and Ease of Use: Look for drill presses that offer adjustable height and other settings for ease of use. A drill press with easy-to-use controls and adjustments will make the drilling process more efficient and precise.

- Availability and Price: Consider the availability and price of the drill press. You want to choose a drill press that is readily available and within your budget. Compare different options to find the best balance between quality and affordability.

By keeping these key factors in mind, you can choose the right size drill press for your 80% lower and ensure successful drilling operations. Remember to always prioritize safety and follow all manufacturer instructions and guidelines when using a drill press.

Benefits of Choosing the Right Size Drill Press

1. Precision and Accuracy

One of the main benefits of choosing the right size drill press for an 80% lower is the increased precision and accuracy it provides. A drill press with the right size and power will allow you to make clean and precise holes in the lower receiver with minimal effort. This is especially important when working with an 80% lower, as any mistakes or inaccuracies can affect the overall functionality of the firearm.

2. Enhanced Safety

Another advantage of using the right size drill press is the enhanced safety it offers. A drill press with the right size and power will provide more stability and control during the drilling process, reducing the risk of accidents or injuries. It also allows you to secure the lower receiver more effectively, preventing any movement or shifting that could potentially lead to mishaps.

3. Time and Effort Efficiency

Choosing the right size drill press will also help you save time and effort. A drill press with the proper size and power will easily handle the task of drilling holes in the lower receiver, minimizing the amount of time and effort required. This allows you to complete the project more efficiently, allowing you to move on to the next steps of the build process.

4. Versatility

A drill press with the right size can also provide you with more versatility in your projects. Depending on the size of the drill press, you may be able to use it for other drilling or cutting tasks, not just for working on an 80% lower. This makes it a versatile tool that can be used for a variety of projects around the workshop.

5. Long-Term Investment

Investing in the right size drill press is also a wise long-term investment. A high-quality drill press with the right size and power will last for a long time, allowing you to use it for multiple projects in the future. It is better to invest in a drill press that meets your current and future needs, rather than having to replace it after a short period of time.

In conclusion, choosing the right size drill press for an 80% lower offers several benefits including enhanced precision and accuracy, increased safety, time and effort efficiency, versatility, and a long-term investment. By selecting the appropriate size and power for your specific needs, you can ensure successful and efficient completion of your lower receiver project.

Top Recommended Drill Press Sizes for 80% Lowers

When it comes to drilling out an 80% lower, a drill press is an essential tool to ensure accuracy and precision. The right size drill press will depend on the specific dimensions of the lower and the type of holes that need to be drilled. Here are the top recommended drill press sizes for 80% lowers:

1. 1/4 inch Drill Press

A 1/4 inch drill press is commonly used for drilling pilot holes in 80% lowers. This size is ideal for most lower receivers and allows for precise alignment and control.

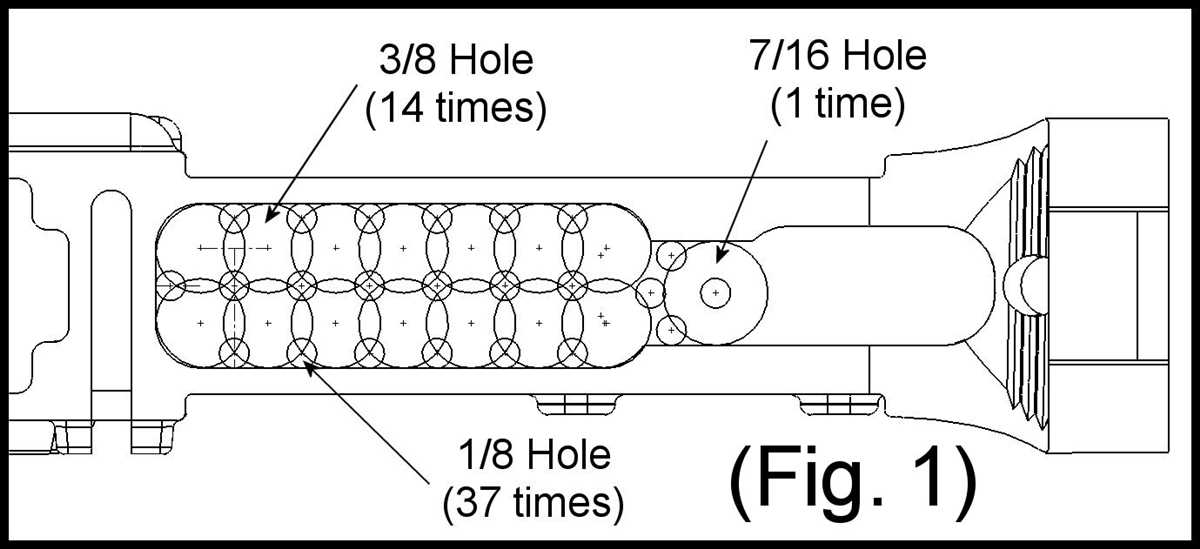

2. 3/8 inch Drill Press

A 3/8 inch drill press is suitable for drilling larger holes or for drilling out the trigger and hammer pin holes in an 80% lower. This size provides enough clearance for most pins and ensures a snug fit.

3. 1/2 inch Drill Press

A 1/2 inch drill press is recommended for drilling larger holes, such as the magazine well, in an 80% lower. This size provides ample clearance and allows for easy installation of components.

4. 5/8 inch Drill Press

For those working on larger caliber builds or have specific requirements, a 5/8 inch drill press is a good choice. This size offers even greater clearance and is suitable for drilling out the barrel extension hole or other larger holes.

5. 3/4 inch Drill Press

A 3/4 inch drill press is the largest size commonly used for drilling out 80% lowers. This size is typically reserved for specialized builds or custom projects that require larger holes or unique configurations.

Ultimately, the right size drill press for an 80% lower will depend on the specific requirements of the build. It is essential to carefully consider the dimensions of the lower and the type of holes that need to be drilled to ensure a successful and accurate completion of the project.

FAQ:

What is an 80% lower?

An 80% lower refers to an unfinished firearm receiver that is not yet considered a firearm by the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). It is a partially completed lower receiver that requires additional machining in order to become a functioning firearm.

Why would someone want to choose the right size drill press for an 80% lower?

Choosing the right size drill press is essential for completing an 80% lower because it determines the accuracy, stability, and precision of the machining process. Using the wrong size drill press can result in improper cuts, misalignment, and a less reliable finished product.

What factors should be considered when choosing the right size drill press for an 80% lower?

Several factors should be considered when choosing the right size drill press for an 80% lower, including the size and material of the lower, the type of operation being performed (such as drilling or milling), the available space in the workshop, the budget, and the operator’s level of experience and skill.

What are the most common sizes of drill presses used for completing 80% lowers?

The most common sizes of drill presses used for completing 80% lowers are the benchtop models with a swing capacity of 8-10 inches. These drill presses are versatile, compact, and offer enough power and stability for most home gunsmithing projects.

Is it necessary to have a drill press to complete an 80% lower?

No, it is not necessary to have a drill press to complete an 80% lower. While it is highly recommended and often preferred due to its precision and stability, some gunsmiths have successfully completed 80% lowers using handheld drill presses, milling machines, or even hand tools. However, a drill press is generally considered to be the most efficient and reliable tool for the job.