Choosing the Right Size Drill Bit for a 3/8 Sleeve Anchor

When it comes to installing a 3/8 sleeve anchor, having the right size drill bit is crucial. The drill bit size determines the diameter of the hole that needs to be drilled in order to properly secure the anchor. Using the incorrect size drill bit can result in a loose or ineffective anchor, which can compromise the stability of whatever is being anchored.

So, how do you choose the right size drill bit for a 3/8 sleeve anchor? The first step is to consult the manufacturer’s instructions or specifications for the particular anchor you are using. These instructions will typically provide guidelines on the recommended drill bit size based on the material you are drilling into and the type of anchor being used.

In general, a 3/8 sleeve anchor requires a drill bit that is slightly smaller in diameter than the anchor itself. This allows for a tight fit and ensures that the anchor will hold securely in place. However, the exact size of the drill bit will depend on factors such as the type of material being drilled into and the intended load capacity of the anchor.

For example, if you are installing a 3/8 sleeve anchor into concrete, the recommended drill bit size may be 5/16 or 11/32 inch. This is because concrete is a hard material and requires a slightly smaller drill bit to create a snug hole.

It is important to note that using a drill bit that is too large can result in a loose anchor, while using a drill bit that is too small can make it difficult or impossible to insert the anchor into the hole. Therefore, it is crucial to carefully follow the manufacturer’s recommendations for the correct drill bit size for your specific anchor and installation requirements.

In conclusion, choosing the right size drill bit for a 3/8 sleeve anchor is a critical step in ensuring a secure and reliable anchor installation. By consulting the manufacturer’s instructions and considering factors such as material and intended load capacity, you can select the appropriate drill bit size for your specific application. Taking the time to choose the right size drill bit will help to ensure a successful installation and provide peace of mind knowing that your anchor is properly secured.

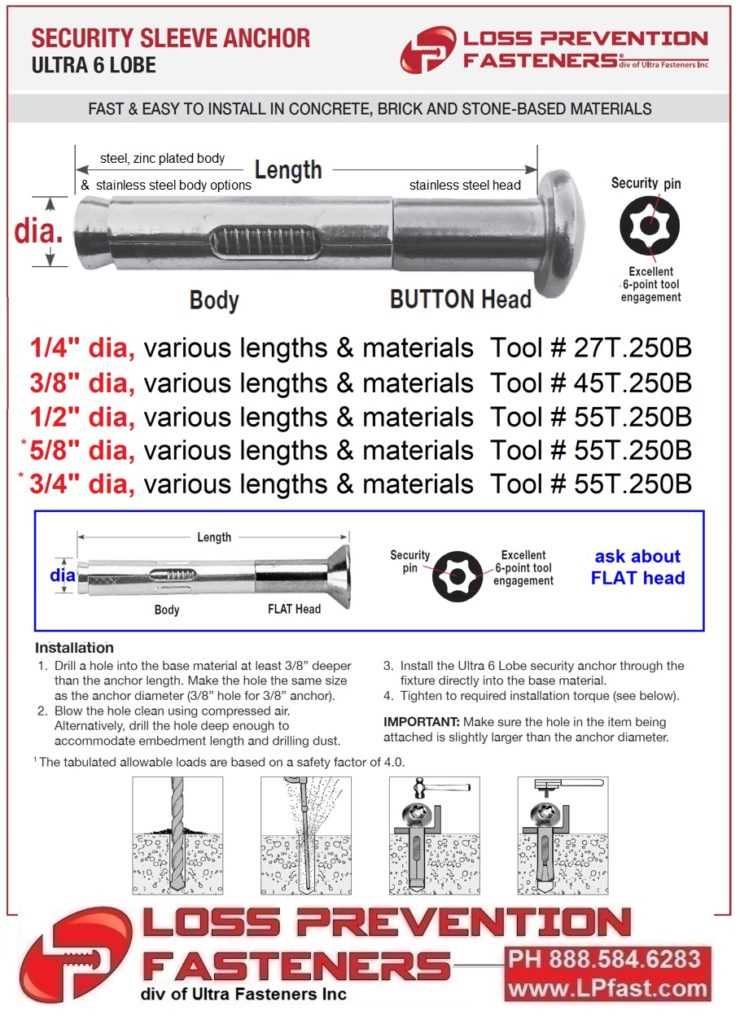

What is a Sleeve Anchor

A sleeve anchor is a type of fastener that is used to secure objects to masonry or concrete surfaces. It is designed to provide a strong and reliable anchoring solution for heavy loads.

The sleeve anchor consists of three main components: the expansion sleeve, the bolt, and the nut. The expansion sleeve is usually made of steel and has grooves or ridges along its length. The bolt and nut are typically made of stainless steel, which provides high strength and corrosion resistance.

How does a Sleeve Anchor work?

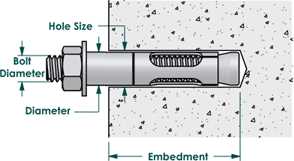

To use a sleeve anchor, a hole is first drilled into the masonry or concrete surface. The size of the hole should be slightly larger than the diameter of the screw sleeve. Once the hole is drilled, the sleeve anchor is inserted into the hole, and the nut is tightened. As the nut is tightened, the bolt is pulled into the sleeve, causing the sleeve to expand and push against the sides of the hole. This expansion creates a tight and secure fit between the anchor and the surrounding material.

The sleeve anchor is versatile and can be used in a variety of applications, such as attaching structural supports, handrails, or machinery to concrete walls or floors. It is commonly used in construction, infrastructure projects, and in industrial settings.

Advantages of Sleeve Anchors

- High load capacity: Sleeve anchors are capable of supporting heavy loads, making them suitable for demanding applications.

- Easy installation: Sleeve anchors can be installed quickly and easily, requiring only basic tools.

- Versatility: They can be used in a wide range of materials, including concrete, brick, and stone.

- Durable: Sleeve anchors are made of materials like stainless steel, which provide durability and resistance to corrosion.

- Removable and adjustable: Sleeve anchors can be removed and reinstalled if needed, allowing for flexibility in construction or renovations.

Conclusion

Sleeve anchors are an efficient and reliable solution for securing objects to masonry or concrete surfaces. They offer high load capacity, easy installation, and versatility in various applications. With their durability and adjustability, sleeve anchors provide a trusted anchoring method for both construction professionals and DIY enthusiasts.

Importance of Choosing the Right Size Drill Bit

Choosing the right size drill bit is crucial when using a 3/8 sleeve anchor. The drill bit size will determine the fit and stability of the sleeve anchor in the concrete or masonry material. Using the wrong size drill bit can lead to weak or loose connections, compromising the integrity of the installation.

Here are a few reasons why choosing the right size drill bit is important:

1. Proper Fit

Using the correct size drill bit ensures a proper fit between the sleeve anchor and the hole. The drill bit should be slightly smaller than the diameter of the anchor to provide a tight fit. This allows for maximum contact between the anchor and the material, increasing its holding strength and reducing the risk of pullout.

2. Improved Stability

A correct-sized hole and anchor combination increase the stability of the installation. When the drill bit is too small, it may not be able to penetrate the material properly, resulting in a loose anchor that can easily come loose over time. On the other hand, using a drill bit that is too big can weaken the surrounding material, making it more prone to cracking or breaking under load.

3. Enhanced Load Capacity

The right size drill bit ensures that the sleeve anchor has a sufficient grip on the material, enabling it to support the intended load. When the anchor fits snugly in the hole, it distributes the load evenly and prevents excessive stress on any one point. This enhances the anchor’s load capacity and helps maintain the structural integrity of the installation.

4. Time and Cost Savings

Choosing the correct drill bit size eliminates the need for rework or retrofitting. Using the wrong size bit may result in a failed installation that needs to be redone, costing additional time and money. By investing a little time upfront to select the right drill bit size, you can avoid potential setbacks and ensure a successful installation.

In conclusion, selecting the right size drill bit is vital for the proper installation and performance of a 3/8 sleeve anchor. It ensures a proper fit, improves stability, enhances load capacity, and saves time and cost in the long run. Always refer to the manufacturer’s guidelines and specifications to determine the appropriate drill bit size for your specific sleeve anchor and material.

Factors to Consider When Choosing the Drill Bit Size

When choosing the drill bit size for a 3/8 sleeve anchor, there are several factors that need to be taken into consideration. The right drill bit size will ensure a proper and secure installation of the sleeve anchor. Here are some important factors to consider:

1. Anchor Diameter

The first factor to consider is the diameter of the sleeve anchor. Sleeve anchors come in different diameters, and the drill bit size you choose should match the anchor diameter. For example, if you are using a 3/8 sleeve anchor, you will need a drill bit that is also 3/8 in diameter.

2. Material of the Base Material

The base material in which you are installing the sleeve anchor is another important factor to consider. Different materials such as concrete, brick, or masonry will require different drill bit sizes. Consult the manufacturer’s guidelines or a drilling chart to determine the appropriate drill bit size for your specific base material.

3. Anchor Length

The length of the sleeve anchor can also impact the drill bit size. Longer anchors may require larger drill bits to accommodate their length. Make sure to consider the overall length of the anchor when selecting the appropriate drill bit size.

4. Installation Depth

The installation depth of the sleeve anchor is another consideration. Some anchor installations may require drilling deeper holes, which may necessitate larger drill bits. The drill bit should be long enough to ensure that the anchor is properly installed at the desired depth.

5. Manufacturer Recommendations

Lastly, it is always important to consult the manufacturer’s recommendations for the specific sleeve anchor you are using. The manufacturer will usually provide guidelines and specifications for the required drill bit size, ensuring a proper and secure installation.

By considering these factors, you will be able to choose the right drill bit size for your 3/8 sleeve anchor installation. This will ensure a secure and reliable attachment to the base material, providing stability and strength for your construction project.

How to Determine the Correct Drill Bit Size

When selecting the correct drill bit size for a 3/8 sleeve anchor, it is important to consider the diameter of the sleeve anchor and the material you are drilling into. Here are the steps to determine the correct drill bit size:

- Refer to the packaging or product documentation: Most sleeve anchors come with recommendations for the appropriate drill bit size. It is always good to start by checking the manufacturer’s specifications for the specific sleeve anchor you are using.

- Measure the diameter of the sleeve anchor: If you do not have access to the packaging or product documentation, you can measure the diameter of the sleeve anchor using a caliper or ruler. Note down the diameter for reference in the next steps.

- Determine the material you are drilling into: The material you are working with will also play a role in selecting the correct drill bit size. Different materials require different drill bit sizes to ensure proper installation. For example, drilling into concrete may require a different drill bit size compared to drilling into wood or metal.

- Consult a drill bit size chart: There are various drill bit size charts available online or at your local hardware store. These charts provide recommendations for drill bit sizes based on the diameter of the anchor and the material you are working with. Consult the chart to find the recommended drill bit size for your sleeve anchor and material.

- Consider using a slightly larger drill bit: Depending on the application and the material, it may be beneficial to use a slightly larger drill bit than the recommended size. This can provide some extra room for expansion and reduce the risk of the anchor coming loose.

Following these steps will help you determine the correct drill bit size for your 3/8 sleeve anchor, ensuring a secure and strong installation.

Tools and Equipment Needed for Drilling

- Power Drill: A power drill is an essential tool for drilling holes. It is recommended to use a drill with variable speed settings for different types of materials.

- Drill Bits: Drill bits come in various sizes and types, such as masonry bits for concrete, wood bits for wood, and metal bits for metal. It is important to use the correct drill bit for the material you are drilling.

- Screwdriver Bits: Screwdriver bits are used to drive screws into the drilled holes. They come in different types, such as Phillips, flathead, and hex bits.

- Hammer or Rubber Mallet: A hammer or rubber mallet is used to tap the drill bit into the material and ensure it stays in place while drilling.

- Clamps: Clamps are useful for holding the material in place while drilling, especially when working with large or heavy pieces.

- Measuring Tape: A measuring tape is used to measure the distance and depth of the holes to be drilled.

- Safety Glasses: Safety glasses are necessary to protect your eyes from debris or sparks that may be generated while drilling.

- Dust Mask: When drilling into materials like concrete or drywall, it is important to wear a dust mask to prevent inhalation of dust particles.

- Work Gloves: Work gloves can provide protection for your hands while drilling, especially if you are working with sharp or rough materials.

It is important to ensure that you have all the necessary tools and equipment before beginning any drilling project. Using the appropriate tools will not only make the task easier and more efficient but also ensure safety while working.

Tips for Using Sleeve Anchors with the Right Size Drill Bit

Choosing the right size drill bit is crucial when using sleeve anchors for your project. Here are some tips to help you ensure that you have the correct size:

1. Read the manufacturer’s instructions

Before starting any drilling, it is important to carefully read and understand the manufacturer’s instructions for the sleeve anchors you are using. The instructions will typically provide the recommended drill bit size for the anchors.

2. Measure the diameter of the sleeve anchor

Use a caliper or ruler to measure the diameter of the sleeve anchor. This will help you determine the appropriate size drill bit to use. Ensure that you measure the actual diameter of the anchor and not the threaded section.

3. Consider the material you are anchoring into

The material you are drilling into will also affect the size of the drill bit you need. Harder materials such as concrete or masonry will require a larger drill bit compared to softer materials like wood or drywall. Refer to drill bit sizing charts for the appropriate bit size.

4. Use a slightly smaller drill bit for expansion anchors

If you are using expansion sleeve anchors, it is recommended to use a drill bit that is slightly smaller than the anchor diameter. This will allow the anchor to expand properly and create a secure hold in the material.

5. Test on a scrap piece of material

Before drilling into your actual project material, it is always a good idea to test the drill bit size on a spare or scrap piece of the same material. This will help you confirm that the drill bit is the right size and prevent any costly mistakes.

6. Consult with a professional

If you are unsure about the right drill bit size to use with sleeve anchors, it is always best to consult with a professional. They will have the knowledge and experience to guide you in choosing the correct size drill bit for your specific application.

By following these tips, you can ensure that you are using the right size drill bit for your sleeve anchors, leading to a successful and secure installation.

FAQ:

What size drill bit should I use for a 3/8 sleeve anchor?

For a 3/8 sleeve anchor, you should use a drill bit with a diameter of 3/8 inch.

Can I use a larger drill bit with a 3/8 sleeve anchor?

No, it is not recommended to use a larger drill bit with a 3/8 sleeve anchor. Using a larger drill bit will result in the anchor not being properly secured and may compromise the strength of the installation.

What happens if I use a smaller drill bit with a 3/8 sleeve anchor?

If you use a smaller drill bit with a 3/8 sleeve anchor, the anchor may not fit properly and you may not be able to fully insert it into the hole. This can lead to a weak and unreliable installation.

Is it important to choose the right size drill bit for a 3/8 sleeve anchor?

Yes, it is crucial to choose the right size drill bit for a 3/8 sleeve anchor. Using the correct drill bit ensures that the anchor will fit securely in the hole and provide the necessary strength and stability for the installation.

Video: