Choosing the Right Drill Bits for Stainless Steel: Top Recommendations

Drilling through stainless steel can be a challenging task, as it is a hard and tough material. Using the wrong drill bits can lead to frustration and ineffective results. To ensure that you get the job done efficiently, it is crucial to choose the right drill bits for stainless steel.

One of the key factors to consider when selecting drill bits for stainless steel is the material composition. High-speed steel (HSS) drill bits are the most common and budget-friendly option. However, for drilling through stainless steel, cobalt drill bits are recommended due to their enhanced hardness and heat resistance.

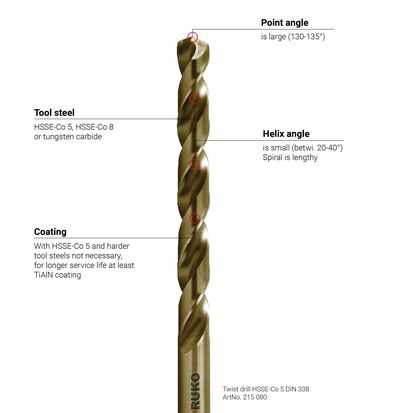

Another important factor to consider is the drill bit’s point angle. For stainless steel, a drill bit with a 135-degree split point is ideal. This design helps to reduce tip walking and ensures a clean and precise hole. Additionally, look for drill bits with a titanium nitride (TiN) coating, as it provides improved lubricity and reduces heat buildup.

When it comes to choosing the right drill bit size, it is advisable to start with a smaller diameter and gradually increase if needed. For stainless steel, a pilot hole is often recommended to prevent the drill bit from slipping and to ensure accuracy. It is also crucial to use the appropriate drilling speed and pressure to avoid damaging the drill bits and the stainless steel.

In conclusion, selecting the right drill bits for stainless steel is essential for achieving successful and efficient drilling results. Choosing cobalt drill bits with a 135-degree split point and a titanium nitride coating can help you overcome the challenges posed by stainless steel. Remember to start with a smaller drill bit size and use proper drilling techniques. With the right tools and techniques, you can tackle any stainless steel drilling project with confidence.

Understanding Stainless Steel

Stainless steel is a versatile and popular material used in various industries due to its durability, corrosion resistance, and aesthetic appeal. It is composed of iron, chromium, and other metallic elements, which give it its unique properties.

Composition

Stainless steel is primarily composed of iron, with a minimum of 10.5% chromium content by mass. The chromium content forms a protective layer on the surface of the steel, known as the passive layer or oxide film, which helps prevent corrosion. Other metallic elements, such as nickel, molybdenum, and manganese, may also be present to enhance specific characteristics of the stainless steel.

Types of Stainless Steel

There are several different types of stainless steel, each with its own unique properties and applications. The most common types include:

- Austenitic stainless steel: This is the most widely used type of stainless steel, known for its excellent corrosion resistance, high ductility, and non-magnetic properties. It is commonly used in kitchen appliances, food processing equipment, and architectural applications.

- Ferritic stainless steel: This type of stainless steel has a higher chromium content, which provides good corrosion resistance and high-temperature strength. It is often used in automotive exhaust systems, heat exchangers, and decorative applications.

- Martensitic stainless steel: Known for its high strength, hardness, and wear resistance, martensitic stainless steel is used in manufacturing cutting tools, knives, and dental and surgical instruments.

- Duplex stainless steel: This type of stainless steel combines the properties of austenitic and ferritic stainless steels, offering high strength, corrosion resistance, and improved toughness. It is commonly used in chemical processing equipment, oil and gas pipelines, and marine environments.

Compatibility with Drill Bits

When working with stainless steel, it is important to choose the right drill bits that are specifically designed for this material. Stainless steel is a tough and hard material, and using regular drill bits may result in slow drilling, overheating, and premature wear of the bits. Carbide or cobalt drill bits are often recommended for drilling stainless steel due to their hardness and heat resistance. It is also important to use cutting lubricant or coolant to reduce friction and heat during the drilling process.

By understanding the properties of stainless steel and choosing the appropriate drill bits, you can ensure successful and efficient drilling in stainless steel materials.

Factors to Consider

When choosing drill bits for stainless steel, there are several factors to consider:

- Material: Stainless steel is a hard material, so it requires drill bits that are specifically designed to handle its toughness. Look for drill bits made from cobalt, carbide, or high-speed steel.

- Bit Type: There are different types of drill bits available, such as twist bits, step bits, and hole saws. Consider the type of hole you need to drill and choose a bit that is suitable for that job.

- Diameter: The size of the hole you need to drill will determine the diameter of the drill bit you should choose. Make sure to select a drill bit with the right diameter for your specific task.

- Coating: Some drill bits have coatings that can enhance their performance and durability. Look for bits with coatings like titanium nitride (TiN) or black oxide, as they can provide better heat resistance and extend the lifespan of the bit.

- Point Angle: The point angle of a drill bit can affect its drilling performance. A larger point angle (135 degrees) is generally better for harder materials like stainless steel, as it reduces dulling and chipping of the bit.

- Speed and Feed Rate: When drilling stainless steel, it is important to use the correct speed and feed rate to ensure the best results. Refer to the manufacturer’s recommendations or consult a drilling speed chart.

- Drill Press vs. Handheld Drill: Depending on the size and complexity of the project, you may need to decide whether to use a drill press or a handheld drill. A drill press can provide more stability and accuracy, especially when drilling larger holes in stainless steel.

- Safety Considerations: Always prioritize safety when working with power tools. Wear appropriate personal protective equipment, such as safety goggles and gloves, and work in a well-ventilated area to reduce exposure to fumes.

Consider these factors when choosing drill bits for stainless steel to ensure that you have the right tools for the job and achieve the desired results.

Types of Drill Bits

When it comes to drilling through stainless steel, choosing the right drill bit is essential for achieving accurate and efficient results. There are several types of drill bits that are commonly used for drilling stainless steel, each with its own unique features and advantages.

1. High-Speed Steel (HSS) Drill Bits

High-speed steel (HSS) drill bits are the most commonly used drill bits for drilling stainless steel. These bits are made from hardened steel alloy and are designed to withstand high temperatures and continuous use. HSS drill bits are suitable for drilling through stainless steel of various thicknesses and can also be used on other materials such as wood and plastic.

2. Cobalt Drill Bits

Cobalt drill bits are another popular choice for drilling stainless steel. These drill bits are made from a combination of cobalt and steel, giving them a higher melting point and greater hardness compared to HSS drill bits. Cobalt drill bits are extremely durable and can drill through stainless steel with ease, making them ideal for heavy-duty drilling tasks.

3. Carbide Drill Bits

Carbide drill bits are specifically designed for drilling through hard materials like stainless steel. These drill bits are made from a combination of carbide and tungsten, making them incredibly strong and resistant to wear. Carbide drill bits are highly effective for drilling through stainless steel, but they can be more expensive than HSS or cobalt drill bits.

4. Diamond Drill Bits

Diamond drill bits are the ultimate choice for drilling through extremely hard materials like stainless steel. These drill bits are made with small diamond particles embedded into the tip, allowing them to cut through the toughest materials. Diamond drill bits are typically used in specialized applications and are more expensive than other types of drill bits.

5. Step Drill Bits

Step drill bits, also known as cone drill bits, are designed to create multiple hole sizes with a single bit. These drill bits have a cone-shaped design with multiple steps of increasing diameter. Step drill bits are particularly useful for drilling holes in stainless steel sheets, as they can quickly and accurately create different-sized holes without the need for changing drill bits.

6. Twist Drill Bits

Twist drill bits are the most basic and commonly used type of drill bits. These drill bits have a spiral shape and are effective for drilling through a variety of materials, including stainless steel. Twist drill bits may not be as specialized as other types of drill bits, but they are readily available and can provide satisfactory results when used correctly.

7. Pilot Point Drill Bits

Pilot point drill bits, also known as self-centering drill bits, are designed to make precise and accurate holes in stainless steel. These drill bits have a pilot point at the tip, which helps to prevent the bit from walking or slipping during drilling. Pilot point drill bits are suitable for drilling through thin stainless steel and can produce clean and accurate holes.

8. Titanium Drill Bits

Titanium drill bits are coated with a layer of titanium nitride, which gives them enhanced hardness and heat resistance. These drill bits are suitable for drilling through stainless steel and other hard materials. The titanium coating helps to reduce friction and increase the lifespan of the drill bit. Titanium drill bits are an excellent choice for general-purpose drilling tasks in stainless steel.

9. Multi-Material Drill Bits

Multi-material drill bits, as the name suggests, are designed for drilling through a variety of materials, including stainless steel. These drill bits typically have a carbide or cobalt tip and are suitable for drilling through stainless steel, wood, plastic, and other materials. Multi-material drill bits are a versatile choice for various drilling applications.

| Drill Bit Type | Advantages | Disadvantages |

|---|---|---|

| High-Speed Steel (HSS) | Widely available, affordable | Less effective on harder stainless steel |

| Cobalt | Highly durable, can withstand high temperatures | More expensive than HSS |

| Carbide | Extremely strong, wear-resistant | Higher cost |

| Diamond | Cuts through the toughest materials | Expensive, specialized use |

| Step | Creates multiple hole sizes with a single bit | Limited to specific hole sizes |

| Twist | Common and readily available | May not provide optimal results for stainless steel |

| Pilot Point | Precision drilling, prevents walking | May not be suitable for thick stainless steel |

| Titanium | Hard and heat-resistant | Coating may wear off over time |

| Multi-Material | Versatile, suitable for various materials | May not provide optimal performance for stainless steel |

Cobalt Drill Bits

- Cobalt drill bits are known for their high performance and durability.

- They are made from a combination of cobalt and steel, which gives them their strength and resistance to heat.

- These drill bits are specifically designed to drill through hard materials like stainless steel.

Advantages of Cobalt Drill Bits

- Extended Lifespan: Cobalt drill bits have a longer lifespan compared to other types of drill bits. This is because they are made from a harder material and can withstand high speeds and pressures.

- Resistance to Heat: Stainless steel can generate a lot of heat during drilling. Cobalt drill bits are designed to handle high temperatures and prevent overheating, which can lead to dulling or breaking of the bit.

- Increased Precision: Cobalt drill bits have sharp cutting edges that allow for clean and precise drilling in stainless steel.

Choosing the Right Cobalt Drill Bit

When choosing a cobalt drill bit for stainless steel, consider the following factors:

- Size: Select the appropriate size of drill bit based on the diameter of the hole you need to drill.

- Coating: Some cobalt drill bits come with a coating to further enhance their durability and reduce friction during drilling.

- Shaft Type: Cobalt drill bits come in various shaft types, such as straight shank, hex shank, and reduced shank. Choose the one that is compatible with your drill.

Tips for Using Cobalt Drill Bits

- Use Lubrication: Apply cutting oil or lubricant to the drill bit to reduce heat build-up and increase the lifespan of the bit.

- Drill at the Right Speed: Cobalt drill bits are designed for high-speed drilling. Ensure that your drill is set at the appropriate speed for stainless steel.

- Apply Steady Pressure: Apply consistent and even pressure while drilling to prevent the bit from wandering or breaking.

- Use Cooling Techniques: To prevent overheating, you can use techniques like peck drilling or periodically dipping the drill bit in water to cool it down.

Cobalt drill bits are an excellent choice for drilling stainless steel due to their durability, heat resistance, and precision. By selecting the right cobalt drill bit and following the proper drilling techniques, you can achieve clean and accurate holes in stainless steel.

Carbide Drill Bits

Carbide drill bits are a popular choice for drilling through stainless steel due to their durability and resistance to wear. These drill bits are made from tungsten carbide, which is a hard and dense material. The carbide tips of the drill bits can withstand high temperatures and can easily cut through stainless steel without dulling.

Carbide drill bits have a unique design that allows them to efficiently remove material while drilling. They usually have a twisted flute shape, which helps to channel away the chips and debris produced during drilling, preventing them from clogging the bit. This design also increases the drilling speed and reduces the risk of overheating.

When using carbide drill bits for stainless steel, it is important to use them at a low speed and with proper lubrication. The high hardness of stainless steel can cause the drill bit to overheat and wear out quickly if not used correctly. Lubricants such as cutting oil or lubricant paste can help to reduce the heat and friction generated during drilling, prolonging the life of the carbide drill bit.

Carbide drill bits come in various sizes and shapes to suit different drilling needs. They can be used with both handheld drills and drill presses. When choosing a carbide drill bit for stainless steel, it is important to consider the size and thickness of the material you are drilling through. Using the correct drill bit size will ensure clean and accurate holes in the stainless steel.

In summary, carbide drill bits are an excellent choice for drilling through stainless steel due to their durability and resistance to wear. Their unique design helps to efficiently remove material and prevent clogging. When used correctly with proper lubrication, carbide drill bits can provide clean and accurate holes in stainless steel.

Titanium Drill Bits

Titanium drill bits are another popular option for drilling through stainless steel. These drill bits are made from high-speed steel (HSS) that has been coated with a layer of titanium nitride. The titanium coating helps to increase the hardness and durability of the drill bits, making them suitable for drilling through tough materials like stainless steel.

Advantages of Titanium Drill Bits

- Increased durability: The titanium coating on these drill bits provides extra protection against wear and tear, which can extend their lifespan.

- Heat resistance: Titanium drill bits can handle high temperatures generated during drilling, preventing overheating and damage to the drill bits.

- Reduced friction: The titanium coating reduces friction between the drill bit and the workpiece, allowing for smoother and faster drilling.

- Precise drilling: Titanium drill bits have sharp cutting edges that enable precise drilling, resulting in clean and accurate holes.

Disadvantages of Titanium Drill Bits

- Price: Titanium drill bits are generally more expensive than regular HSS drill bits.

- Brittleness: The titanium coating can make the drill bits more brittle, increasing the risk of breakage if not used correctly.

- Reduced hardness: While the titanium coating increases the overall hardness of the drill bits, it is not as hard as some other coatings, such as cobalt.

Choosing the Right Titanium Drill Bits

When choosing titanium drill bits for stainless steel, consider the following factors:

- Size: Select the appropriate drill bit size based on the hole diameter you need for your project.

- Coating quality: Look for drill bits with a high-quality titanium coating that provides excellent durability and heat resistance.

- Point angle: Different drill bits have different point angles, which affect their drilling performance. Choose the appropriate point angle for stainless steel drilling.

- Drill bit set: Consider purchasing a drill bit set that includes various sizes and types of titanium drill bits, offering versatility for different projects.

Conclusion

Titanium drill bits are a reliable option for drilling through stainless steel. Their titanium coating enhances durability and heat resistance, enabling precise drilling and smooth performance. However, they may be more expensive and slightly less hard than alternatives like cobalt drill bits. Consider the specific requirements of your project and choose the appropriate titanium drill bits for optimal results.

Diamond Drill Bits

Diamond drill bits are a popular choice for drilling through stainless steel due to their durability and ability to maintain sharpness even after prolonged use. These drill bits feature a diamond coating on the tip, which allows them to easily cut through hard materials like stainless steel.

Advantages of Diamond Drill Bits:

- Diamond drill bits are extremely hard, making them suitable for drilling through tough materials like stainless steel.

- They can maintain their sharpness for a long time, resulting in cleaner and faster drilling.

- Due to their precision and accuracy, diamond drill bits can create clean and smooth holes in stainless steel.

- They are versatile and can be used for various applications, including drilling holes for faucets, pipes, and electrical wiring.

Choosing the Right Diamond Drill Bit:

When selecting a diamond drill bit for stainless steel, there are a few factors to consider:

- Size: Choose a drill bit size that matches the diameter of the hole you need to drill. It is important to select the right size to ensure the desired fit.

- Coating: Look for diamond drill bits with a high-quality diamond coating that can withstand the rigors of drilling through stainless steel.

- Shank Type: Consider the shank type of the diamond drill bit. Some may have a hex shank, while others have a round shank. Choose the one that is compatible with your drill.

Tips for Using Diamond Drill Bits:

- Use a drill press or a stable surface to ensure precise drilling.

- Apply appropriate cutting lubrication to reduce heat and prolong the life of the diamond drill bit.

- Start drilling at a slow speed and gradually increase the speed to prevent overheating.

- Keep the drill bit steady and avoid excessive pressure to prevent the diamond coating from chipping or wearing away.

Overall, diamond drill bits are a reliable option for drilling through stainless steel. With their durability and precision, they make the drilling process easier and more efficient.

Top Recommendations

1. Bosch CO2141 Cobalt Drill Bit Set

The Bosch CO2141 Cobalt Drill Bit Set is a high-quality option for drilling into stainless steel. Made from cobalt alloy, these drill bits are extremely durable and can handle the tough nature of stainless steel. The set includes 14 different sizes ranging from 1/16 inch to 3/8 inch, ensuring you have the right bit for any job.

Pros:

- Durable cobalt alloy construction

- Includes 14 different sizes

- Designed for stainless steel

Cons:

- Relatively expensive

2. DEWALT DW1354 Brad Point Drill Bit Set

The DEWALT DW1354 Brad Point Drill Bit Set is another excellent option for drilling into stainless steel. These bits have a brad point design, which helps to prevent wandering and ensures accurate drilling. The set includes 14 different sizes ranging from 1/16 inch to 1/2 inch.

Pros:

- Brad point design for accurate drilling

- Includes 14 different sizes

- Works well on stainless steel

Cons:

- May require frequent sharpening

3. Norseman Drill Bits 44170 Ultra Dex Type 240-UB 135 Degree Split Point Magnum Super Premium Jobber Drill Set

The Norseman Drill Bits 44170 Ultra Dex Type 240-UB set is a high-end option for drilling stainless steel. These drill bits feature a split point design, which helps to reduce walking and ensures precise drilling. The set includes 29 different sizes ranging from 1/16 inch to 1/2 inch.

Pros:

- Split point design for precise drilling

- Includes 29 different sizes

- High-quality construction

Cons:

- Expensive

4. COMOWARE Cobalt Drill Bit Set

The COMOWARE Cobalt Drill Bit Set offers good value for money and is suitable for drilling into stainless steel. These drill bits have a 5% cobalt alloy construction, which ensures durability and heat resistance. The set includes 13 different sizes ranging from 1/16 inch to 1/4 inch.

Pros:

- Durable cobalt alloy construction

- Good value for money

- Works well on stainless steel

Cons:

- May require frequent re-sharpening

5. Craftsman Evolve 100 pc. Drill Bit Kit

If you’re looking for a versatile drill bit set that can handle stainless steel, the Craftsman Evolve 100 pc. Drill Bit Kit is a great choice. This kit includes a wide range of drill bits in various sizes and types, including some specifically designed for metal and stainless steel. The set also comes with a storage case for easy organization and portability.

Pros:

- Includes a wide range of drill bit sizes and types

- Comes with a storage case

- Some drill bits are specifically designed for stainless steel

Cons:

- May not be as durable as higher-end drill bit sets

FAQ:

What type of drill bits are best for stainless steel?

When it comes to drilling through stainless steel, it is best to use cobalt drill bits. Cobalt drill bits are made from a special high-speed steel alloy that contains cobalt. This makes them extremely durable and able to withstand the heat and pressure that drilling through stainless steel requires.

Can I use regular drill bits on stainless steel?

Regular drill bits are not recommended for drilling through stainless steeel. Stainless steel is a tough and hard material, and drilling through it requires specially designed drill bits that can handle the heat and pressure. Regular drill bits may wear out quickly or even break when used on stainless steel.

What size drill bit do I need for stainless steel?

The size of the drill bit you need for stainless steel will depend on the specific project you are working on. Generally, for small holes, such as pilot holes, you can use a smaller drill bit and gradually increase the size until you reach the desired hole diameter. For larger holes, it is best to use a drill bit specifically designed for larger diameters in stainless steel.

How do I choose the right drill bit for stainless steel?

When choosing a drill bit for stainless steel, there are several factors to consider. First, consider the material the drill bit is made of. Cobalt drill bits are highly recommended for stainless steel due to their durability. Second, consider the type of drill bit – twist drill bits, step drill bits, or hole saws are commonly used for stainless steel. Finally, consider the size and diameter of the hole you need to drill and ensure that the drill bit you choose can accommodate that size.

What are some top recommendations for drill bits for stainless steel?

There are several top recommendations for drill bits for stainless steel. Some popular brands include DEWALT, Bosch, Irwin, and Hymnorq. In terms of specific models, the DEWALT Titanium Drill Bit Set and the Irwin Industrial Tools Cobalt M-35 Metal Index Drill Bit Set are highly recommended for stainless steel. These sets offer a variety of sizes and are made of high-quality materials that can effectively drill through stainless steel.

Are there any tips for drilling through stainless steel?

Yes, here are some tips for drilling through stainless steel. First, use a slow speed setting on your drill to avoid overheating the drill bit. Second, apply cutting fluid or lubricant to the drill bit to reduce friction and heat. Third, start with a small pilot hole and gradually increase the size. This will prevent the drill bit from wandering or slipping on the surface of the stainless steel. Finally, use steady and consistent pressure while drilling to ensure a clean and accurate hole.

Video: