Choosing the Right Drill Bit Size for Rebar: A Comprehensive Guide

Working with rebar can be a challenging task, especially when it comes to drilling into it. Whether you’re a professional contractor or a DIY enthusiast, selecting the right drill bit size for rebar is crucial to ensure a successful and efficient drilling process.

Rebar, which stands for reinforcing bar, is commonly used in construction projects to provide additional strength and support to concrete structures. It’s made of steel and is typically used to reinforce concrete slabs, walls, and foundations. However, drilling into rebar requires specialized tools and techniques to ensure clean and precise holes.

The drill bit size you choose for rebar depends on various factors, including the diameter of the rebar, the type of material you’re drilling through, and the specific application you’re working on. Using the wrong drill bit size can result in excessive heat, increased wear on the drill bit, and potential damage to the rebar or surrounding materials.

This comprehensive guide will walk you through the process of choosing the right drill bit size for rebar. We’ll explore the different factors to consider, provide tips for selecting the appropriate size, and offer advice on drilling techniques to ensure optimal results. By following this guide, you’ll be able to tackle rebar drilling projects with confidence and precision.

Understanding the Importance of Drill Bit Size when Working with Rebar

When working with rebar, it is crucial to use the right drill bit size. This is because the size of the drill bit directly affects the quality and strength of the hole that is drilled into the rebar. The hole needs to be a precise size to accommodate the rebar and ensure a secure and stable connection.

Using the wrong drill bit size can lead to a variety of issues. If the drill bit is too small, the hole may not be large enough to fit the rebar, resulting in a weak connection. On the other hand, if the drill bit is too large, the hole may be too big, causing the rebar to have too much space and decreasing the overall strength of the structure.

When selecting the drill bit size for rebar, it is important to consider the diameter of the rebar and the type of connection being made. Different connections may require different hole sizes, so it is crucial to carefully review the project specifications and consult with professionals if needed.

One common method to determine the appropriate drill bit size for rebar is to use a drill bit gauge. This tool allows you to measure the diameter of the rebar and select the corresponding drill bit size from a chart or guide. This ensures that the hole will be the correct size for the rebar, providing a strong and reliable connection.

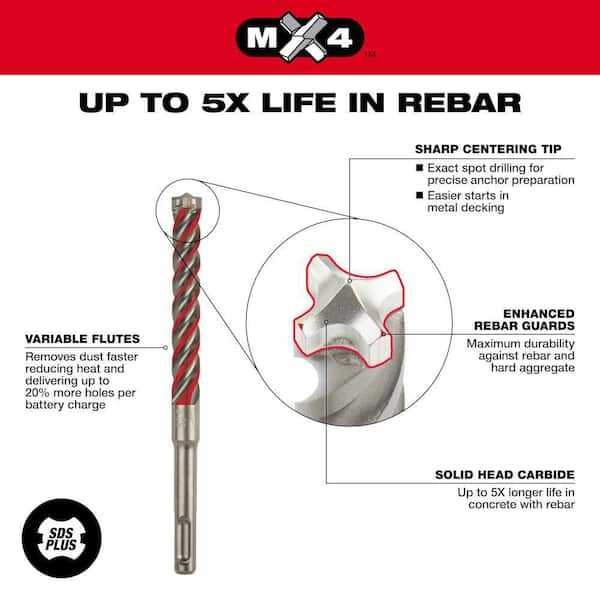

It is also important to consider the material of the drill bit when working with rebar. Carbide-tipped drill bits are often recommended for drilling into rebar as they are able to withstand the hardness of the material and provide a clean and precise hole.

Overall, understanding the importance of drill bit size when working with rebar is crucial for ensuring the strength and stability of the structure. Taking the time to select the correct drill bit size and using the appropriate tools will result in a secure and long-lasting connection.

Factors to Consider when Choosing the Right Drill Bit Size

When it comes to drilling into rebar, choosing the right drill bit size is crucial. Here are a few factors to consider:

1. Rebar Diameter

The diameter of the rebar you are working with will determine the size of the drill bit you should use. Measure the diameter of the rebar carefully to ensure you choose a drill bit that is the right fit.

2. Material Type

The type of material you are drilling into will also play a role in determining the appropriate drill bit size. Different materials, such as concrete or steel, may require different drill bit sizes to achieve the desired result.

3. Desired Hole Size

The size of the hole you want to create will also influence the drill bit size you choose. If you need a small hole, you will need a smaller drill bit. Conversely, if you need a larger hole, you will need a larger drill bit.

4. Drill Type

Consider the type of drill you are using. Some drills may require specific drill bit sizes, so it’s important to check the manufacturer’s recommendations or specifications for the drill to ensure you are using the correct size.

5. Depth of Hole

The depth of the hole you need to drill will also impact the drill bit size. Deeper holes may require longer drill bits, while shallower holes may require shorter ones.

6. Drill Bit Material

The material of the drill bit itself is also important to consider. Different materials, such as carbide or high-speed steel, have different properties and may be better suited for certain applications. Consult the manufacturer’s recommendations for the appropriate drill bit material for your specific needs.

7. Safety Precautions

Always prioritize safety when choosing and using drill bits. Make sure you are wearing proper protective gear, such as safety glasses and gloves, and follow all safety guidelines provided by the manufacturer.

By considering these factors, you can ensure you choose the right drill bit size for your rebar drilling needs, resulting in accurate and efficient drill holes.

Types of Drill Bits Suitable for Drilling Rebar

Drilling through rebar requires specialized drill bits that are designed to handle the toughness and hardness of the material. The following are some of the most commonly used types of drill bits that are suitable for drilling rebar:

- HSS Bits (High-Speed Steel Bits): These drill bits are made from high-speed steel and are generally used for drilling through softer metals like steel. While they can be used to drill through rebar, they may wear out quickly due to the hardness of the material.

- Cobalt Bits: Cobalt drill bits are made from a blend of cobalt and steel, making them more durable and heat-resistant compared to HSS bits. They can effectively drill through rebar without losing their sharpness.

- Carbide-Tipped Bits: These drill bits are made from carbide, a hard and brittle material. The carbide tip provides excellent performance when drilling through rebar, as it is highly resistant to heat and can maintain its sharpness for a longer period of time.

- Diamond Core Bits: Diamond core bits are the most effective drill bits for drilling through rebar. They are constructed with diamond-impregnated segments on the tip, which allows them to cut through rebar quickly and efficiently. These bits are commonly used in professional drilling applications.

When choosing a drill bit for drilling rebar, consider the size and thickness of the rebar, as well as the type of material you will be drilling into. It is also important to use a drill with sufficient power to handle the drilling process effectively and prevent the drill bit from getting stuck or damaged.

The Role of Drill Bit Diameter in Ensuring Precision and Stability

The diameter of the drill bit plays a crucial role in the precision and stability of drilling through rebar. Selecting the right diameter for your drill bit is essential to ensure accurate and efficient drilling operations.

1. Drilling Accuracy:

Choosing the appropriate drill bit diameter is critical for achieving drilling accuracy. A larger diameter bit allows for faster drilling but may sacrifice precision as it can cause the hole to be slightly larger than intended. On the other hand, a smaller diameter bit provides greater precision but may require more time and effort for drilling.

2. Hole Quality:

The diameter of the drill bit also affects the quality of the drilled hole. A properly sized bit will create a clean and uniform hole with smooth walls, minimizing the risk of cracks or damage to the surrounding rebar. Using a bit with a diameter too small or too large may result in an irregular hole, affecting the overall stability of the structure.

3. Stability and Load-Bearing Capacity:

The stability and load-bearing capacity of the rebar structure depend on the accuracy and quality of the drilled holes. Using a drill bit with the right diameter ensures that the rebar is securely placed and allows for proper alignment and connection of the reinforcement bars. A precise and stable drilling operation contributes to the overall strength and durability of the structure.

4. Compatibility with Anchoring Systems:

The diameter of the drill bit should also be compatible with the anchoring system used for securing the rebar. Whether it’s a mechanical anchor or an adhesive anchor, the drill bit should be sized to accommodate the required anchor diameter. Failing to match the bit diameter with the anchoring system can compromise the effectiveness of the connection.

| Diameter (inches) | Diameter (mm) |

|---|---|

| 3/8 | 9.5 |

| 1/2 | 12.7 |

| 5/8 | 15.9 |

| 3/4 | 19.0 |

| 7/8 | 22.2 |

| 1 | 25.4 |

Choosing the right drill bit diameter for rebar drilling depends on various factors such as the specific application, the type of rebar being drilled, and the desired level of precision. It is essential to refer to the manufacturer’s guidelines and consult with experts to ensure the best results in terms of both precision and stability.

Exploring the Different Sizes of Drill Bits for Various Rebar Projects

When working on a project that involves rebar, it is crucial to choose the right drill bit size to ensure precise and efficient drilling. The size of the drill bit you use will depend on the diameter of the rebar and the specific requirements of your project.

Standard Drill Bit Sizes

Standard drill bit sizes typically range from 1/16 inch to 1 inch, and they are designated by fractions or decimal inches. These general-purpose bits come in handy for a variety of tasks and can be used on rebar of smaller diameters.

Here are some common sizes of standard drill bits:

- 1/16 inch

- 1/8 inch

- 3/16 inch

- 1/4 inch

- 5/16 inch

- 3/8 inch

- 1/2 inch

- 5/8 inch

- 3/4 inch

- 7/8 inch

- 1 inch

Specialty Drill Bit Sizes

For larger diameter rebar or specialized projects, specialty drill bits are available. These bits are usually designed to drill through thick or hardened materials and offer extra durability and precision.

Some examples of specialty drill bits for rebar projects include:

- Auger Bits: Perfect for drilling clean and accurate holes in larger diameter rebar. They have a spiral shape that assists in chip removal.

- Diamond Core Bits: Ideal for drilling through reinforced concrete with rebar. These bits feature diamond-impregnated tips for enhanced cutting power.

- Carbide-Tipped Bits: Known for their strength and hardness, carbide-tipped bits can effortlessly drill through concrete with rebar.

- Step Bits: These bits are designed to create different size holes in a single drilling operation. They are often used in electrical or plumbing installations involving rebar.

Choosing the Right Size

When selecting the drill bit size for your rebar project, it is essential to consider the diameter of the rebar you are working with. The diameter of the rebar will determine the size of the hole you will need to drill.

It is crucial to choose a drill bit that is slightly larger than the diameter of the rebar. This ensures that the hole will be able to accommodate the rebar without causing undue stress or damage.

Consulting a drilling chart, which provides recommended drill bit sizes for various rebar diameters, can be helpful in determining the right size to use.

Conclusion

Choosing the correct drill bit size is essential for successful drilling through rebar in any project. Whether you are using standard bits or specialty bits, selecting the appropriate size ensures precise and efficient drilling, minimizing the risk of damage or failure.

Remember to always consider the diameter of the rebar and consult a drilling chart if needed. By doing so, you can confidently tackle any rebar project with the right tools and achieve professional, reliable results.

How to Determine the Ideal Drill Bit Size for Your Rebar Project

1. Measure the Diameter of the Rebar

Before determining the ideal drill bit size, you need to measure the diameter of the rebar you will be drilling into. This can be done using a caliper or a measuring tape. Make sure to measure the widest part of the rebar to get an accurate diameter measurement.

2. Choose the Drill Bit Size

Once you have measured the diameter of the rebar, you can choose the appropriate drill bit size. The drill bit should be slightly larger than the diameter of the rebar to ensure a proper fit. It is recommended to use a drill bit that is 1/32 to 1/16 inch larger than the rebar diameter.

3. Consider the Rebar’s Depth

In addition to the diameter, you should also consider the depth of the rebar you will be drilling into. If the rebar is shorter, a shorter drill bit may be sufficient. However, if the rebar is longer, you may need a longer drill bit to reach the desired depth.

4. Refer to a Drill Bit Size Chart

If you are unsure about the appropriate drill bit size for your rebar project, you can refer to a drill bit size chart. These charts provide recommended drill bit sizes for various rebar diameters. They can be found online or in hardware stores.

5. Test the Drill Bit Size

Before starting your rebar project, it is always a good idea to test the drill bit size on a scrap piece of rebar. This will ensure that the drill bit is the right size and will create the desired hole in the rebar.

6. Use High-Quality Drill Bits

When drilling into rebar, it is important to use high-quality drill bits that are designed for the task. These drill bits are made from strong materials and have sharp cutting edges to penetrate the rebar effectively. Using low-quality drill bits can lead to inaccurate holes and increased risk of accidents.

7. Follow Proper Drilling Techniques

Finally, when drilling into rebar, it is crucial to follow proper drilling techniques. This includes using the correct drilling speed, applying consistent pressure, and ensuring the drill bit remains perpendicular to the rebar. Following these techniques will help you achieve clean and precise holes in the rebar.

By following these steps, you can determine the ideal drill bit size for your rebar project and ensure successful drilling. Remember to always prioritize safety and use the appropriate tools and techniques for the job.

Best Practices for Drilling Rebar with the Correct Bit Size

1. Choose the right drill bit size

One of the most important factors in drilling rebar is choosing the correct drill bit size. Using the wrong size bit can lead to inefficiency, damage to the drill bit, and even potential injury. It is essential to match the size of the drill bit to the diameter of the rebar you are working with.

Refer to the rebar specifications or measuring tools to determine the diameter of the rebar accurately. Once you have this measurement, select a drill bit that aligns with the rebar’s diameter. It is recommended to choose a bit size that is slightly larger to allow for smoother drilling and reduce the risk of binding.

2. Use a high-quality drill bit

Investing in a high-quality drill bit specifically designed for drilling through rebar is crucial for achieving the best results. These bits are typically made with carbide or cobalt materials, which provide excellent durability and can withstand the tough demands of drilling through rebar.

Avoid using cheap or low-quality drill bits, as they may wear out quickly or break during the drilling process. This not only compromises the quality of your work but also poses a safety risk.

3. Secure the rebar properly

Before drilling, ensure that the rebar is securely held in place. Unstable or loose rebar can cause the drill bit to slip or bind, leading to inaccurate holes or potential accidents.

Use clamps or vices to hold the rebar steady and prevent it from moving during drilling. This will not only improve the accuracy of your holes but also increase the overall efficiency of the drilling process.

4. Apply lubrication

Applying lubrication to the drill bit and rebar can significantly improve drilling performance and extend the lifespan of the drill bit. The lubrication reduces the friction between the drill bit and rebar, allowing for smoother drilling and preventing overheating.

Use a cutting fluid or a lubricant specifically designed for drilling metal when working with rebar. Apply the lubrication to the drill bit and the area where you will be drilling. This will help reduce heat buildup and remove metal shavings, ensuring a cleaner and more efficient drilling process.

5. Drill at a lower speed

When drilling through rebar, it is generally recommended to use a lower drill speed setting. This helps prevent overheating and reduces the risk of damaging the drill bit or the rebar itself.

Set your drill to a slower speed and maintain a consistent and steady drilling rhythm. This will allow the drill bit to gradually penetrate the rebar, reducing the likelihood of binding, chipping, or breaking.

6. Clear the holes regularly

As you drill through rebar, metal shavings and debris can accumulate in the holes, causing clogging and obstructing the drilling process. It is crucial to clear these shavings regularly to maintain a smooth and efficient drilling operation.

After drilling each hole, use a wire brush or a drill bit cleaning tool to remove the metal shavings from the hole. This will ensure the next hole is started cleanly, reducing the chances of binding or misalignment.

By following these best practices, you can drill rebar with the correct bit size more effectively and efficiently. Remember to prioritize safety and choose high-quality tools for the best results.

Common Mistakes to Avoid When Selecting Drill Bit Sizes for Rebar

When it comes to drilling into rebar, selecting the right drill bit size is crucial for the success of your project. However, many people make common mistakes when choosing the drill bit size for rebar, which can lead to issues during drilling and compromised structural integrity. To ensure a smooth and efficient drilling process, avoid these mistakes:

1. Choosing a Drill Bit Size that is Too Small

One of the most common mistakes is using a drill bit size that is too small for the thickness of the rebar. When the drill bit is too small, it may not be able to penetrate the rebar effectively, resulting in slow drilling, excessive wear on the bit, and potential damage to the rebar. Always choose a drill bit size that is appropriate for the diameter of the rebar you are drilling into.

2. Ignoring the Type of Rebar

Another mistake is ignoring the type of rebar when selecting a drill bit size. Different types of rebar, such as carbon steel or stainless steel, may require different drill bit sizes. Carbon steel rebar is generally easier to drill into than stainless steel rebar, so you may need a larger drill bit for the latter. Always consider the type of rebar you are working with when choosing the drill bit size.

3. Not Considering the Depth of the Hole

The depth of the hole is an important factor to consider when selecting the drill bit size. If the drill bit is too short for the required hole depth, you may not be able to drill deep enough into the rebar, compromising the structural integrity of the project. Always ensure that the drill bit is long enough to reach the desired hole depth.

4. Failing to Use High-Quality Drill Bits

Using low-quality or worn-out drill bits is a common mistake that can lead to poor drilling performance and premature bit failure. High-quality drill bits are designed to withstand the high forces and pressures involved in drilling through rebar, providing a clean and precise hole. Invest in good-quality drill bits that are specifically designed for drilling into rebar.

5. Not Using Lubrication

Drilling through rebar can generate a significant amount of heat, which can lead to premature bit wear and reduce drilling efficiency. Using lubrication during the drilling process can help dissipate heat and reduce friction, resulting in smoother and faster drilling. Always use a suitable lubricant or cutting oil when drilling into rebar.

6. Overlooking Safety Precautions

Lastly, overlooking safety precautions is a common mistake that can have serious consequences. When drilling into rebar, always wear protective gear such as safety goggles, gloves, and ear plugs to protect yourself from flying debris and excessive noise. Additionally, ensure that the drilling area is clear of obstructions and secure the rebar firmly to prevent it from moving during drilling.

By avoiding these common mistakes, you can ensure that the drill bit size you select for drilling into rebar is appropriate, resulting in efficient drilling and a successful project outcome.

The Impact of Incorrect Drill Bit Size on Rebar Strength and Stability

Introduction

When it comes to drilling into rebar, selecting the right drill bit size is crucial for ensuring the strength and stability of the rebar structure. Using an incorrect drill bit size can have significant consequences, compromising the integrity of the rebar and potentially leading to structural failure.

Decreased Strength

Using a drill bit size that is too small for the rebar can result in decreased strength. When the drill bit is too small, it may not be able to penetrate the rebar effectively, leading to incomplete holes or cracks. This can weaken the rebar and reduce its load-bearing capacity, making it more susceptible to breaking or bending under stress.

Reduced Stability

An incorrect drill bit size can also compromise the stability of rebar structures. If the drill bit is too large, it can create oversized holes in the rebar. These oversized holes can make it difficult to secure the rebar properly, allowing for movement and shifting. This instability can weaken the overall structure and increase the risk of collapse or failure.

Inefficient Load Distribution

Using the wrong drill bit size can result in inefficient load distribution along the rebar. If the holes drilled into the rebar are too small, the load may not be distributed evenly across the bar. This can lead to localized stress concentrations, increasing the likelihood of fatigue and failure. Conversely, if the holes are too large, the load distribution may be uneven, causing certain areas of the rebar to bear more weight than others.

Conclusion

Choosing the correct drill bit size is critical for maintaining the strength and stability of rebar structures. Incorrectly sized drill bits can weaken the rebar, compromise the structure’s stability, and result in inefficient load distribution. It is essential to carefully select the appropriate drill bit size for drilling into rebar to ensure the longevity and safety of the structure.

FAQ:

What is rebar and why is it important to choose the right drill bit size for it?

Rebar, short for reinforcing bar, is a steel bar used to reinforce concrete structures to increase their strength and durability. Choosing the right drill bit size for rebar is important because using the wrong size can result in inefficient drilling, damage to the drill bit, and may compromise the strength of the reinforced concrete.

How do I determine the correct drill bit size for rebar?

To determine the correct drill bit size for rebar, you need to consider the diameter of the rebar and the thickness of the concrete. You can use a chart or consult a drilling expert for guidance. It is important to choose a drill bit size that matches the diameter of the rebar to ensure proper drilling and avoid potential problems.

What are some common drill bit sizes for drilling through rebar?

There are several common drill bit sizes for drilling through rebar, including 5/32 inch, 3/16 inch, 1/4 inch, 5/16 inch, and 3/8 inch. The specific size you choose depends on the diameter of the rebar and the thickness of the concrete. It is important to select a drill bit that matches the size and type of rebar you are working with to achieve the best results.

What are the consequences of using a drill bit that is too small for the rebar?

Using a drill bit that is too small for the rebar can lead to several consequences. The drill bit may become damaged or break due to the excessive force required to drill through the rebar. Additionally, drilling with a small drill bit can result in inefficient drilling, as it may take longer to create the required hole. It can also compromise the structural integrity of the reinforced concrete, leading to potential safety hazards.

Can I use a drill bit that is larger than the rebar diameter?

While it is generally not recommended to use a drill bit that is larger than the diameter of the rebar, there are certain situations where it may be acceptable. For example, if you need to create a larger hole to accommodate other elements in the structure, such as wiring or plumbing, you may need to use a larger drill bit. However, it is important to ensure that the hole still provides sufficient support to the rebar and the overall structural integrity.

Video: