Choosing the Right Drill Bit Size for an 8mm Tap

When it comes to tapping holes, choosing the right drill bit size is crucial. The drill bit size determines the width of the hole, which in turn affects the strength and effectiveness of the tapped thread. For an 8mm tap, selecting the proper drill bit size is especially important to ensure that the resulting thread is secure and functional.

To determine the correct drill bit size for an 8mm tap, it is essential to consider the specific requirements of the job. The material being drilled into, the type of tap being used, and the desired thread engagement all play a role in determining the appropriate drill bit size.

One common method for selecting the drill bit size for an 8mm tap is to use a drill bit that is slightly smaller in diameter than the tap. This allows for the tap to cut its own threads as it is being inserted into the hole. However, if the material being drilled into is particularly hard or brittle, it may be necessary to use a drill bit that is larger in diameter to ensure the threads are properly formed.

It is also important to consider the desired thread engagement when selecting the drill bit size. Thread engagement refers to the amount of the tap that is embedded in the drilled hole. For a secure and functional thread, it is generally recommended to have at least 1.5 times the diameter of the tap as the thread engagement.

Ultimately, choosing the right drill bit size for an 8mm tap requires careful consideration of the specific requirements of the job. By understanding the material, tap type, desired thread engagement, and other factors, you can ensure that the resulting thread is strong, secure, and effective for its intended purpose.

Drill Bit Size Considerations

When choosing the right drill bit size for an 8mm tap, there are a few factors to consider. These considerations will help ensure that the tap fits properly and that the threaded hole is the correct size for the desired project.

1. Tap Size

The size of the tap is the most important factor in determining the drill bit size. In this case, we are using an 8mm tap, so it is crucial to choose a drill bit size that matches this diameter. Using a drill bit that is too small will result in a hole that is too small, preventing the tap from fitting. On the other hand, using a drill bit that is too large may result in a hole that is too big, causing the tap to fit loosely and potentially compromising the integrity of the threaded hole.

2. Material Type

The material type of the workpiece also plays a role in determining the appropriate drill bit size. Different materials have different drilling characteristics, and some materials may require a slightly larger or smaller drill bit size to achieve the desired thread. It is important to consider the material type before selecting a drill bit size to ensure that the drilling process goes smoothly and the tap fits properly.

3. Thread Type

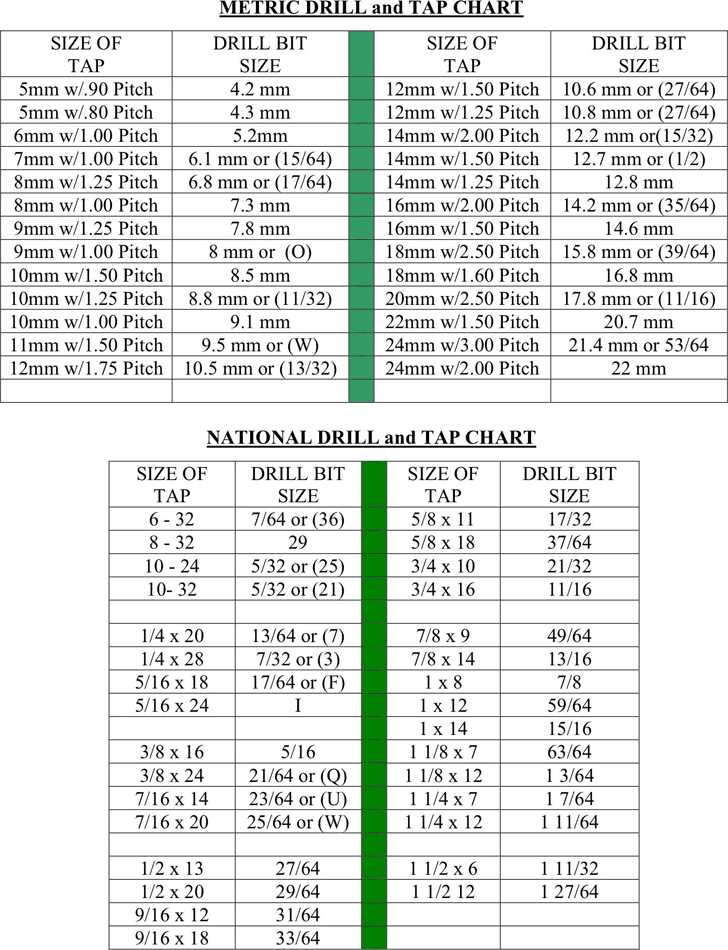

The thread type is another consideration when selecting a drill bit size. Different thread types have specific requirements for the size of the hole that needs to be drilled. It is essential to know the thread type being used with the 8mm tap and select a drill bit size that will create a hole compatible with that thread type. This will ensure that the threads engage properly and that the final project meets the desired specifications.

4. Depth of Hole

The depth of the hole is also a factor to consider when choosing the drill bit size. Depending on the specific project requirements, the hole may need to be drilled to a certain depth. It is important to select a drill bit that will produce a hole of the correct depth to accommodate the tap and allow for the desired thread. Not drilling deep enough can result in incomplete threading, while drilling too deep can compromise the structural integrity of the workpiece.

5. Pilot Hole

In some cases, it may be necessary to create a pilot hole before drilling the final hole for the tap. A pilot hole is a smaller hole that guides the drill bit and helps ensure accurate placement and drilling. The size of the pilot hole will depend on the specific project requirements, but it is generally smaller than the final hole. Consider the need for a pilot hole before choosing the appropriate drill bit size for the final hole.

By considering these factors – tap size, material type, thread type, depth of hole, and the need for a pilot hole – you can select the right drill bit size for your 8mm tap, ensuring a proper fit and successful threading. Remember to consult tap and drill bit size charts for specific recommendations based on the thread type and material being used.

Importance of Proper Drill Bit Size

When it comes to using a tap to create threads in a material, such as metal, it is essential to choose the right drill bit size. The drill bit size determines the diameter of the hole that needs to be drilled before tapping. Properly matching the drill bit size with the tap size is crucial for ensuring clean and accurate threads.

1. Ensures Proper Fit

Using the correct drill bit size ensures that the hole diameter is just slightly smaller than the tap size. This ensures a proper fit between the tap and the hole, allowing the threads to be formed correctly. If the hole is too small, it can cause the tap to bind or break, resulting in damaged threads. On the other hand, if the hole is too large, the tap may not have enough material to grip, resulting in loose or weak threads.

2. Prevents Tapping Difficulties

Choosing the right drill bit size also helps to prevent tapping difficulties. If the drill bit size is too small, it can make it challenging to start the tap. The tap may not catch the metal or may easily veer off-center, leading to crooked or misaligned threads. Additionally, a small drill bit size can cause excessive heat and friction, which can dull the tap prematurely and make tapping more difficult overall.

3. Promotes threading Efficiency

Properly matching the drill bit size with the tap size promotes threading efficiency. When the hole is the correct size, it allows the tap to cut the threads smoothly and effortlessly. This not only saves time but also ensures clean and precise threads. Efficient threading also reduces the risk of tap breakage and extends the lifespan of both the tap and the drill bit.

4. Maximizes Thread Strength

By using the proper drill bit size, the threads created are more likely to have maximum strength. The correct hole diameter ensures that the threads have enough material to form a secure connection. This is especially important when dealing with materials that require strong and reliable threads, such as metal. Proper thread strength contributes to the overall stability and durability of the project or product.

In conclusion, the importance of using the proper drill bit size for tapping cannot be overstated. It ensures a proper fit, prevents tapping difficulties, promotes threading efficiency, and maximizes thread strength. Taking the time to select the right drill bit size before tapping can save time, prevent damage, and result in high-quality threads.

Factors to Take into Account

The process of choosing the right drill bit size for an 8mm tap involves considering several factors. These factors can affect the performance and functionality of the tap, as well as the overall success of the drilling operation. Below are some important factors to take into account:

Material of the Workpiece

The type of material being drilled into is a crucial factor to consider when determining the appropriate drill bit size. Different materials have different hardness levels, which directly influence the drilling process. Harder materials may require larger drill bit sizes to ensure proper hole formation.

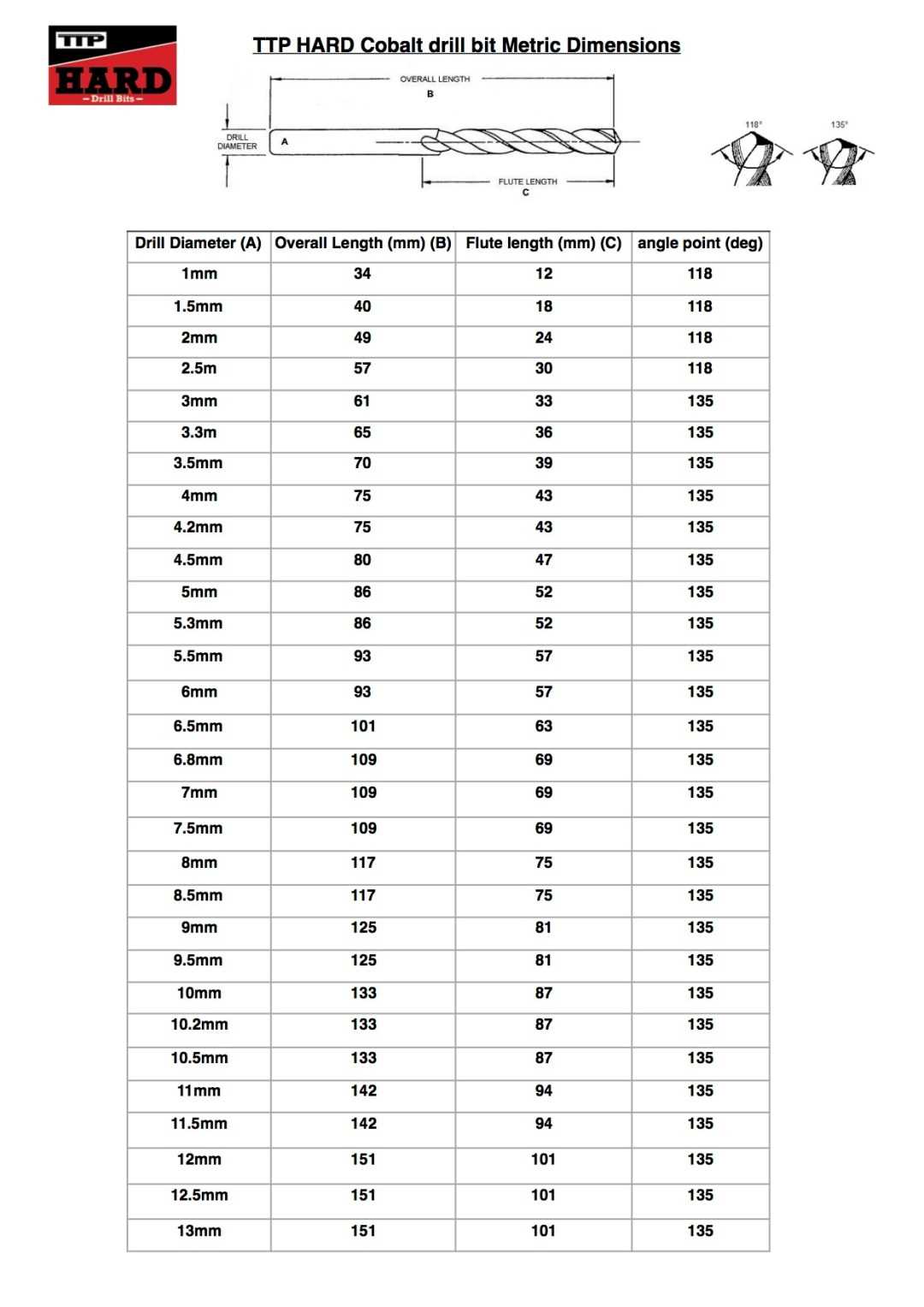

Tap Geometry

The geometry of the tap being used also plays a role in determining the drill bit size. The geometry includes factors such as the tap’s flute length, chamfer length, and pitch. It is important to match the drill bit size to the tap’s geometry to ensure optimal thread formation.

Thread Accuracy Requirements

Another factor to consider is the required accuracy of the threads being formed. If precision and accuracy are crucial, it is important to select a drill bit size that will allow for the desired thread dimensions. This may involve using drill bits of a specific size range or opting for adjustable or custom-sized drill bits.

Drilling Speed and Feed Rate

The drilling speed and feed rate also play a role in determining the appropriate drill bit size. Higher drilling speeds and feed rates may require larger drill bit sizes to maintain stability and prevent overheating. It is important to consult manufacturer guidelines or perform testing to determine the optimal drill bit size for a given drilling speed and feed rate.

Available Drill Bit Sizes

Lastly, the availability of drill bit sizes should be taken into account. It is important to select a drill bit size that is readily available and easily obtainable. This ensures convenience and reduces downtime in case of drill bit replacement or breakage.

| Factors | Importance |

|---|---|

| Material of the Workpiece | High |

| Tap Geometry | High |

| Thread Accuracy Requirements | Medium |

| Drilling Speed and Feed Rate | Medium |

| Available Drill Bit Sizes | Low |

How to Measure an 8mm Tap

A tap is a cutting tool used to create screw threads inside a hole. An 8mm tap is specifically designed to create threads with a diameter of 8mm. In order to choose the right drill bit size for an 8mm tap, you need to accurately measure the tap. Here is how you can measure an 8mm tap:

- Gather the necessary tools: To measure the tap accurately, you will need a caliper and a ruler or tape measure. These tools will help you determine the diameter and length of the tap.

- Measure the diameter: Start by measuring the diameter of the tap. Place the bottom of the caliper on one side of the tap’s cutting edge and the top of the caliper on the opposite side. Take the measurement from this span and ensure that the caliper is parallel to the tap.

- Record the measurement: Note down the measured diameter of the tap. This will help you determine the appropriate drill bit size to use when creating a hole for the tap.

- Measure the length: Use a ruler or tape measure to determine the length of the tap. Place the ruler or tape measure alongside the tap and measure from the base to the tip. You may also want to measure the length of the threaded portion separately.

- Record the length: Keep a record of the measured length of the tap. This information will be useful for determining the depth at which the tap should be inserted into the material.

- Consider the chamfer: Some taps have a chamfered or tapered end to help guide the tap into the hole. Make sure to take this into account when measuring the length of the tap.

By accurately measuring an 8mm tap, you can ensure that you choose the right drill bit size and create threads that fit properly. Taking the time to measure the tap will help you achieve precise and efficient results in your drilling and tapping operations.

Drill Bit Selection Options

When choosing the right drill bit size for an 8mm tap, there are several options to consider. The drill bit should match the diameter of the tap, allowing for proper threading and a secure fit. Here are a few options to consider:

1. Matching Drill Bit

The most common option is to use a drill bit that matches the size of the 8mm tap. In this case, a drill bit with a diameter of 8mm would be used. This will create a hole that is the perfect size for the tap, allowing for precise threading.

2. Slightly Smaller Drill Bit

Sometimes, it may be necessary to use a slightly smaller drill bit than the tap size. This can be done to create a tighter fit or to ensure that the threads are properly formed. For an 8mm tap, a drill bit with a diameter slightly smaller than 8mm, such as 7.5mm, can be used.

3. Pilot Hole Drill Bit

If you are working with a hard material or need to create a hole with more precision, using a pilot hole drill bit can be a good option. A pilot hole drill bit is smaller than the tap size and creates a guide hole for the tap. After drilling the pilot hole, a larger drill bit can be used to create the final hole size for the tap.

4. Step Drill Bit

For situations where multiple hole sizes are needed, a step drill bit can be a useful tool. A step drill bit has multiple steps or levels, each with a different diameter. This allows for drilling holes of various sizes without changing drill bits. By using a step drill bit, you can easily drill different size holes to accommodate different tap sizes.

Ultimately, the best drill bit selection option will depend on the specific project and the desired outcome. Consider factors such as material type, hole size, and desired thread fit when choosing the right drill bit for an 8mm tap.

Common Drill Bit Sizes for 8mm Taps

When it comes to tapping an 8mm hole, it is important to choose the right drill bit size in order to ensure the proper fit for the tap. Here are some common drill bit sizes that are typically used for 8mm taps:

| Tap Size | Drill Bit Size |

|---|---|

| 8mm x 1.0 | 7mm |

| 8mm x 1.25 | 6.8mm |

| 8mm x 1.5 | 6.5mm |

These drill bit sizes are generally recommended for tap sizes in the range of 8mm. However, it is important to note that the exact drill bit size may vary depending on the specific requirements of your project or the material you are working with.

When selecting a drill bit size, it is recommended to choose a slightly smaller size than the tap in order to provide a proper fit. This will create the necessary threads in the hole while ensuring that the tap can be threaded in without much resistance.

It is also essential to use sharp drill bits and maintain proper drilling techniques to achieve clean and accurate holes. Using a drill press or a drilling guide can help ensure precise alignment and prevent any drilling errors.

By using the appropriate drill bit size for your 8mm tap, you can ensure a successful and secure fit for your project. Always refer to the manufacturer’s recommendations and specifications for the specific tap and material you are working with to achieve the best results.

Tips for Choosing the Right Drill Bit Size

When it comes to drilling, choosing the right drill bit size is crucial for achieving the desired results. Whether you’re working on a DIY project or a professional task, the following tips can help you make an informed decision:

1. Determine the Material

Before selecting a drill bit size, consider the material you’ll be drilling into. Different materials require different drill bit sizes to ensure a clean and accurate hole. For example, drilling into wood requires a different size than drilling into metal or concrete.

2. Know the Project Requirements

Take into account the specific requirements of your project. Are you looking to create a pilot hole or a hole for a specific diameter? Understanding the purpose of the hole will help you choose the right drill bit size.

3. Consider the Screw or Fastener Size

If you’re drilling a hole for a screw or fastener, it’s important to match the drill bit size with the size of the screw or fastener. This will ensure a secure and tight fit, preventing any issues down the line.

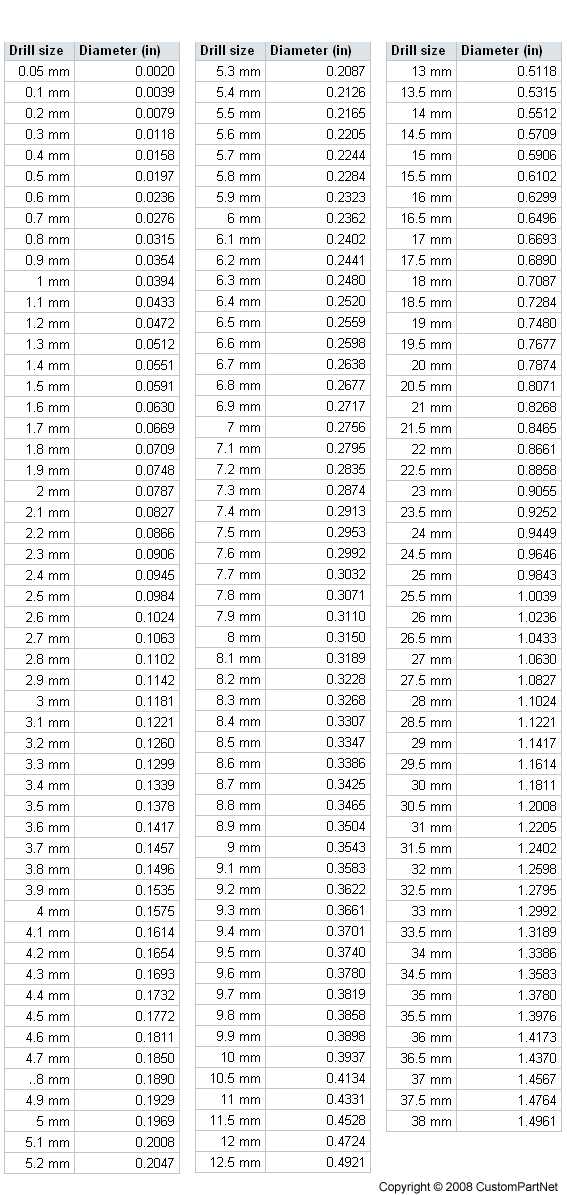

4. Refer to a Drill Bit Size Chart

If you’re unsure about the appropriate drill bit size, consult a drill bit size chart. These charts provide information on the recommended bit size for various screw sizes and materials. They can serve as a valuable reference tool in selecting the right size.

5. Test and Adjust

If you’re still unsure about the drill bit size, it’s always a good idea to test on a scrap piece of material to ensure the size is correct. You can then make any necessary adjustments based on the results.

6. Invest in Quality Drill Bits

Lastly, invest in high-quality drill bits. Cheap or worn-out drill bits can compromise the accuracy and effectiveness of your drilling. Quality drill bits ensure cleaner holes and reduce the chances of breakage or damage.

By following these tips, you can confidently choose the right drill bit size for your project, achieving the best possible results.

Drill Bit Size Chart for 8mm Taps

When using an 8mm tap, it is important to choose the right drill bit size to ensure proper thread engagement and to avoid damaging the tap or the workpiece. Here is a chart that provides the recommended drill bit sizes for various types of material when tapping with an 8mm tap.

| Material | Recommended Drill Bit Size |

|---|---|

| Softwood (e.g. pine, cedar) | 7mm |

| Hardwood (e.g. oak, birch) | 6.5mm |

| Plastic (e.g. acrylic, PVC) | 7.5mm |

| Aluminum | 7mm |

| Steel | 6.5mm |

| Stainless Steel | 6mm |

It is important to note that the drill bit size recommendations provided in this chart are general guidelines. Depending on the specific application and the desired level of thread engagement, slight adjustments to the recommended drill bit size may be necessary.

When drilling, it is also important to use a sharp drill bit and to apply a moderate amount of pressure while drilling to prevent the bit from slipping or breaking. Additionally, using cutting fluid or lubricant can help improve the drilling process and extend the life of the drill bit.

By following the recommended drill bit sizes and best practices for drilling, you can ensure successful tapping with an 8mm tap and create strong, reliable threads in your workpiece.

FAQ:

What is the recommended drill bit size for an 8mm tap?

The recommended drill bit size for an 8mm tap is 6.8mm.

Can I use a different size drill bit for an 8mm tap?

It is not recommended to use a different size drill bit for an 8mm tap, as it may not create the proper threads.

What happens if I use a drill bit that is too small for an 8mm tap?

If you use a drill bit that is too small for an 8mm tap, it may not remove enough material and the threads may not be properly formed.

Is it okay to use a drill bit that is slightly larger than the recommended size for an 8mm tap?

Using a slightly larger drill bit for an 8mm tap may result in slightly larger threads, but it should still work as long as the difference is not too significant.

What type of drill bit should I use for an 8mm tap?

You should use a high-speed steel drill bit for an 8mm tap.

Can I use a drill press to drill the hole for an 8mm tap?

Yes, you can use a drill press to drill the hole for an 8mm tap, as long as you have the appropriate drill bit and set it to the correct speed.

Video: