Choosing the Right Drill Bit Size for a Quarter Inch Tap

When it comes to using a quarter inch tap, having the right drill bit size is crucial. The drill bit size determines the diameter of the hole that needs to be drilled before tapping. If the hole is too small, it will be difficult to tap the threads. On the other hand, if the hole is too big, the threads won’t hold securely.

Before choosing the drill bit size, it’s important to consider the material you’re working with. Different materials require different drill bit sizes. For example, drilling into metal will require a smaller drill bit size compared to drilling into wood.

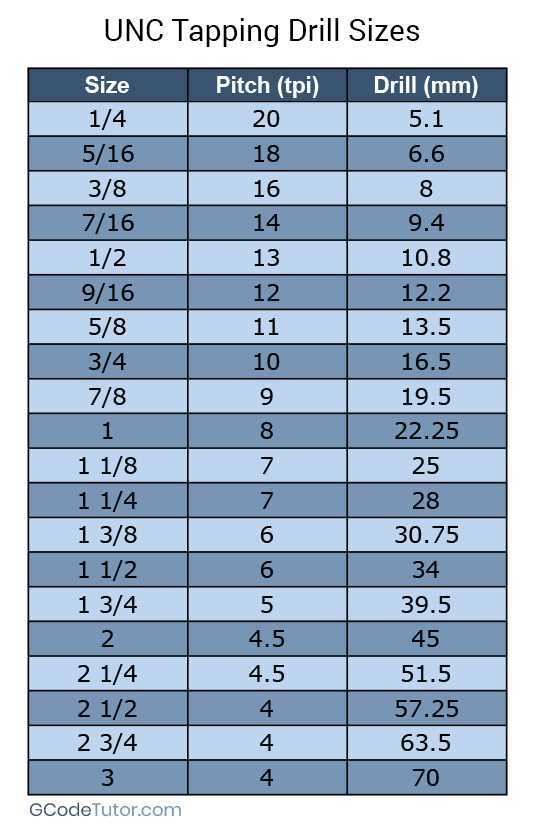

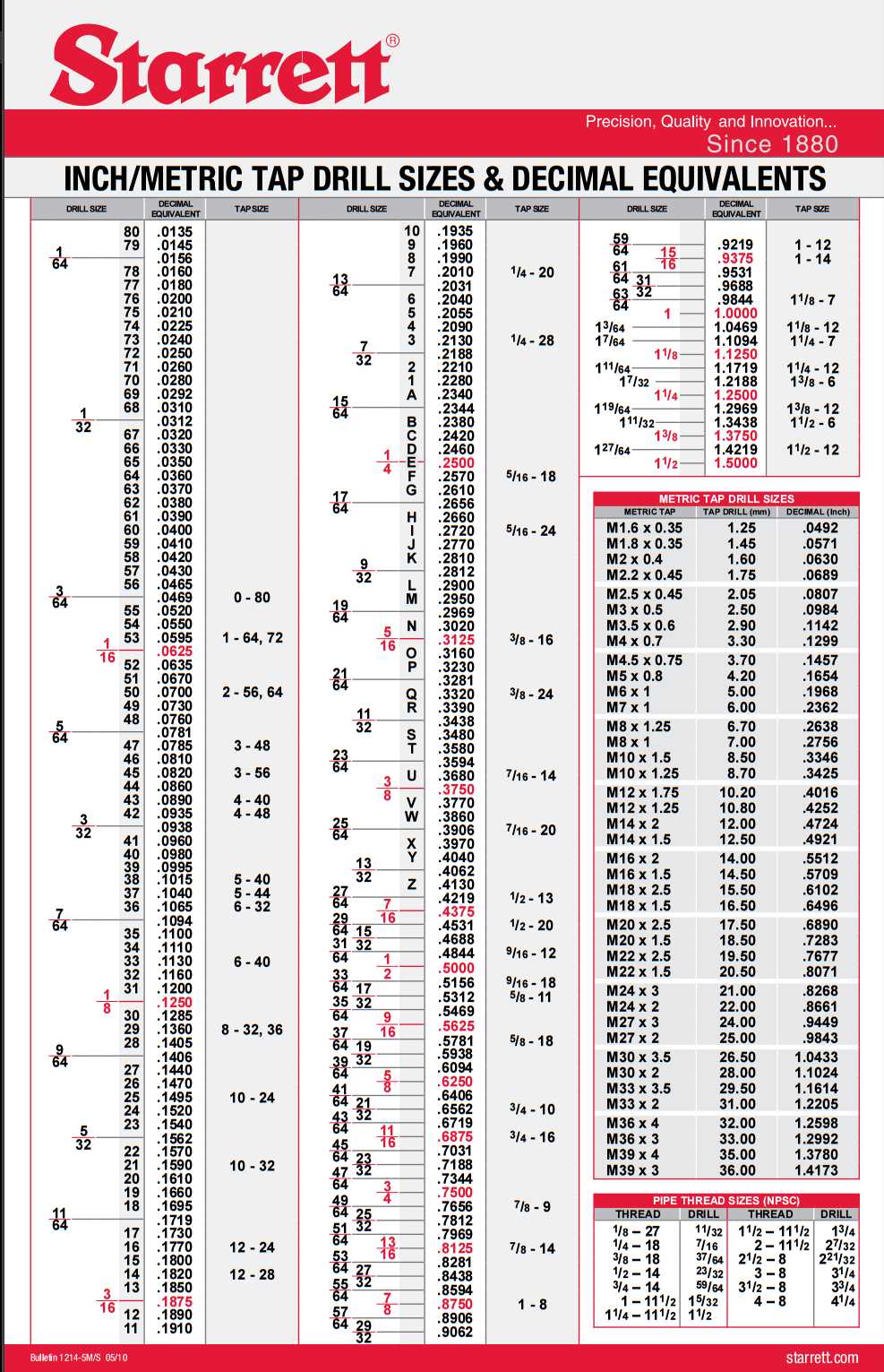

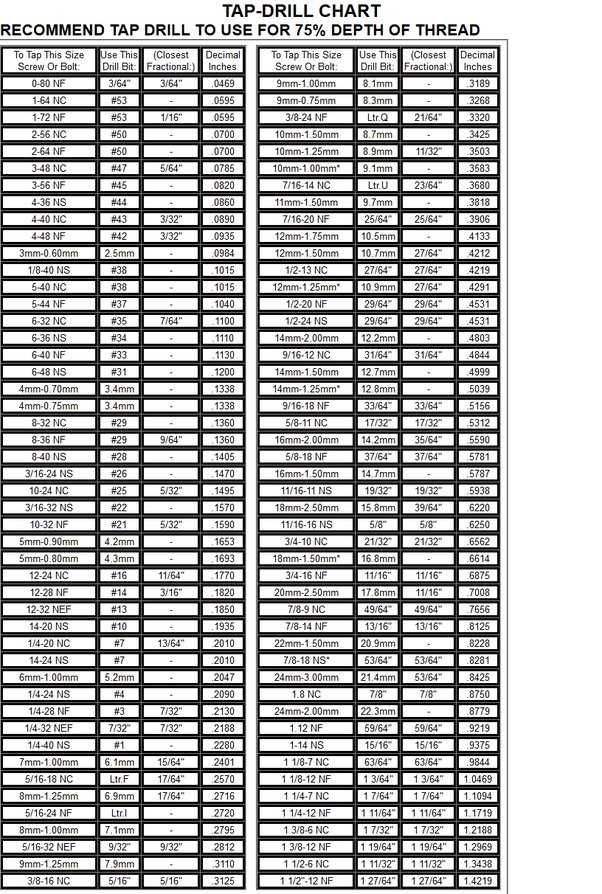

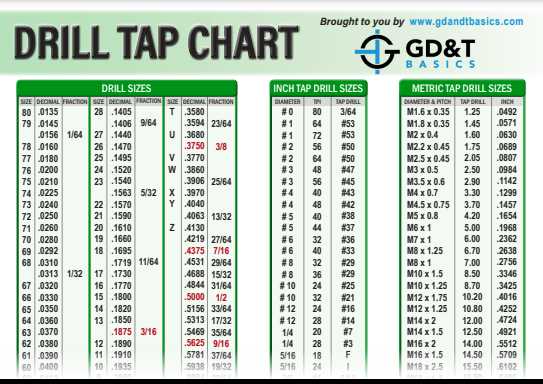

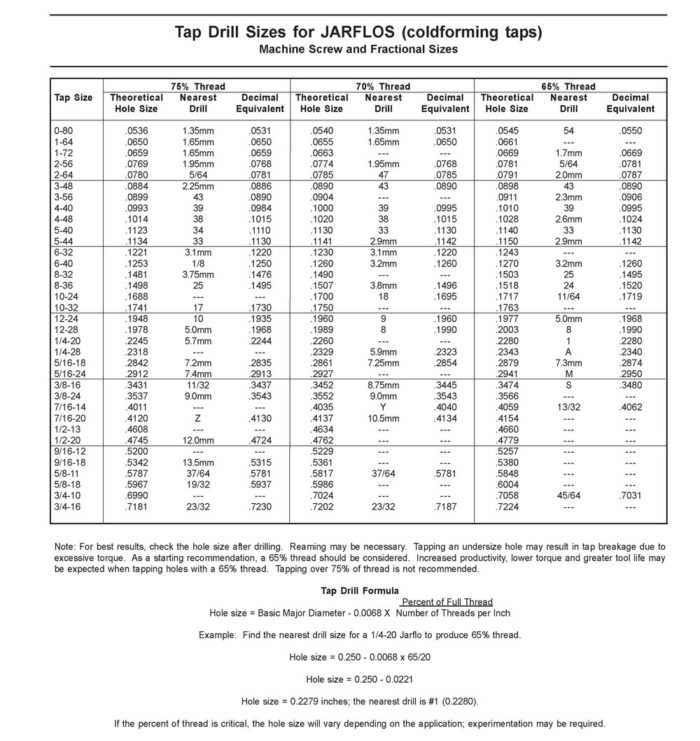

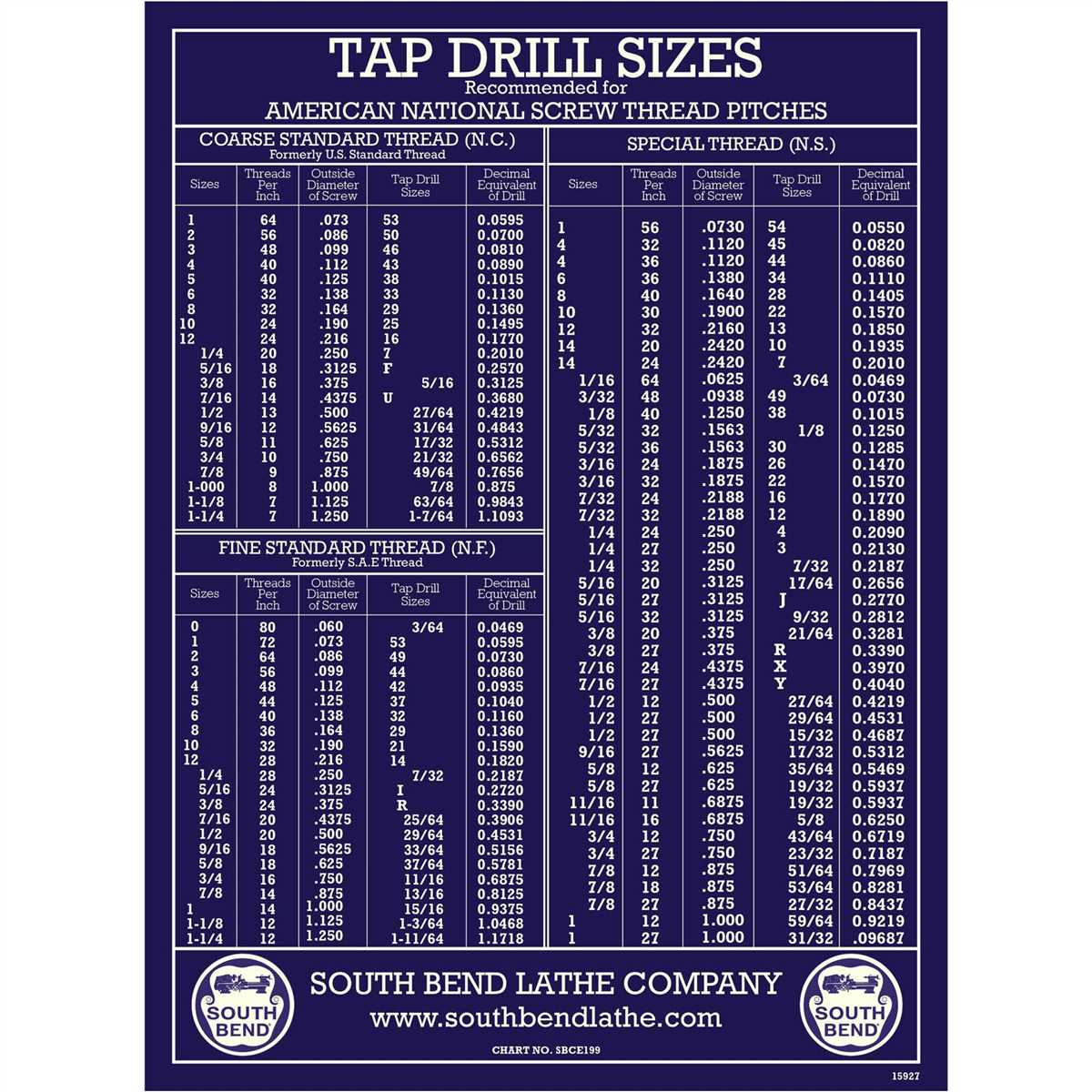

One way to determine the right drill bit size is to consult a drill bit size chart. These charts provide recommendations for different tap sizes and materials. They usually list the standard drill bit sizes for each tap size. However, keep in mind that these are general recommendations and may not work for every situation.

Understanding Drill Bit Sizing

When it comes to drilling holes, it is important to understand drill bit sizing. The size of the drill bit you choose will determine the size of the hole you will be able to create. In this article, we will discuss the different aspects of drill bit sizing to help you choose the right drill bit for your needs.

Standard Drill Bit Sizes

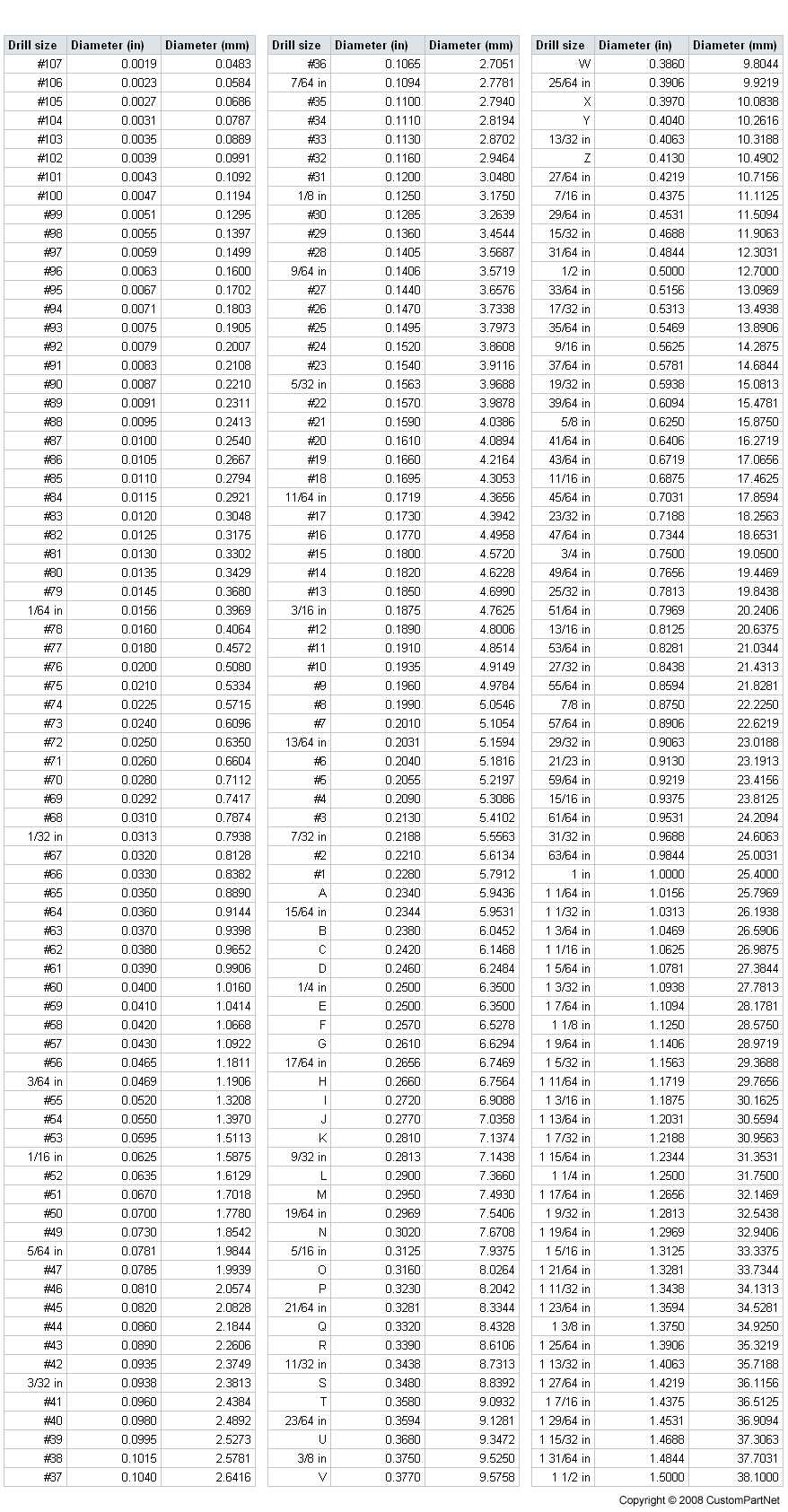

Drill bits are typically measured in fractions of an inch. The most common standard drill bit sizes range from 1/16 inch to 1 inch. These sizes are often available in increments of 1/64 inch or 1/32 inch. For example, you can find drill bits in sizes such as 1/8 inch, 3/16 inch, 1/4 inch, and so on.

Numbered Drill Bit Sizes

Another way to size drill bits is by using a numbered drill bit system. Numbered drill bits are similar to standard drill bit sizes, but they are assigned a number instead of a fraction. The lower the number, the smaller the drill bit. Numbered drill bits range from size 80 (smallest) to size 1 (largest).

Letter Drill Bit Sizes

In addition to standard and numbered drill bit sizes, there are also letter drill bit sizes. Letter drill bits are designated by a letter of the alphabet, with the smaller letters representing smaller drill bits and vice versa. The letter sizes range from size Z (smallest) to size A (largest).

Drill Bit Size Selection

When choosing a drill bit size, it is important to consider the specific requirements of your project. Factors such as the material you are drilling into and the size of the hole you need to create will influence your decision. It is recommended to consult a drill bit size chart or consult with experts to ensure you select the correct size.

In conclusion, understanding drill bit sizing is essential for successful drilling. By familiarizing yourself with standard, numbered, and letter drill bit sizes, you can make informed decisions when choosing the right drill bit for your needs. Remember to consider the specific requirements of your project and consult resources or experts for guidance if needed.

Key Considerations for Tap Hole Sizes

1. Material

The type of material you are working with is an important factor to consider when choosing the tap hole size. Different materials have different characteristics, such as hardness and brittleness, which can affect the size of the hole needed for tapping.

2. Tap Type

The type of tap you are using will also determine the appropriate hole size. There are various types of taps, including taper taps, plug taps, and bottoming taps, each requiring a specific hole size for optimal performance.

3. Tap Size

The size of the tap itself is another factor to consider when determining the tap hole size. Different tap sizes require different hole sizes in order to achieve the desired thread depth and engagement.

4. Thread Engagement

The amount of thread engagement you require is an important consideration. A larger hole size will provide more thread engagement, while a smaller hole size will result in less engagement. The level of thread engagement needed will depend on the specific application and the strength requirements of the threaded connection.

5. Tap Drill Chart

Consulting a tap drill chart can be extremely helpful in determining the appropriate tap hole size. These charts provide recommended hole dimensions based on the specific tap size and material being used.

6. Pilot Holes

In some cases, it may be necessary to create pilot holes before tapping. Pilot holes are smaller diameter holes that serve as a guide for the tap and help ensure accurate threading. The size of the pilot hole will depend on the specific tap size and material.

7. Testing and Adjusting

If you are unsure about the correct tap hole size, it is always recommended to test and adjust as needed. Start with a slightly smaller hole and gradually increase the size until the desired thread engagement and fit are achieved.

8. Professional Advice

If you are new to tapping or unsure about the appropriate tap hole size for your specific application, it is best to seek professional advice. Experienced machinists and professionals can provide valuable guidance and recommendations based on their expertise and knowledge.

By considering these key factors, you can ensure that you choose the right tap hole size for your specific needs, resulting in strong and reliable threaded connections.

Importance of Accuracy in Drill Bit Selection

Drill bits are an essential tool for any DIY enthusiast or professional, as they allow for precise drilling and create clean, accurate holes. However, selecting the right drill bit size is crucial to ensure the desired results. Accurate drill bit selection plays a significant role in various aspects of the drilling process.

Ensuring Proper Fit

One of the primary reasons for accuracy in drill bit selection is to ensure a proper fit. When drilling holes for a quarter inch tap, for example, it is essential to select a drill bit that matches the tap’s size precisely. Using a drill bit that is too large or too small can result in an improper fit and compromise the overall integrity of the connection.

Preventing Damage to Workpiece

Using an inaccurate drill bit size can also lead to damage to the workpiece. If the drill bit is too large, it may cause the hole to be oversized, resulting in loose or wobbly connections. On the other hand, a drill bit that is too small can cause the hole to be undersized, making it difficult or impossible to fit the desired component or fastener.

Maintaining Precision and Accuracy

Accuracy in drill bit selection is crucial to maintain precision and accuracy throughout the drilling process. It ensures that the drilled holes are the intended size and shape, allowing for a proper fit and optimal functionality of the components or fasteners used. Whether it is a woodworking project or metal fabrication, accurate drill bit selection is vital to achieve the desired results.

Optimizing Efficiency

Choosing the right drill bit size can also improve the efficiency of the drilling process. An accurate drill bit helps to minimize the time and effort required to create the desired holes. It allows for smooth and effortless drilling, reducing the chances of mistakes or damage to the workpiece, and ultimately speeding up the overall project completion time.

Reducing Costs

Accurate drill bit selection can also help reduce costs in the long run. By selecting the right drill bit size, you can avoid the need to purchase additional materials or tools to fix mistakes caused by using an incorrect drill bit. It minimizes the chances of rework or repairs, saving both time and money.

In conclusion, accuracy in drill bit selection is of utmost importance to ensure proper fit, prevent damage to the workpiece, maintain precision and accuracy, optimize efficiency, and reduce costs. Taking the time to select the correct drill bit size for the task at hand can make a significant difference in the overall success and quality of your drilling projects.

Optimal Drill Bit Size for a Quarter Inch Tap

When it comes to using a quarter inch tap, it is important to choose the right drill bit size to ensure proper drilling and tapping. The drill bit size you use will depend on the specific requirements and dimensions of the project you are working on.

Factors to Consider

- Tap Drill Chart: One of the first things you should consult is a tap drill chart. This chart provides the recommended drill bit sizes for various tap sizes. It is important to match the tap size with the appropriate drill bit.

- Material: The material you are working with will also play a role in determining the optimal drill bit size. Harder materials may require a larger drill bit size to accommodate the tap, while softer materials may require a smaller drill bit size.

- Thread Engagement: Another important factor to consider is the desired thread engagement. Thread engagement refers to the amount of contact between the tap and the material being tapped. For a quarter inch tap, you will want to choose a drill bit size that provides an appropriate amount of thread engagement.

Choosing the Right Drill Bit Size

To choose the optimal drill bit size for a quarter inch tap, follow these steps:

- Consult a tap drill chart to determine the recommended drill bit sizes for a quarter inch tap.

- Consider the material you are working with. If the material is harder, you may need to select a slightly larger drill bit size. If the material is softer, you may need to select a slightly smaller drill bit size.

- Take into account the desired thread engagement. If you require a deeper thread engagement, you may need to select a larger drill bit size. If a shallower thread engagement is sufficient, you may opt for a smaller drill bit size.

- Before proceeding with drilling and tapping, double-check that you have the correct drill bit size. Using the wrong drill bit size can lead to improper threading and potentially damage the material.

By considering the factors mentioned above and taking the necessary steps to choose the right drill bit size, you can ensure successful drilling and tapping when using a quarter inch tap.

Recommended Drill Bit Size Chart

When it comes to choosing the right drill bit size for a quarter inch tap, it is important to have a drill bit that matches the desired thread size. Here is a recommended drill bit size chart to help you find the right match:

| Tap Size | Drill Bit Size |

|---|---|

| 1/4″ – 20 | 7/32″ |

| 1/4″ – 28 | 15/64″ |

| 1/4″ – 32 | 9/32″ |

| 1/4″ – 40 | 19/64″ |

These drill bit sizes are recommended for tapping holes with quarter inch thread sizes. It is important to note that these sizes may vary depending on the specific threading requirements of your project, so always consult the manufacturer’s specifications for the tap you are using.

Using the correct drill bit size ensures that the tap can thread the hole properly and securely. If the drill bit is too small, it may not provide enough space for the tap to create the necessary threads. On the other hand, if the drill bit is too large, it can weaken the threads or cause the tap to become loose.

When in doubt, it is always best to err on the side of caution and choose a slightly smaller drill bit size. You can always enlarge the hole if necessary, but it is much more difficult to fix a hole that is too large for the desired thread size.

Remember to use the appropriate cutting lubricant when tapping holes to ensure smooth and accurate threading. This will help extend the life of your tap and improve the overall quality of the threads.

Common Mistakes when Choosing Drill Bit Sizes

1. Guessing the Size

One of the most common mistakes when choosing drill bit sizes is simply guessing the size. Many people choose a drill bit based on estimated measurements, which can lead to incorrect hole sizes and ultimately, ineffective drilling. It’s important to measure the diameter of the desired hole accurately before selecting a drill bit size.

2. Not Considering the Material

Another mistake is not considering the material being drilled. Different materials require different drill bit sizes to achieve the best results. For example, drilling into metal may require a smaller drill bit compared to drilling into wood. Always take into account the material’s hardness and density before choosing the drill bit size.

3. Using Standard Sizing Perceptions

Many people make the mistake of assuming that standard sizing perceptions apply to drill bits as well. While some drill bits may have a similar size to common objects like pencils or screws, it’s vital to use precise measurements instead of relying on general assumptions. Don’t rely on visual comparisons; always use the appropriate measuring tools.

4. Ignoring Depth Requirements

Drill bit sizes also need to consider the required depth of the hole. Ignoring depth requirements can lead to incomplete or uneven drilling that may compromise the stability or effectiveness of the project. Always refer to the depth measurements provided in the project plans or adjust accordingly based on personal requirements.

5. Overlooking Pilot Holes

When drilling into certain materials, particularly hardwoods, it’s crucial to use pilot holes to ensure clean and accurate drilling. A pilot hole is a small hole drilled before the main hole to guide the larger drill bit and prevent wood splitting or damage. Overlooking the need for pilot holes can result in messy and uneven drilling.

6. Neglecting Bit Sharpness

Using dull drill bits can cause various issues, such as increased drilling time, overheating, and poor hole quality. Neglecting to check the sharpness of the drill bit before use is a common mistake. Always inspect the drill bit’s cutting edge and consider sharpening or replacing it if necessary to ensure optimal drilling results.

7. Not Double-Checking Metric and Imperial Sizes

When working with both metric and imperial systems, it’s important to double-check the drill bit sizes to ensure compatibility. Mixing up metric and imperial sizes can lead to incorrect drilling and incompatible fasteners. Always confirm the measurement system and choose the appropriate drill bit size accordingly.

8. Neglecting Safety Precautions

Finally, one of the biggest mistakes is neglecting safety precautions when selecting drill bit sizes. Safety goggles and gloves should always be worn when drilling to protect against flying debris and potential injuries. Additionally, following proper drilling techniques and guidelines can help prevent accidents and ensure a successful outcome.

In conclusion, avoiding these common mistakes when choosing drill bit sizes can greatly improve drilling accuracy, efficiency, and project outcomes. Taking the time to measure accurately, consider the material and depth requirements, use pilot holes when necessary, and prioritize safety precautions are essential for a successful drilling experience.

Expert Tips for Choosing the Right Drill Bit Size

1. Consider the Material

When choosing the right drill bit size, it’s important to consider the material you’ll be drilling into. Different materials require different drill bit sizes to ensure clean and accurate holes.

For example, if you’re drilling into wood, you’ll generally need a smaller drill bit size compared to drilling into metal or concrete. This is because wood is a softer material and requires less force to create a hole.

2. Determine the Hole Size

Before selecting a drill bit size, determine the size of the hole you need to create. You can measure the diameter of the hole required or refer to any specifications or drawings that indicate the desired hole size.

Using the wrong drill bit size can result in a hole that is either too small or too large, which can affect the stability and functionality of the project you’re working on.

3. Refer to Drill Bit Size Charts

Drill bit size charts are readily available online and can be a valuable resource when choosing the right drill bit size. These charts provide recommendations for drill bit sizes based on the desired hole size and the material you’re drilling into.

By referring to a drill bit size chart, you can quickly find the appropriate drill bit size for your specific needs, saving you time and ensuring accurate results.

4. Test on Scrap Material

If you’re unsure about the drill bit size to use, it’s always a good idea to test on a scrap piece of material before drilling the final hole. This allows you to determine if the selected drill bit size is suitable and to make any necessary adjustments before committing to the actual project.

By testing on a scrap material, you can avoid costly mistakes and ensure that the holes you drill are the correct size and depth.

5. Consult with Experts

If you’re still uncertain about the right drill bit size for your specific application, don’t hesitate to consult with experts in the field. They can provide valuable insights and recommendations based on their experience and expertise.

Reach out to professionals or consult with knowledgeable individuals who have experience drilling into similar materials or working on similar projects. Their guidance can help you make an informed decision and ensure successful drilling.

6. Always Use the Right Tool

Finally, it’s crucial to always use the right tool for the job. Using the wrong drill bit size can result in damage to the drill, the material, or even injury to yourself. Always select a drill bit that is designed to work with the specific material, task, and drill you are using.

Using the right drill bit size ensures efficient drilling, accurate holes, and overall project success.

By following these expert tips, you can confidently choose the right drill bit size for your next drilling project, whether it’s hanging a picture frame or tackling a larger construction task.

FAQ:

What is a quarter inch tap used for?

A quarter inch tap is used for creating threads in holes that are a quarter inch in diameter.

How do I choose the right drill bit size for a quarter inch tap?

To choose the right drill bit size for a quarter inch tap, you need to consider the material you are drilling into, as well as the specific tap size and thread pitch you are using. There are charts available online that can help you determine the appropriate drill bit size for your specific application.

What happens if I use the wrong drill bit size with a quarter inch tap?

If you use a drill bit that is too small with a quarter inch tap, the threads may not be properly formed and the tap could become stuck in the hole. If you use a drill bit that is too large, the threads may be too loose and the connection could be weak.

Can I use a standard drill bit with a quarter inch tap?

Yes, you can use a standard drill bit with a quarter inch tap. However, it is important to ensure that the drill bit size matches the desired thread size and pitch.

What are some common drill bit sizes for quarter inch taps?

Some common drill bit sizes for quarter inch taps include 7/64″, 1/8″, and 9/64″. The specific drill bit size you choose will depend on the material and thread pitch you are working with.

Is it better to use a smaller or larger drill bit size with a quarter inch tap?

The drill bit size you choose should be based on the desired thread size and pitch, as well as the material you are working with. It is generally better to err on the side of using a slightly smaller drill bit size to ensure that the threads are properly formed.

Video: