Choosing the Right Drill Bit Size for a 5/16 Lag Screw

When it comes to working on DIY projects or any kind of construction, using the right tools is crucial for achieving the desired results. One such tool is a drill, which is commonly used for making holes in various materials. However, when it comes to using a drill for lag screws, it’s important to choose the right drill bit size to ensure a secure and tight fit. In this article, we will discuss how to determine the appropriate drill bit size for a 5/16 lag screw.

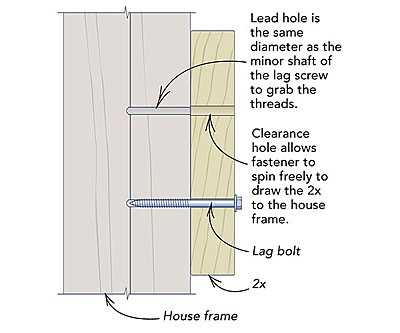

Before we get into the specifics of choosing the right drill bit size, let’s first understand what a lag screw is. A lag screw, also known as a lag bolt, is a type of fastener that is used to join two pieces of wood or other materials together. Unlike other screws, lag screws have a thick, tapered shaft and a hexagonal head that allows for high torque applications. These screws are commonly used in construction projects where a strong and durable connection is required, such as building decks or fences.

Now that we know what a lag screw is, let’s move on to choosing the appropriate drill bit size. The drill bit size you choose should be slightly smaller than the diameter of the screw’s shaft. In the case of a 5/16 lag screw, which has a shaft diameter of 5/16 inch, you should choose a drill bit size that is slightly smaller than this measurement. This ensures that the screw fits tightly in the hole without being too loose or too tight.

It is recommended to use a drill bit that is one size smaller than the shaft diameter of the lag screw. In the case of a 5/16 lag screw, you should use a 1/4 inch drill bit. This will allow for a tight fit and ensure that the screw is securely held in place. If you use a drill bit that is too large, the screw may not hold properly and could become loose over time. On the other hand, using a drill bit that is too small can lead to the wood splitting or the screw getting stuck.

What is a lag screw?

A lag screw, also known as a lag bolt, is a type of fastener that is designed to securely fasten two or more objects together. It is a large, heavy-duty screw with a pointed tip and a thick shaft. The head of a lag screw is often hexagonal or square-shaped, allowing for easy tightening and loosening using a wrench or socket driver.

Lag screws are commonly used in construction, woodworking, and other applications where a strong, durable connection is required. They are often used to attach heavy objects to walls, floors, or other surfaces, or to join pieces of wood or metal together.

One of the key features of a lag screw is its thread design. Unlike the threads on a regular screw, which are spaced closely together, the threads on a lag screw are spaced further apart and have a steeper incline. This allows the screw to grip the material more securely and provide a stronger hold.

When installing a lag screw, it is important to choose the right size and type of screw for the job. This includes selecting the appropriate length, diameter, and thread type. Using the wrong size screw can result in a weak or unstable connection, or even damage to the material.

Before using a lag screw, it is also important to pre-drill a pilot hole in the material. This helps to prevent the wood from splitting or the screw from breaking. The size of the pilot hole should be slightly smaller than the diameter of the screw, to allow for a snug fit.

In summary, a lag screw is a large, heavy-duty screw with a pointed tip and thick shaft, designed to securely fasten two or more objects together. It is commonly used in construction and woodworking applications where a strong, durable connection is required.

Importance of choosing the right drill bit size

Choosing the right drill bit size is crucial for any drilling project. It directly affects the success and quality of the job, as using the wrong size can lead to various issues and potential hazards. Whether you are a professional or a DIY enthusiast, understanding the importance of drill bit size selection is essential for achieving accurate and effective results.

1. Proper fit and alignment

One of the primary reasons for selecting the correct drill bit size is to ensure a proper fit and alignment. Using a drill bit that is too small can result in a loose fit, causing instability and potential damage to the material being drilled. On the other hand, using a drill bit that is too large can lead to oversize holes, compromising the structural integrity and aesthetics of the project.

2. Precision and accuracy

Another important factor to consider is precision and accuracy. The drill bit size directly affects the size of the hole, and using the wrong size can lead to inaccuracies, especially when working on projects that require specific measurements and tight tolerances. Using the correct drill bit size ensures that the hole is drilled precisely as intended, allowing for proper insertion of screws, bolts, or other fasteners.

3. Efficient and effective drilling

The right drill bit size can greatly impact the efficiency and effectiveness of the drilling process. Using the correct size allows for smooth and effortless drilling, reducing the risk of the bit getting stuck or breaking. It also helps to minimize the amount of time and effort required to complete the task, especially when drilling through tougher materials.

4. Safety

Using the wrong drill bit size can pose safety hazards. A loose fit or oversize hole may result in the fastener becoming loose or failing to securely hold the material in place. This can lead to unexpected accidents or injuries, especially if the project involves structural or load-bearing applications. By choosing the right drill bit size, you can ensure the safety and stability of the project.

Conclusion

In summary, selecting the right drill bit size is crucial for achieving accurate, precise, and safe drilling results. It ensures a proper fit and alignment, improves precision and accuracy, enhances drilling efficiency, and reduces potential hazards. Taking the time to choose the correct drill bit size for each project will ultimately lead to better outcomes and increased satisfaction with the final result.

Factors to consider when choosing a drill bit size

When choosing a drill bit for a specific project, it is important to consider several factors to ensure the best results. These factors include:

1. Screw Size:

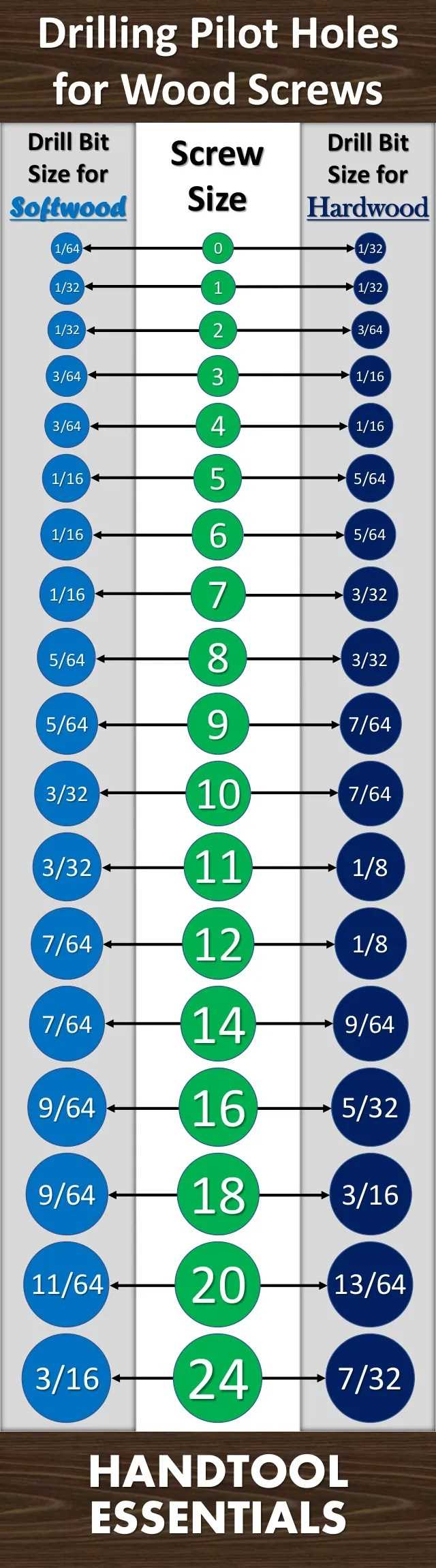

The size of the screw you plan to use determines the appropriate drill bit size. Each screw size has a corresponding drill bit size that is recommended for use. In the case of a 5/16 lag screw, you will need to choose a drill bit that matches that size.

2. Material:

The material you are drilling into also affects the drill bit size selection. Different materials require different drilling techniques and bit sizes. For example, drilling into wood may require a different size bit compared to drilling into metal or concrete.

3. Pilot Hole Depth:

The depth of the pilot hole you plan to drill is another important factor to consider. The pilot hole depth should be slightly shorter than the length of the screw to ensure it has enough material to grip onto without breaking through the other side. The drill bit size should be chosen accordingly.

4. Type of Bit:

There are different types of drill bits available, such as twist bits, spade bits, and brad point bits. Each type is designed for specific applications and materials. Consider the type of bit that is most suitable for your project and choose the appropriate size accordingly.

5. Desired Hole Size:

If you have a specific hole size requirement for your project, it is important to choose a drill bit size that will achieve that diameter. Make sure to measure and consider the desired hole size before selecting the appropriate drill bit.

6. Manufacturer’s Recommendations:

It is always a good idea to check the manufacturer’s recommendations for the specific screw or material you are working with. They may provide specific guidelines for drill bit sizes to ensure optimal performance and durability.

By considering these factors, you can choose the right drill bit size for your project, ensuring proper fit and efficient drilling. Remember to always wear appropriate safety equipment and follow proper drilling procedures for the best results.

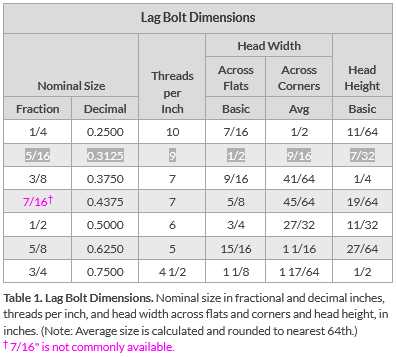

Thread size of the lag screw

When choosing the right drill bit size for a 5/16 lag screw, it is important to consider the thread size of the screw. The thread size refers to the diameter of the screw threads, which determines the compatibility with the drill bit.

The thread size of a 5/16 lag screw is 18 threads per inch (TPI). This means that there are 18 threads per inch of the screw’s length. This information is crucial when selecting the appropriate drill bit size.

Using a drill bit that matches the thread size ensures a proper fit and prevents stripping or damaging the threads of the screw. It also ensures that the screw can be securely tightened into the material.

When drilling a pilot hole for a 5/16 lag screw, it is recommended to use a drill bit slightly smaller than the screw’s thread size. This allows for a tight fit and ensures that the screw will hold securely in the material.

Here is a comparison of the recommended drill bit sizes for different thread sizes:

| Thread Size (TPI) | Recommended Drill Bit Size (in inches) |

|---|---|

| 18 | 17/64 |

| 16 | 7/32 |

| 14 | 1/4 |

| 12 | 7/32 |

It is important to note that these are general guidelines, and the specific material being drilled into may require adjustments to the drill bit size. It is always recommended to consult the manufacturer’s instructions or seek professional advice to ensure the appropriate drill bit size is used.

By considering the thread size of the lag screw and using the recommended drill bit size, you can ensure a proper fit and secure installation of the screw for your project.

Material of the lag screw

The material of the lag screw is an important factor to consider when choosing the right drill bit size. Different materials require different levels of drilling power and precision.

Some common materials of lag screws include:

- Steel: Lag screws made of steel are strong and durable. They are commonly used for heavy-duty applications and can withstand high levels of pressure.

- Stainless Steel: Lag screws made of stainless steel are resistant to rust and corrosion. They are ideal for outdoor applications or environments with high moisture content.

- Brass: Lag screws made of brass have a decorative appearance and are often used in furniture assembly or for aesthetic purposes.

- Galvanized Steel: Lag screws made of galvanized steel are coated with a protective layer of zinc. This makes them more resistant to rust and corrosion compared to regular steel lag screws.

- Aluminum: Lag screws made of aluminum are lightweight and corrosion-resistant. They are often used in applications where weight is a concern, such as in aerospace or automotive industries.

Each material has its own specific characteristics and drilling requirements. It is important to match the drill bit size to the material of the lag screw to ensure a secure and effective installation.

Drill type and power

Types of Drills

When choosing a drill for the job, it’s important to consider the type of drill that will best suit the task at hand. Some common types of drills include:

- Standard Drill: This type of drill is suitable for general purpose drilling tasks and is widely used for a variety of applications.

- Hammer Drill: Designed specifically for drilling into masonry, a hammer drill uses a hammering action to create holes in hard materials.

- Impact Drill: Similar to a hammer drill, an impact drill combines rotation with a striking action. It is ideal for drilling through tough materials.

Power

The power of a drill is an important consideration, as it determines the drilling speed and performance. The power is typically measured in terms of volts (V) for cordless drills and amps (A) for corded drills. Higher voltage or amperage generally indicates greater power.

For lag screws, which are larger and require more power to drive into the material, it is recommended to use a drill with higher power. A drill with at least 18V or 7A would provide sufficient power for driving in a 5/16 lag screw.

Depth of the hole

When drilling a hole for a 5/16 lag screw, it is important to consider the depth of the hole. The depth of the hole determines how securely the lag screw will be anchored in the material.

There are a few factors to consider when determining the depth of the hole:

- Type of Material: The type of material you are drilling into will determine the depth of the hole. Different materials have different densities and strengths, so the depth of the hole should be adjusted accordingly. For softer materials, such as wood, a shorter hole depth may be sufficient. For harder materials, such as concrete or metal, a deeper hole may be necessary to ensure a secure connection.

- Length of the Lag Screw: The length of the lag screw you are using will also determine the depth of the hole. The hole should be deep enough to accommodate the entire length of the screw, including the threaded portion that will be inserted into the material. It is recommended to add an extra 1/4 inch to the length of the lag screw when determining the depth of the hole to ensure there is enough room for the screw.

- Embedment Requirements: Depending on the application and load requirements, there may be specific embedment requirements for the lag screw. This refers to the minimum depth that the screw must be embedded into the material to ensure proper strength and stability. These requirements can vary based on the type of material and the intended use of the lag screw.

It is important to take these factors into consideration when determining the depth of the hole for a 5/16 lag screw. Failure to provide an adequate hole depth can result in a weak connection or instability, which could lead to failure and potential damage or injury.

| Material Type | Recommended Hole Depth |

|---|---|

| Wood | 1 inch |

| Concrete | 1 1/2 inches |

| Metal | 1 3/4 inches |

Please note that these are general recommendations and may vary depending on the specific application and load requirements. It is always best to consult the manufacturer’s guidelines or a professional for specific guidance when drilling holes for lag screws.

Desired snugness of the lag screw fit

When choosing the right drill bit size for a 5/16 lag screw, it is important to consider the desired snugness of the fit. The fit between the lag screw and the hole should be tight enough to provide stability and prevent the screw from coming loose, but not so tight that it becomes difficult to insert the screw or risks damaging the wood.

The snugness of the fit can be influenced by several factors:

- Wood type: Different types of wood have different densities and strengths. Hardwoods like oak or maple may require a slightly larger drill bit size compared to softwoods like pine or cedar. It is recommended to consult a drill bit size chart or manufacturer guidelines for the specific wood type being used.

- Size of the pilot hole: A pilot hole is often drilled before inserting the lag screw. The size of the pilot hole can impact the snugness of the fit. A larger pilot hole will result in a looser fit, while a smaller pilot hole will create a tighter fit.

- Drill bit size: The drill bit size refers to the diameter of the hole that will be drilled. Choosing the right drill bit size is crucial for achieving the desired snugness. Using a drill bit that is slightly smaller than the diameter of the lag screw can help create a tighter fit, while using a drill bit that is slightly larger can result in a looser fit.

It is recommended to test the fit with a scrap piece of wood before drilling into the final project. This will allow you to gauge the snugness of the fit and make any necessary adjustments before drilling the actual hole.

Remember, the desired snugness of the lag screw fit may vary depending on the specific project and application. It is always a good idea to consult with professionals or refer to manufacturer guidelines for specific recommendations.

How to determine the right drill bit size

When it comes to choosing the right drill bit size for a 5/16 lag screw, it’s important to consider the following factors:

1. Screw size

The first step in determining the right drill bit size is to identify the size of the screw you will be using. In this case, we have a 5/16 lag screw. The size of the screw will determine the diameter of the hole that needs to be drilled.

2. Shank diameter

Next, you will need to determine the shank diameter of the screw. The shank diameter is the diameter of the unthreaded portion of the screw. In the case of a 5/16 lag screw, the shank diameter would also be 5/16 inch.

3. Pilot hole size

Once you have determined the screw size and shank diameter, you can use this information to determine the pilot hole size. A pilot hole is a smaller hole that is drilled before the main hole to ensure that the screw can be driven in smoothly without splitting the wood.

For a 5/16 lag screw, the recommended pilot hole size is usually 1/8 inch smaller than the shank diameter. Therefore, for a 5/16 lag screw, the pilot hole size would be 7/32 inch.

4. Pre-drilling depth

In addition to the drill bit size, it’s also important to consider the pre-drilling depth. This refers to the length of the hole that needs to be drilled before inserting the lag screw. Generally, the pre-drilling depth should be equal to the length of the threaded portion of the screw.

5. Using a drill bit guide

To ensure accurate drilling, it’s recommended to use a drill bit guide. A drill bit guide is a tool that helps to align the drill bit properly and maintain the correct drilling angle. It can be especially useful when drilling into hard surfaces such as metal or concrete.

In conclusion, determining the right drill bit size for a 5/16 lag screw requires considering the screw size, shank diameter, pilot hole size, pre-drilling depth, and using a drill bit guide. By taking these factors into account, you can ensure a successful and secure installation of the lag screw.

Measure the diameter of the lag screw shank

To choose the correct drill bit size for a 5/16 lag screw, you need to measure the diameter of the lag screw shank. The shank is the unthreaded portion of the screw, which typically has a constant diameter.

To measure the diameter, you can use a pair of calipers or a measuring tool with a sharp edge. Place the lag screw on a flat surface and align the measuring tool with the edges of the shank. Carefully tighten the calipers or measuring tool until they are snug against the screw.

Once the calipers or measuring tool are in position, read the measurement on the tool’s scale. Make sure to take the measurement in inches or millimeters, depending on the units you prefer. This measurement represents the diameter of the lag screw shank.

It’s important to measure the shank accurately to ensure a proper fit between the drill bit and the screw. Using an incorrect drill bit size can lead to stripped threads, weak connections, or the screw not fitting securely in the material.

FAQ:

What is a lag screw?

A lag screw is a type of fastener that is used to join two pieces of wood or metal together. It has a pointed tip and a threaded shaft, which allows it to be easily driven into the material.

Why do I need to choose the right drill bit size for a 5/16 lag screw?

Choosing the right drill bit size for a 5/16 lag screw is important because it ensures a proper fit between the screw and the hole. If the hole is too small, the screw may not be able to fit through or it may not hold securely. If the hole is too large, the screw may not have enough grip and could become loose.

How do I determine the right drill bit size for a 5/16 lag screw?

To determine the right drill bit size for a 5/16 lag screw, you need to measure the diameter of the screw. In this case, the diameter is 5/16 inch. You then need to choose a drill bit that is slightly smaller than the diameter of the screw. For a 5/16 lag screw, a 1/4 inch drill bit would be a good choice.

What happens if I use the wrong drill bit size for a 5/16 lag screw?

If you use a drill bit that is too small, the screw may not be able to fit into the hole or it may not hold securely. If you use a drill bit that is too large, the screw may not have enough grip and could become loose over time.

Can I use a drill bit that is slightly larger or smaller than the diameter of a 5/16 lag screw?

It is generally recommended to use a drill bit that is slightly smaller than the diameter of the screw. This ensures a tight fit and secure hold. However, using a drill bit that is slightly larger may still work, but there is a higher chance of the screw becoming loose over time.

Video: