Choosing the Right Drill Bit Size for a 5/16 Lag Bolt: What You Need to Know

When it comes to using a 5/16 lag bolt, one of the most important things to consider is the drill bit size. While it may seem like a small detail, using the right size drill bit can make a big difference in the success and effectiveness of your project. Whether you’re working on a DIY project at home or tackling a larger construction job, understanding the importance of choosing the correct drill bit size is essential.

The drill bit size will determine the diameter of the hole that is drilled into the material you are working with. When using a 5/16 lag bolt, you will want to choose a drill bit that matches the bolt’s diameter. In this case, you would want to select a 5/16 drill bit. This ensures that the hole is the correct size to accommodate the lag bolt, allowing it to be securely fastened.

Using the wrong drill bit size can lead to a variety of issues. If the drill bit is too small, it will not create a hole large enough for the lag bolt to fit properly. This can result in a loose or weak connection, which is not ideal for any type of construction or repair job. On the other hand, if the drill bit is too large, it can weaken the material by removing too much material and compromising its structural integrity.

Before starting any project that involves using a 5/16 lag bolt, it is essential to check the manufacturer’s instructions or the specifications of the bolt itself. These will often provide recommendations for the correct drill bit size to use. Following these guidelines will ensure that you are using the appropriate drill bit size for the specific lag bolt you are working with.

In conclusion, choosing the right drill bit size when using a 5/16 lag bolt is crucial for the success and effectiveness of your project. It is important to match the diameter of the drill bit to the diameter of the lag bolt to ensure a secure and tight connection. By using the correct drill bit size, you can avoid issues such as loose connections or compromised structural integrity. Always consult the manufacturer’s instructions or specifications to determine the appropriate drill bit size for the specific lag bolt you are using.

Understanding Lag Bolts and Drill Bits

Lag bolts are heavy-duty fasteners commonly used in woodworking and construction projects. They are designed to securely fasten two pieces of material together, such as wood, metal, or concrete. To properly install lag bolts, it is important to choose the right drill bit size for the job. Here is what you need to know:

Lag Bolts

A lag bolt, also known as a lag screw, is a type of screw with a hexagonal head and a pointed tip. It is threaded along its entire length, which provides excellent holding power. Lag bolts are typically used in applications where strength and stability are crucial, such as building structures or securing heavy objects.

Drill Bits for Lag Bolts

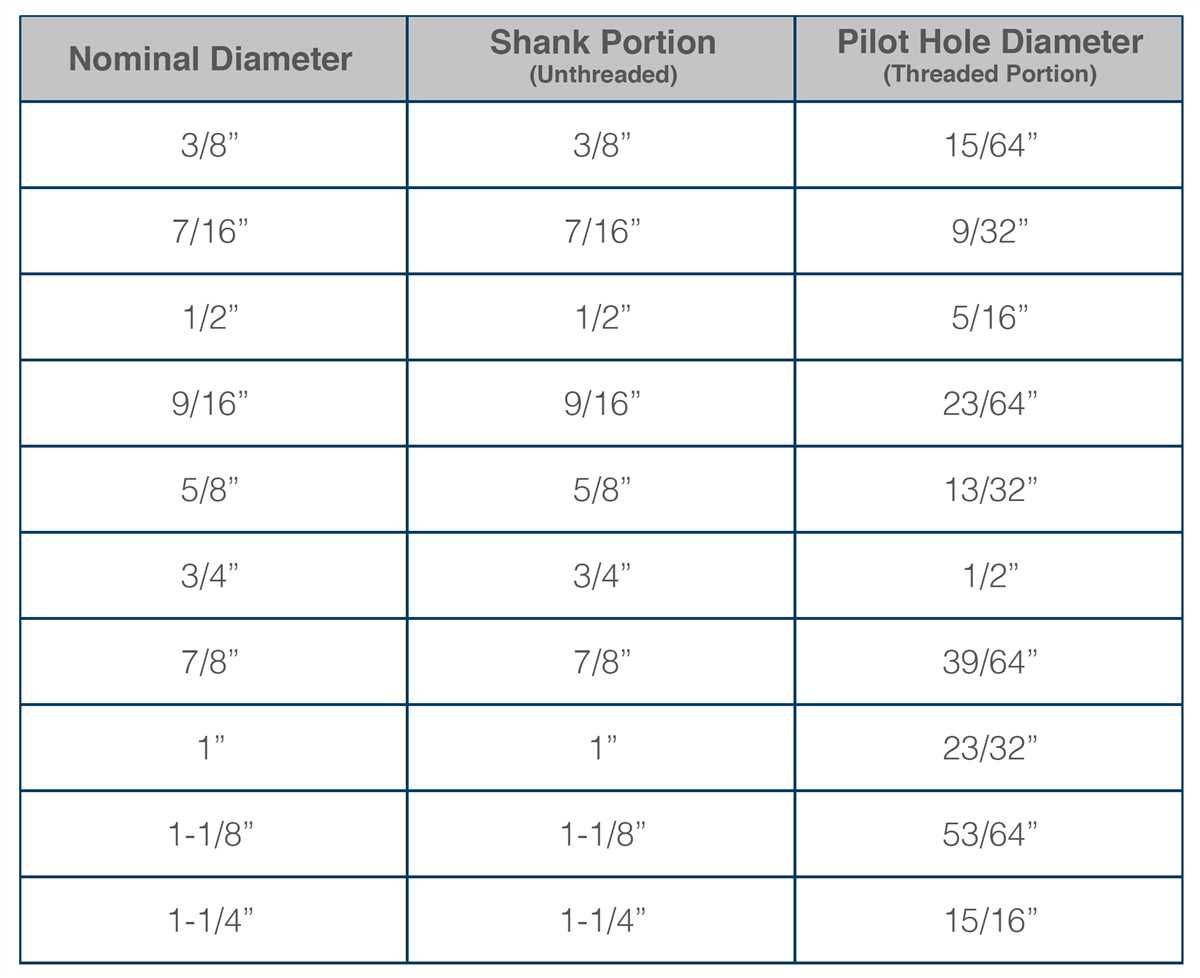

When choosing a drill bit size for a lag bolt, it is important to match the size of the bit to the diameter of the lag bolt shank, excluding the threads. This ensures a proper fit and allows the bolt to be securely tightened without stripping or damaging the material.

Typically, the drill bit size for a lag bolt is slightly smaller than the actual diameter of the bolt shank. This provides a tight fit and helps prevent the bolt from becoming loose over time. For most lag bolts, a 5/16 inch drill bit or slightly smaller is commonly used.

Choosing the Right Drill Bit Size

To ensure the proper fit and strength of the lag bolt installation, it is essential to choose the right drill bit size. Here are some steps to help you determine the correct size:

- Measure the diameter of the lag bolt shank, excluding the threads.

- Select a drill bit size that is slightly smaller than the measurement from step 1. For example, if the shank diameter measures 5/16 inch, you can choose a 1/4 inch drill bit.

- Test the drill bit size by drilling a pilot hole in a scrap piece of material to ensure a snug fit.

- If the drill bit is too small and the lag bolt cannot be inserted easily, use a slightly larger drill bit until the bolt fits securely.

- Always consider the type and thickness of the material you are drilling into when choosing the drill bit size. Harder materials may require a larger drill bit.

By choosing the right drill bit size, you can ensure a proper and secure installation of lag bolts in your woodworking or construction projects. Remember to always measure the shank diameter of the lag bolt and select a drill bit size that is slightly smaller for the best results.

Importance of Choosing the Right Drill Bit Size

Choosing the right drill bit size is crucial when it comes to drilling holes for lag bolts. Using an incorrect size can lead to a variety of issues, such as loose bolts, weak connections, or even damage to the surrounding material. Here are some key reasons why it is important to choose the right drill bit size:

- Ensures a Secure Fit: Using a drill bit that is too small can result in a loose fit between the lag bolt and the hole. This can cause the bolt to easily come loose over time, leading to an unstable or unsafe connection. On the other hand, using a drill bit that is too large can compromise the structural integrity of the hole, making it easier for the bolt to pull out under pressure.

- Prevents Damage to the Material: Drilling a hole that is too large can cause the surrounding material to crack or splinter. This is especially important when working with fragile materials, such as wood or ceramic. Using the correct drill bit size ensures that the hole is just the right size to accommodate the lag bolt without causing any damage to the material.

- Maximizes Holding Power: When a lag bolt is properly installed, it should provide a strong and stable connection. Choosing the right drill bit size ensures that the threads of the bolt can grip the material properly, maximizing the holding power of the connection. This is particularly important when working with heavy loads or in applications where safety is a concern.

- Promotes Efficiency: Using the correct drill bit size allows for a smooth drilling process. It reduces the risk of the bit getting stuck or breaking and increases drilling speed and accuracy. This can save both time and effort, especially when dealing with multiple holes.

In conclusion, the importance of choosing the right drill bit size for a lag bolt cannot be overstated. It ensures a secure fit, prevents damage to the material, maximizes holding power, and promotes efficiency. Taking the time to select the appropriate drill bit size will result in a stronger and more reliable connection, ultimately ensuring the success of your project.

Factors to Consider When Choosing the Size

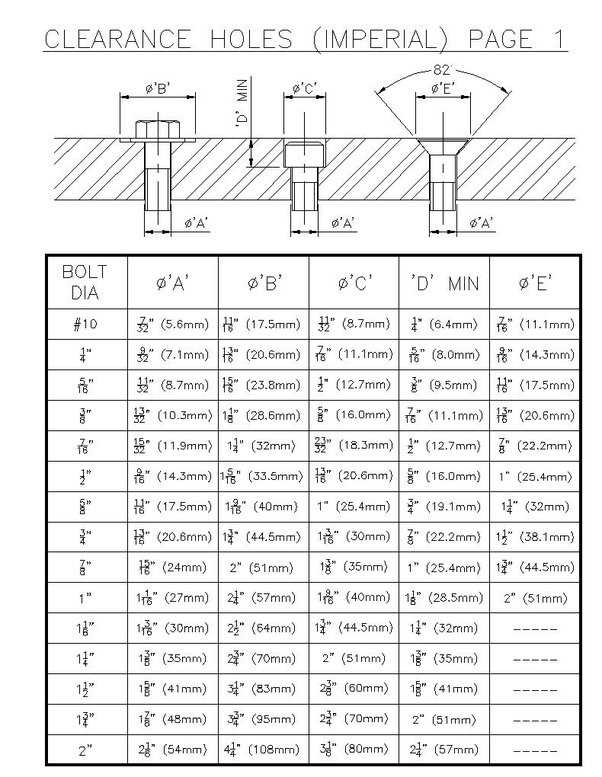

When choosing the right drill bit size for a 5/16 lag bolt, there are several factors that you need to consider. These factors will ensure that the hole you drill is the correct size for the bolt, allowing it to fit snugly and securely in place. Here are the key factors to keep in mind:

- Bolt Size: The first consideration is the size of the lag bolt itself. In this case, we are dealing with a 5/16 lag bolt. You need to find a drill bit that matches this size to ensure a proper fit.

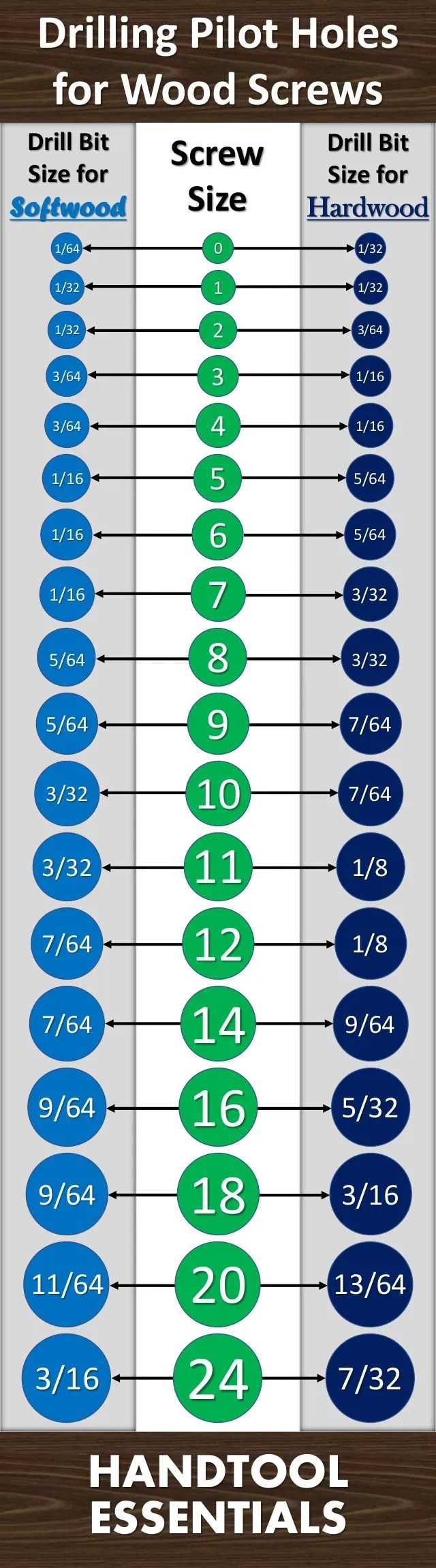

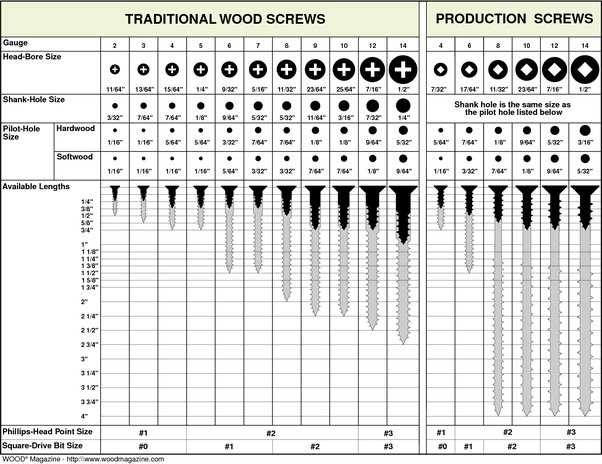

- Material: Different materials require different drill bit sizes. For example, if you are drilling into softwood, you may need a different drill bit size compared to drilling into hardwood or metal. Take the material into account when selecting the drill bit.

- Pilot Hole: A pilot hole refers to a smaller hole that is drilled first before drilling the final hole for the lag bolt. This helps ensure precise placement and reduces the risk of splitting the material. The size of the pilot hole will depend on the specific recommendations for the lag bolt you are using.

- Depth: Consider the depth of the hole you need to drill. This will depend on the length of the lag bolt and how far you want it to be embedded into the material. Make sure to choose a drill bit that is long enough to achieve the desired depth.

- Fastening Strength: The size of the drill bit will also affect the strength of the fastening. Using a drill bit that is too small may result in a loose connection, while using a drill bit that is too large may weaken the material. It’s important to find the right balance to ensure a secure and strong connection.

By considering these factors, you can select the correct drill bit size for your 5/16 lag bolt. Taking the time to choose the right size will ensure a proper fit and a secure connection, reducing the risk of damage or failure.

Steps to Determine the Right Drill Bit Size

- Measure the diameter of the lag bolt

- Calculate the pilot hole size

- Choose the appropriate drill bit size

- Check the drill bit size conversion chart

- Test the fit

- Drill the pilot hole

- Secure the lag bolt

Using a caliper or a ruler, measure the diameter of the lag bolt. This will give you the size in inches or millimeters.

For hardwood, the pilot hole diameter should be about 60-70% of the lag bolt diameter. For softwood, the pilot hole diameter should be about 80-90% of the lag bolt diameter. Use the following formula to calculate the pilot hole size:

Pilot Hole Size = Lag Bolt Diameter x Percentage

Once you have calculated the pilot hole size, choose a drill bit that is slightly smaller than the pilot hole diameter. This will ensure a tight fit and prevent the wood from splitting.

If you are working with a metric measurement, you may need to convert the drill bit size from inches to millimeters or vice versa. Refer to a drill bit size conversion chart to ensure you have the correct size.

Before drilling into the actual surface, it is always a good idea to test the fit of the drill bit and lag bolt on a scrap piece of wood. This will help you determine if the size is correct and make any necessary adjustments before drilling.

Using the appropriate drill bit, drill a pilot hole into the surface where you plan to install the lag bolt. Make sure to drill to the appropriate depth for the length of the lag bolt you are using.

Once the pilot hole is drilled, you can now insert the lag bolt and secure it into place using a socket wrench or a power drill.

Common Drill Bit Size for 5/16 Lag Bolts

When it comes to choosing the right drill bit size for a 5/16 lag bolt, it’s important to select a bit that matches the diameter of the bolt, ensuring a secure and snug fit. The drill bit size needed for a 5/16 lag bolt is typically 1/4 inch or 6.35mm.

A 1/4 inch drill bit is the most common size used for drilling pilot holes for 5/16 lag bolts. This size provides enough clearance for the bolt to be inserted with ease, while still allowing for a tight fit that prevents the bolt from loosening over time.

Using a drill bit that is slightly smaller than the diameter of the bolt ensures that the threads of the lag bolt will grip the wood securely, providing maximum stability. However, using a drill bit that is too small can cause the wood to split or the bolt to become stuck during installation.

It’s worth noting that the recommended drill bit size may vary based on the specific type and material of the lag bolt, as well as the type of wood being drilled into. It’s always a good idea to refer to the manufacturer’s guidelines or consult with a professional for specific recommendations.

Alternative Drill Bit Sizes to Consider

If you don’t have access to a 21/64 drill bit, there are a few alternative sizes you can consider for drilling a hole for a 5/16 lag bolt. Keep in mind that these sizes may not provide an exact fit, but they can still work depending on the specific circumstances.

11/32 Drill Bit

An 11/32 drill bit is slightly larger than the recommended 21/64 size. While it may result in a slightly looser fit, it can still work well for most applications. Make sure to test the fit and adjust as needed.

8mm Drill Bit

If you have access to metric drill bits, an 8mm size is roughly equivalent to a 21/64 inch. This size can also be used as an alternative for drilling a hole for a 5/16 lag bolt. Again, test the fit and make any necessary adjustments to ensure a secure connection.

Letter “U” Drill Bit

Another option to consider is a letter “U” drill bit. The U size drill bits are commonly used for screw clearance holes. While not an exact match, a letter “U” drill bit closest to 21/64 is a U drill bit size U (0.368 inch or 9.350 mm). This size can be used as an alternative for a 21/64 drill bit for a 5/16 lag bolt.

Remember, it’s important to choose a drill bit that is slightly larger than the actual lag bolt size to allow for easy installation and a secure fit. Always test the fit before finalizing your drilling and make any necessary adjustments to ensure a proper connection.

Tips for Drilling with the Right Drill Bit Size

When it comes to drilling, using the right drill bit size is crucial for achieving optimal results. Here are some useful tips to keep in mind:

1. Choose the Correct Drill Bit Size

Before you begin drilling, make sure you have the correct drill bit size for the task at hand. Using the wrong size can result in a poorly drilled hole or even damage to the material you are drilling into. Refer to the manufacturer’s guidelines or consult a drilling guide to determine the appropriate size.

2. Consider the Material

The type of material you are drilling into should also be taken into consideration when selecting the drill bit size. Softer materials like wood may require a smaller drill bit size, while harder materials like metal may require a larger size. Be sure to choose a drill bit that is suitable for the specific material you are working with.

3. Take Safety Measures

Safety should always be a top priority when drilling. Wear safety goggles and protective gloves to prevent any potential injuries. Additionally, ensure that your work area is clear of any obstructions or hazards that could interfere with the drilling process.

4. Start with a Pilot Hole

If you are drilling into a hard or dense material, it is recommended to start with a pilot hole. This smaller hole helps guide the drill bit and prevent it from wandering off course. Choose a drill bit size slightly smaller than the final hole size to create the pilot hole.

5. Use the Proper Drilling Technique

To achieve the best results, use a steady hand and apply consistent pressure when drilling. Avoid pushing too hard, as this can cause the drill bit to overheat or break. Allow the drill bit to do the work and let the cutting edges do their job.

6. Regularly Clean the Drill Bit

During drilling, the drill bit can accumulate debris such as wood shavings or metal filings. It is important to regularly clean the drill bit to prevent clogging and maintain its cutting efficiency. Use a brush or compressed air to remove any debris from the drill bit.

7. Test the Drill Bit Size

Before drilling into your actual workpiece, it is always a good idea to test the drill bit size on a scrap piece of material. This allows you to ensure that the size is appropriate and make any necessary adjustments before drilling into your final piece.

| Lag Bolt Size | Recommended Drill Bit Size |

|---|---|

| 5/16″ | 1/4″ |

| 3/8″ | 5/16″ |

| 1/2″ | 7/16″ |

By following these tips and using the appropriate drill bit size, you can ensure successful drilling and achieve the desired results for your project.

FAQ:

What is a lag bolt?

A lag bolt is a type of fastener that is used to securely attach heavy objects to wood or other materials. It is a large, heavy-duty screw that has a hexagonal head and a pointed tip.

What is the importance of choosing the right drill bit size for a 5/16 lag bolt?

Choosing the right drill bit size for a 5/16 lag bolt is important because it ensures a proper fit and tight connection between the bolt and the wood. If the drill bit size is too small, the bolt may not fit properly and may not provide enough grip. If the drill bit size is too large, the bolt may not have enough material to grip onto and may become loose over time.

How do I determine the correct drill bit size for a 5/16 lag bolt?

To determine the correct drill bit size for a 5/16 lag bolt, you can use a drill bit sizing chart or a drill bit gauge. The recommended drill bit size for a 5/16 lag bolt is typically 1/8 inch smaller than the bolt diameter, which in this case would be a 7/32 drill bit. However, it is always a good idea to refer to the manufacturer’s instructions or consult a professional if you are unsure.

What are the consequences of using the wrong drill bit size for a 5/16 lag bolt?

Using the wrong drill bit size for a 5/16 lag bolt can lead to various issues. If the drill bit is too small, it may cause the wood to split, resulting in a weakened connection. If the drill bit is too large, the lag bolt may not have enough material to grip onto, causing it to become loose and potentially fall out over time. It is important to ensure a proper fit to ensure the safety and stability of the attached objects.

Video: