Choosing the Right Drill Bit Size for a .308 Suppressor: A Comprehensive Guide

When it comes to choosing the right drill bit size for a .308 suppressor, there are a few key factors to consider. The size of the hole drilled into the suppressor determines the amount of gas that can escape and therefore affects the level of noise reduction. By understanding the fundamentals of drill bit sizes and their impact on suppressor performance, you can make an informed decision that will optimize your shooting experience.

First and foremost, it’s important to know the specific diameter of your suppressor’s muzzle. This information can typically be found in the manufacturer’s specifications. Matching the drill bit size to the muzzle diameter ensures a precise and secure fit. A snug fit eliminates any wobbling or movement of the suppressor, which can negatively impact accuracy and safety.

Additionally, the type of material the suppressor is made of plays a role in the drill bit size selection. Different materials have different hardness levels and require different drill bit sizes. For example, a suppressor made of stainless steel will require a different drill bit size than one made of titanium. It’s essential to consult the manufacturer’s recommendations or a knowledgeable gunsmith to determine the appropriate drill bit size for your specific suppressor.

Lastly, consider the intended use of your .308 suppressor. If you plan on using it primarily for target shooting or competition shooting, a larger hole size may be suitable. This allows for maximum gas flow, resulting in optimal noise reduction. However, if you also plan on using the suppressor for hunting, a smaller hole size may be more appropriate. This reduces the risk of muzzle blast obscuring your vision and potentially scaring off game.

Understanding the Importance of Drill Bit Size

When it comes to drilling holes for a .308 suppressor, the drill bit size you choose plays a crucial role in the final outcome. The size of the drill bit directly affects the diameter of the hole you create, and this can have a significant impact on the performance of your suppressor.

There are a few key factors to consider when selecting the right drill bit size:

- Suppressor Design: Different suppressor models might have specific requirements when it comes to the size of the hole. Make sure to consult the manufacturer’s guidelines or seek advice from experienced professionals in order to ensure optimal performance.

- Noise Reduction: The size of the hole drilled in the barrel determines the amount of gas that can escape and the overall efficiency of the suppressor. A larger hole may allow more gas to escape, resulting in reduced noise reduction. On the other hand, a smaller hole can restrict gas flow and potentially cause issues with backpressure.

- Barrel Thickness: The thickness of the barrel is another important consideration when choosing a drill bit size. A thicker barrel may require a larger drill bit to maintain structural integrity, while a thinner barrel may need a smaller drill bit to minimize the risk of damage.

- Regulations: It is essential to research and comply with any relevant local laws and regulations regarding suppressors. Some jurisdictions may have restrictions on the size of the hole that can be drilled, so be sure to understand the legal implications before proceeding.

Ultimately, the right drill bit size will depend on a variety of factors specific to your suppressor and its intended use. It is always best to consult with professionals who are knowledgeable in this field to ensure you select the appropriate drill bit size for your specific needs.

Key Factors to Consider when Selecting a Drill Bit Size

Choosing the right drill bit size is crucial for the successful installation of a .308 suppressor. Here are some key factors to consider when selecting a drill bit size:

1. Suppressor Mounting System

The type of mounting system used with your .308 suppressor will play a significant role in determining the appropriate drill bit size. Some suppressors may require drilling directly into the barrel, while others may use a muzzle device or a dedicated suppressor mount. Each of these mounting systems will have specific instructions for drill bit size, so it is essential to consult the manufacturer’s guidelines.

2. Barrel Material and Thickness

The material and thickness of your barrel are critical considerations when selecting a drill bit size. Different barrel materials, such as stainless steel or chrome-moly steel, may have different hardness levels, affecting the drill bit’s performance and the required size. Additionally, the thickness of the barrel will determine the depth of the hole and potentially impact the drill bit size needed.

3. Suppressor Outer Diameter

The outer diameter of the suppressor will also help determine the appropriate drill bit size. The hole drilled into the barrel should accommodate the suppressor snugly, ensuring a secure and proper fit. Measure the outer diameter of your suppressor and consult the manufacturer’s guidelines or specifications to find the corresponding drill bit size.

4. Thread Size and Pitch

If your .308 suppressor uses a threaded mounting system, it is essential to consider the thread size and pitch when selecting a drill bit size. The drilled hole should match the thread size and pitch, allowing the suppressor to be properly screwed onto the barrel.

5. Manufacturer Recommendations

Lastly, always refer to the manufacturer’s recommendations or guidelines when selecting a drill bit size. They will have specific instructions tailored to their suppressor’s design, ensuring the proper installation and performance of the suppressor.

By considering these key factors, you can ensure that the drill bit size you select is suitable for your .308 suppressor and achieve a successful installation. It is important to prioritize safety and accuracy when working with firearms, so take the time to choose the right drill bit size for your specific suppressor and barrel combination.

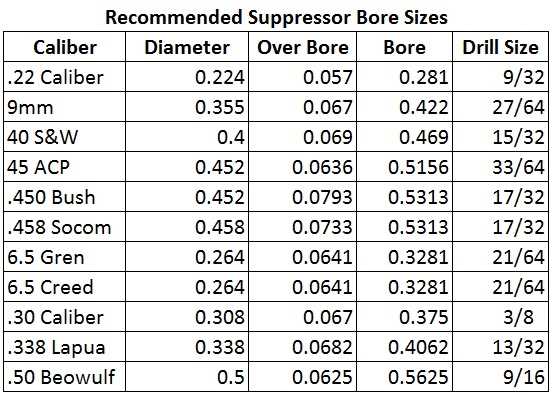

Commonly Used Drill Bit Sizes for .308 Suppressors

When it comes to choosing the right drill bit size for a .308 suppressor, there are several commonly used sizes that you should be familiar with. These sizes are widely accepted and recommended by professionals in the industry.

1. 5/32-inch Drill Bit

The 5/32-inch drill bit is one of the most commonly used sizes for drilling the initial hole in a .308 suppressor. This size provides a good balance between removing sufficient material and maintaining structural integrity.

2. 7/32-inch Drill Bit

If you need to enlarge the hole in your .308 suppressor, the 7/32-inch drill bit is a popular choice. It allows for a slightly larger bore size while still being within the acceptable range for most suppressors.

3. 3/8-inch Drill Bit

In some cases, you may need to significantly enlarge the hole in your .308 suppressor. The 3/8-inch drill bit is commonly used for this purpose, as it provides a substantial increase in bore size.

4. 1/2-inch Drill Bit

The 1/2-inch drill bit is the largest commonly used size for drilling .308 suppressors. This size is typically reserved for situations where you need to remove a significant amount of material or create a larger bore size for specific purposes.

It’s important to note that these drill bit sizes are general recommendations and may vary depending on the specific suppressor design and manufacturer specifications. Always refer to the manufacturer’s guidelines and consult with a professional if you are unsure about the appropriate size for your .308 suppressor.

Effect of Drill Bit Size on Suppressor Performance

The size of the drill bit used to create the hole in a suppressor can have an impact on its overall performance. While the calibration of the drill bit is generally determined by the specific requirements of the suppressor manufacturer, it is important to understand the potential effects of different drill bit sizes on the suppressor’s performance and functionality.

1. Bore Size and Pressure

The diameter of the hole drilled into the suppressor, known as the bore size, directly affects the internal pressure created when a round is fired. A larger bore size allows for greater gas flow, reducing the pressure buildup within the suppressor. This can help maintain optimal performance and reduce the risk of damage to the suppressor.

On the other hand, a smaller bore size restricts gas flow, resulting in increased pressure build-up. This may cause the suppressor to become less effective at reducing noise and recoil, as the high-pressure gas has a harder time expanding and dissipating within the suppressor.

2. Sound Suppression

The drill bit size can also affect the sound suppression capabilities of the suppressor. A larger bore size allows for increased gas flow and expansion, which can help dissipate the sound energy more effectively. This can result in better sound suppression performance and a quieter shooting experience.

Conversely, a smaller bore size restricts gas flow and limits the expansion of gases, which can result in reduced sound suppression capabilities. This may lead to louder shots and potentially compromise the overall effectiveness of the suppressor.

3. Recoil Reduction

The drill bit size can indirectly impact recoil reduction when considering the overall design of the suppressor. A larger bore size may allow for better gas expansion and a more efficient redirecting of gas to counteract recoil forces. This can result in improved recoil reduction and a smoother shooting experience.

However, it is important to note that there are other factors, such as suppressor design and weight distribution, that can influence the recoil reduction capabilities of a suppressor. The drill bit size alone should not be the sole deciding factor in determining the recoil reduction performance.

4. Manufacturer Recommendations

It is important to follow the manufacturer’s recommendations for drill bit size when modifying a suppressor. Each manufacturer may have specific requirements or guidelines to ensure optimal performance and safety. Deviating from these recommendations could result in a compromised suppressor performance or potential damage.

Additionally, it is important to exercise caution and proper safety measures when modifying a suppressor. When in doubt, it is always recommended to consult with the manufacturer or a professional gunsmith for guidance and assistance.

| Aspect | Effect of Larger Drill Bit Size | Effect of Smaller Drill Bit Size |

|---|---|---|

| Bore Size | Allows for greater gas flow and reduction in pressure build-up | Restricts gas flow, leading to increased pressure build-up |

| Sound Suppression | Improved sound suppression capabilities | Reduced sound suppression capabilities |

| Recoil Reduction | Potentially improved recoil reduction | No direct impact, but other factors may affect recoil reduction |

Overall, the choice of drill bit size for a .308 suppressor can have significant implications on its performance. It is essential to consider the bore size, sound suppression capabilities, and recoil reduction when selecting the appropriate drill bit size. Following manufacturer recommendations and seeking professional advice can help ensure optimal performance and safety.

Choosing the Ideal Drill Bit Size for Accuracy and Noise Reduction

When it comes to choosing the right drill bit size for a .308 suppressor, accuracy and noise reduction are two important factors to consider. The size of the hole drilled in the suppressor affects both the accuracy of the rifle and the level of noise reduction achieved.

Factors to Consider

Before selecting a drill bit size, you should consider the following factors:

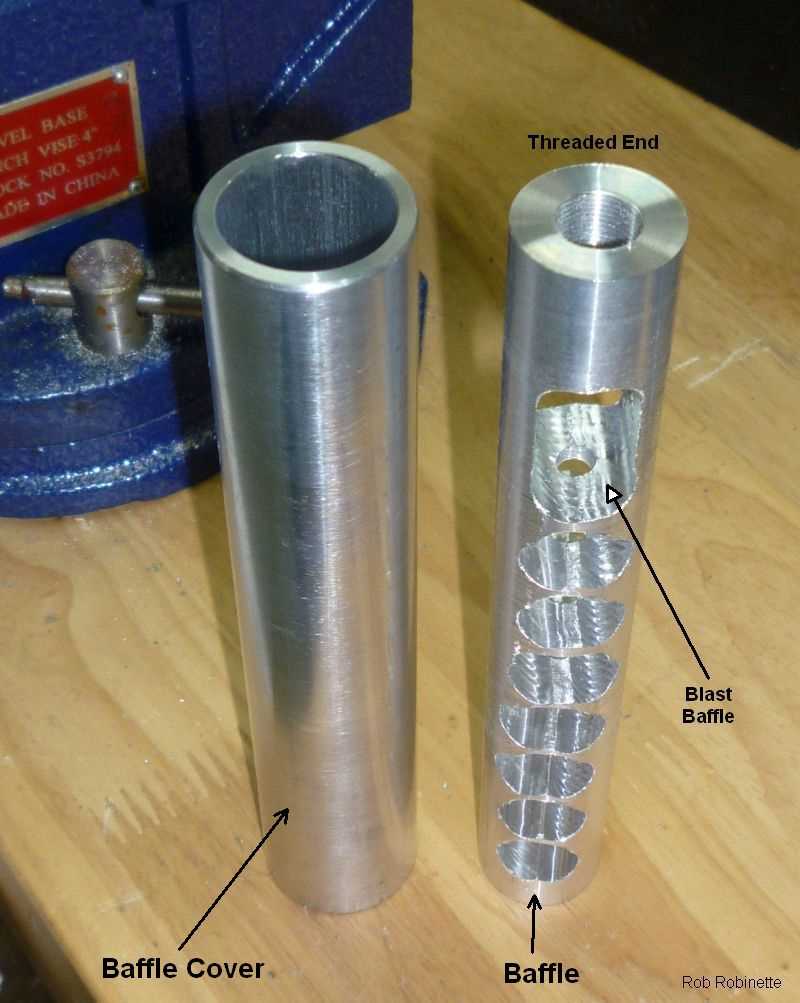

- Suppressor Design: The design of the suppressor, particularly the internal baffles and chambers, can influence the drill bit size needed. Different designs have different volume requirements and may require specific sizes to achieve optimal performance.

- Ammunition Type: The type of ammunition used in the rifle also plays a role. Different types of ammunition produce varying levels of pressure and gas, which may require different drill bit sizes to properly accommodate.

- Desired Noise Reduction Level: If noise reduction is a top priority, a larger drill bit size may be needed to create a larger opening, allowing more gases to escape and reducing the sound signature. However, this may come at the cost of some accuracy.

- Desired Accuracy: If accuracy is the primary concern, a smaller drill bit size may be more appropriate. A smaller opening will provide better support to the bullet as it exits the barrel, resulting in improved accuracy. However, this may result in less noise reduction.

Testing and Fine-Tuning

Choosing the ideal drill bit size often requires a process of trial and error. It is recommended to start with a slightly larger drill bit size than necessary and then test the rifle for accuracy and noise reduction. If the results are not satisfactory, gradually increase or decrease the drill bit size until the desired balance between accuracy and noise reduction is achieved.

Consulting with Experts

If you are uncertain about the ideal drill bit size for your .308 suppressor, it is recommended to consult with professionals or experienced individuals who have knowledge of suppressor design and performance. They can provide valuable insights and recommendations based on their expertise.

Conclusion

Choosing the right drill bit size for a .308 suppressor requires careful consideration of various factors, including suppressor design, ammunition type, desired noise reduction level, and desired accuracy. Through testing, fine-tuning, and consulting with experts, you can find the ideal drill bit size that balances accuracy and noise reduction to meet your specific needs.

Drilling Techniques for Different Drill Bit Sizes

When it comes to drilling holes for a .308 suppressor, the size of the drill bit is crucial. The drill bit size will determine the diameter of the hole and can greatly affect the performance of the suppressor. Here are some drilling techniques for different drill bit sizes:

Small Drill Bit Sizes (5/64″ to 1/8″)

- Use a center punch to create a pilot hole on the desired spot.

- Secure the workpiece firmly in a vice or clamp to prevent movement.

- Start drilling slowly with light pressure, allowing the drill bit to create an initial groove.

- Gradually increase the drilling speed and apply more pressure, maintaining a steady hand to keep the drill bit centered.

- Periodically pause to clear away chips and lubricate the drill bit to prevent overheating.

- Continue drilling until the hole reaches the desired depth.

Medium Drill Bit Sizes (9/64″ to 1/4″)

- Follow the same steps as for small drill bit sizes, but adjust the drilling speed and pressure accordingly.

- Keep a firm grip on the drill and use a steady, controlled motion to avoid wobbling or drifting off-center.

- Pay attention to the depth of the hole, as it is more critical with larger drill bit sizes.

- Use a tapping fluid or cutting oil for lubrication to reduce friction and extend the life of the drill bit.

- If necessary, use a peck drilling technique – drill a short distance, then retract the drill bit to remove chips before continuing.

Large Drill Bit Sizes (5/16″ or larger)

- Use a center punch to create a pilot hole, as it will help guide the larger drill bit.

- Set the drill to a slower speed and use more pressure to make a clean cut.

- Secure the workpiece with clamps or a vice to prevent movement.

- Monitor the heat buildup and lubricate the drill bit frequently to reduce friction.

- Consider pre-drilling a smaller hole with a medium-sized drill bit first before using the larger drill bit.

- Always wear safety goggles to protect your eyes from flying debris.

Remember, drilling holes for a .308 suppressor requires precision and attention to detail. Take your time, use the appropriate techniques for each drill bit size, and prioritize safety throughout the process.

Safety Precautions when Using Different Drill Bit Sizes

Drilling is an essential part of working with a .308 suppressor, but it can be dangerous if proper safety precautions are not taken. Here are some important safety measures to consider when using different drill bit sizes:

- Wear appropriate safety gear: Before starting any drilling work, ensure you are wearing safety goggles, ear protection, and gloves. This will help protect your eyes, ears, and hands from any potential hazards, including metal shavings and sharp edges.

- Secure the workpiece: Make sure the workpiece is securely fastened in place before drilling. This will prevent it from moving or spinning during the drilling process, reducing the risk of accidents or injuries.

- Choose the right drill bit: Select a drill bit that is appropriate for the material you are drilling. Using the wrong type of bit can lead to excessive heat, breakage, or drill bit dulling, which can compromise your safety and the effectiveness of your drilling.

- Start with a smaller pilot hole: It is recommended to start with a smaller drill bit for the initial pilot hole. This helps to ensure better accuracy and control, and reduces the risk of the drill bit “walking” or slipping on the surface of the workpiece.

- Use lubrication: Lubricating the drill bit and workpiece during drilling can help to reduce friction and dissipate heat. This can extend the life of the drill bit and prevent it from becoming too hot, which can be dangerous to touch.

- Drill at a suitable speed: Drill at a speed that matches the material you are working with. Drilling too fast or too slow can cause the drill bit to become jammed or break, potentially causing injury. Refer to the drill manufacturer’s recommendations for the appropriate drilling speed.

- Take breaks: Drilling can be physically demanding. Take regular breaks to avoid fatigue, as this can lead to less control over the drill and an increased risk of accidents.

- Clean up debris: Remove any debris, such as metal shavings, from the work area to prevent slipping or tripping hazards. Use a brush or vacuum to clean up the area around the drill press or workbench.

- Store drill bits properly: After using drill bits, store them in a safe place where they will not be damaged or pose a risk of injury. Keep them in a designated container or rack to prevent them from getting mixed up or lost.

By following these safety precautions, you can minimize the risk of accidents and injuries while using different drill bit sizes for your .308 suppressor. Remember, safety should always be the top priority in any drilling operation.

FAQ:

What is a .308 suppressor?

A .308 suppressor is a device specifically designed to reduce the noise and recoil produced by a .308 caliber firearm. It is attached to the muzzle of the gun to capture and redirect the expanding gas and reduce the sound signature of each shot.

Why do I need a specific drill bit size for a .308 suppressor?

The drill bit size for a .308 suppressor is crucial because it determines the diameter of the hole to be drilled in the barrel of the firearm. This hole is necessary for attaching the suppressor and ensuring its proper alignment and function.

What happens if I use the wrong drill bit size for a .308 suppressor?

If you use the wrong drill bit size for a .308 suppressor, the hole drilled in the barrel may be either too small or too large. If the hole is too small, the suppressor may not fit or align properly, affecting its performance. If the hole is too large, the suppressor may not securely attach to the barrel, leading to potential safety issues and reduced effectiveness in reducing noise and recoil.

How do I choose the right drill bit size for a .308 suppressor?

Choosing the right drill bit size for a .308 suppressor involves several factors. You need to consider the specific suppressor manufacturer’s instructions, which will outline the recommended drill bit size. Additionally, you should take into account the type of barrel material, the desired level of suppressor attachment, and the overall alignment of the suppressor with the barrel.

Video: