Choosing the Right Drill Bit Size for a 3/8-18 NPT Tap

When it comes to using a 3/8-18 NPT (National Pipe Taper) tap, choosing the right drill bit size is essential for a successful and precise thread cutting process. The drill bit size determines the diameter of the hole that needs to be drilled before tapping the thread, which in turn affects the functionality and integrity of the final thread.

The 3/8-18 NPT tap is commonly used for creating threads on pipe fittings and connections. It features a tapered design that allows for a tight and secure fit between the male and female parts. However, in order to achieve this reliable connection, the hole that is drilled before tapping must have the correct diameter to match the tap size.

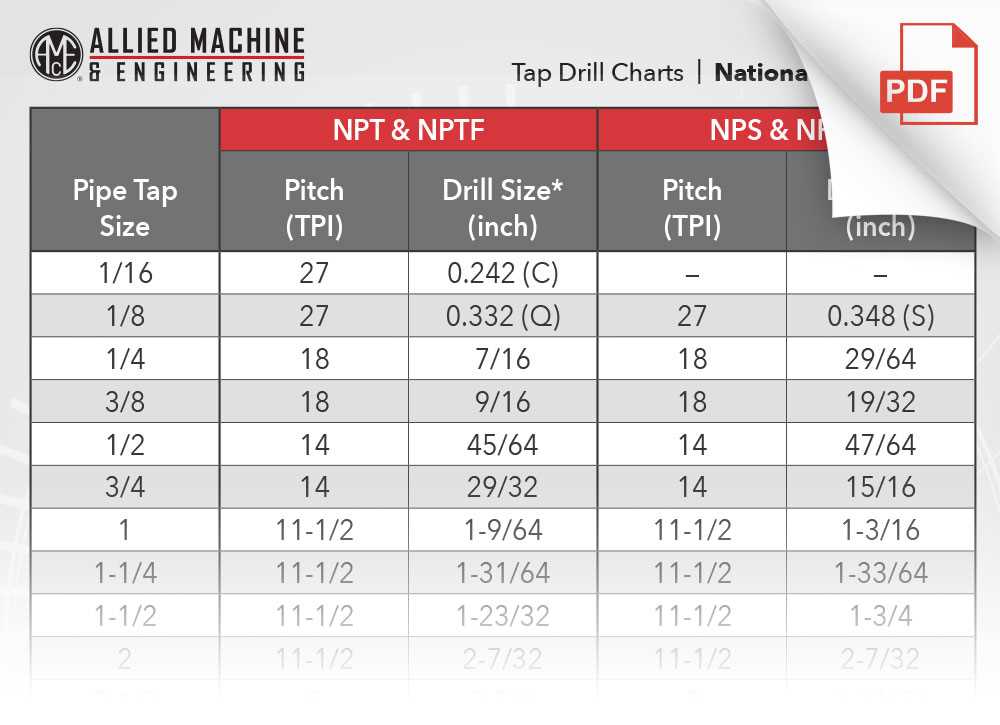

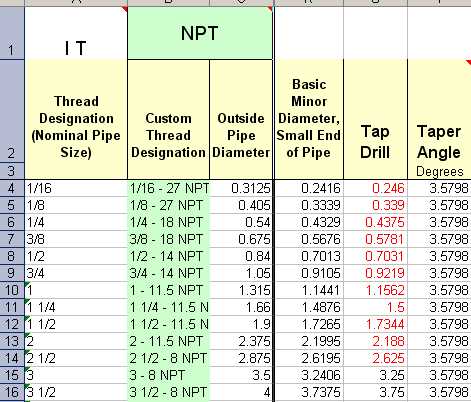

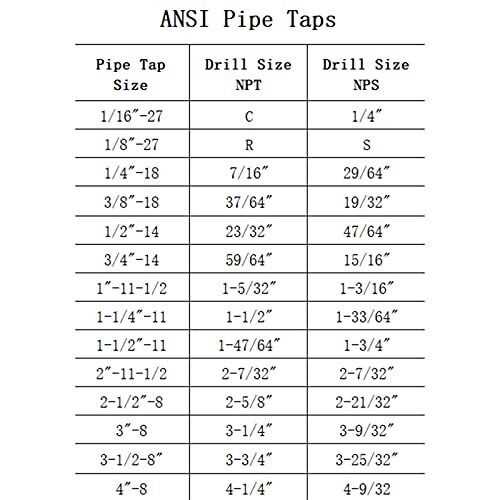

To determine the right drill bit size for a 3/8-18 NPT tap, one can refer to tap drill charts that provide the recommended hole sizes based on the thread size. These charts take into consideration factors such as tap pitch, thread depth, and material properties to ensure proper thread engagement. It is important to note that different materials may require different drill bit sizes, as harder materials may require slightly larger holes for smoother tapping.

In general, for a 3/8-18 NPT tap, the recommended drill bit size is 23/64 inch or 0.3594 inches in diameter. This drill bit size allows for slight clearance between the tap and the hole to accommodate the taper design of the NPT tap. It is crucial to use this recommended drill bit size to ensure that the threads are properly cut and engage securely with the fitting or connection.

Factors to Consider

- Material: The material of the workpiece is an important factor to consider when choosing the right drill bit size for a 3/8-18 NPT tap. Different materials require different drill bit sizes to achieve the desired thread depth and strength. For example, harder materials like steel may require a larger drill bit size compared to softer materials like aluminum.

- Tap Size: The size of the tap, in this case, a 3/8-18 NPT tap, will determine the appropriate drill bit size to be used. The drill bit size should match the minor diameter of the tap, which is the smallest diameter of the threaded portion. Using the correct drill bit size ensures that the tap can be easily threaded into the hole without excessive force.

- Thread Depth: The desired thread depth is another crucial factor to consider. The thread depth determines how many threads are engaged between the tap and the workpiece. The drill bit size should be chosen in such a way that it provides sufficient thread engagement depth to ensure a strong and secure connection.

- Reference Charts: Reference charts are available that provide drill bit size recommendations for various taps and thread types. These charts are based on industry standards and can be a helpful resource in determining the appropriate drill bit size for a 3/8-18 NPT tap based on the material and desired thread depth.

- Considerations for Tapping Fluids: It is important to consider whether tapping fluids will be used during the drilling and tapping process. Tapping fluids can reduce heat, friction, and wear, resulting in smoother and more accurate threads. If tapping fluids will be used, the drill bit size should be chosen accordingly to allow for the presence of the fluid.

- Testing and Experience: Lastly, it is always a good practice to perform a test run or consult with experienced professionals to determine the optimal drill bit size for a specific application. Factors such as the type of tap, material, and threading requirements can vary, and expert advice can help ensure the best results.

Material Type and Hardness

When choosing the right drill bit size for a 3/8-18 NPT tap, it is important to consider the material type and hardness of the workpiece. The material type and hardness will determine the appropriate drill bit size to use.

1. Material Type

The material type refers to the type of material that the workpiece is made of. Common materials used for drilling and tapping include steel, aluminum, brass, and cast iron.

- Steel: Steel is a common material used for drilling and tapping. It comes in various grades, such as carbon steel, stainless steel, and alloy steel. Each grade has different hardness and requires a specific drill bit size.

- Aluminum: Aluminum is a lightweight material that is commonly used in industries such as automotive and aerospace. It is softer than steel and requires a larger drill bit size.

- Brass: Brass is a metal alloy made of copper and zinc. It is softer than steel and requires a larger drill bit size. Brass is commonly used in plumbing and electrical applications.

- Cast Iron: Cast iron is a hard and brittle material that requires a smaller drill bit size. It is commonly used in applications that require high strength and durability.

2. Hardness

The hardness of the workpiece also plays a crucial role in determining the appropriate drill bit size. The hardness is typically measured on the Rockwell hardness scale.

- Soft materials: Soft materials like aluminum and brass have lower hardness and require larger drill bit sizes.

- Hard materials: Hard materials like steel and cast iron have higher hardness and require smaller drill bit sizes.

Conclusion

Choosing the right drill bit size for a 3/8-18 NPT tap requires considering the material type and hardness of the workpiece. Different materials and hardness levels will require different drill bit sizes to ensure proper tapping. It is always recommended to refer to manufacturer guidelines or consult an expert when unsure about the appropriate drill bit size to use.

Tap Size and Design

When it comes to choosing the right drill bit size for a 3/8-18 NPT tap, the tap size and design are two important factors to consider. The tap size refers to the size of the hole that needs to be drilled before using the tap, while the tap design determines the type of threads it will create in the material.

Tap Size

The tap size for a 3/8-18 NPT tap is determined by the diameter of the tap itself. In this case, the tap has a 3/8-inch diameter. When choosing the drill bit size for this tap, it’s important to select a bit that matches the tap size. In this case, a 3/8-inch drill bit would be the appropriate choice.

Using the correct tap size ensures that the threads created by the tap will fit properly and securely in the material being tapped. Using a drill bit that is too small can result in loose or weak threads, while using a drill bit that is too large can lead to oversized threads that won’t securely hold the fastener.

Tap Design

The design of the tap determines the type of threads it will create in the material. In the case of a 3/8-18 NPT tap, the design is specifically for creating National Pipe Taper (NPT) threads. NPT threads are commonly used in plumbing and gas systems and have a tapered shape that allows for a tight seal.

The 18 in the tap designation refers to the number of threads per inch. In this case, there are 18 threads per inch. Understanding the tap design is important because it determines the pitch of the threads and the type of fastener that will be compatible with the tapped hole. Using a tap with a different design can result in incompatible threads that won’t fit with the intended fastener.

It’s also worth noting that the tap design may require additional steps in the drilling and tapping process. Some taps require pre-drilling with a smaller size drill bit, while others may require the use of cutting oil for lubrication. It’s important to refer to the manufacturer’s instructions for the specific tap being used to ensure the proper drilling and tapping procedure.

In conclusion, when choosing the right drill bit size for a 3/8-18 NPT tap, it’s important to consider both the tap size and design. Selecting a drill bit that matches the tap size ensures proper thread fit, while understanding the tap design ensures compatibility with the intended fastener. Following the manufacturer’s instructions for the specific tap being used will help ensure a successful drilling and tapping process.

Thread Engagement

Thread engagement refers to the amount of thread contact between the tap and the hole being threaded. The depth of thread engagement is important for proper tapping and thread strength.

When tapping a hole with a 3/8-18 NPT tap, it is necessary to have the correct amount of thread engagement to ensure the tap can properly cut the threads into the hole.

Factors Affecting Thread Engagement

There are several factors that determine the appropriate thread engagement for a tap:

- Tap type: The type of tap being used will affect the recommended thread engagement. For example, a taper tap may require less engagement than a bottoming tap.

- Material: Different materials have different thread engagement requirements. Harder materials may require deeper thread engagement for proper thread cutting and strength.

- Hole size: The size of the hole being tapped will also affect the thread engagement. Larger holes may require deeper engagement to ensure proper thread formation.

Recommended Thread Engagement

When tapping a hole with a 3/8-18 NPT tap, it is generally recommended to have a thread engagement of at least 1.5 times the nominal diameter of the tap. For a 3/8-18 NPT tap, the nominal diameter is 3/8 inch, so the recommended thread engagement would be at least 9/16 inch.

Having sufficient thread engagement ensures that the tap can fully cut the threads without bottoming out or running out of thread. It also provides proper thread strength and reduces the risk of thread stripping or failure.

Measuring Thread Engagement

To measure thread engagement, use a depth gauge or a ruler to measure the distance from the tip of the tap to the end of the threaded section. This measurement should be compared to the recommended thread engagement to ensure it meets the minimum requirement.

It is important to note that the thread engagement should be measured after the tap has been fully inserted into the hole and before it is backed out. This will provide an accurate measurement of the actual thread engagement.

Importance of Proper Thread Engagement

Proper thread engagement is crucial for ensuring the threaded connection is secure and leak-free. Insufficient thread engagement can result in loose connections or leaks, while excessive thread engagement may cause thread stripping or failure.

By following the recommended thread engagement guidelines for a 3/8-18 NPT tap, you can ensure a strong and reliable threaded connection. Proper thread engagement will also extend the lifespan of both the tap and the threaded hole.

Remember to always refer to the manufacturer’s recommendations and guidelines when determining the appropriate thread engagement for your specific application.

Drill Bit Material and Coating

Materials

Drill bits come in a variety of materials, each with its own strengths and weaknesses. The material of the drill bit affects its durability, cutting speed, and heat resistance. Here are some common materials used in drill bits:

- High-Speed Steel (HSS): HSS drill bits are the most common type and offer good performance across a wide range of materials. They are durable and can withstand high cutting speeds.

- Cobalt Steel: Cobalt steel drill bits are harder and more heat-resistant than HSS. They are suitable for drilling in tough materials like stainless steel and cast iron.

- Carbide: Carbide drill bits are extremely hard and durable. They are ideal for drilling in hard materials such as concrete, tile, and masonry.

Coatings

Coatings are applied to drill bits to improve their performance and extend their lifespan. The coating reduces friction and heat build-up during drilling, allowing for faster cutting speeds and reducing wear on the bit. Here are some common coatings used on drill bits:

- Titanium Nitride (TiN): TiN is a gold-colored coating that increases the surface hardness of the drill bit, reducing friction and extending its lifespan. It is commonly used on HSS drill bits.

- Titanium Aluminum Nitride (TiAlN): TiAlN is a similar coating to TiN but offers increased hardness and heat resistance. It is often used on cobalt steel and carbide drill bits.

- Black Oxide: Black oxide coating provides lubricity and corrosion resistance. It is commonly used on cheaper drill bits.

Choosing the Right Combination

When choosing a drill bit for tapping a 3/8-18 NPT hole, it is important to consider both the material and coating. For general-purpose drilling in materials like steel and aluminum, a high-speed steel (HSS) drill bit with a titanium nitride (TiN) coating would be a suitable choice. If drilling in harder materials like stainless steel, a cobalt steel drill bit with a titanium aluminum nitride (TiAlN) coating would be more appropriate. For drilling in concrete or masonry, a carbide drill bit would be the best option.

| Material | Coating | Recommended Use |

|---|---|---|

| High-Speed Steel (HSS) | Titanium Nitride (TiN) | General-purpose drilling in steel and aluminum |

| Cobalt Steel | Titanium Aluminum Nitride (TiAlN) | Drilling in tougher materials like stainless steel |

| Carbide | N/A (does not require coating) | Drilling in concrete, tile, and masonry |

Optimal Tap Hole Size

In order to achieve the best results when using a 3/8-18 NPT tap, it is important to choose the right drill bit size for the tap hole. The tap hole size is crucial because it determines the fit of the tap and the thread quality. The tap hole should be slightly smaller than the tap size to ensure a tight fit and prevent the tap from slipping or becoming loose.

Determining the Tap Hole Size

The recommended tap hole size for a 3/8-18 NPT tap can be determined using the standard drill bit size chart for NPT threads. According to the chart, the recommended drill bit size for a 3/8-18 NPT tap is 37/64 inch or 0.5781 inches in diameter.

Drilling the Tap Hole

Before drilling the tap hole, it is important to securely clamp the workpiece to prevent any movement or slipping during the drilling process. The drill bit should be centered on the desired location for the tap hole and held perpendicular to the surface to ensure a straight hole.

Care should be taken to drill the hole to the recommended depth. This depth depends on the length of the tap and the desired thread length. A tap depth gauge can be used to measure the depth accurately.

Using the Tap

Once the tap hole is drilled, the tap can be used to create the thread. It is essential to use cutting oil or a suitable lubricant to reduce friction and prevent the tap from becoming stuck or breaking. The tap should be started slowly and turned in a clockwise direction to create the thread.

During the tapping process, it is important to periodically back off the tap to remove chips and prevent clogging. This will ensure smooth and accurate threading.

Final Recommendations

Choosing the optimal tap hole size is crucial for achieving accurate and high-quality threads with a 3/8-18 NPT tap. Following the recommended drill bit size and using the correct drilling techniques and lubrication will help ensure the best results. It is always recommended to test the fit of the tap in the threaded hole before proceeding with the final assembly to ensure a proper fit and functionality.

Drill Bit Size Guidelines

When tapping a 3/8-18 NPT hole, it is crucial to choose the right drill bit size to ensure a proper fit and prevent any threading issues. Here are some guidelines to help you choose the correct drill bit size:

- Start by determining the thread pitch of the NPT tap. In this case, it is 18 threads per inch.

- Refer to a drill chart or use a formula to calculate the tap drill size. The formula for NPT taps is:

Tap Drill Size = Major Diameter of Tap – (Constant x Number of Threads Per Inch)

The constant value for a 3/8-18 NPT tap is 0.6495.

For example:

Tap Drill Size = 0.375 – (0.6495 x 18) = 0.375 – 11.691 = 0.363″

Therefore, the recommended drill bit size for a 3/8-18 NPT tap is 0.363 inches.

It is important to note that this is just a guideline, and depending on the specific application, you may need to adjust the drill bit size slightly. It is always a good idea to consult a drill chart or tap and drill size calculator for accurate measurements.

Additionally, consider the material you are working with when selecting a drill bit size. Softer materials may require a slightly larger drill bit to accommodate for easier threading, while harder materials may require a smaller drill bit for more precise threading.

Remember to always use a sharp drill bit to ensure clean and accurate holes. Using a dull or worn-out drill bit can cause difficulties during tapping and may result in damaged threads.

By following these drill bit size guidelines, you can ensure a proper fit and successful tapping when using a 3/8-18 NPT tap.

Charts and Tables

Drill Bit Sizes for Tapping NPT Threads

When tapping NPT threads, it is important to use the correct drill bit size to ensure proper thread engagement. The following chart provides the recommended drill bit sizes for tapping various NPT thread sizes:

| NPT Thread Size | Drill Bit Size (inches) |

|---|---|

| 1/8-27 | 0.332 |

| 1/4-18 | 0.438 |

| 3/8-18 | 0.613 |

| 1/2-14 | 0.750 |

| 3/4-14 | 0.969 |

| 1-11.5 | 1.312 |

How to Use the Chart

To determine the correct drill bit size for tapping a specific NPT thread, locate the corresponding NPT thread size in the chart. The recommended drill bit size for that thread size will be listed under the “Drill Bit Size (inches)” column. Use a drill bit with that diameter to prepare the hole for tapping.

Important Considerations

- It is crucial to use the correct drill bit size to ensure proper thread engagement and prevent thread stripping or leakage.

- For best results, it is recommended to use a drill press or a tapping machine to ensure accurate and perpendicular drilling.

- Always use cutting lubricant or tapping oil when tapping NPT threads to reduce friction and extend tool life.

Other Considerations and Tips

1. Lubrication

When tapping into metal, it is important to use a lubricant to reduce friction and heat. This will help prolong the life of both the tap and the drill bit. Apply a generous amount of cutting fluid or oil to the drill bit and tap before beginning the process.

2. Speed and Pressure

Tapping requires a steady hand and a consistent pressure. Use a drill press or a hand drill set to a low speed to ensure precision and control. Apply a steady, even pressure when drilling and tapping to avoid breaking the bit or tap.

3. Pilot Hole

In some cases, it may be necessary to drill a pilot hole before using the tap. This is especially true for harder metals. The pilot hole should be slightly smaller than the diameter of the tap to ensure a proper fit.

4. Backing Material

When using a tap, it is important to have a sturdy backing material to prevent tearing or damage. Use a clamp, vise, or other securing method to hold the workpiece securely in place.

5. Chip Clearing

During the tapping process, chips and debris can accumulate in the hole. Use a brush or compressed air to clear the chips and keep the hole clean. This will help prevent thread damage and ensure a smooth and accurate tap.

6. Safety Precautions

When using power tools, it is important to take safety precautions. Always wear safety goggles to protect your eyes from flying debris. Use gloves to protect your hands and use caution when handling sharp cutting tools.

7. Practice and Patience

Tapping can be a challenging process, especially for beginners. It requires practice and patience to achieve good results. Take your time, start with small holes and work your way up, and don’t be discouraged if it takes a few tries to get it right.

8. Seek Professional Help

If you are unsure about the tapping process or don’t have the necessary equipment, it is always best to seek professional help. A professional machinist or workshop can provide the expertise and tools needed to ensure a successful tapping operation.

By following these considerations and tips, you can increase your chances of successfully tapping a 3/8-18 NPT thread hole and achieve a precise and secure fit for your project.

FAQ:

What size drill bit should I use for a 3/8-18 NPT tap?

The recommended drill bit size for a 3/8-18 NPT tap is 37/64 inch.

Can I use a 9/16 inch drill bit for a 3/8-18 NPT tap?

No, a 9/16 inch drill bit is not the correct size for a 3/8-18 NPT tap. The recommended drill bit size is 37/64 inch.

I don’t have a 37/64 inch drill bit. Can I use a 9.5mm drill bit instead?

Yes, a 9.5mm drill bit is approximately equivalent to a 37/64 inch drill bit, so it can be used as an alternative for a 3/8-18 NPT tap.

What happens if I use a drill bit that is too small for a 3/8-18 NPT tap?

If the drill bit is too small, the tap won’t be able to properly thread the hole, resulting in weak or incomplete threads.

Is it better to use a drill bit that is slightly larger than the recommended size?

No, it is not recommended to use a drill bit that is larger than the recommended size. This can result in oversized holes and loose threads.

What material should the drill bit be made of for tapping a 3/8-18 NPT hole?

It is recommended to use a high-speed steel (HSS) drill bit for tapping a 3/8-18 NPT hole.

Can I use a carbide drill bit for tapping a 3/8-18 NPT hole?

While carbide drill bits are generally more durable, they are not recommended for tapping a 3/8-18 NPT hole as they can be more prone to breakage.

Video: