Choosing the Right Drill Bit Size for a 1/4″ Pipe Tap

When it comes to working with pipes, having the right drill bit size is crucial for ensuring a proper fit and preventing any leaks. One common size of pipe tap that is frequently used is the 1/4″ pipe tap. However, choosing the correct drill bit size for this particular tap can be a bit tricky if you don’t know where to start.

The first thing to consider when choosing a drill bit size for a 1/4″ pipe tap is the material you will be working with. Different materials require different drill bit sizes in order to achieve the proper thread depth. For softer materials such as plastic or aluminum, a smaller drill bit size may be needed. On the other hand, harder materials like stainless steel or cast iron may require a larger drill bit size.

Another important factor to consider is the thread depth you want to achieve. The thread depth refers to how deep the tap will cut into the material. If you want a more secure fit, you may want to choose a drill bit size that allows for a deeper thread depth. However, if you want a looser fit, a smaller drill bit size with a shallower thread depth may be more appropriate.

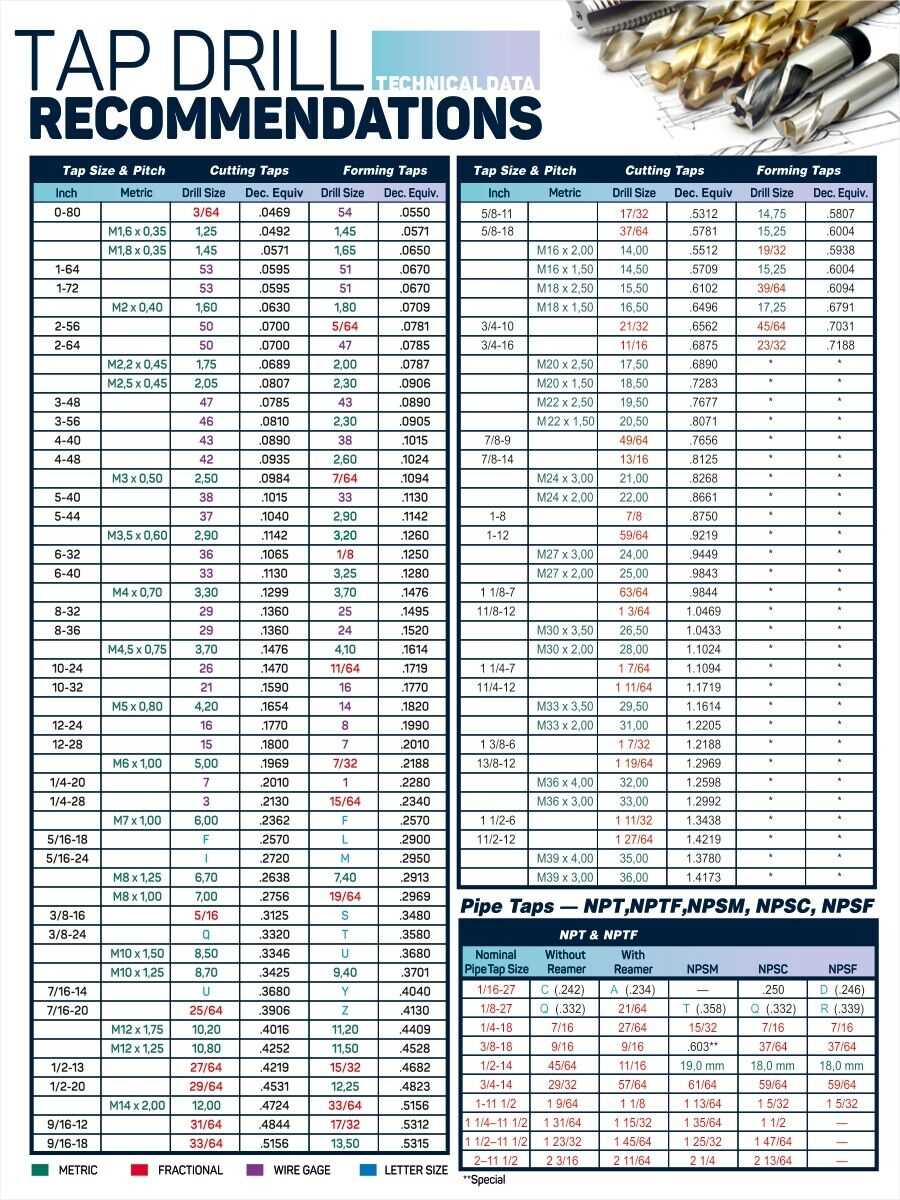

Once you have determined the material and thread depth you need for your 1/4″ pipe tap, you can consult a drill bit size chart to find the exact size you should use. These charts provide recommendations based on the specific tap size and material you are working with, making it easier to find the right drill bit size for your project.

Factors to Consider When Choosing Drill Bit Size for a 1/4″ Pipe Tap

- Tap Size: The first factor to consider when choosing a drill bit size for a 1/4″ pipe tap is the size of the tap itself. In this case, the tap size is already specified as 1/4″.

- Material: The material that you will be drilling the hole into is another important factor. Different materials require different drill bit sizes. For example, drilling into soft wood may require a smaller drill bit size compared to drilling into hard metal.

- Thread Engagement: The desired thread engagement should also be considered. Thread engagement refers to the depth at which the tap will create threads in the hole. A shallower thread engagement may require a smaller drill bit size, while a deeper thread engagement may require a larger drill bit size.

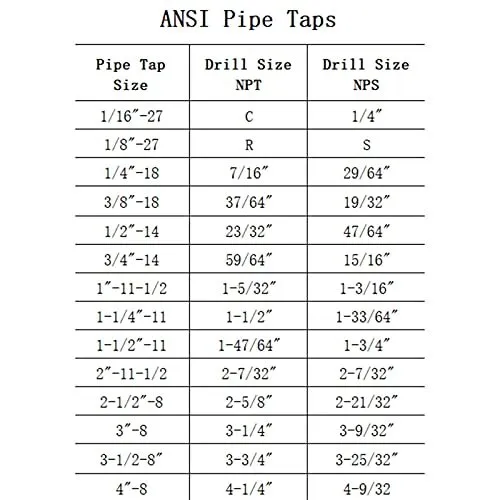

- Tap Type: The type of tap being used can also affect the drill bit size selection. For example, a tapered pipe tap may require a different size drill bit compared to a straight fluted tap.

- Recommended Drill Bit Size: It is important to refer to the manufacturer’s recommendations or industry standards for the recommended drill bit size for a 1/4″ pipe tap. These recommendations are often based on extensive testing and experience.

Considering these factors will help ensure that you choose the correct drill bit size for your 1/4″ pipe tap, resulting in a properly threaded hole.

Pipe Tap Size and Material

When choosing the right drill bit size for a 1/4″ pipe tap, it is important to consider both the tap size and the material you will be working with. The tap size refers to the size of the threads on the tap, while the material refers to the type of metal or other material the tap will be used on.

Tap Size

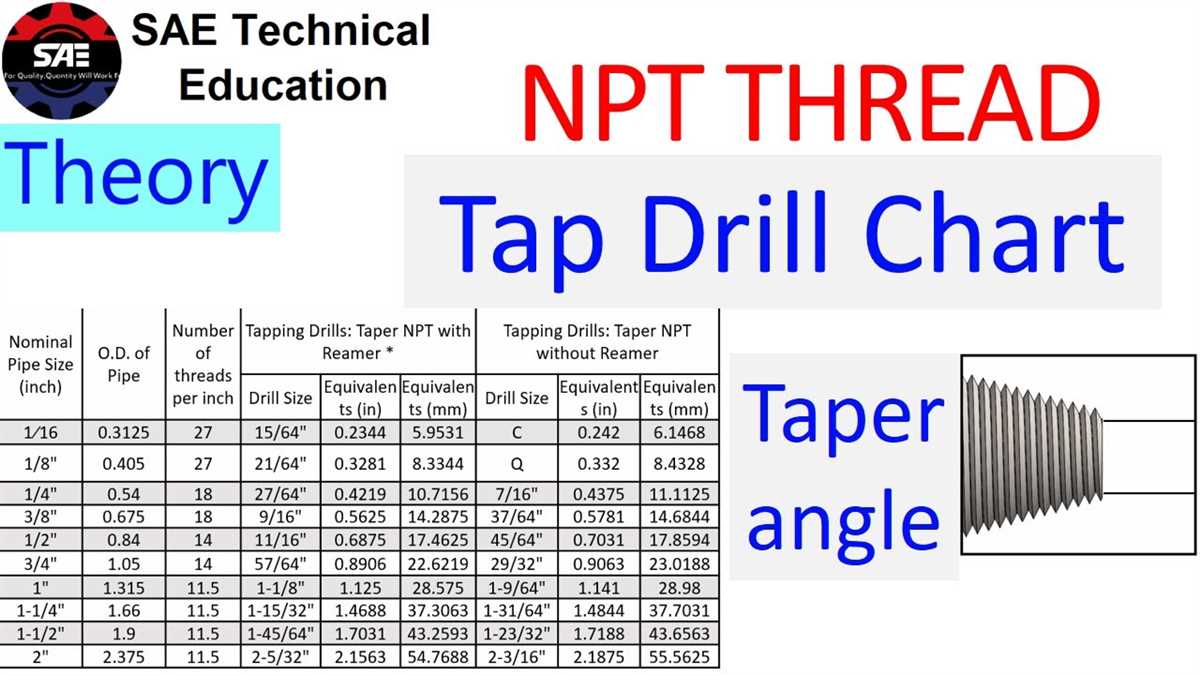

The tap size is denoted by the specific number of threads per inch (TPI) that the tap has. For a 1/4″ pipe tap, the standard tap size is 18 TPI. This means that there are 18 threads per inch on the tap, allowing it to cut threads into the material as it is turned.

Material

The material you are working with will also play a role in determining the right drill bit size for a 1/4″ pipe tap. Different materials have different hardness and characteristics, which can affect how easily the tap can cut threads into the material.

For softer materials such as aluminum or plastic, a smaller drill bit size may be appropriate to ensure that the threads are properly formed. On the other hand, for harder materials such as stainless steel or cast iron, a larger drill bit size may be needed to allow the tap to easily cut through the material.

It is important to consult a drill bit size chart or tap and drill size chart to determine the recommended drill bit size for the specific material you are working with.

Summary

- The tap size for a 1/4″ pipe tap is typically 18 TPI.

- The material you are working with will affect the appropriate drill bit size.

- Softer materials may require a smaller drill bit size, while harder materials may require a larger drill bit size.

- Refer to a drill bit size chart or tap and drill size chart for specific recommendations based on material.

Drill Bit Material and Type

Choosing the right drill bit material and type is essential when drilling holes for a 1/4″ pipe tap. The material and type of the drill bit can affect the drilling process and the quality of the hole. Here are some factors to consider when selecting the drill bit material and type:

Material:

- High-Speed Steel (HSS): HSS drill bits are commonly used for general-purpose drilling. They are durable and can withstand high-speed drilling. HSS drill bits work well with various materials, including metals, plastics, and wood.

- Cobalt: Cobalt drill bits are made from a high-speed steel alloy that includes cobalt. They are more resistant to heat and can handle hard materials like stainless steel and cast iron.

- Carbide: Carbide drill bits are made from a composite material composed of carbide and other metals. They are extremely hard and can drill through tough materials such as concrete, tile, and masonry.

Type:

- Twist Drill Bit: Twist drill bits are the most common type of drill bits. They have a spiral-shaped groove called flutes that allow for efficient chip removal. Twist drill bits come in various sizes and can be used for many drilling applications.

- Step Drill Bit: Step drill bits have a conical shape with multiple steps. They are ideal for drilling holes of different diameters without needing to change the drill bit. Step drill bits are commonly used in metalworking and electrical applications.

- Forstner Drill Bit: Forstner drill bits are used for drilling flat-bottomed holes with smooth sides. They are commonly used for woodworking and can create clean and precise holes.

Summary:

When choosing a drill bit for a 1/4″ pipe tap, consider the material and type that suits your specific drilling needs. HSS drill bits are versatile and suitable for general-purpose drilling, while cobalt drill bits are better for hard materials. Carbide drill bits are ideal for drilling through tough materials like concrete. Twist drill bits are the most common type, but step drill bits and Forstner drill bits offer specialized drilling capabilities.

Recommended Drill Bit Sizes for 1/4″ Pipe Taps

Introduction

When working with 1/4″ pipe taps, it is important to choose the right drill bit size to ensure proper thread engagement and a secure connection. Using the incorrect drill bit size can result in weak threads or a loose fit, compromising the durability and effectiveness of the pipe connection.

Standard Drill Bit Sizes

There are several standard drill bit sizes that are commonly recommended for use with 1/4″ pipe taps. These sizes are based on the specific requirements of the tap and the material being drilled.

The most commonly recommended drill bit sizes for 1/4″ pipe taps are:

- #7 Drill Bit: This drill bit size is recommended for softer materials such as plastics or wood.

- #21 Drill Bit: This drill bit size is recommended for general use with 1/4″ pipe taps in a variety of materials.

- #25 Drill Bit: This drill bit size is recommended for harder materials such as metals or alloys.

Choosing the Right Drill Bit Size

When selecting the drill bit size for your 1/4″ pipe tap, it is important to consider the material you are working with and the specific requirements of the tap. Softer materials may require a smaller drill bit size to prevent thread damage, while harder materials may require a larger drill bit size to ensure proper thread engagement.

Additionally, it is important to use a sharp drill bit and maintain a steady drilling speed to ensure clean and accurate holes. Dull or worn drill bits can cause irregular holes and hinder the tapping process.

Conclusion

Choosing the right drill bit size for your 1/4″ pipe tap is essential for achieving strong, secure pipe connections. By following the recommended drill bit sizes and considering the material and tap requirements, you can ensure proper thread engagement and a successful pipe installation.

Remember to always take proper safety precautions when working with power tools and wear appropriate protective gear.

Considerations for Hole Depth

When choosing the right drill bit size for a 1/4″ pipe tap, it is important to consider the hole depth. The hole depth refers to how deep the hole needs to be drilled in order for the tap to fully thread into the material.

There are a few factors to consider when determining the appropriate hole depth for a 1/4″ pipe tap:

- Material thickness: The thickness of the material being tapped will determine the minimum hole depth required. It is important to ensure that the hole is deep enough to accommodate the tap’s threads without bottoming out.

- Type of material: Different materials may require different hole depths. Some materials, such as soft metals, may require a deeper hole to ensure proper threading, while others may require a shallower hole.

- Thread engagement: The desired thread engagement will also influence the required hole depth. Thread engagement refers to how many threads are engaged between the tap and the material. A deeper hole will allow for a longer thread engagement, which can provide greater strength and stability.

It is recommended to consult a tap drill chart or a tap and drill size guide to determine the appropriate hole depth for a 1/4″ pipe tap based on the specific material and application requirements. These resources will provide the recommended drill bit size and corresponding hole depth for various tap sizes and materials.

Ensuring the proper hole depth is essential for achieving a secure and reliable threaded connection when using a 1/4″ pipe tap. Taking into consideration material thickness, type of material, and desired thread engagement will help determine the appropriate hole depth and drill bit size for a successful tapping process.

Importance of Pilot Hole

A pilot hole is a small-diameter hole drilled before inserting a larger drill bit into a material. It serves several important purposes and can greatly improve the efficiency and accuracy of the drilling process.

1. Ensures Proper Alignment

Using a pilot hole helps ensure that the larger drill bit is properly aligned and centered on the desired drilling location. This is especially important when drilling into hard or dense materials where it can be difficult to start a hole without wandering off course.

2. Reduces Chances of Cracking or Splitting

Drilling a pilot hole helps prevent the material from cracking or splitting when the larger drill bit is inserted. By creating a small hole first, the pressure exerted by the larger drill bit is distributed more evenly, reducing the likelihood of damage to the material.

3. Improves Control and Precision

A pilot hole provides better control over the drilling process, allowing for greater precision. It helps guide the larger drill bit and prevents it from wandering or slipping, ensuring that the hole is drilled at the desired location and depth.

4. Reduces Friction and Heat

When drilling into certain materials, such as metal or hardwood, friction and heat can build up, causing the drill bit to overheat and dull more quickly. By first drilling a pilot hole, the larger drill bit encounters less resistance, reducing friction and heat buildup.

5. Minimizes Risk of Breakage

Using a pilot hole reduces the risk of breakage, especially when drilling into brittle materials like glass or ceramics. The pilot hole helps relieve pressure on the material, making it less likely to crack or shatter under the force of the larger drill bit.

6. Enhances Efficiency

In addition to the above benefits, using a pilot hole can also improve the overall efficiency of the drilling process. By preparing the material with a smaller hole first, it becomes easier and quicker to drill the larger hole with the desired drill bit.

In conclusion, using a pilot hole is essential when drilling holes with a larger drill bit. It ensures proper alignment, reduces the risk of cracking or splitting, improves control and precision, reduces friction and heat, minimizes the risk of breakage, and enhances efficiency.

Factors Affecting Tap Drill Bit Size

The size of the drill bit required for tapping a 1/4″ pipe is determined by several factors. These factors include the type of material being drilled, the size of the tap, and the requirements of the specific application. Understanding these factors can help ensure that the correct drill bit size is chosen for the job.

Type of Material

The type of material being drilled plays a significant role in determining the drill bit size for tapping a 1/4″ pipe. Different materials have different hardness levels, which affects the amount of force required to penetrate the material. Softer materials such as wood or plastic may require smaller drill bit sizes, while harder materials such as metal may require larger sizes.

Tap Size

The tap size refers to the dimensions of the threading tool being used. The size of the tap determines the size of the hole that needs to be drilled before tapping can begin. In the case of a 1/4″ pipe tap, the tap size is already specified. Therefore, the drill bit size needs to match the tap size to ensure proper threading.

Application Requirements

The specific requirements of the application also play a role in determining the drill bit size for tapping a 1/4″ pipe. Certain applications may require a tighter fit or stronger threading, which may necessitate a larger drill bit size. Understanding the specific requirements of the application can help in choosing the appropriate drill bit size.

Consulting Reference Guides

When in doubt, it is always beneficial to consult reference guides or drill size charts to determine the appropriate drill bit size for tapping a 1/4″ pipe. These guides provide recommended drill bit sizes based on the specific tap and material being used. They can serve as a valuable resource to ensure that the correct drill bit size is chosen for the job.

Conclusion

Choosing the right drill bit size for tapping a 1/4″ pipe involves considering factors such as the type of material, tap size, and application requirements. By taking these factors into account and consulting reference guides, one can ensure that the correct drill bit size is selected, resulting in properly threaded holes.

Calculating the Correct Drill Bit Size

Choosing the correct drill bit size is crucial when tapping a hole for a 1/4″ pipe tap. The drill bit size determines the diameter of the hole, which in turn affects the effectiveness of the pipe tap and ensures proper thread engagement.

Tip: It is always recommended to refer to the pipe tap manufacturer’s specifications and guidelines for the appropriate drill bit size.

Step 1: Determine the Tap’s Size

The first step in calculating the correct drill bit size is to determine the size of the pipe tap. In this case, we are using a 1/4″ pipe tap.

Step 2: Identify the Thread Size

The next step is to identify the thread size. In the case of a 1/4″ pipe tap, the thread size is 1/4″-18. The “1/4” refers to the nominal size of the pipe, and the “18” indicates the number of threads per inch.

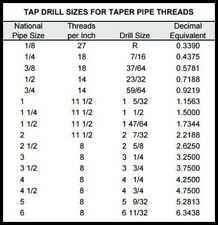

Step 3: Use a Tap Drill Chart

Tap drill charts are valuable tools for determining the correct drill bit size based on the thread size. These charts provide the corresponding drill bit size for each thread size. Refer to a tap drill chart specific to pipe threads to find the appropriate drill bit size for a 1/4″-18 thread size.

Note: Although the tap drill chart provides a general guideline, it is important to consider factors such as the material being tapped, desired thread engagement, and specific requirements of the application. Always refer to the manufacturer’s specifications when available.

Step 4: Check for Clearance

After selecting the drill bit size based on the tap drill chart, it is important to check for clearance. The hole should be slightly larger than the tap’s outside diameter to ensure easy insertion and proper threading. Additionally, the diameter of the hole should provide enough space for chips and debris to clear during the tapping process.

Tip: Using a center punch to create a starting point on the drilling surface can help prevent the drill bit from wandering or slipping during the initial drilling.

When tapping a hole for a 1/4″ pipe tap, calculating the correct drill bit size is essential for achieving secure and functional thread engagement. By following these steps and referring to the appropriate resources, you can ensure that the hole is drilled to the correct diameter for successful tapping.

Common Mistakes to Avoid

- Using the wrong drill bit size: One of the most common mistakes when tapping threads is using the wrong drill bit size. It is important to choose the correct drill bit size that matches the tap size specified for the 1/4″ pipe tap. Using the wrong size can result in a poor fit and weak threads.

- Not using a center punch: Failure to use a center punch before drilling can lead to misalignment and off-center holes. A center punch creates a small indentation in the material, providing a guide for the drill bit to start in the correct position.

- Not using cutting oil: When drilling into metal, it is essential to use cutting oil to lubricate the drill bit. This helps to reduce friction and heat buildup, allowing the drill bit to cut through the material more smoothly. Failing to use cutting oil can cause excessive heat, resulting in a dull drill bit and poor thread formation.

- Incorrect drilling speed: Drilling too fast or too slow can both lead to problems. Drilling too fast can cause the drill bit to overheat and lose its cutting ability. On the other hand, drilling too slow can cause the drill bit to wear out quickly and produce rough holes. It is important to use the correct drilling speed specified for the material being drilled.

- Not clearing chips: During the drilling process, chips and debris can accumulate in the hole. Failing to clear these chips can cause the drill bit to bind and break. It is important to periodically remove the chips by withdrawing the drill bit and clearing the hole.

- Not using proper safety precautions: When using a drill, it is crucial to wear safety goggles to protect your eyes from flying debris. Additionally, secure the workpiece securely in a vice or clamp to prevent it from moving during drilling.

FAQ:

What is a 1/4″ pipe tap?

A 1/4″ pipe tap is a type of tap used for creating threads in pipes or fittings that have a 1/4″ outer diameter.

Why is choosing the right drill bit size important?

Choosing the right drill bit size is important because it determines the size and fit of the hole that will be drilled for the pipe tap. Using the wrong size drill bit can result in a hole that is too small or too large for the tap, leading to problems with thread engagement and the overall strength and integrity of the connection.

How do I determine the right drill bit size for a 1/4″ pipe tap?

To determine the right drill bit size for a 1/4″ pipe tap, you need to consult a tap drill size chart. This chart will provide you with the recommended drill bit size based on the type of material you are drilling and the type of tap you are using. The chart will typically list the tap size, the thread pitch, and the corresponding drill bit size.

What happens if I use a drill bit size that is too small for a 1/4″ pipe tap?

If you use a drill bit size that is too small for a 1/4″ pipe tap, the hole you drill will not be large enough for the tap to fit properly. This can result in difficulty threading the tap and could potentially damage the tap or the material being drilled. It may also lead to weak threads that are prone to stripping or breaking under pressure.

Can I use a slightly larger drill bit size for a 1/4″ pipe tap?

While it is generally recommended to use the recommended drill bit size for a 1/4″ pipe tap, it is possible to use a slightly larger drill bit size. However, you need to be cautious, as using a significantly larger drill bit can result in a hole that is too large for the tap, leading to weak threads and potential leaks or failures in the connection.

What type of drill bit should I use for a 1/4″ pipe tap?

For drilling holes for a 1/4″ pipe tap, it is recommended to use a high-speed steel (HSS) drill bit. HSS drill bits are designed for drilling into metal and are capable of providing clean, accurate holes. They are also durable and can withstand the heat generated during the drilling process.

Can I use a different type of tap with a 1/4″ pipe tap drill bit?

Yes, you can use a different type of tap with a 1/4″ pipe tap drill bit, as long as the tap is compatible with the size and type of hole created by the drill bit. However, it is important to ensure that the tap and drill bit are properly matched in size and thread pitch to ensure a secure and reliable connection.

Video: