Choosing the Right Drill Bit Size for a 1/2 Inch Hole

When it comes to drilling holes, one of the most important factors to consider is the size of the drill bit. The right drill bit size ensures that you can create a hole of the correct diameter without causing any damage to the material or compromising the integrity of the hole. In this article, we will focus on choosing the right drill bit size for a 1/2 inch hole.

Firstly, it’s important to note that the size of the drill bit you will need for a 1/2 inch hole will depend on the type of material you are drilling into. For softer materials such as wood or plastic, a slightly smaller drill bit size may be sufficient to create a clean hole. On the other hand, for harder materials like metal or concrete, a slightly larger drill bit size may be required to ensure a proper hole.

Additionally, the depth of the hole you need to drill will also impact the drill bit size. If you only need to drill a shallow hole, a standard drill bit size may be suitable. However, if you require a deeper hole, you may need to select a longer drill bit, which will also affect the overall diameter of the hole.

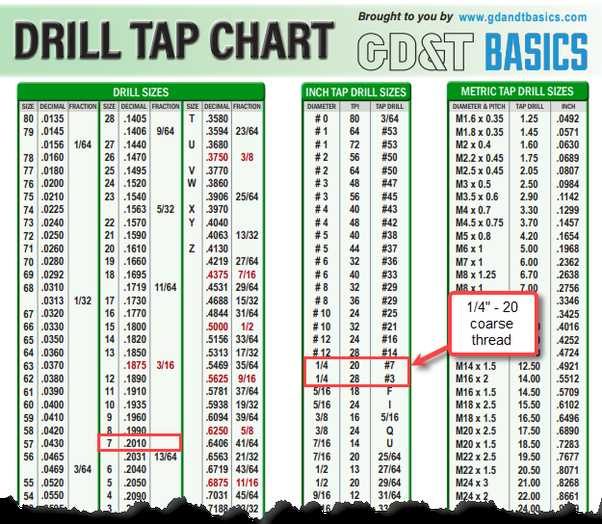

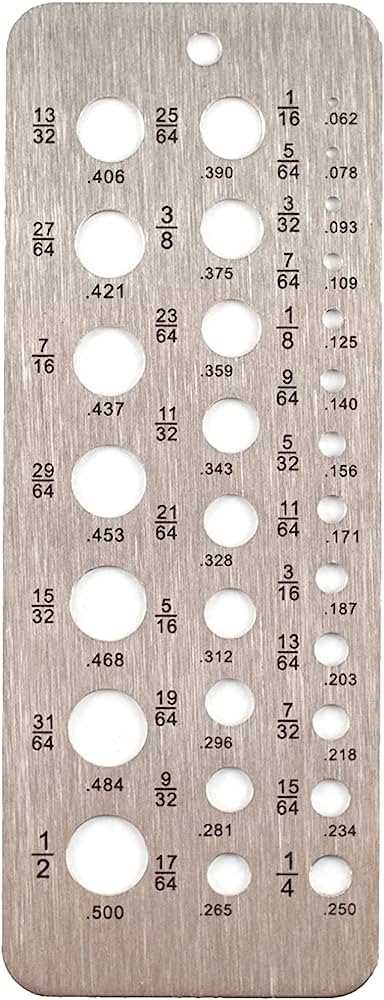

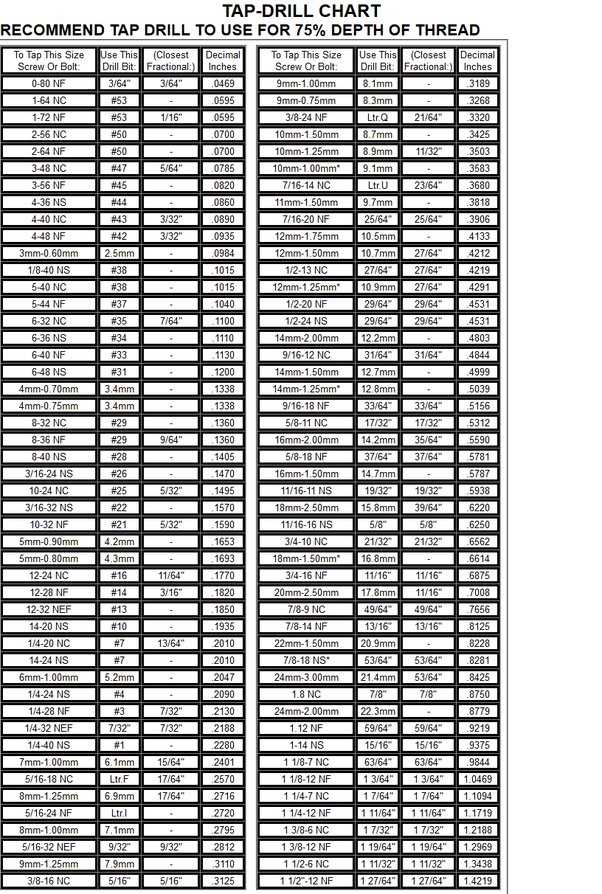

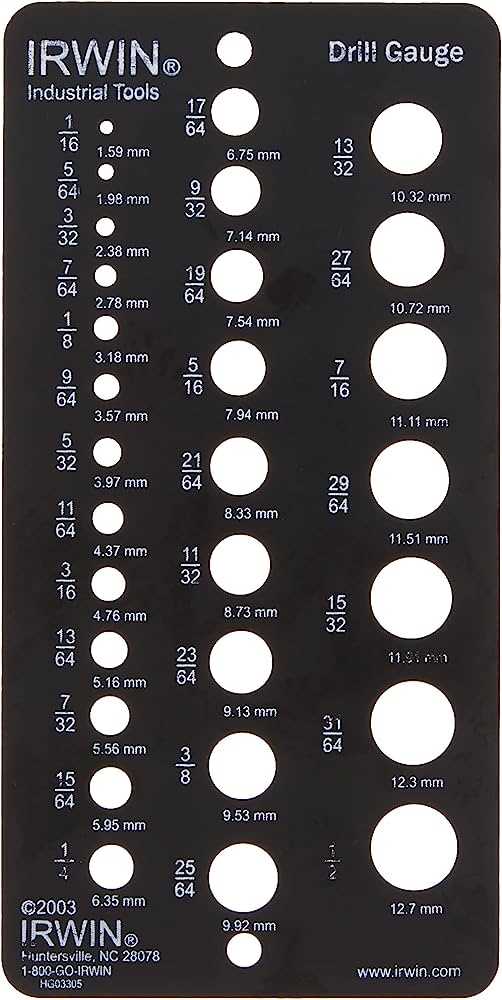

In summary, when choosing the right drill bit size for a 1/2 inch hole, you need to consider the type of material you are drilling into, the depth of the hole, and any specific requirements of your project. It’s always a good idea to consult a drill bit size chart or consult a professional if you’re unsure which size to choose. By selecting the correct drill bit size, you can ensure accurate and efficient drilling for your 1/2 inch hole.

Overview

When it comes to drilling a 1/2 inch hole, choosing the right drill bit size is crucial. The drill bit size determines the diameter of the hole, and using the wrong size can result in an improperly sized hole or a damaged drill bit.

In this article, we will cover the different types of drill bits available for drilling a 1/2 inch hole, as well as the factors to consider when selecting the right drill bit size.

We will also provide a step-by-step guide on how to choose the right drill bit size for a 1/2 inch hole, ensuring that you can complete your drilling project with precision and efficiency.

Factors to Consider

When choosing the right drill bit size for a 1/2 inch hole, there are several factors to consider. These factors will determine the size and type of drill bit that is most suitable for your needs. Here are some important aspects to keep in mind:

- Material: The type of material you are drilling into plays a significant role in selecting the appropriate drill bit size. Different materials require different drill bit types and sizes. For example, drilling into wood will require a different bit size compared to drilling into metal or concrete.

- Drill Type: The type of drill you are using will also impact the drill bit size you need. Certain drills are designed for specific tasks and may require specialized bits. Make sure to use a drill that is compatible with the bit you plan to use.

- Depth: The depth of the hole you need to drill is another important consideration. If you only need to drill a shallow hole, you may not need a long drill bit. On the other hand, for deeper holes, you will need a longer bit to reach the desired depth.

- Accuracy: If you require precise drilling, such as for creating holes for dowels or screws, you may need to select a drill bit size that matches the diameter of the dowel or screw. This will ensure a snug fit and reduce the risk of the dowel or screw becoming loose over time.

- Drilling Speed: The speed at which you plan to drill can also impact the size of the drill bit you use. Higher drilling speeds may require larger bits to effectively remove debris and prevent overheating.

- Desired Finish: The finish you desire for your hole is another factor to consider. If you want a smooth, clean hole, you may need to use a drill bit size that matches the desired hole size accurately. This will help prevent chipping or damage to the surrounding material.

By taking these factors into account, you can choose the right drill bit size for a 1/2 inch hole that meets your specific requirements.

Determining the Correct Size

When choosing the right drill bit size for a 1/2 inch hole, there are several factors to consider. These factors include the material you are drilling into, the type of drill you are using, and the specific project or application you are working on.

Material

The first step in determining the correct size is to consider the material you are drilling into. Different materials require different drill bit sizes to achieve the desired hole size. For example, drilling into wood may require a different size drill bit than drilling into metal or concrete. It is important to research the specific material you are working with and determine the appropriate drill bit size accordingly.

Drill Type

The type of drill you are using also plays a role in determining the correct size. Some drills are designed for specific drill bit sizes, while others are more versatile and can accommodate a range of sizes. It is important to consult the instruction manual or specifications of your drill to determine its capabilities and limitations in terms of drill bit sizes.

Project or Application

The specific project or application you are working on will also affect the drill bit size you should choose. For example, if you are drilling holes for screws, you will need to select a drill bit size that matches the diameter of the screws you are using. Similarly, if you are drilling holes for plumbing pipes, you will need to select a drill bit size that matches the diameter of the pipes.

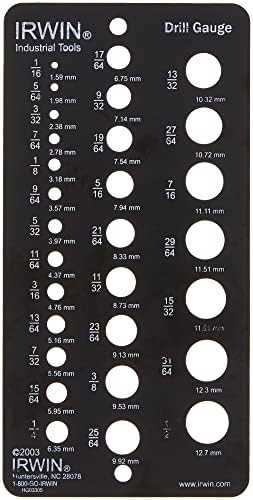

It is always a good idea to consult a drill bit size chart or guide to help you determine the correct size for your specific project or application. These resources provide a reference for matching drill bit sizes to hole sizes and can help ensure you achieve the desired result.

Conclusion

Choosing the right drill bit size for a 1/2 inch hole requires careful consideration of the material, drill type, and project or application. By taking these factors into account and consulting a drill bit size chart or guide, you can ensure that you select the correct size for your specific needs and achieve accurate and precise holes.

Common Drill Bit Sizes

When it comes to choosing the right drill bit size for your project, it’s important to consider the common sizes that are available. Having a variety of drill bit sizes on hand will allow you to tackle a wider range of tasks efficiently and effectively. Here are some of the most commonly used drill bit sizes:

1. 1/16 inch (1.6mm)

This small drill bit size is great for pilot holes and delicate tasks. It’s often used for drilling into soft materials such as wood or plastic.

2. 1/8 inch (3.2mm)

This size is commonly used for general drilling tasks. It’s suitable for drilling into various materials including wood, plastic, and soft metals.

3. 3/16 inch (4.8mm)

A 3/16 inch drill bit is often used for drilling holes in wood and metal. It provides a good balance between strength and precision.

4. 1/4 inch (6.4mm)

Known as a standard size, a 1/4 inch drill bit is widely used in woodworking and metalworking projects. It’s suitable for drilling into thicker materials with ease.

5. 3/8 inch (9.5mm)

A 3/8 inch drill bit is commonly used for larger holes in wood and metal. It’s ideal for installing hardware or creating larger openings.

6. 1/2 inch (12.7mm)

For even bigger holes, a 1/2 inch drill bit is the way to go. It’s typically used for tasks that require larger openings, such as plumbing or electrical work.

These are just a few of the common drill bit sizes that you may encounter. However, it’s important to remember that specific projects may require different sizes or specialty drill bits. Always refer to the instructions or consult with a professional if you’re unsure about the appropriate size for your specific task.

Drilling Techniques

1. Marking the Hole

Before drilling a hole, it is essential to mark the exact spot where the hole needs to be made. This can be done by using a pencil or a marker to create a small dot or an X on the surface. This will serve as a guide for the drilling process.

2. Selecting the Right Drill Bit

Choosing the correct drill bit is crucial to achieving a precise and clean hole. Consider the material you are drilling into and select a drill bit that is suitable for that specific material. Different drill bits are designed to drill into different materials such as wood, metal, or concrete.

3. Securing the Workpiece

Before drilling, it is important to secure the workpiece properly to prevent any movement during the drilling process. This can be done using clamps or a vice, ensuring that the workpiece is tightly held in place.

4. Drilling at the Right Speed

The speed at which you drill can affect the quality of the hole. For smaller holes, it is recommended to drill at a higher speed, while for larger holes, a slower speed is preferable. Adjust the drilling speed on the drill accordingly to achieve the best results.

5. Using Proper Technique

When drilling, it is important to maintain a steady hand and apply consistent pressure. Avoid excessive force, as it may lead to the drill bit getting stuck or breaking. Additionally, periodically withdrawing the drill bit while drilling can help clear away debris and prevent overheating.

6. Cooling the Drill Bit

For longer drilling sessions or when working with tougher materials, it is recommended to cool the drill bit periodically to prevent overheating. This can be done by dipping the drill bit in coolant or water and allowing it to cool down before resuming drilling.

7. Cleaning the Hole

After drilling the hole, it is important to clean out any debris or dust that may have accumulated. This can be done using a brush or compressed air. A clean hole will ensure a better fit for any screws or anchors that need to be inserted.

8. Safety Precautions

Always wear protective eyewear and gloves when drilling to protect yourself from flying debris. Additionally, secure loose clothing and remove any jewelry that may pose a safety hazard during the drilling process. It is also important to understand and follow the safety guidelines provided by the drill manufacturer.

By following these drilling techniques, you can ensure accurate and clean holes for your specific project needs.

Matching the Bit to the Material

When choosing the right drill bit size for a 1/2 inch hole, it is important to consider the type of material you are working with. Different materials require different drill bits in order to achieve the best results.

Wood

- For drilling holes in wood, a standard twist bit is typically the best choice. These bits have a pointed tip and spiraling flutes that help to remove material as they drill.

- If you are drilling into hardwood or dense woods, a brad point bit may be a better option. These bits have a center point and sharp edges that help to create clean holes with minimal splintering.

Metal

- When drilling holes in metal, a cobalt or high-speed steel (HSS) bit is recommended. These bits are specifically designed to withstand the high temperatures generated when drilling into metal.

- If you are drilling into stainless steel or other hard metals, a carbide tip bit is the best choice. These bits have a carbide tip that is extremely hard and can easily cut through tough metals.

Concrete

- For drilling holes in concrete, a masonry bit is required. These bits have a carbide tip that is designed to handle the hardness of concrete and other masonry materials.

- If you are drilling into reinforced concrete or other extremely dense materials, a diamond-tipped bit is recommended. These bits have diamond particles embedded in the tip, making them extremely durable and capable of drilling through the toughest materials.

Plastic

- When drilling holes in plastic, a standard twist bit or a spade bit can be used. It is important to use a slow speed and light pressure to avoid melting or warping the plastic.

Glass

- Drilling holes in glass requires a special glass bit or diamond bit. These bits have a specialized design that helps to prevent cracking and chipping.

- It is important to use a lubricant, such as water or oil, while drilling glass to keep the bit cool and prevent the glass from shattering.

By matching the right drill bit to the material you are working with, you can ensure clean and precise holes that are perfect for your project.

Using a Drill Press

A drill press is a powerful tool that allows for precise drilling and boring of holes. It consists of a motorized drill head mounted on a column, with a table that can be adjusted for height and angle. The drill press also has a chuck to hold drill bits of different sizes.

1. Preparation

Before using a drill press, it is important to wear safety glasses or goggles to protect your eyes from flying debris. Additionally, make sure to secure the workpiece firmly in place using clamps or a vise to prevent it from moving during drilling.

2. Adjusting the Table

Start by adjusting the height of the drill press table to ensure proper alignment. The table should be positioned so that the tip of the drill bit is just above the surface of the workpiece when it is fully extended.

Then, adjust the angle of the table if needed, depending on the desired hole orientation. The table can typically be tilted up to a certain degree both to the left and right.

3. Selecting and Installing the Drill Bit

Choose the appropriate drill bit for the size and type of hole you need to create. Make sure the drill bit is compatible with the drill press chuck and firmly insert it into the chuck.

4. Setting the Speed and Depth

Most drill presses have adjustable speed settings. Consult the manufacturer’s guidelines or the drill bit manufacturer’s specifications to determine the appropriate speed for the material you are drilling into.

Next, set the desired depth of the hole using the depth stop. This will prevent the drill bit from going too deep and damaging the workpiece.

5. Drilling

Turn on the drill press and lower the drill bit onto the workpiece using the feed handle. Apply consistent and steady pressure as you feed the bit into the material. Avoid forcing the drill bit, as this can cause it to break or overheat.

Once the hole is complete, release the feed handle and wait for the drill bit to stop spinning before lifting it out of the hole. Clean any debris from the drill press and work area before proceeding to the next hole.

6. Safety Considerations

Always follow the manufacturer’s instructions and safety guidelines when using a drill press. Keep your hands and loose clothing away from moving parts, and never attempt to adjust or change the drill bit while the machine is still running.

Remember to disconnect the power source before making any adjustments or changing drill bits. Ensure a stable and clutter-free work area to prevent accidents and maintain a safe working environment.

Conclusion: Using a drill press can help you achieve accurate and professional-looking holes in your workpieces. By following these steps and taking proper safety precautions, you can make the most of this versatile tool.

FAQ:

What drill bit size should I use for a 1/2 inch hole in wood?

To drill a 1/2 inch hole in wood, you should use a 1/2 inch drill bit. Make sure to choose a bit designed for wood drilling.

Can I use a different drill bit size to make a 1/2 inch hole in metal?

No, if you want to make a 1/2 inch hole in metal, you should use a 1/2 inch drill bit specifically designed for metal drilling. Using a different size bit may result in an improper hole.

What other types of drill bits can be used for a 1/2 inch hole in different materials?

For drilling a 1/2 inch hole in different materials, you can use various types of drill bits such as twist bits, spade bits, hole saws, or step drill bits. The choice depends on the material you are drilling into and the specific application.

Is it possible to use a drill bit smaller than 1/2 inch to make a 1/2 inch hole?

No, if you want to make a 1/2 inch hole, you should use a 1/2 inch drill bit or a bit specifically designed for that size hole. Using a smaller size bit will result in a smaller hole.

What should I consider when choosing a drill bit for a 1/2 inch hole?

When choosing a drill bit for a 1/2 inch hole, you should consider the material you are drilling into, the type of drill you are using, and the desired hole quality. It’s also important to use the correct bit type for the material, such as a wood bit for wood or a metal bit for metal.

Video: