Choosing the Right Drill Bit Size for 10 Machine Screw

When it comes to drilling holes for machine screws, selecting the right drill bit size is crucial. Using the wrong size can lead to stripped threads, loose connections, or even damage to the material you are working on. In the case of #10 machine screws, it is important to understand the appropriate drill bit size to ensure a secure and successful installation.

The #10 machine screw is a common size used in a variety of applications, such as woodworking, metalworking, and general construction. To determine the right drill bit size for this particular screw, you need to consider its thread pitch and diameter. The #10 machine screw typically has a diameter of 0.190 inches and a thread pitch of 24 threads per inch.

Based on these specifications, a suitable drill bit size for a #10 machine screw would be around 0.1935 inches or 4.92 millimeters in diameter. This size will create a hole slightly larger than the screw’s diameter, allowing for easy insertion and a snug fit without compromising the structural integrity of the material.

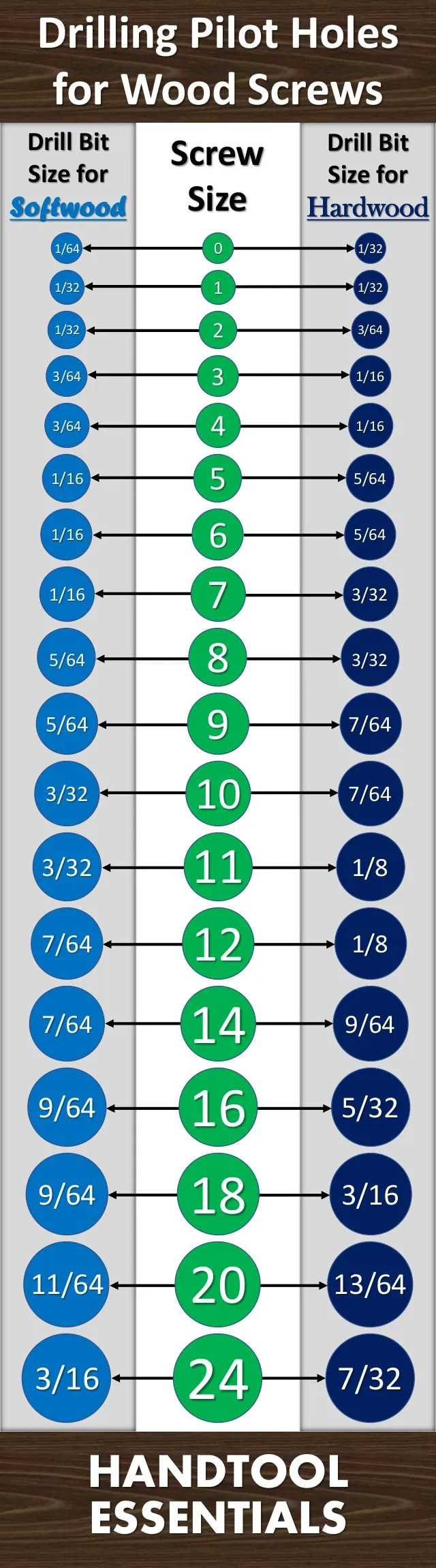

It is important to note that the recommended drill bit size can vary depending on the specific material you are working with. For softer materials, such as wood or plastic, a slightly smaller drill bit size may be suitable to ensure a tighter fit. On the other hand, harder materials like metal may require a slightly larger drill bit size to accommodate for the increased resistance.

Always remember to test the fit of the drill bit by trying to insert the screw into the hole before proceeding with the installation. If the screw can easily slide in without resistance, the hole may be too big and you may need to use a slightly larger drill bit size. Conversely, if the screw doesn’t fit or requires a lot of force to insert, the hole may be too small and you may need to use a slightly smaller drill bit size.

Choosing the right drill bit size for a #10 machine screw is essential for a secure and successful installation. By considering the screw’s specifications and the material you are working on, you can ensure a proper fit and avoid any potential issues down the line.

Why drill bit size is important

When it comes to drilling holes, using the right drill bit size is crucial for several reasons. Whether you are a professional or a DIY enthusiast, understanding the importance of drill bit size can greatly improve your drilling accuracy and efficiency.

1. Accuracy

- Choosing the correct drill bit size ensures that the hole you drill matches the size requirements of the fastener or component you are working with. A hole that is too small will not accommodate the fastener, while a hole that is too large will result in a loose and unreliable connection.

- Using the appropriate drill bit size also helps prevent damage to the surrounding material. If the drill bit is too big, it may cause the material to crack or break, compromising the integrity of your project.

2. Efficiency

- Using the right drill bit size allows for faster and more efficient drilling. A properly sized drill bit can cut through the material more easily and with less effort, saving you time and energy.

- Drilling with the correct bit size also reduces the likelihood of the bit getting stuck or jammed in the material. This can help prevent unnecessary delays and frustrations during your drilling process.

3. Safety

- Using the wrong drill bit size can be dangerous. If the bit is too small, it may cause the drill to become unstable and slip, potentially causing injury. On the other hand, a bit that is too large can put excessive strain on the drill, leading to overheating or even breakage.

- Using the correct drill bit size ensures that the drilling process is smoother and safer, minimizing the risk of accidents or damage to yourself and your equipment.

Overall, understanding and using the proper drill bit size is essential for achieving accurate, efficient, and safe drilling results. It is always recommended to consult the manufacturer’s guidelines or seek professional advice to ensure you are using the correct drill bit size for your specific project.

Factors to consider when choosing a drill bit size

Choosing the right drill bit size is crucial to ensure proper installation and functionality of machine screws. Here are some factors to consider when selecting the drill bit size:

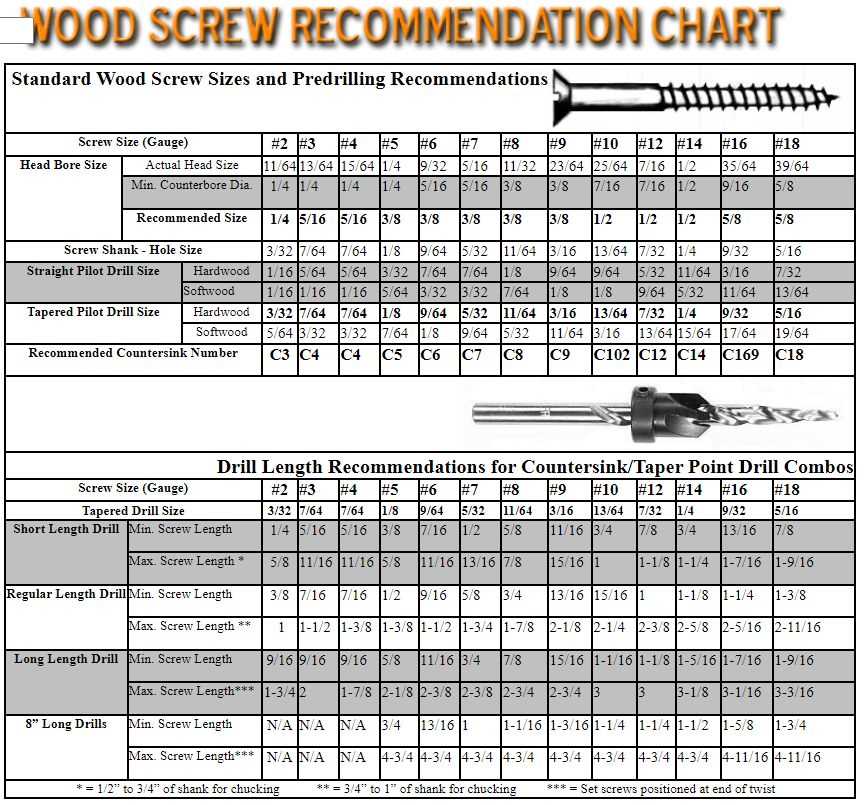

- Screw size: The first and most important factor is the size of the machine screw you will be using. Different screw sizes require different drill bit sizes to create the proper hole for the screw to fit into. It is important to refer to the screw manufacturer’s guidelines or consult a drill bit size chart to determine the correct size.

- Material: The material you will be drilling into also plays a role in choosing the drill bit size. Harder materials like metal may require a larger drill bit size to create a hole that is large enough for the screw to fit into securely. Softer materials like wood may require a smaller drill bit size to prevent the hole from being too wide and compromising the integrity of the material.

- Depth: Consider the depth of the hole you need to drill. If you are drilling a through-hole, where the screw will pass completely through the material, you may need a longer drill bit to accommodate the depth. On the other hand, if you are drilling a pilot hole, where the screw will only go partially into the material, a shorter drill bit may be sufficient.

- Accuracy: The accuracy of the hole you drill is important for the proper alignment and stability of the screw. If you want to ensure a precise and snug fit, you may need to choose a drill bit size that is slightly smaller than the screw’s diameter. This will allow for a tighter grip and reduce the risk of the screw becoming loose over time.

Before drilling any holes, it is always recommended to test the chosen drill bit size on a small piece of scrap material to ensure that it is the correct size and provides the desired results. Remember to use proper safety precautions while drilling and always follow the manufacturer’s guidelines for the specific drill bit you are using.

Understanding Machine Screw Sizes

When it comes to choosing the right drill bit size for a 10 machine screw, understanding machine screw sizes is crucial. Machine screws come in various sizes, and it’s essential to know how they are measured to ensure a proper fit.

Machine Screw Size Measurement

Machine screws are measured using two primary dimensions: diameter and length. The diameter is measured across the outside of the threads, while the length is measured from the underside of the head to the tip of the screw.

Machine screw sizes are denoted by either a number or a letter. Numbered sizes are commonly used for smaller screws, while letter sizes are often used for larger screws. The higher the number or letter, the larger the screw.

Screw Threads and Pitch

Machine screws have threads that allow them to be tightened into a tapped hole or nut. The thread size is determined by the number of threads per inch or pitch. Common thread sizes include coarse threads (UNC) and fine threads (UNF).

UNC threads are used for general-purpose applications and have a higher pitch. They are identified by a number, such as 10-24, which means it is a number 10 screw with 24 threads per inch. On the other hand, UNF threads have a finer pitch and are used for applications requiring greater strength and precision.

Drill Bit Size for 10 Machine Screw

To determine the right drill bit size for a 10 machine screw, you need to match the screw diameter. A number 10 machine screw has a diameter of approximately 0.190 inches or 4.8 millimeters.

The recommended drill bit size for a 10 machine screw is a #12 drill bit, which has a diameter of 0.189 inches or 4.8 millimeters. This size will ensure a proper fit and allow the screw to tighten securely.

Conclusion

Understanding machine screw sizes is essential when choosing the right drill bit size. By knowing how machine screws are measured and the different thread sizes available, you can ensure a proper fit and effectively complete your projects.

Remember to always consult the screw manufacturer’s recommendations to confirm the correct drill bit size for your specific machine screw.

What are machine screws

Machine screws are types of screws that are designed to be used with tapped holes or nuts in machinery or equipment. They are typically made of metal and have a cylindrical shaft with a threaded end. Machine screws are often used in applications where a secure and reliable fastening is essential, such as in the assembly of electronic devices, appliances, automotive components, and industrial machinery.

Features of machine screws

- Threaded shaft: Machine screws have a fully threaded shaft, which means that the entire length of the screw has a uniform threaded pattern. This allows them to securely fasten two or more objects together.

- Head types: Machine screws can have different types of heads, such as flat head, round head, oval head, or pan head. The choice of head type depends on the specific application and the desired aesthetics.

- Standard sizes: Machine screws are available in a wide range of sizes, typically measured by their thread diameter and length. Standard sizes are specified using various systems, including the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO).

- Materials: Machine screws can be made from various materials, including steel, stainless steel, brass, and nylon. The choice of material depends on factors such as the application requirements, environment, and desired level of corrosion resistance.

Uses of machine screws

Machine screws are commonly used in a variety of industries and applications, including:

- Electronics: Machine screws are used to secure components in electronic devices, such as computers, smartphones, and televisions.

- Appliances: They are used in the assembly of appliances, such as refrigerators, washing machines, and ovens.

- Automotive: Machine screws are used in the manufacturing and repair of automotive components, including engines, transmissions, and chassis.

- Industrial machinery: They are used in the assembly of industrial machinery and equipment, such as conveyor systems, pumps, and motors.

Conclusion

Machine screws are versatile fasteners that play a crucial role in various applications where secure and reliable fastening is required. They are available in a wide range of sizes, materials, and head types, allowing for flexibility in design and application. Understanding the features and uses of machine screws can help in choosing the right fastener for specific projects and ensure proper assembly and functionality.

How machine screw sizes are determined

A machine screw is a type of fastener that is typically used to secure two or more parts together. Machine screw sizes are determined based on a number of factors, including the diameter of the screw, the length of the screw, and the thread size.

The diameter of a machine screw is measured across the widest part of the screw’s threads. This measurement is typically expressed in fractions of an inch or in millimeters. Common machine screw diameters range from #2 to #14 in the United States, and from M1 to M12 in metric sizes.

The length of a machine screw is measured from the top of the head to the end of the screw. This measurement is typically expressed in inches or millimeters. Common machine screw lengths range from 1/8″ to 3″ in the United States, and from 3mm to 100mm in metric sizes.

The thread size of a machine screw refers to the number of threads per inch or millimeter. Common thread sizes for machine screws include coarse thread (UNC/UNF) and fine thread (UNEF). Coarse thread machine screws are typically used for general applications, while fine thread machine screws are used for more precise installations.

Machine screw sizes are usually designated by a combination of numbers and letters. The number indicates the diameter of the screw, while the letter indicates the thread size. For example, a #8-32 machine screw has a diameter of 8/32 of an inch and a 32 thread size.

It is important to choose the right machine screw size for your application to ensure a secure and reliable fastening. Using the wrong size screw can result in a loose connection or stripped threads, which may compromise the integrity of the assembled parts.

In summary, machine screw sizes are determined based on the diameter, length, and thread size of the screw. Understanding these factors will help you choose the right size machine screw for your specific application.

Choosing the Right Drill Bit Size

When it comes to drilling holes for machine screws, it is important to choose the right drill bit size. The size of the drill bit will determine the diameter of the hole and ensure a proper fit for the screw. Here are a few factors to consider when selecting the appropriate drill bit size:

1. Screw Size

The first thing to consider is the size of the machine screw you will be using. The drill bit should match the diameter of the screw to ensure a snug fit. For example, if you are using a 10 machine screw, you will need a drill bit with a diameter that matches the size 10 thread.

2. Thread Type

Another factor to consider is the type of thread on the machine screw. There are different types of threads, such as coarse threads and fine threads. Each thread type requires a different drill bit size. Make sure to check the specifications of the screw to determine the correct drill bit size for the specific thread type.

3. Material

The material you will be drilling into also affects the choice of drill bit size. Different materials require different drill bit sizes to achieve the best results. For example, drilling into wood may require a different size than drilling into metal or concrete. Be sure to choose a drill bit that is suitable for the material you are working with.

4. Pilot Hole

In some cases, it may be necessary to create a pilot hole before drilling the final hole for the machine screw. A pilot hole helps to guide the drill bit and prevent the wood from splitting. The size of the pilot hole should be smaller than the diameter of the screw. Refer to a drill bit size chart to determine the appropriate size for the pilot hole.

5. Test and Adjust

It is always a good idea to test the drill bit size with a scrap piece of material before drilling into the actual workpiece. This allows you to make any necessary adjustments and ensures that the hole will be the correct size for the screw.

Remember, choosing the right drill bit size is crucial for a successful drilling operation and proper installation of machine screws. Take into consideration the screw size, thread type, material, and the need for a pilot hole. With the right drill bit size, you can achieve accurate and secure screw installations.

Why you need to match drill bit size to machine screw size

Choosing the correct drill bit size is essential when it comes to installing machine screws. In order to ensure a secure and tight fit, the drill bit size must match the size of the machine screw. Here are a few reasons why matching the drill bit size to the machine screw size is important:

- Proper alignment: When you use a drill bit that is too small, the screw may not fit properly. This can lead to misalignment and cause the screw to be crooked or not fully embedded in the material. On the other hand, using a drill bit that is too large can result in a loose fit, making the screw less stable.

- Preventing damage: Using the wrong size drill bit can cause damage to the material you are drilling into. If the drill bit is too small, it may not create enough space for the screw, causing the material to crack or split. Conversely, if the drill bit is too large, it can create a hole that is too large for the screw, making it difficult to secure the screw properly.

- Ensuring a secure connection: Matching the drill bit size to the machine screw size is crucial for creating a secure connection. When the drill bit and screw are the same size, the threads of the screw will grip the material tightly, providing a strong and sturdy connection. This is especially important for applications that require a high level of stability, such as construction or mechanical projects.

To determine the correct drill bit size for a specific machine screw, you can refer to a drill bit size chart or use a drill bit gauge. These resources will provide you with the recommended drill bit size based on the diameter of the screw. It’s important to note that different types of materials may require different drill bit sizes, so consider the material you are working with when selecting the appropriate drill bit.

Overall, matching the drill bit size to the machine screw size is crucial for achieving a proper fit, preventing damage, and ensuring a secure connection. Taking the time to choose the correct drill bit size will result in a successful and professional-looking installation.

Tips for choosing the right drill bit size for 10 machine screws

When it comes to choosing the right drill bit size for 10 machine screws, there are a few important factors to consider. By selecting the appropriate drill bit size, you can ensure that the screws are securely and correctly fastened, preventing any potential issues with loosening or damage to the material being drilled.

1. Determine the screw size

The first step in choosing the right drill bit size is to determine the size of the machine screws you will be using. In this case, we are considering size 10 machine screws. These screws have a nominal diameter of 3/16 of an inch or 0.190 inches.

2. Select the correct drill bit size

To create pilot holes for size 10 machine screws, you will need to select a drill bit that matches the diameter of the screws. In this case, a drill bit with a diameter of 0.190 inches would be the appropriate choice. It is important to use a drill bit that matches the screw size to ensure a proper fit.

3. Consider the material being drilled

The material being drilled is another important factor to consider when choosing the drill bit size. Different materials have different hardness levels and may require different drill bit sizes. For example, drilling into wood may require a different drill bit size compared to drilling into metal. Consider the material and its properties to determine the appropriate drill bit size for your specific application.

4. Use a drill bit gauge

If you are unsure about the drill bit size to use, you can use a drill bit gauge. A drill bit gauge is a handy tool that allows you to determine the size of a drill bit by comparing it to the holes in the gauge. This can help you quickly and accurately identify the correct drill bit size for your machine screws.

5. Test your drill bit size

Before drilling into your material, it is always a good idea to test your drill bit size. You can do this by drilling a pilot hole in a scrap piece of material to ensure that the drill bit is the correct size for your machine screws. This will help you avoid any issues when drilling into your actual material.

6. Consider using a countersink bit

If you are using size 10 machine screws for a flush finish, you may also want to consider using a countersink bit. A countersink bit creates a conical hole that allows the screw head to sit flush with the surface of the material. This can provide a more professional and finished look to your project.

By following these tips, you can choose the right drill bit size for your size 10 machine screws, ensuring a secure and effective fastening solution for your project.

Common Drill Bit Sizes for #10 Machine Screw

When it comes to drilling holes for #10 machine screws, it is important to use the proper drill bit size. Using a drill bit that is too small can cause the screw to strip the threads, while using a bit that is too large can result in a loose connection. Here are some common drill bit sizes for #10 machine screws:

Standard Pilot Hole Sizes

The most commonly used pilot hole size for #10 machine screws is 3/32 inch. This size provides a good balance between creating a hole that is large enough for the screw to pass through easily, but small enough to ensure a secure fit.

Another common pilot hole size for #10 machine screws is 7/64 inch. This size is slightly larger than 3/32 inch and can be used when a slightly looser fit is desired.

Tapping Drill Bit Sizes

When tapping holes for #10 machine screws, different drill bit sizes are required. The most common tap drill bit size for a #10 machine screw is #25. This size provides the proper hole diameter for the screw to fully engage the threads.

Other tap drill bit sizes that can be used for #10 machine screws include #24 and #26. These sizes can be used when a slightly larger or smaller hole is desired, respectively.

Summary

Choosing the right drill bit size for #10 machine screws is important to ensure a strong and secure connection. The most common pilot hole size is 3/32 inch, while the most common tap drill bit size is #25. However, it is always recommended to refer to the specific screw and drill bit manufacturer’s guidelines for the best results.

Here’s a quick summary of the common drill bit sizes for #10 machine screws:

| Pilot Hole Size | Tap Drill Bit Size |

|---|---|

| 3/32 inch | #25 |

| 7/64 inch | Can be used when a slightly looser fit is desired |

| <Other sizes> | #24 or #26 |

Overview of common drill bit sizes for 10 machine screws

When it comes to choosing the right drill bit size for 10 machine screws, it is important to consider the size and threading of the screw as well as the material you are drilling into. Here is an overview of some common drill bit sizes that are often used for 10 machine screws:

1. #21 Drill Bit

- Useful for drilling pilot holes for 10-24 machine screws.

- Has a diameter of approximately 0.159 inches or 4.04 millimeters.

2. 7/32″ Drill Bit

- Suitable for drilling pilot holes for 10-32 machine screws.

- Has a diameter of approximately 0.219 inches or 5.56 millimeters.

3. #3 Drill Bit

- Commonly used for drilling clearance holes for 10-32 machine screws.

- Has a diameter of approximately 0.213 inches or 5.41 millimeters.

4. 15/64″ Drill Bit

- Ideal for drilling pilot holes for 10-24 machine screws.

- Has a diameter of approximately 0.234 inches or 5.94 millimeters.

5. #25 Drill Bit

- Commonly used for drilling pilot holes for 10-32 machine screws.

- Has a diameter of approximately 0.1495 inches or 3.79 millimeters.

6. 17/64″ Drill Bit

- Suitable for drilling pilot holes for 10-24 machine screws.

- Has a diameter of approximately 0.265 inches or 6.73 millimeters.

Remember, these are just some of the common drill bit sizes used for 10 machine screws. It’s always a good idea to consult a drill bit size chart or refer to the manufacturer’s recommendations to ensure the proper drill bit size for your specific application.

FAQ:

What size drill bit do I need for a #10 machine screw?

You will need a drill bit size of 3/32 inches for a #10 machine screw.

Can I use a smaller drill bit for a #10 machine screw?

No, it is recommended to use the appropriate size drill bit for the #10 machine screw to ensure a proper fit and prevent damage to the screw or material.

What happens if I use a larger drill bit for a #10 machine screw?

If you use a larger drill bit, the hole will be too large for the screw, resulting in a loose and potentially weak connection between the screw and the material.

Do I need to use a pilot hole for a #10 machine screw?

It is generally recommended to use a pilot hole for a #10 machine screw, especially if you are working with hardwood or other hard materials. This helps to prevent the screw from splitting the material and makes it easier to drive the screw in.

What is the best type of drill bit for a #10 machine screw?

A titanium-coated drill bit or a high-speed steel drill bit is recommended for drilling holes for #10 machine screws. These types of drill bits are durable and can effectively cut through metal and other materials.

What precautions should I take when drilling a hole for a #10 machine screw?

When drilling a hole for a #10 machine screw, it is important to wear safety goggles and work in a well-ventilated area. Make sure to secure the material properly and keep your hands and fingers away from the drill bit. Take your time and apply steady pressure to avoid any accidents.

Video: