Choosing the Right Drill Bit for Tapping a 1/4 20 Bolt

Tapping threads into a 1/4 20 bolt can be a challenging task if you don’t have the right tools. One of the most important tools you’ll need is a drill bit. However, not all drill bits are created equal, and choosing the right one for the job can make all the difference in your success.

When it comes to tapping a 1/4 20 bolt, you’ll want to look for a drill bit that matches the size and pitch of the desired thread. In this case, a 1/4 inch drill bit is the perfect choice. It will create a hole that is just the right size for the 1/4 20 bolt, allowing it to fit snugly and securely.

But size isn’t the only consideration when choosing a drill bit for tapping a 1/4 20 bolt. You’ll also want to think about the material you’re working with. If you’re tapping threads into a soft material like wood or plastic, a standard high-speed steel drill bit will work just fine. However, if you’re working with a harder material like metal, you may want to consider a cobalt drill bit. Cobalt is known for its durability and ability to withstand high temperatures, making it a great choice for tougher materials.

Another factor to consider is the type of drill bit you want to use. There are two main types to choose from: spiral and straight flute. Spiral drill bits are known for their excellent chip removal and are great for drilling through soft materials. Straight flute drill bits, on the other hand, are better suited for harder materials and produce cleaner, more precise holes. Depending on the material you’re working with, you’ll want to choose the appropriate type of drill bit for the best results.

Types of Drill Bits

When it comes to drilling holes for tapping 1/4-20 bolts, there are a few types of drill bits that are commonly used. Each type has its own advantages and disadvantages, so it’s important to choose the right one for your specific needs. Here are some of the most common types of drill bits:

1. Twist Drill Bits

Twist drill bits are the most commonly used type of drill bits. They have a spiral shape and are designed to cut through wood, metal, plastic, and other materials. They come in a variety of sizes, and you’ll need to choose a size that is appropriate for the diameter of your 1/4-20 bolt. Twist drill bits are versatile and can be used for a wide range of drilling tasks.

2. Brad Point Drill Bits

Brad point drill bits are similar to twist drill bits, but they have a pointed tip that helps to keep the bit centered on the material you’re drilling. This makes them a good choice for drilling precise holes. Brad point drill bits are commonly used for woodworking, but they can also be used for other materials.

3. Step Drill Bits

Step drill bits are designed to drill holes with different diameters. They have multiple cutting edges and gradually increase in size as you drill deeper into the material. Step drill bits are commonly used for sheet metal and thin materials. They are also useful for enlarging existing holes.

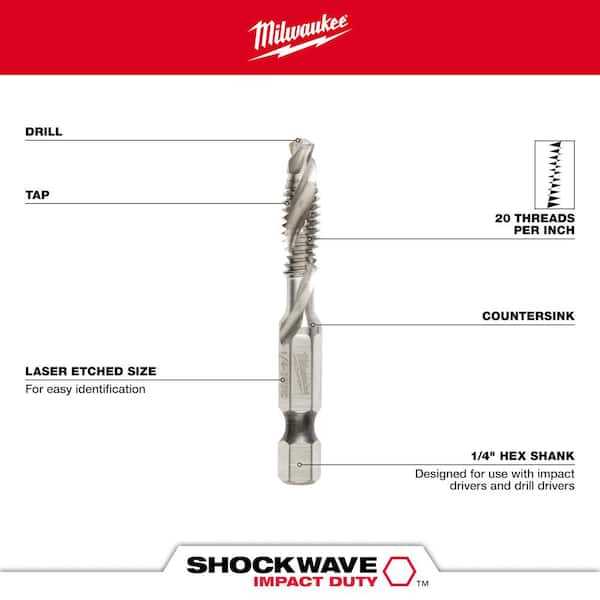

4. Countersink Bits

Countersink bits are used to create a conical hole at the top of a drilled hole. This allows the head of a screw or bolt to be recessed into the material. Countersink bits are commonly used in woodworking, but they can also be used in metalworking and other applications.

5. Hole Saw Bits

Hole saw bits are used to create larger-diameter holes in materials like wood and plastic. They have a cylindrical shape with sharp teeth that cut through the material. Hole saw bits are often used for tasks like installing doorknobs or creating holes for pipes and cables.

6. Forstner Bits

Forstner bits are similar to hole saw bits, but they are designed for drilling flat-bottomed holes. They are commonly used in woodworking to create holes for dowels and other joinery techniques.

7. Masonry Bits

If you need to drill holes in concrete, brick, or other masonry materials, you’ll need a masonry drill bit. These bits have a carbide or diamond tip that helps them to cut through the tough material. Masonry bits are usually used with a hammer drill or rotary hammer to provide the necessary force.

8. Auger Bits

Auger bits are designed for drilling deep holes in wood. They have a threaded screw tip that helps to pull the bit into the material. Auger bits are commonly used for tasks like drilling holes for dowels or creating holes for wiring in wooden beams.

These are just a few of the most common types of drill bits available for tapping 1/4-20 bolts. It’s important to choose the right type and size of drill bit for your specific needs to ensure a clean and precise hole.

Twist Drill Bits

Twist drill bits are the most commonly used type of drill bit for general drilling purposes. They are versatile and can be used on a wide range of materials, including wood, metal, and plastic. Twist drill bits are designed with a spiral-shaped fluted shaft, which helps to remove chips and debris from the hole as it is being drilled.

Twist drill bits come in a variety of sizes and are usually labeled with a number, which indicates the diameter of the bit in fractions of an inch. For example, a #8 twist drill bit has a diameter of 1/8 inch. When tapping a 1/4 20 bolt, you would typically use a #7 or #7/64 twist drill bit to create the correct size hole for the tap.

It is important to use a sharp twist drill bit when drilling holes for tapping, as a dull bit can cause the hole to be out of round or result in excessive burrs. You should also use cutting fluid or lubricant to reduce heat and friction during drilling.

When using a twist drill bit for tapping, it is important to keep the drill bit perpendicular to the surface being drilled. This can be accomplished by using a center punch to create a small indentation in the material before drilling.

Twist drill bits can be purchased individually or in sets, which typically include a range of sizes. It is a good idea to have a variety of sizes on hand to accommodate different tapping needs.

Overall, twist drill bits are a reliable and cost-effective option for drilling holes when tapping a 1/4 20 bolt. With proper technique and the right size drill bit, you can easily create clean and accurate holes for your tapping needs.

Step Drill Bits

A step drill bit is a specialized type of drill bit that is designed to create multiple hole sizes with just one bit. These bits are often used for tapping holes for bolts, such as a 1/4 20 bolt. Step drill bits have a conical shape with multiple steps of increasing diameter.

Advantages of Step Drill Bits:

- Multiple hole sizes: Step drill bits allow you to create multiple hole sizes without the need to change bits. This can save time and effort when drilling holes for tapping a 1/4 20 bolt.

- Smooth drilling: Step drill bits are designed to penetrate materials smoothly and without causing damage. The conical shape helps to eliminate the need for excessive force when drilling.

- Reduced risk of cracking: The stepped design of these bits helps to reduce the risk of cracking or damaging the material being drilled. This is especially important when working with brittle materials such as ceramics or glass.

- Versatility: Step drill bits can be used for various drilling applications, not just tapping holes for bolts. They can be used for enlarging existing holes, deburring, and countersinking.

- Durable: Step drill bits are typically made from high-speed steel or cobalt, which makes them durable and long-lasting.

How to Use a Step Drill Bit for Tapping a 1/4 20 Bolt:

- Secure the material to be drilled in a vise or clamp to prevent it from moving.

- Select the appropriate step on the step drill bit for the desired hole size. The step size may be labeled on the bit or indicated by markings.

- Apply moderate pressure to the drill while keeping it aligned with the desired hole location.

- Start drilling at a slow speed to ensure accuracy and control. Increase the speed as the hole begins to form.

- Drill until the desired depth is reached, taking care not to drill too deep.

- Remove the drill bit from the hole and clean out any debris.

- Tap the hole using a tap designed for 1/4 20 bolts.

Notes:

- It is important to use the appropriate size step on the step drill bit to avoid creating oversized or undersized holes.

- Take breaks and use cutting fluid when drilling through tough materials to prevent overheating and extend the life of the bit.

- Always wear protective eyewear and gloves when drilling to ensure safety.

Overall, step drill bits are a versatile and efficient option for tapping holes for a 1/4 20 bolt. With the ability to create multiple hole sizes and their durable construction, these bits are a valuable addition to any toolkit.

Brad Point Drill Bits

Brad point drill bits are a type of drill bit that is specifically designed for woodworking projects. These bits feature a sharp, pointed tip that helps to reduce the likelihood of the bit slipping or wandering while drilling into wood.

One of the key advantages of using brad point drill bits for tapping a 1/4 20 bolt is their ability to create clean, precise holes. The sharp, centered tip of these bits easily pierces the wood, producing a clean entry hole with minimal tear-out.

Brad point drill bits are available in a variety of sizes, including the specific size needed for tapping a 1/4 20 bolt. It is important to select a bit that matches the size of the bolt to ensure a proper fit.

When using brad point drill bits, it is important to apply steady, even pressure to avoid overheating or damaging the bit. It is also recommended to use a drill speed that matches the type of wood you are working with, as high speeds can cause burn marks or splintering.

Overall, brad point drill bits are an excellent choice for tapping a 1/4 20 bolt in woodworking projects. Their sharp, pointed tip and precise drilling capabilities make them a reliable tool for creating clean, accurate holes in wood.

Forstner Drill Bits

Forstner drill bits are a type of woodworking drill bit that is commonly used for creating flat-bottomed holes with clean edges. They are often used in woodworking projects, such as drilling holes for dowels, hinges, or installing hardware.

Benefits of Forstner Drill Bits:

- Accurate and clean holes: Forstner bits are designed to produce precise holes with clean edges. This makes them ideal for projects that require a high level of precision.

- Flat-bottomed holes: Unlike some other drill bits, Forstner bits create flat-bottomed holes. This is particularly useful when installing hardware or when a flat surface is required.

- Reduce tear-out: Forstner bits have a sharp center point and cutting edges that cut into the wood, rather than tearing it. This reduces the risk of tear-out and produces cleaner holes.

- Versatility: Forstner bits can be used in a variety of materials, including wood, plywood, and some plastics.

How to Use Forstner Drill Bits:

Using Forstner drill bits is relatively simple, although they do require some care to ensure the best results:

- Secure your workpiece: Clamp or secure the workpiece firmly before drilling to prevent movement and ensure stability.

- Choose the right size: Select a Forstner bit that matches the size of the hole you need to create. Forstner bits are available in various sizes, so choose the one that matches your requirements.

- Mark the center: Use a ruler and pencil to mark the center point of the hole you want to drill.

- Position the drill bit: Align the center point of the Forstner bit with the marked center point on the workpiece.

- Start drilling: Begin drilling slowly and steadily at a low speed. Apply even pressure and let the bit do the cutting. Avoid pushing too hard or drilling too fast, as this can cause overheating and dull the bit.

- Clean the hole: After drilling the hole, remove any wood chips or debris from the hole to ensure a clean finish.

Conclusion:

Forstner drill bits are a versatile and reliable choice for creating accurate and clean holes in woodworking projects. With their ability to produce flat-bottomed holes and reduce tear-out, they are often the preferred choice for professionals and hobbyists alike.

Drilling Techniques

1. Choose the Right Drill Bit

Start by selecting the appropriate drill bit for the size of the hole you need. For tapping a 1/4 20 bolt, you will typically use a 13/64″ drill bit. Make sure the bit is sharp and in good condition to ensure clean and precise drilling.

2. Mark the Center

Before drilling, use a center punch to mark the exact center of the hole you are going to drill. This will help prevent the drill bit from wandering and ensure accuracy.

3. Secure the Workpiece

Secure the workpiece firmly in place using clamps or a vise to prevent it from moving during drilling. This will help maintain stability and accuracy during the drilling process.

4. Use Cutting Fluid

If you are drilling through a hard material such as metal, it is recommended to use cutting fluid to lubricate the drill bit and reduce heat buildup. This will help prolong the life of the drill bit and improve drilling efficiency.

5. Start Slowly

When starting the drilling process, begin at a low speed to create a small pilot hole. This will provide a guide for the drill bit and prevent it from slipping off the mark. Once the pilot hole is created, you can increase the speed and apply more pressure.

6. Maintain Proper Pressure

While drilling, it is important to maintain steady and consistent pressure on the drill. Too much pressure can damage the drill bit, while too little pressure can result in an uneven hole. Find the right balance and let the drill do the work.

7. Cool the Drill Bit

If you notice the drill bit getting hot during drilling, stop and cool it down. Excessive heat can cause the drill bit to wear out faster and reduce drilling efficiency. You can use a cool mist or water to cool down the drill bit.

8. Clean the Hole

After drilling the hole, make sure to remove any debris or burrs from the hole using a brush or compressed air. This will ensure a clean and smooth surface for tapping the bolt.

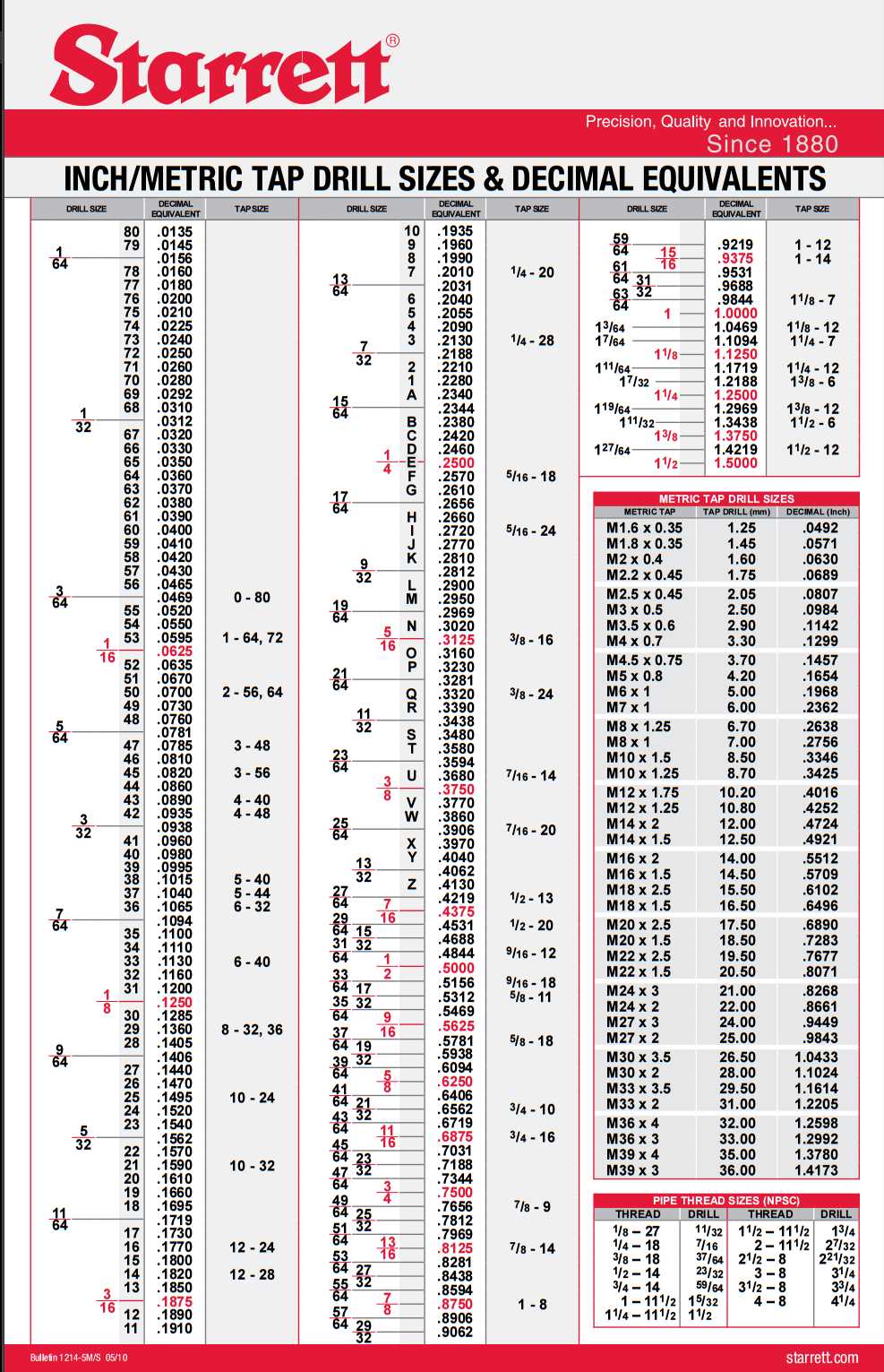

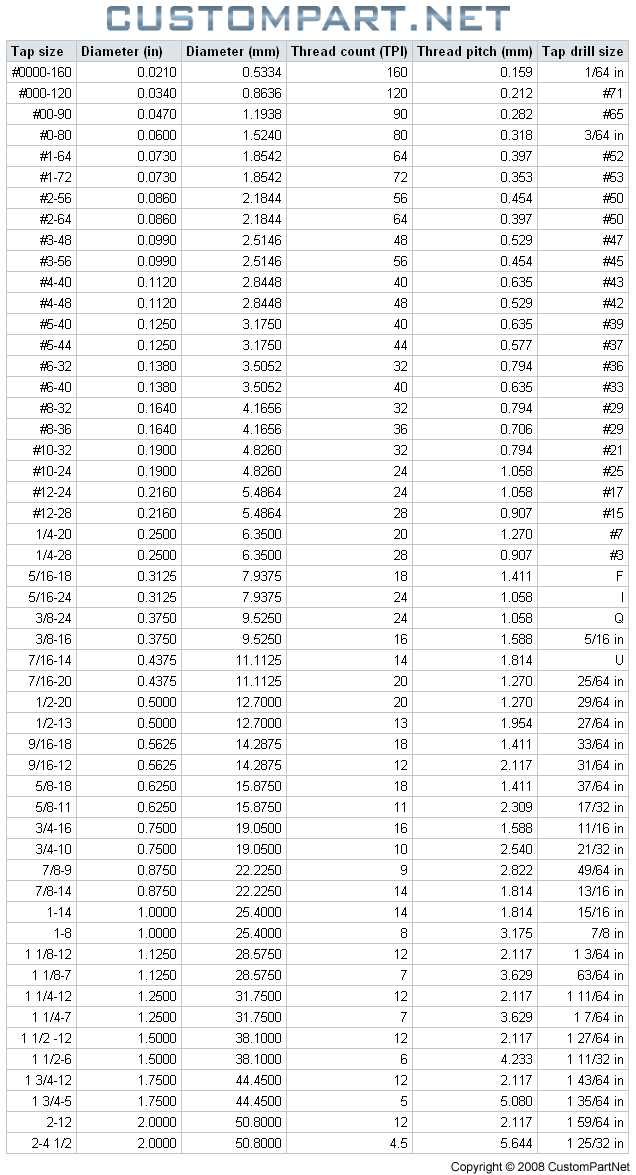

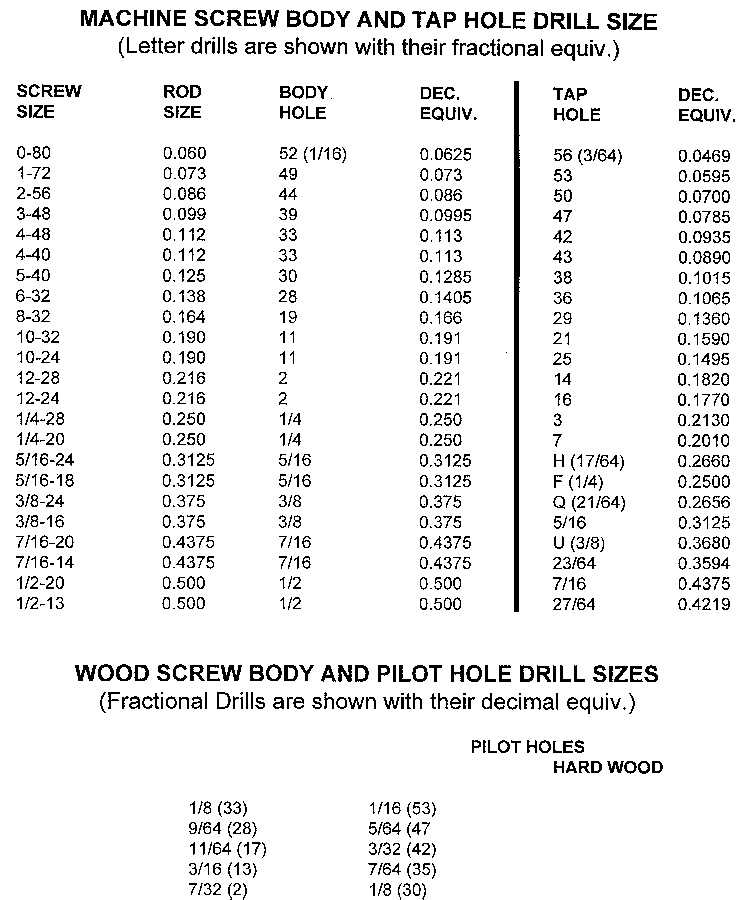

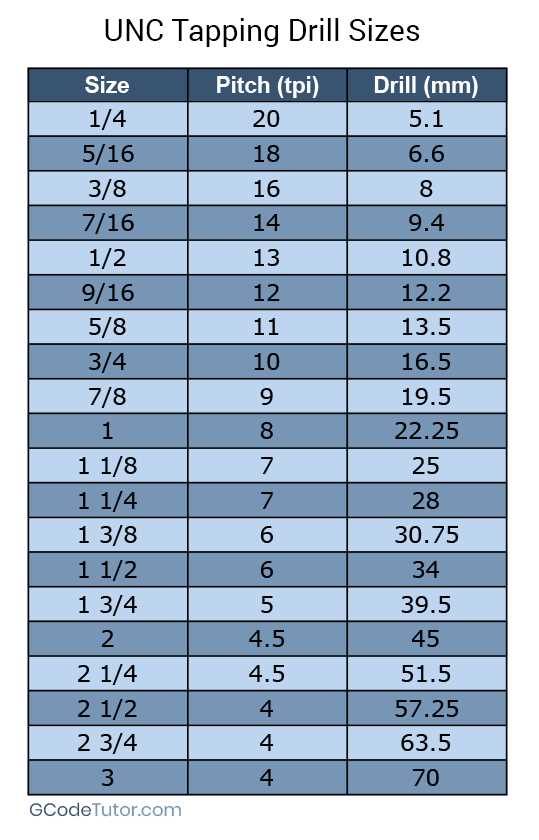

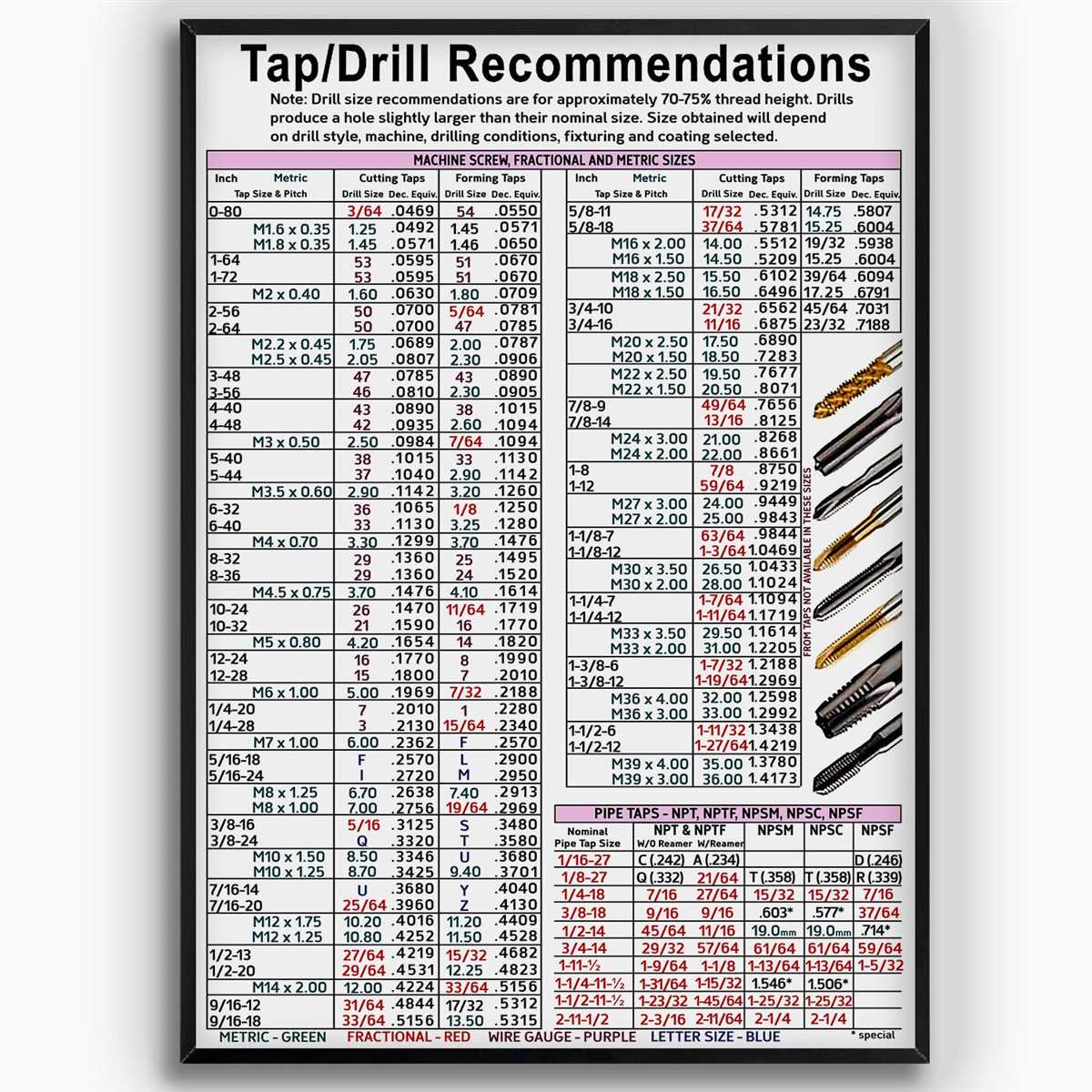

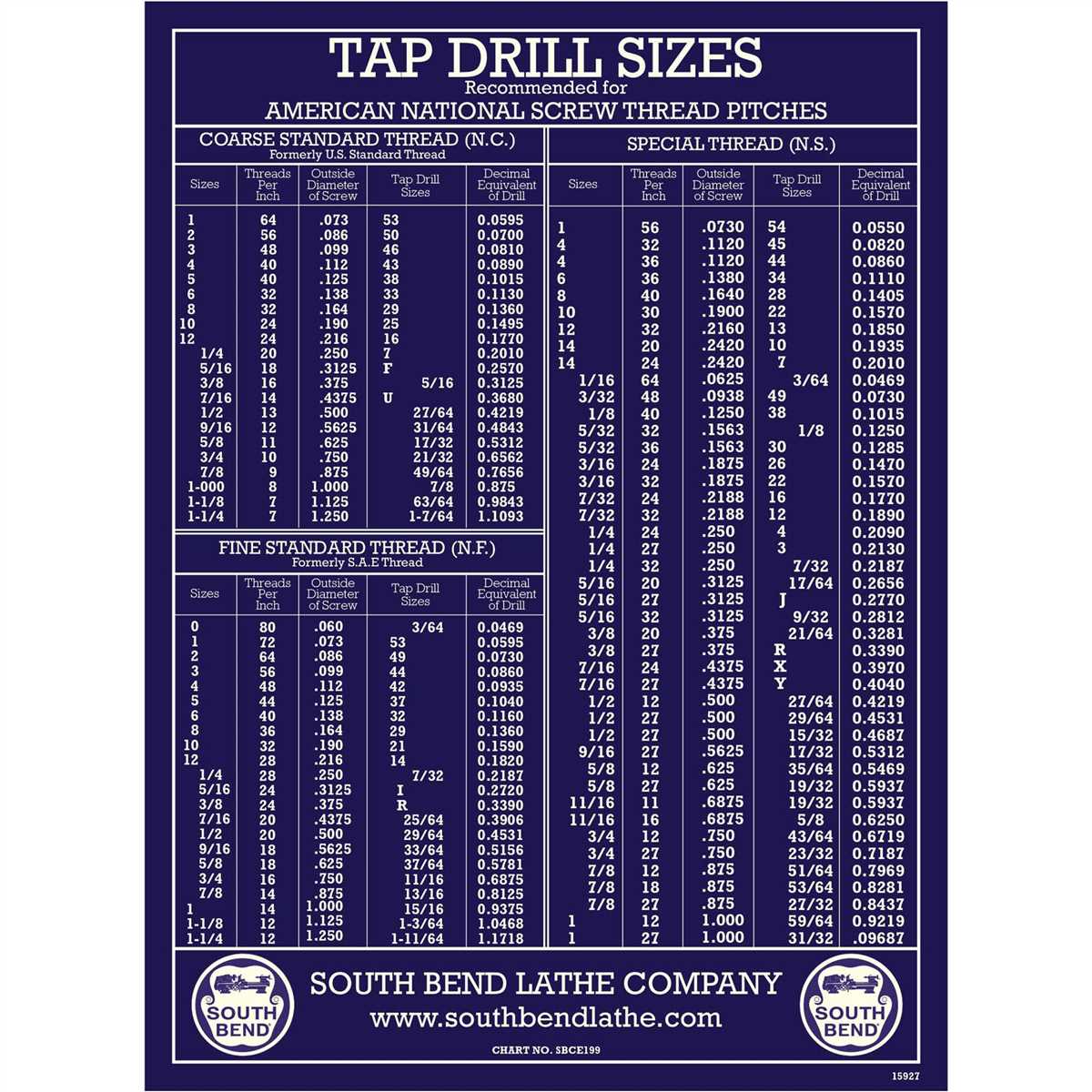

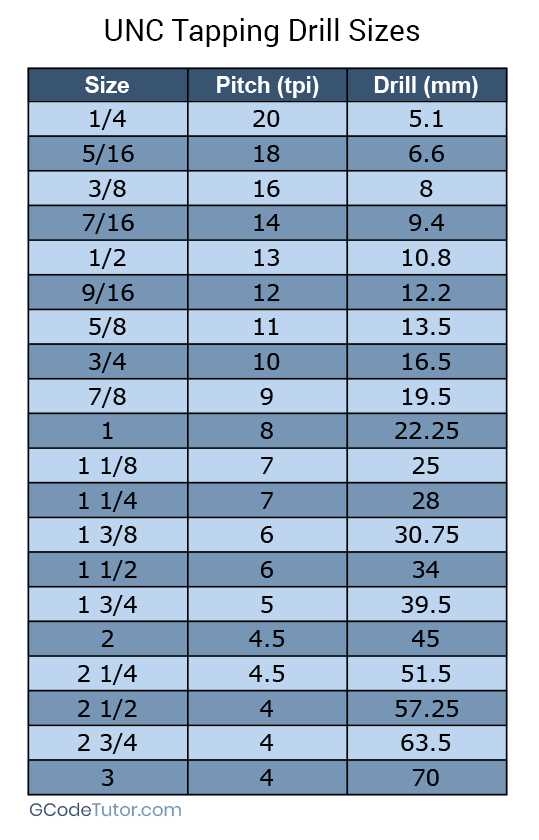

9. Use a Tap Drill Chart

Refer to a tap drill chart to determine the appropriate drill bit size for tapping the specific thread size of the bolt. This will help achieve the correct thread depth and ensure a secure fit.

10. Practice Proper Safety Precautions

Always wear safety goggles to protect your eyes from flying debris. Avoid wearing loose clothing or jewelry that may get caught in the drill. Additionally, make sure to read and follow the manufacturer’s instructions for your specific drill and drill bit.

| Drill Bit Size (inch) | Thread Size | Tap Drill Size (inch) |

|---|---|---|

| 13/64 | 1/4 20 | 13/64 |

| 7/32 | 1/4 20 | 7/32 |

| 15/64 | 1/4 20 | 15/64 |

Pilot Hole Drilling

When tapping a 1/4 20 bolt, it is essential to start with a pilot hole. A pilot hole is a small-diameter hole drilled into a material to guide the larger drill bit during the tapping process.

Drilling a pilot hole has several advantages:

- Accuracy: A pilot hole ensures that the tapping process is started at the right location and angle, resulting in a properly threaded hole for the 1/4 20 bolt.

- Reduces Friction: By creating a pilot hole, you reduce the amount of material that the larger drill bit needs to remove. This reduces friction and makes the tapping process easier and more efficient.

- Prevents Cracks: Without a pilot hole, the larger drill bit can put excessive pressure on the material, leading to cracks or damage. A pilot hole distributes the force more evenly, reducing the risk of damage.

Here is a step-by-step guide on how to drill a pilot hole for a 1/4 20 bolt:

- Choose the appropriate drill bit size for the pilot hole. The recommended size for a 1/4 20 bolt is typically 7/64 or 5/32 inches.

- Secure the material you are drilling into. You can use clamps or a vise to hold it in place.

- Mark the desired location for the hole using a marker or pencil.

- Put on safety glasses to protect your eyes from any flying debris.

- Drill the pilot hole at a slow speed, making sure to stay perpendicular to the material. Apply steady pressure to gradually create the hole.

- Periodically remove the drill bit to clear out any wood chips or debris that may accumulate.

- Once the pilot hole is complete, you can proceed with the tapping process using the appropriate tap and die set for a 1/4 20 bolt.

By drilling a pilot hole before tapping a 1/4 20 bolt, you ensure a successful and accurate thread connection. Remember to always use caution and follow proper safety guidelines when drilling.

Bottoming Hole Drilling

Bottoming hole drilling is a technique used when tapping a 1/4 20 bolt. When tapping a hole, it is important to create the right size and depth to ensure a secure and accurate thread for the bolt. Bottoming hole drilling is the final step in the process and ensures that the hole is drilled to the correct depth.

Unlike other drilling techniques, bottoming hole drilling involves drilling the hole to the full depth of the tap. This means that the hole will be slightly larger than the tap itself, allowing the tap to easily thread the bolt into place.

To perform bottoming hole drilling, you will need a drill bit that matches the size of the tap you are using. In this case, a 1/4 inch drill bit would be appropriate. Make sure the drill bit is sharp and in good condition to ensure clean and accurate drilling.

When drilling the bottoming hole, it is important to use a steady hand and apply consistent pressure. Start by marking the desired depth on the drill bit or using a drill depth stop to ensure you do not drill too deep. Place the drill bit perpendicular to the surface and slowly begin drilling, keeping the drill as straight as possible.

As you drill, periodically pull the drill out to remove any chips or debris that may be caught in the flutes of the drill bit. This will help maintain a clean and accurate hole.

Once the desired depth is reached, carefully remove the drill bit while maintaining pressure to prevent the hole from becoming distorted or damaged. Inspect the hole to ensure that it is clean and free of any burrs or rough edges.

Bottoming hole drilling is an important step in the tapping process as it ensures that the threads will engage properly and securely with the 1/4 20 bolt. Taking the time to drill the bottoming hole correctly will result in a stronger and more reliable connection for your application.

Tapping Hole Drilling

Drilling a tapping hole is an important step in the process of tapping a 1/4 20 bolt. The tapping hole needs to be properly sized and prepared to ensure a secure and accurate thread is formed.

Choosing the Right Drill Bit

The first step in tapping hole drilling is selecting the appropriate drill bit. In the case of a 1/4 20 bolt, a #7 drill bit is commonly used. This drill bit size matches the specifications of the 1/4 20 bolt, ensuring a proper fit for tapping.

It is crucial to use a sharp drill bit to prevent any issues such as wandering or wobbling during the drilling process. A dull drill bit can lead to inaccurate holes and difficulties when tapping the thread.

Preparing the Workpiece

Before drilling the tapping hole, it is important to secure the workpiece firmly in place. This can be done using clamps or a vise to prevent any movement or instability during the drilling process.

Make sure to mark the precise location for the tapping hole on the workpiece using a center punch or a marking tool. This will provide a guide for drilling and help ensure accuracy.

Drilling the Tapping Hole

Now that the drill bit and workpiece are prepared, place the drill bit into the chuck of the drill. Make sure the drill bit is secured tightly to avoid any slippage during the drilling process.

Start drilling the tapping hole at a slow speed, gradually increasing the speed as the hole progresses. This will help prevent overheating of the drill bit and ensure a smooth drilling action.

Apply gentle pressure while drilling to avoid any damage to the workpiece or drill bit. Let the drill bit do the work and avoid forcing it through the material.

Cleaning the Tapping Hole

Once the tapping hole has been drilled, it is important to clean it thoroughly to remove any chips or debris. This can be done using compressed air or a brush to ensure the tapping process is not impeded by any obstructions.

Inspect the tapping hole to ensure it is clean, smooth, and properly sized. Any irregularities or damage should be addressed before proceeding with the tapping process.

By following these steps for tapping hole drilling, you can ensure a properly prepared hole for tapping a 1/4 20 bolt. This will result in a strong and secure thread that is essential for the overall integrity of the fastening application.

Choosing the Right Drill Bit

When it comes to tapping a 1/4 20 bolt, choosing the right drill bit is essential to ensure a proper fit and avoid damaging the threads. Here are some factors to consider when selecting the appropriate drill bit:

Diameter

The first thing to determine is the diameter of the drill bit that matches the tap size of the 1/4 20 bolt. In this case, a drill bit with a diameter of 0.201 inches is required. This provides enough clearance for the tap to create threads without compromising the integrity of the bolt.

Material

The material of the drill bit should be able to handle the hardness of the material being drilled. For tapping a 1/4 20 bolt, a high-speed steel (HSS) drill bit is a suitable choice. HSS drill bits are designed to cut through metals and can withstand the high heat generated while drilling.

Type

There are several types of drill bits available, including twist drill bits, brad point bits, and spade bits. For tapping a 1/4 20 bolt, a twist drill bit is the most commonly used type. Twist drill bits have a pointed tip and spiral flutes that help in removing material while drilling.

Coating

Consider using drill bits with a coating to increase durability and reduce friction during drilling. Titanium nitride (TiN) and black oxide are popular coatings that provide improved wear resistance and help prevent heat buildup.

Length

The length of the drill bit should be long enough to penetrate the material being drilled. For tapping a 1/4 20 bolt, a standard-length drill bit of around 2.5 to 3 inches should suffice, depending on the thickness of the material.

Speed and Feed Rate

Finally, it’s crucial to match the drill bit’s speed and feed rate to the material being drilled. For tapping a 1/4 20 bolt in metal, a slower speed and a steady feed rate are recommended to prevent overheating and ensure clean, accurate holes.

By considering these factors and selecting the right drill bit, you can ensure a successful tapping operation for your 1/4 20 bolt.

FAQ:

Can I use any drill bit to tap a 1/4 20 bolt?

No, you need to use a specific drill bit size for tapping a 1/4 20 bolt. Using the wrong size drill bit can result in improper threading and a weak connection.

What is the recommended drill bit size for tapping a 1/4 20 bolt?

The recommended drill bit size for tapping a 1/4 20 bolt is a 7/32 drill bit. This allows for proper thread engagement and a secure connection.

What happens if I use a drill bit that is too large for tapping a 1/4 20 bolt?

If you use a drill bit that is too large, the threads may not properly engage with the bolt, resulting in a loose or weak connection. It is important to use the correct drill bit size for optimal results.

What happens if I use a drill bit that is too small for tapping a 1/4 20 bolt?

If you use a drill bit that is too small, it may not create enough space for the threads to properly engage with the bolt. This can result in stripped threads and a weak connection.

Can I tap a 1/4 20 bolt without using a drill bit?

No, it is not recommended to tap a 1/4 20 bolt without using a drill bit. The drill bit creates the necessary space for the threads to fit properly and ensures a secure connection.

Are there any other factors to consider when choosing the right drill bit for tapping a 1/4 20 bolt?

Yes, it is important to consider the material you are drilling into and adjust the drill bit size accordingly. Different materials may require different drill bit sizes for optimal results.

Can I use a metric drill bit for tapping a 1/4 20 bolt?

No, it is not recommended to use a metric drill bit for tapping a 1/4 20 bolt. The 1/4 20 bolt is imperial, and using a metric drill bit may result in improper threading and a weak connection.

Video: