Choosing the Right Drill Bit for Stainless Steel: A Comprehensive Guide

Drilling through stainless steel can be a daunting task. The hardness and strength of this metal make it more difficult to work with than other materials. However, with the right drill bit and technique, you can achieve clean and precise holes in stainless steel.

One of the most important factors in drilling through stainless steel is selecting the right drill bit. Not all drill bits are created equal, and using the wrong one can result in damage to your material or the drill itself. In this comprehensive guide, we will explore the different types of drill bits that are best suited for stainless steel and provide tips on how to choose the right one for your project.

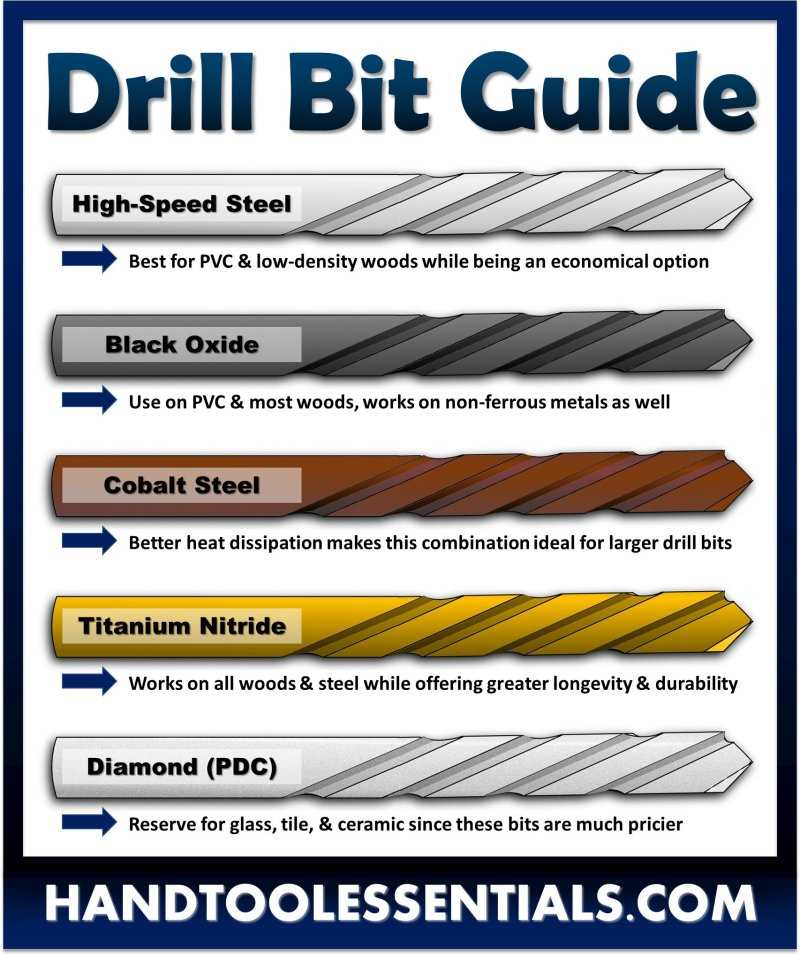

When it comes to drilling stainless steel, high-speed steel (HSS) drill bits are a popular choice. These drill bits are made from a high-carbon steel that is heat-treated to provide durability and strength. HSS drill bits can withstand the high-speeds and force required for drilling through stainless steel, making them a reliable option for this material.

Another option for drilling stainless steel is cobalt drill bits. These drill bits are made from a mix of cobalt and steel, which gives them exceptional hardness and heat resistance. Cobalt drill bits can easily handle the high temperatures generated during drilling stainless steel, making them a great choice for tougher projects.

When choosing a drill bit for stainless steel, it’s also important to consider the size and coating of the bit. Smaller drill bits are generally better for stainless steel as they create less heat and friction during drilling. Additionally, opting for a drill bit with a coating, such as titanium or black oxide, can improve the bit’s performance and longevity.

Understanding Stainless Steel and Its Properties

Stainless steel is a versatile material that is commonly used in various industries due to its unique properties. Understanding the properties of stainless steel can help you choose the right drill bit for your specific application. Here are some key properties of stainless steel:

Corrosion Resistance

One of the main advantages of stainless steel is its excellent corrosion resistance. Stainless steel contains chromium, which forms a thin, invisible layer on the surface of the material, known as the passive layer. This passive layer protects stainless steel from corrosion, making it highly resistant to rust and staining.

Strength and Durability

Stainless steel is known for its high strength and durability. It is a very strong material that can withstand heavy loads and high temperatures. This makes it suitable for applications where strength and durability are essential, such as construction, automotive, and aerospace industries.

Heat Resistance

Stainless steel has excellent heat resistance properties, making it suitable for high-temperature applications. It can withstand temperatures up to 1600°F (870°C) without losing its structural integrity. This makes stainless steel ideal for applications that involve exposure to high temperatures, such as exhaust systems and heat exchangers.

Hygiene and Cleanability

Stainless steel is a hygienic material that is easy to clean and maintain. Its smooth surface prevents the growth of bacteria and other pathogens, making it ideal for applications in the food and medical industries. Stainless steel is also resistant to chemicals and can be easily cleaned with various cleaning agents without causing damage.

Aesthetic Appeal

Stainless steel is widely appreciated for its aesthetic appeal. It has a modern and sleek appearance that can enhance the visual appeal of any application. Stainless steel is available in various finishes, such as brushed, polished, or satin, allowing you to choose the desired look for your project.

Magnetic Properties

Most stainless steels are non-magnetic, but some can be slightly magnetic depending on their composition. This property can affect certain applications, such as magnetic resonance imaging (MRI) machines, where non-magnetic materials are required. It is important to consider the magnetic properties of stainless steel when selecting a drill bit for a specific application.

Conclusion

Understanding the properties of stainless steel is crucial when selecting the right drill bit for your project. Stainless steel’s corrosion resistance, strength, heat resistance, cleanability, aesthetic appeal, and magnetic properties all play a role in determining the most appropriate drill bit for the job. By considering these properties, you can ensure a successful drilling operation and achieve the desired results in your stainless steel applications.

Importance of Using the Right Drill Bit

When working with stainless steel, using the right drill bit is of utmost importance. Stainless steel is a hard material that requires a specific type of drill bit to ensure accuracy and efficiency in drilling. Using the wrong drill bit can result in inefficiency, damage to the material, and the need for rework.

1. Efficient Drilling

Using the right drill bit for stainless steel ensures efficient drilling. Stainless steel has a high melting point and hardness, making it difficult to penetrate. A proper drill bit designed for stainless steel will have a sharp cutting edge and precise flute design, allowing it to effortlessly cut through the material without creating excessive heat or wear on the bit.

2. Accurate Hole Creation

Using the wrong drill bit can lead to inaccurate hole creation. Stainless steel is known for its strength and durability, which means that improper drilling techniques or inadequate drill bits can result in uneven or poorly shaped holes. This can be problematic when precision is required, such as when installing hardware or joining different components together.

3. Preventing Damage to the Material

Using the wrong drill bit can cause damage to the stainless steel material. Stainless steel is susceptible to scratching and marring, and using an incorrect drill bit can result in surface damage or burrs. This can not only compromise the appearance of the material but also weaken its structural integrity. Using the appropriate drill bit reduces the risk of damage and ensures that the material remains in good condition.

4. Avoiding the Need for Rework

Using the right drill bit from the beginning can help you avoid the need for rework. Incorrectly drilled holes may not be suitable for their intended use, resulting in the need to fill, patch, or redrill. This not only wastes time and resources but can also compromise the overall quality of the project. By selecting the right drill bit for stainless steel, you can minimize the likelihood of errors and the need for rework.

| Benefits |

|---|

| Efficient drilling |

| Accurate hole creation |

| Preventing damage to the material |

| Avoiding the need for rework |

Types of Drill Bits

- Twist Drill Bits: Twist drill bits are the most common type of drill bits used for stainless steel. They have a helical groove along the body, which helps to quickly remove material and provide a clean hole. Twist drill bits come in various sizes and can be used for a wide range of applications.

- Cobalt Drill Bits: Cobalt drill bits are specifically designed for drilling through hard materials like stainless steel. They are made from cobalt alloy, which provides excellent heat resistance and helps to prolong the life of the drill bit. Cobalt drill bits are available in different sizes and are ideal for professional use.

- Titanium Drill Bits: Titanium drill bits are coated with a layer of titanium nitride, which makes them extremely durable and reduces friction during drilling. This coating also helps to keep the drill bit cool and prevents it from overheating. Titanium drill bits are suitable for drilling into stainless steel and other hard materials.

- Carbide Drill Bits: Carbide drill bits are another type of drill bit commonly used for stainless steel. They are made from tungsten carbide, which is a very hard and brittle material. Carbide drill bits are known for their durability and can be used for drilling into abrasive materials like stainless steel.

- Diamond Drill Bits: Diamond drill bits are the hardest drill bits available and are used for drilling through extremely hard materials like stainless steel. These drill bits have diamond particles embedded in the tip, which helps to make them incredibly sharp and efficient. Diamond drill bits are often used in industries that require precise and clean drilling.

Cobalt Drill Bits

Cobalt drill bits are some of the best options when it comes to drilling through stainless steel. They are known for their durability and ability to withstand high temperatures, making them ideal for tough materials like stainless steel.

Advantages of Cobalt Drill Bits:

- High heat resistance: Cobalt drill bits can withstand high temperatures generated during drilling, preventing them from becoming dull or overheating.

- Hardness: Cobalt drill bits are harder than traditional high-speed steel drill bits, allowing them to cut through stainless steel with ease.

- Long lifespan: Due to their hardness and heat resistance, cobalt drill bits have a longer lifespan compared to other types of drill bits.

- Improved accuracy: Cobalt drill bits provide better control and accuracy when drilling, resulting in clean and precise holes.

Disadvantages of Cobalt Drill Bits:

- Cost: Cobalt drill bits are generally more expensive than other types of drill bits due to their higher quality and performance.

- Brittleness: Cobalt drill bits can be more brittle compared to other types of drill bits, which means they may break more easily if not properly handled or used with excessive force.

Tips for Using Cobalt Drill Bits:

- Use appropriate speed and pressure: To prevent overheating and premature dulling, use slow and steady speed when drilling with cobalt drill bits. Apply consistent but not excessive pressure.

- Use lubrication: Applying lubricant or coolant while drilling can help reduce heat and prolong the lifespan of cobalt drill bits.

- Start with a pilot hole: When drilling through stainless steel, it is often helpful to start with a smaller pilot hole before using a larger cobalt drill bit. This can help prevent the larger bit from wandering and ensure a more accurate hole.

- Inspect the drill bit regularly: Check the cutting edges of the cobalt drill bit for signs of dullness or damage. Replace the bit if needed to maintain optimal performance.

Conclusion:

Cobalt drill bits are a reliable choice for drilling through stainless steel. Their heat resistance, hardness, and long lifespan make them suitable for the demanding nature of stainless steel drilling. Although they may be more expensive and slightly more brittle than other types of drill bits, with proper use and maintenance, cobalt drill bits can provide excellent results and precision.

Carbide Drill Bits

Carbide drill bits are widely considered the best option for drilling stainless steel due to their incredible hardness and durability. Made from a combination of tungsten carbide particles and a binder material, carbide drill bits offer excellent cutting performance and long-lasting service life. They are designed to handle the high heat and abrasion that drilling stainless steel often entails.

Carbide drill bits are available in various shapes and sizes, including twist drills, jobber drills, and other specialty designs. They come in both solid carbide and carbide-tipped variations. Solid carbide drill bits are made entirely of carbide material and are best suited for high-speed drilling with minimal feed rates. Carbide-tipped drill bits, on the other hand, have a carbide cutting edge brazed onto a steel body, offering a more affordable option while still providing excellent cutting performance.

When drilling stainless steel with carbide drill bits, it is essential to use the appropriate cutting speed and feed rate to prevent overheating and premature wear. Higher cutting speeds and lower feed rates are generally recommended for stainless steel compared to other materials. Using coolant or lubricant during the drilling process can also help dissipate heat and prolong the life of the carbide drill bit.

Although carbide drill bits are highly efficient and durable, they are typically more expensive than other types of drill bits. However, their exceptional performance and longevity make them a worthwhile investment for anyone regularly working with stainless steel.

Titanium Drill Bits

Titanium drill bits are a popular choice for drilling through stainless steel due to their durability and ability to maintain sharpness for a longer period of time. These drill bits are made from high-speed steel coated with a layer of titanium nitride, a hard and heat-resistant material that provides excellent protection and increases the lifespan of the drill bit.

Titanium drill bits are known for their ability to drill through tough materials such as stainless steel without getting dull quickly. They can also withstand high temperatures generated during the drilling process, reducing the chances of the drill bit overheating and losing its hardness. This makes them ideal for drilling into stainless steel, which is a hard and abrasive material.

Advantages of Titanium Drill Bits for Stainless Steel

- Durability: The titanium coating on these drill bits provides increased hardness and toughness, making them highly durable and resistant to wear and tear.

- Heat Resistance: Titanium nitride coating helps in dissipating heat generated during the drilling process, preventing the drill bit from overheating and losing its sharpness.

- Longevity: Titanium drill bits have a longer lifespan compared to regular drill bits, as the titanium nitride coating protects the cutting edges from abrasion and corrosion.

- Efficiency: The sharpness and hardness of titanium drill bits allow them to cut through stainless steel more efficiently, reducing the drilling time and effort required.

- Versatility: Titanium drill bits can be used for drilling through various materials including stainless steel, wood, plastic, and more. This makes them a versatile option for both DIY enthusiasts and professionals.

Choosing the Right Titanium Drill Bit

When selecting a titanium drill bit for drilling through stainless steel, there are a few factors to consider:

- Diameter: Choose a drill bit with the appropriate diameter for the hole you want to drill. It is essential to use the correct size to ensure a clean and precise hole.

- Length: Consider the length of the drill bit based on the depth of the hole you need to drill.

- Shank type: Check if the drill bit has a hex shank or a round shank, depending on the type of drill you will be using.

It is also important to use the right drilling technique to maximize the performance and lifespan of your titanium drill bits when drilling through stainless steel.

| Tip | Description |

|---|---|

| Use appropriate drilling speed | High speed is generally recommended for drilling stainless steel, but avoid excessive speed as it can cause overheating. |

| Apply steady pressure | Apply consistent and steady pressure while drilling to maintain control and prevent the bit from slipping or breaking. |

| Use lubrication | Applying a lubricant like cutting oil or a lubricant stick can help reduce friction and heat during the drilling process. |

| Clear chips frequently | Clear away the chips and debris from the hole using a brush or compressed air to prevent clogging and maintain a smooth drilling process. |

| Cool down the drill bit | If the drill bit starts to overheat, stop drilling and allow it to cool down before continuing. |

Diamond Drill Bits

Diamond drill bits are specifically designed for drilling holes in hard materials such as stainless steel. Instead of using traditional cutting edges, diamond drill bits feature a diamond-impregnated tip that creates friction to penetrate the material.

Advantages:

- Exceptional Hardness: Diamond is one of the hardest substances known to man, making diamond drill bits extremely durable and long-lasting.

- High Precision: Diamond drill bits offer excellent precision and can create clean, accurate holes without causing damage to the surrounding material.

- Efficient Performance: Due to their hardness and design, diamond drill bits are highly efficient and can drill through stainless steel quickly and effortlessly.

Disadvantages:

- Higher Cost: Diamond drill bits tend to be more expensive compared to other types of drill bits. However, their long lifespan and superior performance often make them worth the investment.

- Special Handling: Diamond drill bits require special handling and care to prevent damage to the diamond coating. They should be used at lower speeds and with appropriate cooling methods.

Best Practices for Using Diamond Drill Bits:

- Ensure the stainless steel surface is secure and clamped down to prevent movement during drilling.

- Begin drilling at a slow speed and gradually increase the speed as the hole deepens.

- Apply adequate water or coolant to the diamond drill bit to prevent overheating and prolong its lifespan.

- Use light, steady pressure while drilling to maintain control and prevent the bit from wandering.

- Regularly inspect the diamond drill bit for signs of wear or damage. Replace if necessary to maintain optimal performance.

Conclusion:

Diamond drill bits are the ideal choice for drilling holes in stainless steel due to their exceptional hardness, precision, and efficiency. Although they may come at a higher cost, their durability and performance make them a worthwhile investment for any industrial or DIY project.

Factors to Consider When Choosing a Drill Bit

When working with stainless steel, it is important to choose the right drill bit to ensure the best results. Here are some important factors to consider when choosing a drill bit:

- Material of the Drill Bit: The drill bit must be made of a material that is suitable for drilling through stainless steel. High-speed steel (HSS) drill bits are a popular choice for stainless steel drilling due to their hardness and heat resistance.

- Drill Bit Coating: Some drill bits come with a coating that improves their performance and prolongs their lifespan. Titanium nitride (TiN) and black oxide coatings offer increased hardness and higher resistance to wear and heat.

- Drill Bit Size: The drill bit size should be chosen based on the specific application. It is important to select a drill bit that is capable of creating a hole of the desired diameter without causing excessive heat or strain.

- Drill Bit Point Angle: The point angle of the drill bit affects the drilling performance. For stainless steel, a drill bit with a point angle between 135 and 140 degrees is recommended to reduce the chance of the bit wandering or skating on the surface.

- Flute Design: The flute design of the drill bit affects chip evacuation. For stainless steel, a drill bit with a helical flute design is preferable as it helps in removing chips from the hole more effectively.

- Speed and Feed Rate: The speed and feed rate at which the drill bit is used also play a crucial role in achieving optimal results. It is important to follow the manufacturer’s recommendations regarding the speed and feed rate for drilling stainless steel.

- Drilling Lubricant: Using a drilling lubricant or cutting fluid is highly recommended when drilling stainless steel. It helps in reducing heat buildup and prolongs the life of the drill bit.

By considering these factors, you can choose the right drill bit for your stainless steel drilling needs and achieve precise, clean, and efficient results.

Material and Hardness of Stainless Steel

Stainless steel is a commonly used material in various applications due to its corrosion resistance and durability. However, not all stainless steel is the same. There are different types and grades of stainless steel, each with its own characteristics and properties.

Types of Stainless Steel

Stainless steel is categorized into different types based on their microstructure. The two main types of stainless steel are:

- Austenitic Stainless Steel: This type of stainless steel is non-magnetic and contains high levels of chromium and nickel. It is known for its excellent corrosion resistance and high ductility. Austenitic stainless steel is often used in applications where corrosion resistance is critical, such as in the food industry and pharmaceutical industry.

- Ferritic Stainless Steel: Ferritic stainless steel is magnetic and contains a lower level of nickel compared to austenitic stainless steel. It has a higher carbon content and is known for its good resistance to stress corrosion cracking. Ferritic stainless steel is commonly used in automotive exhaust systems and architectural applications.

Grades of Stainless Steel

In addition to different types, stainless steel is also classified into different grades. The grade of stainless steel indicates its chemical composition and physical properties. Some common grades of stainless steel include:

- 304/304L: This is the most commonly used grade of stainless steel and is often referred to as “18-8” stainless steel. It contains 18% chromium and 8% nickel, and offers good corrosion resistance and weldability.

- 316/316L: This grade of stainless steel is commonly used in marine environments due to its high corrosion resistance. It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

- 430: This is a ferritic stainless steel grade, known for its good corrosion resistance and magnetic properties. It contains 16-18% chromium and has limited weldability.

Hardness of Stainless Steel

The hardness of stainless steel is an important factor to consider when choosing a drill bit for stainless steel. Stainless steel can range in hardness from relatively soft to very hard, depending on its composition and treatment.

The hardness of stainless steel is typically measured using the Rockwell hardness scale. Common hardness scales used for stainless steel include HRC (Rockwell C) and HRB (Rockwell B). A higher hardness value indicates a harder material, which may require a more robust and specialized drill bit.

It is important to consult the manufacturer’s specifications or conduct hardness testing to determine the appropriate drill bit for the specific stainless steel material being drilled.

Drill Bit Coatings and Treatments

When it comes to drilling through stainless steel, using the right drill bit is crucial. However, the type of drill bit alone is not always enough. Certain coatings and treatments can significantly improve the performance and longevity of the drill bit, especially when drilling through tough materials such as stainless steel.

Coatings

Coatings are applied to drill bits to enhance their hardness, lubricity, and thermal resistance. Here are some common coatings used for drill bits:

- Titanium Nitride (TiN): This golden-colored coating provides excellent hardness and lubricity, reducing friction between the drill bit and the stainless steel. TiN-coated drill bits are known for their long life and resistance to wear.

- Titanium Carbonitride (TiCN): Similar to TiN, TiCN offers improved hardness and wear resistance. It has a dark gray color and provides better thermal stability, making it suitable for high-speed drilling.

- Titanium Aluminum Nitride (TiAlN): This coating combines the advantages of TiN and AlTiN, offering excellent heat resistance, hardness, and lubricity. TiAlN-coated drill bits are ideal for drilling through stainless steel at high speeds.

- Diamond-like Carbon (DLC): DLC coatings provide high hardness and low friction, allowing for smooth drilling through stainless steel. They are especially effective when drilling at high temperatures.

Treatments

In addition to coatings, drill bits can undergo various treatments to improve their performance. Here are some common treatments for stainless steel drill bits:

- Heat Treatment: Heat treatment involves subjecting the drill bit to high temperatures and then cooling it rapidly to increase its hardness and strength. This treatment helps to prevent the drill bit from dulling quickly when drilling through stainless steel.

- Cryo Treatment: Cryo treatment involves freezing the drill bit at extremely low temperatures to enhance its hardness and wear resistance. It can significantly increase the lifespan of the drill bit when drilling through tough materials.

- Surface Treatment: Surface treatments, such as shot peening or nitriding, can be applied to the drill bit to increase its surface hardness and resistance to wear and corrosion. These treatments help the drill bit maintain its sharpness and performance during drilling.

Remember, the choice of coating or treatment depends on the specific drilling application and the type of stainless steel being drilled. It is important to select the right combination of coating and treatment to ensure the drill bit performs optimally and lasts longer.

| Coating/Treatment | Advantages | Disadvantages |

|---|---|---|

| Titanium Nitride (TiN) | Excellent hardness and lubricity | May not be effective for high-speed drilling |

| Titanium Carbonitride (TiCN) | Improved hardness and wear resistance | Higher cost compared to other coatings |

| Titanium Aluminum Nitride (TiAlN) | Excellent heat resistance, hardness, and lubricity | Relatively higher cost |

| Diamond-like Carbon (DLC) | High hardness and low friction | Higher cost compared to other coatings |

| Heat Treatment | Increased hardness and strength | Requires specialized equipment and techniques |

| Cryo Treatment | Enhanced hardness and wear resistance | Requires specialized equipment and careful handling |

| Surface Treatment | Increased surface hardness and resistance to wear | May alter the dimensions of the drill bit |

FAQ:

Why is it important to choose the right drill bit for stainless steel?

Choosing the right drill bit for stainless steel is important because stainless steel is a hard material that can easily damage or break regular drill bits. Using a specialized drill bit designed specifically for stainless steel ensures clean and precise cuts without damaging the material or the drill bit.

What types of drill bits are suitable for stainless steel?

There are several types of drill bits that are suitable for stainless steel, including cobalt drill bits, carbide drill bits, and titanium-coated drill bits. These drill bits are specifically designed to withstand the hardness and heat generated when drilling through stainless steel.

How do I choose the right size of drill bit for stainless steel?

To choose the right size of drill bit for stainless steel, you should consider the thickness of the material you are drilling. It’s important to select a drill bit with a diameter slightly smaller than the size of the hole you want to create. This ensures that the drill bit can easily penetrate the stainless steel without causing excessive heat or pressure.

What are some tips for drilling through stainless steel?

When drilling through stainless steel, it’s important to use cutting fluid or lubricant to reduce friction and heat. This helps to prolong the life of the drill bit and ensures a cleaner cut. Additionally, it’s recommended to use a slower drilling speed to prevent overheating and avoid putting excessive pressure on the drill bit.

Video: