Choosing the Right Drill Bit for Plexiglass: A Comprehensive Guide

When it comes to drilling holes in plexiglass, using the right drill bit is crucial. Plexiglass, also known as acrylic glass, is a popular material in various applications due to its durability, transparency, and lightweight nature. However, it requires special care when drilling to prevent cracks and chips.

There are several types of drill bits available for drilling plexiglass, each with its own set of advantages and disadvantages. The most commonly recommended drill bits for plexiglass are spiral drill bits and brad point drill bits.

Spiral drill bits are ideal for drilling clean holes in plexiglass. They have a pointed tip and a fluted design, which helps to remove material efficiently. The spiral design also prevents the bit from grabbing or slipping, reducing the risk of cracking or chipping the plexiglass.

Brad point drill bits, on the other hand, are designed with a sharp, pointed tip that helps to accurately position the hole before drilling. These bits also have a centering spur that prevents the bit from wandering, ensuring a clean and precise hole. However, they may cause more chipping compared to spiral drill bits.

Before drilling, it is important to secure the plexiglass firmly to prevent it from vibrating or moving during drilling. You should also use a low speed and apply steady pressure to avoid overheating the material. Additionally, using lubrication such as water or cutting oil can help to reduce friction and prevent cracks.

Understanding Plexiglass and Its Properties

Plexiglass, also known as acrylic glass or Perspex, is a popular material in various industries due to its versatility and unique properties.

Transparency

Plexiglass offers excellent transparency, allowing for high clarity and visibility. It can transmit up to 92% of visible light, making it a popular choice for applications where optical clarity is essential, such as windows, displays, and signage.

Durability

Plexiglass is highly durable and resistant to impact, making it a suitable choice for applications that require strength and reliability. It is around 17 times stronger than glass, yet only half the weight, making it easier to handle and install.

Weatherability

Plexiglass is designed to withstand various weather conditions and can resist fading, cracking, and yellowing caused by sunlight exposure. This weatherability makes it an ideal material for outdoor applications such as skylights, greenhouses, and outdoor signs.

Chemical Resistance

Plexiglass has good resistance to a wide range of chemicals, including many solvents and cleaning agents. This property makes it suitable for applications where exposure to chemicals is expected, such as laboratory equipment, chemical storage, and protective barriers.

Machinability

Plexiglass is relatively easy to machine and shape, making it a versatile material for various fabrication processes. It can be cut, drilled, sawed, and machined using standard tools, allowing for customization and precise manufacturing.

Thermal Stability

Plexiglass has good thermal stability and can withstand high temperatures without significant deformation, up to around 160°C (320°F). This property makes it suitable for applications that involve heat, such as oven windows, automotive components, and lighting fixtures.

Understanding the properties of plexiglass is crucial when selecting the right drill bit. By considering the specific characteristics of the material, you can ensure efficient and effective drilling without causing damage or compromising the integrity of the plexiglass.

Importance of Using the Correct Drill Bit

When it comes to drilling plexiglass, using the correct drill bit is of utmost importance. Plexiglass, also known as acrylic glass, is a versatile material commonly used in various applications, including signage, windows, and even furniture. However, drilling plexiglass can be a bit tricky and requires special attention to avoid cracking or damaging the material.

The correct drill bit is crucial for drilling plexiglass because it helps to reduce the risk of chipping, cracking, or melting the material. Plexiglass has a tendency to crack easily, especially if too much pressure or heat is applied during drilling. Using the wrong drill bit can easily cause these problems, leading to a damaged or unusable piece of plexiglass.

One important aspect to consider when choosing a drill bit for plexiglass is the type of cutting edge it has. Drill bits specifically designed for use with plexiglass typically have a sharp and pointed tip, which helps to create a clean and precise hole without putting excessive pressure on the material. These types of drill bits also have a high helix angle, allowing for efficient chip removal and reducing the chances of heat buildup.

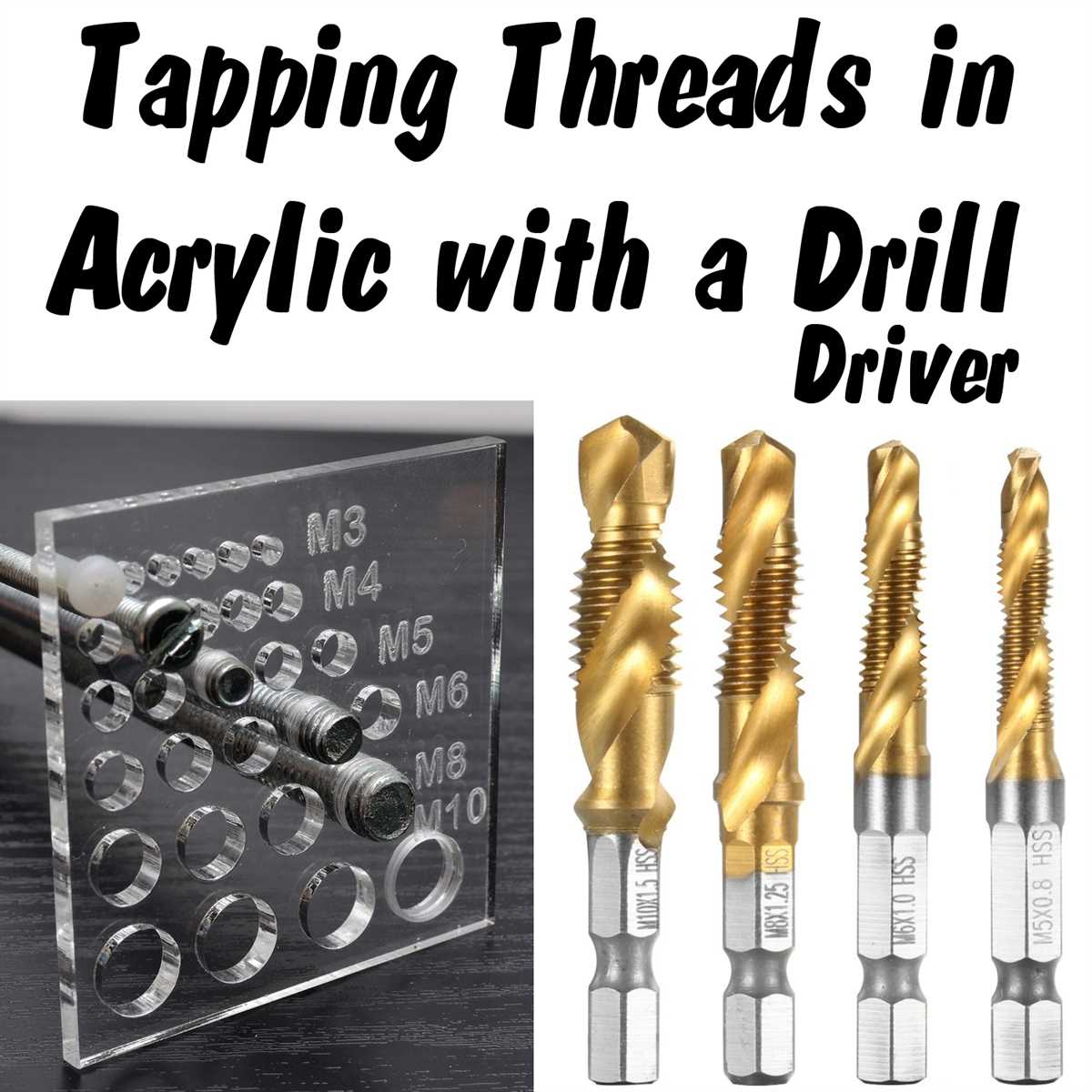

Additionally, the material of the drill bit is important to consider. High-speed steel (HSS) or carbide drill bits are commonly recommended for drilling plexiglass due to their durability and ability to withstand high speeds and heat. These types of drill bits can also provide a smoother and cleaner cut, minimizing the risk of cracking or chipping the plexiglass.

Using the correct drill bit also helps to ensure the longevity and effectiveness of your tools. When you use the wrong drill bit, it can quickly become dull or even break, resulting in wasted time and money. By using the correct drill bit, you can preserve the lifespan of your drill bits and avoid unnecessary replacements.

In conclusion, choosing the correct drill bit is vital when drilling plexiglass. It helps to prevent cracking, chipping, and melting, ensuring a clean and precise hole. Using a drill bit with a sharp cutting edge and the right material will provide better results and preserve the lifespan of your tools. Remember to always take the time to select the appropriate drill bit for the job to achieve optimal outcomes when working with plexiglass.

Factors to Consider When Choosing a Drill Bit

When choosing a drill bit for working with plexiglass, it is important to consider several factors to ensure a clean and accurate result. Below are some key factors to consider:

- Material: Choose a drill bit that is specifically designed for working with plexiglass or other acrylic materials. These drill bits are made of materials such as carbide or diamond, which are harder than plexiglass and can cut through it effectively without causing cracks or chips.

- Size: The size of the hole you need to drill will determine the size of the drill bit you should choose. Make sure to select a drill bit that matches the size requirements of your project.

- Point Angle: The point angle of a drill bit refers to the angle at the tip of the bit. For plexiglass, it is recommended to use drill bits with a point angle of 60 degrees or more. This helps reduce the risk of chipping or cracking the material during drilling.

- Flute Design: The flute design of a drill bit affects its ability to remove debris and prevent overheating. Look for drill bits with wide and open flutes, as they are more efficient at clearing away chips and keeping the drill bit cool.

- Coating: Some drill bits for plexiglass come with a coating that helps reduce friction and heat buildup. Look for drill bits with coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) for improved performance and longevity.

By considering these factors when choosing a drill bit, you can ensure a smooth and precise drilling process when working with plexiglass.

Types of Drill Bits Suitable for Plexiglass

Plexiglass, also known as acrylic, is a versatile material that is commonly used in various applications, such as windows, signs, and displays. When drilling through plexiglass, it is important to use the right type of drill bit to avoid cracking or damaging the material. Here are some types of drill bits that are suitable for drilling plexiglass:

1. Brad Point Bits

Brad point bits are the most commonly used drill bits for drilling plexiglass. They feature a sharp, pointed tip that helps to prevent the bit from wandering, ensuring accurate drilling. The flutes on brad point bits also help to remove chips and shavings from the hole.

2. Spade Bits

Spade bits, also known as paddle bits, can be used to drill through plexiglass, especially for larger diameter holes. These bits have a flat, paddle-like tip and a wide cutting edge that helps to create clean, smooth holes in the material.

3. Twist Bits

Twist bits, also known as high-speed steel (HSS) bits, are another option for drilling plexiglass. However, caution must be taken when using twist bits, as they can cause the material to crack or chip if not used properly. It is recommended to use a slower drill speed and apply gentle pressure when using twist bits on plexiglass.

4. Forstner Bits

Forstner bits are often used for drilling clean, flat-bottomed holes in woodworking, but they can also be used for plexiglass. These bits have a center point and flat cutting edges that create precise holes with little to no tear-out. Forstner bits are especially useful when drilling larger diameter holes in plexiglass.

Remember to use proper safety precautions when drilling plexiglass, such as wearing safety glasses and securing the material to prevent it from moving. It is also advisable to start with a small pilot hole before drilling the final hole to reduce the risk of cracking. Choosing the right drill bit and using the correct drilling techniques will help to ensure a successful drilling experience with plexiglass.

Common Mistakes to Avoid When Drilling Plexiglass

- Not using the right drill bit: One of the most common mistakes when drilling plexiglass is using the wrong type of drill bit. Plexiglass is a delicate material that can crack and shatter easily if you use a regular drill bit. Instead, use a drill bit specifically designed for drilling plexiglass, such as a brad point or an acrylic cutting bit. These bits have a sharper point and are less likely to cause damage to the material.

- Not using the correct drill speed: Plexiglass requires a slower drill speed compared to drilling through other materials like wood or metal. Using a high drill speed can generate too much heat, leading to melting or cracking of the plexiglass. It is recommended to set your drill to a low speed and apply gentle pressure to avoid overheating and damage to the material.

- Not securing the plexiglass: When drilling plexiglass, it is important to properly secure the material to prevent it from vibrating or moving during the drilling process. Failure to do so can cause the drill bit to catch or slip, resulting in uneven holes or cracks. Use clamps or a vice to hold the plexiglass firmly in place before drilling.

- Not lubricating the drill bit: Plexiglass can generate a significant amount of heat when being drilled. To reduce heat buildup and prevent the material from melting or cracking, it is crucial to use a lubricant while drilling. Apply a small amount of cutting fluid, soap, or even water to the drill bit before drilling into the plexiglass. This will help to cool down the bit and provide lubrication, making the drilling process smoother and safer.

- Not using adequate pressure: Applying too much pressure while drilling plexiglass can cause the material to crack or shatter. On the other hand, using too little pressure can result in the drill bit skidding or creating a rough hole. Maintain a steady and moderate amount of pressure on the drill while drilling. This will help to prevent any unnecessary damage to the plexiglass.

- Not wearing safety gear: Plexiglass can produce small shards and debris while being drilled. To protect yourself from potential eye injuries or skin irritation, always wear safety goggles and gloves. It is also recommended to work in a well-ventilated area to avoid inhaling any dust or fumes generated during the drilling process.

Step-by-Step Guide to Drilling Plexiglass

1. Gather the necessary tools and materials

Before you begin drilling plexiglass, it’s important to gather all the tools and materials you will need. Make sure you have the following:

- Plexiglass sheet

- Power drill

- Drill bit specifically designed for plexiglass or acrylic

- Masking tape or painter’s tape

- Wax or cutting fluid (optional)

- Clamp or vise to secure the plexiglass

- Safety goggles

2. Mark the drilling spots

Using a pencil or marker, make small marks on the plexiglass where you want to drill your holes. Take measurements and ensure the marks are evenly spaced and aligned properly.

3. Secure the plexiglass

Place the plexiglass sheet on a stable surface and use a clamp or vise to secure it firmly. This will prevent the sheet from moving while you drill and minimize the chances of cracking or splintering.

4. Apply masking tape

Take a strip of masking tape or painter’s tape and place it over the area where you will be drilling. This will help reduce the risk of chipping or splintering during the drilling process.

5. Prepare the drill bit

Choose a drill bit specifically designed for drilling plexiglass or acrylic. Before using it, check if it is in good condition and free from any damage. If desired, apply a small amount of wax or cutting fluid to the drill bit to lubricate it and reduce friction.

6. Set the drill speed

Set your power drill to a low speed. High speeds can generate excessive heat and damage the plexiglass. It’s better to use slower speeds to prevent melting or cracking. Refer to the manufacturer’s instructions for the appropriate speed setting.

7. Start drilling

Position the drill bit on one of the marked spots and gently apply steady pressure. Start drilling at a low speed, gradually increasing it as you go. Take your time and avoid forceful drilling, as this can lead to cracking or chipping. Let the drill bit do the work.

8. Use a backing material

If you are drilling completely through the plexiglass, place a piece of scrap wood or another soft material underneath to prevent chipping or splintering as the drill bit exits the other side.

9. Remove the masking tape

Once you have completed drilling all the holes, carefully remove the masking tape from the plexiglass sheet. Peel it off slowly and gently to avoid any damage or residue on the surface.

10. Clean up

After drilling is complete, clean the plexiglass sheet to remove any debris or dust. Use a soft cloth and a gentle cleaner specifically designed for plexiglass or acrylic. Avoid using harsh chemicals or abrasive materials that can scratch or damage the surface.

Following these steps will help you safely and effectively drill plexiglass without causing any damage. Remember to always wear safety goggles and work in a well-ventilated area when working with power tools.

Maintenance and Care for Drill Bits

1. Regular Cleaning

After each use, it is important to clean your drill bits to remove any debris or residue that may have accumulated. This can be done by using a soft cloth or brush to wipe away any dirt or dust. Avoid using harsh chemicals or solvents, as they can damage the coating or material of the drill bit.

2. Sharpening

Over time, drill bits can become dull and less effective. To ensure optimal performance, it is recommended to regularly sharpen your drill bits. This can be done using a drill bit sharpener or a grinding wheel. Follow the manufacturer’s instructions for sharpening your specific type of drill bit.

3. Storage

Proper storage is essential to prevent damage to your drill bits. Make sure to store them in a dry and clean place, away from moisture or extreme temperatures. It is also a good idea to keep them in a case or organizer to prevent them from getting lost or damaged.

4. Lubrication

Using a lubricant can help reduce friction and heat buildup during drilling, which can prolong the lifespan of your drill bits. Apply a small amount of lubricant to the drill bit before each use. Be sure to choose a lubricant that is suitable for the material you are drilling into.

5. Inspect for Damage

Before each use, inspect your drill bits for any signs of damage or wear. Look for chips, cracks, or other abnormalities that may affect their performance. If you notice any damage, it is recommended to replace the drill bit with a new one to ensure safe and efficient drilling.

6. Use the Right Speed and Pressure

Using the correct speed and pressure while drilling can help prevent overheating and excessive wear on your drill bits. Consult the manufacturer’s recommendations for the optimal speed and pressure settings for your specific type of drill bit and material.

7. Replace When Necessary

Drill bits, especially those made of softer materials, will eventually wear out and become less effective. If you notice a significant decrease in performance or if the drill bit is visibly damaged, it is time to replace it. Using a worn-out drill bit can lead to poor results and potential accidents.

| Step | Action |

|---|---|

| 1 | Regular cleaning with a soft cloth or brush |

| 2 | Sharpening as needed |

| 3 | Proper storage in a dry and clean place |

| 4 | Applying lubricant before each use |

| 5 | Inspecting for damage before each use |

| 6 | Using the right speed and pressure while drilling |

| 7 | Replacing worn-out or damaged drill bits |

Choosing the Right Drill Bit Supplier for Plexiglass Projects

1. Quality

When choosing a drill bit supplier for plexiglass projects, it is important to prioritize quality. Look for suppliers that offer drill bits made from high-quality materials such as carbide or diamond. These materials are known for their durability and ability to handle the unique characteristics of plexiglass.

2. Variety

Another important factor to consider when selecting a drill bit supplier for plexiglass projects is the variety of drill bits they offer. Different projects may require specific types or sizes of drill bits, so it is beneficial to choose a supplier that offers a wide range of options. This way, you can easily find the drill bits that best suit your needs.

3. Experience

Experience is also crucial when choosing a drill bit supplier for plexiglass projects. Look for suppliers that have been in the industry for a significant amount of time and have a proven track record of providing high-quality drill bits. This demonstrates their expertise and knowledge in the field.

4. Customer Reviews

Reading customer reviews and testimonials can give you valuable insights into the reliability and performance of a drill bit supplier. Look for suppliers that have positive reviews and satisfied customers. This can help ensure that you are choosing a supplier that consistently delivers satisfactory products and services.

5. Price

While price should not be the sole determining factor, it is still important to consider when selecting a drill bit supplier for plexiglass projects. Compare prices from different suppliers and consider the quality and variety they offer in relation to their prices. This will help you find a supplier that offers a balance between affordability and quality.

6. Additional Services

Consider whether the drill bit supplier offers any additional services that may be beneficial for your plexiglass projects. For example, some suppliers may provide sharpening or customization services. These additional services can add value to your purchase and make the supplier more convenient to work with.

7. Warranty

Finally, inquire about the warranty or guarantee offered by the drill bit supplier. A reputable supplier will stand behind their products and offer a warranty that protects against defects or faulty materials. This provides added peace of mind and ensures that you can rely on the supplier in case of any issues.

By considering these factors and conducting thorough research, you can choose the right drill bit supplier for your plexiglass projects and ensure that you have the necessary tools for success.

FAQ:

What is plexiglass?

Plexiglass is a transparent, lightweight, and durable plastic material that is used as an alternative to glass in various applications.

Why is it important to choose the right drill bit for plexiglass?

Choosing the right drill bit is important because using the wrong bit can cause the plexiglass to crack, chip, or shatter.

What type of drill bit is suitable for drilling plexiglass?

A brad point or a twist drill bit with a sharp, pointed tip is most suitable for drilling plexiglass.

What precautions should I take when drilling plexiglass?

Some precautions to take when drilling plexiglass include clamping the material down securely, using a slow drilling speed, and cooling the drill bit with water or lubricant.

Can I use a regular drill bit for plexiglass?

While it is possible to use a regular drill bit for plexiglass, it is not recommended as it increases the risk of the material cracking or shattering.

Video: