Choosing the Right Drill Bit for Metal: A Comprehensive Guide

When it comes to drilling into metal, using the right drill bit is essential. Metal is a tough material that requires specialized tools to work with, and using the wrong drill bit can result in damaged bits, wasted time, and frustration. In this comprehensive guide, we will walk you through everything you need to know about choosing the right drill bit for metal.

Types of Drill Bits for Metal:

There are several types of drill bits that are suitable for drilling into metal. The most common types include twist drill bits, step drill bits, and hole saws. Twist drill bits are the most versatile option and are ideal for drilling small holes in metal. Step drill bits are designed for drilling larger holes with different diameters, making them perfect for tasks that require a range of hole sizes. Hole saws, on the other hand, are best suited for cutting larger holes in metal.

Factors to Consider:

When choosing a drill bit for metal, there are several factors to consider. The first is the material you will be drilling into. Different metals have different hardness levels, so it’s important to choose a drill bit that can handle the specific metal you are working with. The second factor to consider is the size of the hole you need to drill. Different drill bits are designed to create different sized holes, so be sure to choose one that matches your needs.

Pro Tip: Always use a cutting lubricant when drilling into metal. This will help to reduce heat and friction, which can cause the drill bit to wear out more quickly.

Choosing the Right Drill Bit:

To choose the right drill bit for metal, start by determining the type of metal you will be drilling into. Then, consider the size of the hole you need to drill and the type of drill bit that will best suit your needs. It’s also important to consider the quality of the drill bit – investing in a high-quality bit will ensure better performance and longer life. Finally, don’t forget to use a cutting lubricant to extend the life of your drill bit and improve drilling efficiency.

Understanding Drill Bit Materials for Metal

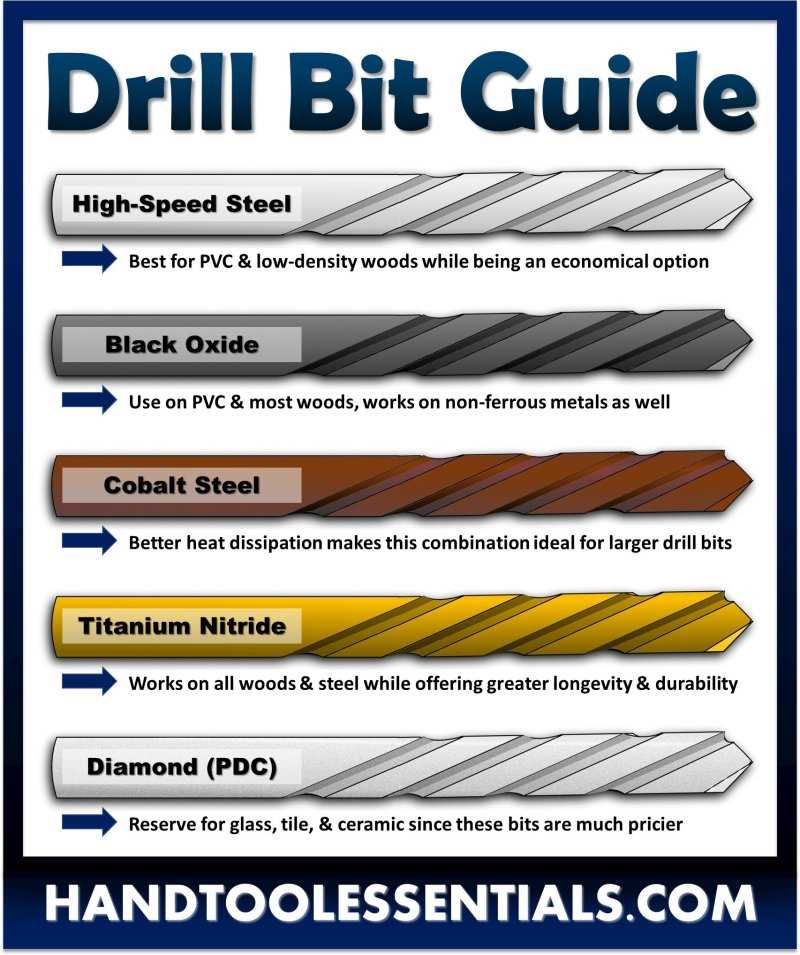

When it comes to drilling through metal, choosing the right drill bit material is crucial for achieving clean and efficient results. Different materials offer varying levels of durability, heat resistance, and cutting performance. Here are some common materials used for drill bits designed specifically for metal:

1. High-Speed Steel (HSS)

- High-speed steel (HSS) is one of the most commonly used materials for drill bits.

- HSS drill bits are suitable for drilling through most metals, including stainless steel and cast iron.

- They are durable, affordable, and can withstand high drilling speeds and temperatures.

2. Cobalt Steel

- Drill bits made from cobalt steel are known for their excellent heat resistance.

- These bits can withstand high temperatures generated during drilling, making them ideal for drilling hard metals like stainless steel, cast iron, and titanium.

- However, cobalt steel bits are more expensive than HSS bits.

3. Carbide-Tipped

- Carbide-tipped drill bits have a strong steel body with a carbide insert at the tip.

- They are extremely hard and can cut through even the toughest metals, including hardened steel and masonry.

- Carbide-tipped bits are more expensive than HSS or cobalt bits but offer superior longevity and cutting performance.

4. Titanium Coated

- Titanium-coated drill bits have a thin layer of titanium nitride coating.

- This coating improves the hardness and heat resistance of the drill bit.

- These bits are suitable for drilling through softer metals like aluminum and copper.

- However, they may not be as effective for drilling through harder metals.

5. HSS with Cobalt

- HSS with cobalt drill bits, also known as HSS-Co bits, are made from a combination of high-speed steel and cobalt.

- These bits offer a good balance of durability and heat resistance.

- HSS with cobalt bits are suitable for drilling through a wide range of metals, including stainless steel and aluminum.

Choosing the right drill bit material will depend on the specific metal you are working with, the intended application, and the desired level of performance. It is essential to consider these factors carefully to ensure optimal drilling results.

High-Speed Steel Drill Bits

High-speed steel (HSS) drill bits are among the most common and versatile types of drill bits used for metal. They are made from a type of tool steel known as high-speed steel, which contains a combination of tungsten, chromium, vanadium, and carbon. This composition gives HSS drill bits several important properties that make them suitable for drilling through metal.

Advantages of High-Speed Steel Drill Bits

- Toughness: HSS drill bits are known for their toughness, which allows them to withstand the high heat generated during drilling. This toughness helps to prevent the bits from becoming dull or chipped, ensuring a longer lifespan and improved performance.

- High-Speed Performance: As their name suggests, HSS drill bits are designed to operate at high speeds. They can handle rapid drilling without overheating, making them ideal for quick and efficient drilling through metal.

- Versatility: HSS drill bits are suitable for drilling through various types of metal, including steel, aluminum, brass, and copper. They can also be used for drilling through wood and plastic, making them a versatile choice for different projects.

- Cost-Effective: High-speed steel drill bits are generally more affordable compared to other types of drill bits, such as cobalt or carbide. This makes them a cost-effective option, especially for DIY enthusiasts or those on a budget.

Limitations of High-Speed Steel Drill Bits

While HSS drill bits offer many advantages, they do have a few limitations:

- Not Ideal for Hardened Steel: Although HSS drill bits are suitable for drilling through most types of metal, they are not recommended for drilling through hardened steel or other hardened materials. For such applications, specialized drill bits like cobalt or carbide are more appropriate.

- Can Dull Over Time: Despite their toughness, HSS drill bits can still become dull over time, especially when used for intensive drilling. Regular sharpening or replacing of the bits may be necessary to maintain their cutting performance.

- Not Suitable for High-Torque Applications: HSS drill bits are not designed to handle high-torque applications, such as drilling through thick or solid metal plates. In such cases, a more powerful drill and specialized drill bit are recommended.

Overall, high-speed steel drill bits are a versatile and cost-effective option for drilling through metal. They offer a balance of toughness, speed, and versatility that makes them suitable for various projects. However, it’s important to consider the specific requirements of your project and material before choosing the right drill bit.

Cobalt Drill Bits

Cobalt drill bits are made from a special type of high-speed steel that contains cobalt as an alloying element. This makes them much harder and more heat-resistant than standard high-speed steel drill bits. Cobalt drill bits are designed for drilling through tough and hard materials, such as stainless steel, cast iron, and titanium.

Advantages of Cobalt Drill Bits

- Hardness: Cobalt drill bits are extremely hard, which allows them to maintain their cutting edge for longer periods of time, even when drilling through hard materials.

- Heat Resistance: Thanks to their high cobalt content, these drill bits can withstand high temperatures without losing their hardness or becoming dull. This makes them ideal for high-speed drilling applications.

- Sharper Cutting Edge: Cobalt drill bits have a sharper cutting edge compared to standard drill bits. This allows for faster and more efficient drilling, especially in tough materials.

- Reduced Breakage: The increased hardness and heat resistance of cobalt drill bits make them less prone to breaking or chipping, resulting in longer tool life.

Applications

Cobalt drill bits are commonly used in the following applications:

- Drilling through stainless steel, cast iron, and other tough metals

- Creating holes in hardened surfaces

- Drilling into heat-treated materials

- Industrial and automotive applications

- Construction and metalworking projects

Tips for Using Cobalt Drill Bits

- Use a slow speed and apply consistent, firm pressure to prevent overheating and extending the life of the drill bit.

- Use cutting fluid or lubricant to further reduce heat and friction during drilling.

- Consider using a pilot hole when drilling into hard materials to prevent the drill bit from walking or wandering.

- Keep the drill bit cool by periodically dipping it in water or using a cooling agent.

- Store cobalt drill bits separately from other drill bits to avoid potential damage or contamination.

In conclusion, cobalt drill bits are an excellent choice for drilling through tough metals and hard materials. Their hardness, heat resistance, and sharp cutting edge make them essential tools for professionals and DIY enthusiasts alike.

Carbide Drill Bits

Carbide drill bits are a popular choice for drilling into metal due to their durability and strength. They are made from a combination of tungsten carbide and cobalt, which gives them their hard-wearing properties.

Carbide drill bits are specifically designed to cut through tough materials like hardened steel, cast iron, and stainless steel. They have a sharp cutting edge that allows them to penetrate the metal with ease. This makes them ideal for use in heavy-duty applications where other drill bits may struggle.

Advantages of Carbide Drill Bits

- Durability: Carbide drill bits are extremely durable and can withstand high temperatures and pressures. This means they are less likely to break or wear out quickly, making them a cost-effective choice in the long run.

- Speed: Carbide drill bits have excellent cutting speeds and can drill through metal faster than other types of drill bits. This can save you time and effort when working on metal projects.

- Versatility: Carbide drill bits can be used on a variety of metal surfaces, including stainless steel, cast iron, and hardened steel. This makes them a versatile option for both DIY enthusiasts and professionals.

Considerations when Using Carbide Drill Bits

- Proper Lubrication: When using carbide drill bits, it is important to use a lubricant to reduce friction and heat buildup. This will help extend the life of the drill bit and improve cutting performance.

- Proper Technique: To get the best results with carbide drill bits, it is essential to use the right drilling technique. This includes starting with a small pilot hole and gradually increasing the size, using moderate pressure, and maintaining a consistent drilling speed.

- Wear Safety Gear: When working with carbide drill bits, it is important to wear appropriate safety gear, including safety glasses, gloves, and ear protection. This will help protect you from any potential hazards.

Overall, carbide drill bits are an excellent choice for drilling into metal due to their durability, cutting speed, and versatility. By following proper drilling techniques and taking necessary safety precautions, you can achieve accurate and efficient results with these drill bits.

Considerations for Drill Bit Size and Shape

When choosing a drill bit for metal, one of the most important considerations is the size and shape of the bit. These factors can greatly affect the effectiveness and efficiency of drilling. Here are some considerations to keep in mind:

1. Diameter

The diameter of the drill bit determines the size of the hole it will make in the metal. The size of the hole needed will depend on the specific application. It’s important to select a drill bit with the appropriate diameter to ensure a proper fit for screws or other fasteners.

2. Length

The length of the drill bit is another factor to consider. It determines the depth of the hole that can be drilled. Longer drill bits are necessary for drilling deep holes, while shorter ones are ideal for shallow holes.

3. Point Angle

The point angle refers to the angle at the tip of the drill bit. It affects the cutting action and the ability to penetrate the metal. Common point angles for metal drilling bits range from 118 to 135 degrees. The appropriate point angle will depend on the type of metal being drilled and the desired drilling speed.

4. Flute Design

The flute design of a drill bit refers to the number and shape of the grooves that run along the length of the bit. Flutes help to remove chips and debris from the hole being drilled. For metal drilling, straight flutes or spiral flutes are commonly used. Straight flutes are suitable for drilling shallow holes, while spiral flutes work well for deep holes and better chip evacuation.

5. Coating

Drill bits for metal are often coated with a material that provides wear resistance and reduces friction. Common coatings include titanium nitride (TiN), cobalt, and black oxide. These coatings help prolong the life of the drill bit and improve its performance.

By considering the size and shape of the drill bit, you can ensure that you select the right tool for your metal drilling needs. Taking these factors into account will help you achieve accurate and efficient drilling results.

Twist Drill Bits

- Twist drill bits are the most common type of drill bits used for metal.

- They have a spiral fluted design, which helps in removing chips and debris from the hole.

- Twist drill bits are available in various materials, such as high-speed steel (HSS), cobalt, and carbide.

- HSS twist drill bits are the most commonly used for general-purpose drilling in metal.

- They are affordable and provide good performance in most applications.

When choosing a twist drill bit for metal, consider the following factors:

- Diameter: The diameter of the drill bit determines the size of the hole that will be drilled. Choose a drill bit with the appropriate diameter for your specific application.

- Length: The length of the drill bit determines how deep the hole can be drilled. Ensure that the length of the drill bit is sufficient for the depth of the hole you need.

- Material: Different materials require different drill bits. HSS twist drill bits can handle most metal drilling tasks. However, if you are drilling harder metals, such as stainless steel or titanium, consider using cobalt or carbide twist drill bits for better performance.

- Coating: Some twist drill bits come with coatings, such as titanium nitride (TiN) or black oxide. These coatings help reduce friction and increase the lifespan of the drill bit.

It’s important to use the appropriate drilling technique when using twist drill bits for metal:

- Mark the spot where you want to drill the hole.

- Use a center punch to create a small indentation at the center of the mark. This will help the drill bit stay centered during drilling.

- Secure the metal piece in a vise or clamp it down to prevent it from moving.

- Apply cutting fluid or oil to the area being drilled to lubricate and cool the drill bit.

- Start drilling at a low speed and gradually increase the speed as the hole gets deeper.

- Apply steady, firm pressure while drilling to avoid overheating the drill bit and workpiece.

- Periodically withdraw the drill bit to remove chips and debris from the hole.

- Once the desired depth is reached, slow down the drill and gradually withdraw the bit from the hole.

By choosing the right twist drill bit and using the correct drilling technique, you can achieve clean and accurate holes in metal.

Step Drill Bits

A step drill bit, also known as a unibit or cone drill, is a versatile tool that can be used for drilling holes in various materials, including metal. It features a stepped design with multiple cutting edges that gradually increase in diameter. This allows it to create different-sized holes without the need for changing bits.

Step drill bits are particularly useful when working with thin metal sheets or when you need to create multiple holes of different sizes. They are commonly used in applications such as electrical work, plumbing, and automotive repairs.

Advantages of Step Drill Bits

1. Versatility: Step drill bits can create holes of various diameters, making them an excellent choice for tasks that require drilling holes of different sizes.

2. Smooth drilling: The stepped design of these bits reduces the chance of binding or snagging, resulting in smoother drilling and cleaner holes.

3. Easy to use: Step drill bits can be used with a regular corded or cordless drill, making them easy to use for both professionals and DIY enthusiasts.

Choosing a Step Drill Bit

When choosing a step drill bit for metal, there are a few factors to consider:

- Material: Make sure the step drill bit is designed for use on metal. It should be made of high-speed steel (HSS) or cobalt for maximum durability and heat resistance.

- Size range: Consider the range of hole sizes you need to drill. Step drill bits come in various sizes, so choose one that can accommodate your requirements.

- Coating: Some step drill bits have a coating, such as titanium or cobalt, which helps reduce friction and increase the lifespan of the bit.

Using a Step Drill Bit

Here are some guidelines for using a step drill bit:

- Secure the workpiece: Clamp or secure the metal sheet or workpiece properly to prevent it from moving during drilling.

- Start with a pilot hole: If the metal is thick or hard, it is advisable to start with a small pilot hole before using the step drill bit.

- Select the desired hole size: Determine the desired hole size and locate the appropriate step on the bit. Place the tip of the bit on the surface of the metal.

- Apply steady pressure: Start drilling slowly and apply steady pressure to avoid overheating and ensure a clean, precise hole.

- Remove metal shavings: Periodically remove the metal shavings from the hole to prevent clogging and ensure efficient drilling.

Remember to wear appropriate safety gear, such as safety glasses and gloves, when using a step drill bit or any other power tools.

Essential Features to Look for in a Metal Drill Bit

When it comes to drilling into metal, it’s crucial to choose the right drill bit for the job. The right drill bit can make a significant difference in the efficiency and effectiveness of your drilling operations. Here are some essential features to look for in a metal drill bit:

1. Material

The material of the drill bit is vital when drilling into metal. High-speed steel (HSS) is a common material used for metal drill bits. HSS drill bits are durable and can withstand high temperatures and friction generated during drilling.

Another option is cobalt drill bits, which are made from a mix of cobalt and steel. Cobalt drill bits are even more robust and can handle tougher metals like stainless steel and cast iron.

2. Coating

A high-quality coating on a metal drill bit can enhance its performance. Titanium nitride (TiN) coating is a popular choice as it increases the hardness of the drill bit’s surface and reduces friction. This coating also helps prevent heat build-up and prolongs the life of the drill bit.

Other coatings like titanium aluminum nitride (TiAlN) and black oxide are also commonly used and offer similar benefits.

3. Point Angle

The point angle of the drill bit determines its aggressiveness and affects how it penetrates the metal. For general metal drilling, a drill bit with a point angle of 118 degrees is commonly used. This angle provides a good balance between cutting efficiency and strength.

However, for drilling harder metals, a drill bit with a point angle of 135 degrees or even 140 degrees might be more suitable, as it can provide better performance and reduce the risk of the drill bit wandering or slipping on the metal surface.

4. Flutes

The flutes on a drill bit help to remove chips and debris from the hole while drilling. The number of flutes can vary, but commonly, metal drill bits have two flutes. Two-fluted drill bits are more effective at clearing chips and provide better stability during drilling.

However, for drilling larger holes in thicker metals, drill bits with more flutes, like four or six, can be used to improve chip removal and prevent clogging.

5. Shank Type

The shank is the part of the drill bit that fits into the drill chuck. For metal drilling, drill bits with a straight shank or a hex shank are commonly used.

Straight shank drill bits are compatible with most drill chucks and offer good stability. On the other hand, hex shank drill bits are designed for use with impact drivers and provide better torque transfer and reduced slippage.

Conclusion

Choosing the right drill bit for metal is essential to ensure successful drilling operations. By considering factors like material, coating, point angle, flutes, and shank type, you can select a drill bit that will provide optimal performance and longevity for your metal drilling needs.

FAQ:

What factors should I consider when choosing a drill bit for metal?

When choosing a drill bit for metal, you should consider factors such as the type of metal you will be drilling, the size of the hole you need, the speed and accuracy required, and the type of drill you will be using.

What are the different types of drill bits available for drilling metal?

There are several types of drill bits available for drilling metal, including twist drill bits, step drill bits, cobalt drill bits, carbide drill bits, and titanium drill bits. Each type has its own advantages and is suited for specific metal drilling applications.

Which drill bit is best for drilling stainless steel?

For drilling stainless steel, it is best to use a cobalt drill bit or a carbide drill bit. These types of drill bits are specifically designed to withstand the high heat generated when drilling stainless steel and are able to maintain their sharpness for longer periods of time.

How do I determine the appropriate size of drill bit for my metal drilling needs?

To determine the appropriate size of drill bit for your metal drilling needs, you should consider the size of the hole you need to drill. You can refer to a drill bit size chart, which provides the recommended drill bit sizes for different hole diameters.

Can I use a regular drill bit for drilling metal?

While it is possible to use a regular drill bit for drilling metal, it is not recommended. Regular drill bits are typically designed for drilling softer materials, such as wood or plastic, and may not be able to withstand the high heat and pressure generated when drilling metal. It is best to use a drill bit specifically designed for metal drilling.

What is the difference between cobalt drill bits and titanium drill bits?

The main difference between cobalt drill bits and titanium drill bits is the type of coating used. Cobalt drill bits are coated with cobalt, which provides increased heat resistance and durability, making them ideal for drilling hard metals. Titanium drill bits, on the other hand, are coated with titanium nitride, which reduces friction and heat buildup, allowing for faster drilling speeds.

What type of drill bit should I use for drilling aluminum?

For drilling aluminum, it is best to use a high-speed steel (HSS) drill bit or a cobalt drill bit. These types of drill bits are able to cut through aluminum easily and are less likely to cause damage to the material.

Video: