Choosing the Right Drill Bit for Hardened Steel: A Guide

Drilling through hardened steel can be a challenging task, especially if you don’t have the right drill bit. With so many options available on the market, it can be overwhelming to know which one to choose. In this guide, we will walk you through the different types of drill bits available and provide you with some tips on how to select the right one for your specific needs.

One of the most important factors to consider when choosing a drill bit for hardened steel is the material it is made of. High-speed steel (HSS) drill bits are a popular choice due to their durability and ability to withstand high temperatures. They are capable of drilling through hardened steel, but may dull quickly. Cobalt drill bits, on the other hand, are specifically designed to withstand heat and are more effective for drilling through hardened steel. They are made with a mix of cobalt and high-speed steel, making them harder and more resistant to wear.

Another important consideration is the type of drill bit point. A split point drill bit has a split tip that helps to reduce the amount of force needed to drill through hardened steel. It also provides faster cutting action and better accuracy. A self-centering drill bit has a tapered point that makes it easier to start drilling and helps to prevent the bit from wandering. Both types are effective for drilling through hardened steel, so it ultimately comes down to personal preference.

“When drilling through hardened steel, it is crucial to use the right speed and pressure. Too much pressure can cause the bit to overheat, while too little pressure can lead to the bit spinning and not making any progress. Take your time and apply steady pressure to ensure a clean and precise hole.”

In conclusion, drilling through hardened steel requires the right drill bit. Consider the material and type of point when selecting a drill bit, and always use the proper speed and pressure for the best results. Keep in mind that drilling through hardened steel can be a slow process, so be patient and take breaks if needed. With the right drill bit and technique, you will be able to tackle any drilling project on hardened steel with ease.

Why Choose the Right Drill Bit for Hardened Steel?

When it comes to drilling into hardened steel, choosing the right drill bit is crucial. Hardened steel is a tough material that requires a drill bit specifically designed to handle its hardness and density. Using the wrong drill bit can result in damage to the bit, decreased drilling performance, and even potential injury.

Here are a few reasons why it’s important to choose the right drill bit for hardened steel:

- Efficient Drilling: Hardened steel is much harder than regular steel or other common materials. A regular drill bit may not be able to penetrate the surface effectively, resulting in increased drilling time and effort. Choosing a drill bit specifically designed for hardened steel ensures efficient drilling by providing the necessary cutting power and durability.

- Minimized Heat Build-up: Drilling into hardened steel generates a significant amount of heat due to the high density and hardness of the material. Using a drill bit that is not designed for hardened steel can result in excessive heat build-up. This can lead to the bit getting too hot, causing it to wear out quickly or even causing the material to melt. A drill bit specifically designed for hardened steel will have features such as a specialized coating or carbide tips that help dissipate heat and ensure optimal performance.

- Reduced Risk of Damage: Using the wrong drill bit can increase the risk of damaging the material being drilled. Hardened steel is often used in applications where its strength and durability are critical. Using the wrong drill bit can cause the material to crack, chip, or even shatter. By selecting the right drill bit, you can minimize the risk of damaging the hardened steel and ensure a clean and precise hole.

- Longevity: Using a drill bit that is not designed for hardened steel can result in premature wear and tear. Hardened steel is highly abrasive and can quickly dull or chip a regular drill bit. By choosing a drill bit specifically designed for hardened steel, you can ensure its longevity and maximize its performance.

Overall, choosing the right drill bit for hardened steel is essential to achieve efficient drilling, minimize heat build-up, reduce the risk of damage, and ensure the longevity of the drill bit. Investing in high-quality drill bits specifically designed for hardened steel will save you time, effort, and money in the long run.

Understanding the Types of Steel

Steel is a versatile and widely used material in various industries. It is commonly used in construction, manufacturing, and even in everyday household items. However, not all steel is created equal. There are several different types of steel, each with its own unique properties and characteristics.

1. Carbon Steel

Carbon steel is one of the most common types of steel. It is primarily made up of iron and carbon, with trace amounts of other elements. Carbon steel is known for its strength and hardness, which makes it suitable for a wide range of applications. It is widely used in construction, automotive, and industrial equipment.

2. Alloy Steel

Alloy steel is a type of steel that contains additional alloying elements such as manganese, nickel, chromium, and vanadium. The addition of these elements enhances the strength, hardness, and toughness of the steel. Alloy steel is commonly used in the manufacturing of high-strength automotive parts, aircraft components, and industrial equipment.

3. Stainless Steel

Stainless steel is a corrosion-resistant type of steel that contains a high percentage of chromium. This chromium content helps to prevent rust and corrosion, making stainless steel ideal for applications where resistance to moisture and harsh environments is required. It is commonly used in kitchen appliances, medical instruments, and architectural structures.

4. Tool Steel

Tool steel is a type of steel that is specifically designed for the production of tools and tooling components. It is known for its high hardness, toughness, and wear resistance. Tool steel is commonly used in the manufacturing of drills, cutting tools, dies, and molds.

5. High-Speed Steel

High-speed steel is a type of tool steel that is specifically designed for high-speed machining operations. It contains additional elements such as tungsten, molybdenum, and vanadium, which improve its heat resistance and hardness at elevated temperatures. High-speed steel is commonly used in the production of drills, taps, milling cutters, and other cutting tools.

| Steel Type | Properties | Applications |

|---|---|---|

| Carbon Steel | Strong and hard | Construction, automotive, industrial equipment |

| Alloy Steel | High strength and hardness | Automotive parts, aircraft components, industrial equipment |

| Stainless Steel | Corrosion-resistant | Kitchen appliances, medical instruments, architectural structures |

| Tool Steel | High hardness, toughness, and wear resistance | Tools, tooling components |

| High-Speed Steel | Heat resistance, hardness at high speeds | Drills, taps, milling cutters, cutting tools |

Understanding the different types of steel is essential when selecting the right drill bit for hardened steel. Each type of steel has its own unique properties, which determine the drilling requirements and the appropriate drill bit to use. By considering the type of steel you are working with, you can choose the right drill bit that will ensure efficient and effective drilling.

Factors to Consider Before Choosing a Drill Bit

- Type of Material: The first factor to consider is the type of material you will be drilling into. Different drill bits are designed for specific materials, such as wood, metal, concrete, or hardened steel. It is important to choose a drill bit that is specifically designed for drilling into hardened steel.

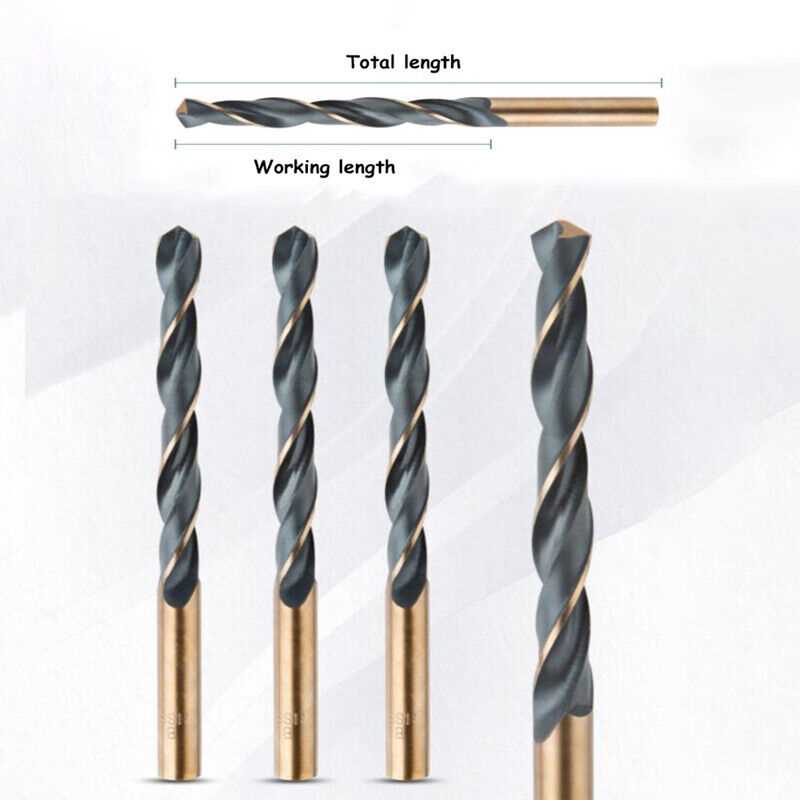

- Bit Size: The size of the drill bit is also an important consideration. The size of the hole you need to drill will determine the size of the drill bit you should use. Make sure to choose a drill bit that is the correct size for your specific application.

- Coating: The coating of the drill bit can affect its performance and durability. There are various coatings available, such as titanium nitride (TiN), black oxide, or cobalt. Coated drill bits generally have improved heat resistance and can last longer when drilling into hardened steel.

- Point Angle: The point angle of the drill bit refers to the angle of the tip. Different point angles are suitable for different materials. When drilling into hardened steel, a point angle of 135 degrees is commonly recommended, as it provides a good balance between drilling speed and durability.

- Flute Design: The flute design of the drill bit can affect chip evacuation and cutting performance. For drilling into hardened steel, a drill bit with a parabolic flute design is often recommended. This design helps to reduce heat build-up and allows for efficient chip evacuation.

- Brand and Quality: Finally, it is important to consider the brand and quality of the drill bit. Reputable brands often offer higher quality drill bits that are specifically designed for drilling into hardened steel. Investing in a good-quality drill bit can ensure better performance and longer tool life.

High-Speed Steel (HSS) Bits: Pros and Cons

When it comes to drilling through hardened steel, one of the most commonly used types of drill bits is the High-Speed Steel (HSS) bit. These bits are known for their durability and versatility, making them an excellent choice for a wide range of drilling applications. However, like any tool, HSS bits have their pros and cons that you should be aware of before using them.

Pros of High-Speed Steel (HSS) Bits

- Durability: HSS bits are made from a special type of steel alloy that allows them to withstand high temperatures and maintain their hardness. This durability ensures that the bits can withstand the rigors of drilling through hardened steel without losing their sharpness or breaking.

- Versatility: HSS bits can be used with a wide range of materials in addition to hardened steel, including wood, plastic, and non-ferrous metals. This versatility makes HSS bits a valuable tool to have in your collection, as they can be used for various projects and applications.

- Cost-effective: Compared to other types of drill bits designed for drilling through hardened steel, HSS bits are generally more affordable. This makes them a cost-effective option, especially if you need to drill through hardened steel infrequently or on a budget.

- Availability: HSS bits are widely available and can be found in most hardware stores and online retailers. This accessibility makes it easier to replace or replenish your supply of HSS bits whenever needed.

Cons of High-Speed Steel (HSS) Bits

- Lower hardness compared to other options: While HSS bits are durable, they are not as hard as some other types of drill bits specifically designed for hardened steel, such as carbide or cobalt bits. This means that HSS bits may take slightly longer to drill through hardened steel or wear out faster compared to these specialized bits.

- Less suitable for high-speed drilling: Despite being called “high-speed” steel, HSS bits may not be the best choice for high-speed drilling applications. The heat generated during high-speed drilling can affect the hardness of the bit, leading to reduced performance and potentially damaging the bit.

In conclusion, High-Speed Steel (HSS) bits are a popular choice for drilling through hardened steel due to their durability, versatility, cost-effectiveness, and availability. However, they may not be the ideal option for high-speed drilling or when other specialized drill bits designed for hardened steel are available.

Cobalt Bits: Benefits and Limitations

Cobalt bits are a type of drill bit that is made from a combination of high-speed steel and cobalt. These bits are specifically designed to handle drilling through hard materials, such as hardened steel.

Benefits of Cobalt Bits

- Durability: Cobalt bits are known for their durability and can withstand high temperatures and friction while drilling. This makes them ideal for drilling through tough materials without breaking or wearing down.

- Increased Heat Resistance: The cobalt content in these bits helps to dissipate heat during drilling, reducing the chance of the bit overheating and dulling. This allows for longer drilling sessions without having to stop and let the bit cool down.

- Higher Hardness: Cobalt bits have a higher hardness rating compared to regular high-speed steel bits. This hardness allows them to maintain their cutting edge for longer periods, resulting in cleaner and more precise holes.

- Efficient Chip Evacuation: The flute design of cobalt bits helps to efficiently remove chips and debris from the hole being drilled. This prevents clogging and allows for smoother and faster drilling.

Limitations of Cobalt Bits

- Cost: Cobalt bits tend to be more expensive compared to other types of drill bits. This can be a significant factor to consider, especially if you have a limited budget or if you don’t anticipate using the bit frequently.

- Brittleness: While cobalt bits are generally more durable than other types of bits, they can still be susceptible to breaking or chipping if they are subjected to excessive force or used improperly. It’s important to use them cautiously and follow the recommended drilling guidelines.

- Specific Use: Cobalt bits excel at drilling through hard materials like hardened steel, but they may not perform as well on softer materials. For drilling tasks involving softer materials, such as wood or plastic, other types of bits may be more appropriate.

In conclusion, cobalt bits offer numerous benefits that make them an excellent choice for drilling through hardened steel and other tough materials. However, they do have their limitations and may not be the best option for all drilling applications. Consider your specific needs and the materials you will be drilling before choosing the right bit for the job.

Carbide Bits: The Best Choice for Hardened Steel?

When it comes to drilling through hardened steel, choosing the right drill bit is crucial for achieving the desired results. One option that stands out as a top choice for this task is carbide drill bits.

What Are Carbide Drill Bits?

Carbide drill bits are made of a composite material called carbide, which is a combination of tungsten and carbon. This material is known for its extreme hardness and durability, making it ideal for drilling through hardened steel.

Advantages of Carbide Bits for Hardened Steel

- High Hardness: Carbide drill bits are extremely hard, allowing them to cut through hardened steel with ease. This hardness also ensures that the drill bits maintain their sharpness for a long time, resulting in longer tool life.

- Heat Resistance: When drilling through hardened steel, the heat generated can be a major concern. Carbide drill bits have excellent heat resistance, allowing them to withstand the high temperatures associated with drilling through tough materials without losing their cutting ability.

- Chip Removal: Hardened steel can produce large chips when drilling, which can hinder the drilling process. Carbide bits are designed with special flute designs that ensure efficient chip removal, preventing clogging and improving drilling efficiency.

- Versatility: Carbide drill bits can also be used on other tough materials such as cast iron, stainless steel, and titanium. This makes them a versatile option for various drilling applications.

Considerations for Using Carbide Bits

While carbide drill bits offer many advantages when drilling through hardened steel, there are a few factors to consider:

- Cost: Carbide drill bits tend to be more expensive compared to other types of drill bits. However, their superior performance and longer lifespan justify the higher cost.

- Proper Handling: Carbide bits are brittle and can be prone to chipping or breaking if not handled properly. It’s important to use them with caution and apply the appropriate drilling techniques.

- Speed and Feed Rate: To achieve optimal results, it’s crucial to use the correct speed and feed rates when drilling with carbide bits. Consult the manufacturer’s recommendations to ensure proper usage.

Overall, carbide drill bits are considered the best choice for drilling through hardened steel. Their unmatched hardness, heat resistance, and chip removal capabilities make them an excellent investment for any project involving tough materials.

Surface Coatings for Drill Bits: Which One to Choose?

Introduction

When it comes to drilling through hardened steel, having the right drill bit is crucial. However, another factor that can greatly impact the performance of your drill bit is the surface coating. Surface coatings enhance the durability and performance of drill bits, providing them with additional hardness, heat resistance, and lubricity. In this guide, we will explore some of the popular surface coatings for drill bits and help you choose the right one for your needs.

1. Titanium Nitride (TiN) Coating

One of the most common surface coatings for drill bits is titanium nitride (TiN). This coating is known for its hardness and resistance to wear, making it ideal for drilling through tough materials like hardened steel. TiN coating also provides a low coefficient of friction, reducing heat build-up and extending the life of the drill bit. It has a distinctive gold color, which makes it easy to identify.

2. Black Oxide Coating

Black oxide coating is another popular choice for drill bits. This coating enhances the surface hardness of the drill bit, making it more resistant to wear and heat. The black oxide also provides some lubricity, reducing friction during drilling. Black oxide-coated drill bits are easily recognizable by their black color. They are ideal for general-purpose drilling in materials like steel and iron.

3. Cobalt Coating

Cobalt coating is a great option for drilling through hardened steel. The cobalt coating enhances the drill bit’s hardness and heat resistance, allowing it to maintain sharpness even at high temperatures. Cobalt-coated drill bits are generally blue or gold in color. They are recommended for drilling in tough materials, especially stainless steel and cast iron.

4. Diamond Coating

Diamond coating is the top choice for drilling through extremely hard materials like carbide and ceramics. The diamond coating is highly wear-resistant and provides excellent heat resistance. This coating allows the drill bit to cut through hard materials with ease and precision. Diamond-coated drill bits are often silver or metallic in color.

5. Aluminum Titanium Nitride (AlTiN) Coating

Aluminum titanium nitride (AlTiN) coating is a newer surface coating that provides exceptional hardness and heat resistance. It has a higher lubricity than TiN coating, reducing friction and heat during drilling. AlTiN-coated drill bits are black or silver in color. They are suitable for drilling in a wide range of materials, including hardened steel, stainless steel, and titanium.

Conclusion

Choosing the right surface coating for your drill bits can significantly improve their performance and lifespan. Consider the hardness, heat resistance, and lubricity requirements for your drilling project, and choose a coating that best suits your needs. Whether it’s titanium nitride, black oxide, cobalt, diamond, or aluminum titanium nitride, a well-coated drill bit will make drilling through hardened steel a breeze.

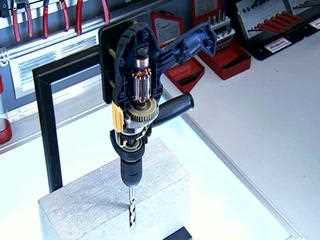

Drill Bit Sizes and Speeds: Matching the Right Bit and Drill Press

When it comes to drilling through hardened steel, using the right drill bit and matching it with the appropriate drill press speed is crucial. The size of the drill bit and the speed at which it rotates can greatly affect the drilling process and the quality of the hole produced. Here, we will discuss drill bit sizes and speeds and how to match them for optimal drilling performance.

Drill Bit Sizes

Drill bits come in various sizes, and choosing the right size for your drilling needs is important. The size of the hole you want to create determines the size of the drill bit you should use. Common drill bit sizes for hardened steel range from 1/16 inch to 1/2 inch, with larger sizes available for heavy-duty drilling tasks.

It is essential to select a drill bit that matches the desired hole size, as using a bit that is too small or too large can result in subpar drilling performance. If the bit is too small, it may break or wear down quickly. On the other hand, if the bit is too large, it may create an oversized hole that is not suitable for the intended purpose.

Drill Press Speeds

Drill presses offer various speed settings to accommodate different drilling tasks and materials. When drilling through hardened steel, it is important to use the correct speed to prevent overheating and ensure efficient drilling. Different drill bit materials and sizes require different speeds for optimal performance.

Consult the manufacturer’s guidelines or the drill bit packaging to determine the recommended operating speeds for drilling through hardened steel. In general, lower speeds are suitable for larger drill bits and harder materials, while higher speeds are used for smaller drill bits and softer materials.

Matching the Right Bit and Drill Press

Matching the right drill bit size and drill press speed is essential for successful drilling through hardened steel. Here are some guidelines to help you match the two:

- Refer to the drill bit manufacturer’s recommendations or packaging for the appropriate drill press speed for drilling through hardened steel.

- Choose a drill bit that matches the desired hole size. Ensure the bit is made of a material suitable for drilling through hardened steel.

- Select the corresponding speed setting on the drill press based on the recommendations provided by the drill bit manufacturer.

- Always wear appropriate safety gear, such as safety glasses and gloves, when operating a drill press.

By following these guidelines and matching the right drill bit size and drill press speed, you can achieve optimal drilling results when working with hardened steel. Remember to take your time and proceed with caution to ensure safety and accuracy in your drilling project.

Proper Techniques for Drilling Hardened Steel

Drilling hardened steel can be a challenging task, but with the right techniques, you can achieve success. Here are some tips to help you drill through hardened steel effectively:

1. Use a High-Speed Steel (HSS) Drill Bit

When drilling through hardened steel, it is important to use a drill bit made of high-speed steel (HSS). This type of drill bit is designed to withstand the high temperatures that are generated during the drilling process. It is also harder and more durable than standard drill bits, making it ideal for drilling through hardened steel.

2. Start with a Small Pilot Hole

Before drilling the main hole, it is recommended to start with a small pilot hole. This will help guide the larger drill bit and prevent it from wandering off course. Use a smaller HSS drill bit to create the pilot hole and ensure it is centered and straight.

3. Use Cutting Fluid

Applying cutting fluid to the drill bit and the surface of the hardened steel can greatly reduce the friction and heat generated during drilling. This helps to prevent the drill bit from overheating and becoming dull. Apply cutting fluid regularly while drilling to keep the temperature under control.

4. Use Slow Speed and High Pressure

When drilling through hardened steel, it is important to use a slow drill speed and high pressure. This allows the drill bit to cut through the metal more effectively without causing damage. High pressure helps to keep the drill bit engaged with the material and prevent it from slipping or bouncing.

5. Take Breaks and Cool Down

Drilling hardened steel can generate a significant amount of heat. To prevent the drill bit from becoming too hot and losing its cutting ability, it is important to take regular breaks and allow the drill bit to cool down. This will help maintain the drill bit’s sharpness and prolong its lifespan.

6. Use Lubrication

Using lubrication can further reduce friction and heat buildup during drilling. Apply a lubricant such as cutting oil or a paste specifically designed for drilling hardened steel. This will help to prolong the life of the drill bit and improve the overall drilling performance.

7. Maintain a Steady Hand

Keeping a steady hand and maintaining control over the drill can greatly improve the drilling accuracy. Ensure that the drill is held securely and aligned properly with the pilot hole. Avoid putting excessive pressure on the drill, as this can cause the drill bit to break or become damaged.

By following these proper techniques for drilling hardened steel, you can increase your chances of drilling through the material successfully. Remember to always wear protective gear such as safety glasses and gloves and take necessary precautions to ensure your safety.

FAQ:

What is the best type of drill bit to use for drilling into hardened steel?

The best type of drill bit to use for drilling into hardened steel is a cobalt or carbide drill bit. These drill bits are specifically designed to withstand the heat and pressure generated when drilling into hardened steel.

Are cobalt drill bits better than carbide drill bits for drilling into hardened steel?

Both cobalt and carbide drill bits are excellent choices for drilling into hardened steel. Cobalt drill bits are known for their strength and durability, while carbide drill bits are known for their superior hardness. It ultimately depends on your specific needs and preferences.

Can I use a regular steel drill bit to drill into hardened steel?

No, using a regular steel drill bit to drill into hardened steel is not recommended. Regular steel drill bits are not strong enough to withstand the hardness of the steel, and they may break or become dull very quickly. It is best to use a drill bit specifically designed for drilling into hardened steel.

What are the key factors to consider when choosing a drill bit for hardened steel?

When choosing a drill bit for hardened steel, it is important to consider the type of steel you are drilling into, the hardness of the steel, the size of the hole you need to drill, and the type of drill you will be using. These factors will help determine the appropriate type and size of drill bit to use.

Can I use a regular drill with a drill bit for hardened steel?

You can use a regular drill with a drill bit for hardened steel, but it is important to use a drill with enough power and torque to handle the drilling process. Hardened steel can be tough to drill through, so a more powerful drill will make the task easier and more efficient.

Video: