Choosing the Right Drill Bit for Hardened Steel: A Comprehensive Guide

When it comes to drilling through hardened steel, choosing the right drill bit is crucial. Hardened steel is notoriously tough and can quickly destroy a standard drill bit if not approached with the right tools and techniques. In this comprehensive guide, we will explore the different types of drill bits available for drilling through hardened steel and provide tips and recommendations to help you select the best one for your project.

One of the most important factors to consider when choosing a drill bit for hardened steel is the material it is made from. High-speed steel (HSS) drill bits are the most commonly used for drilling through hardened steel. These drill bits are designed to withstand the heat generated by drilling into the tough metal and maintain their sharpness. However, for extra durability and performance, you may want to consider cobalt drill bits, which are made from a cobalt alloy and are known for their superior strength.

Another crucial factor to consider is the drill bit’s point angle. The point angle refers to the angle at the tip of the drill bit and determines its drilling efficiency. For drilling through hardened steel, a point angle of 135 degrees is highly recommended. This angle provides a sharper cutting edge and better chip clearing, resulting in faster and more efficient drilling.

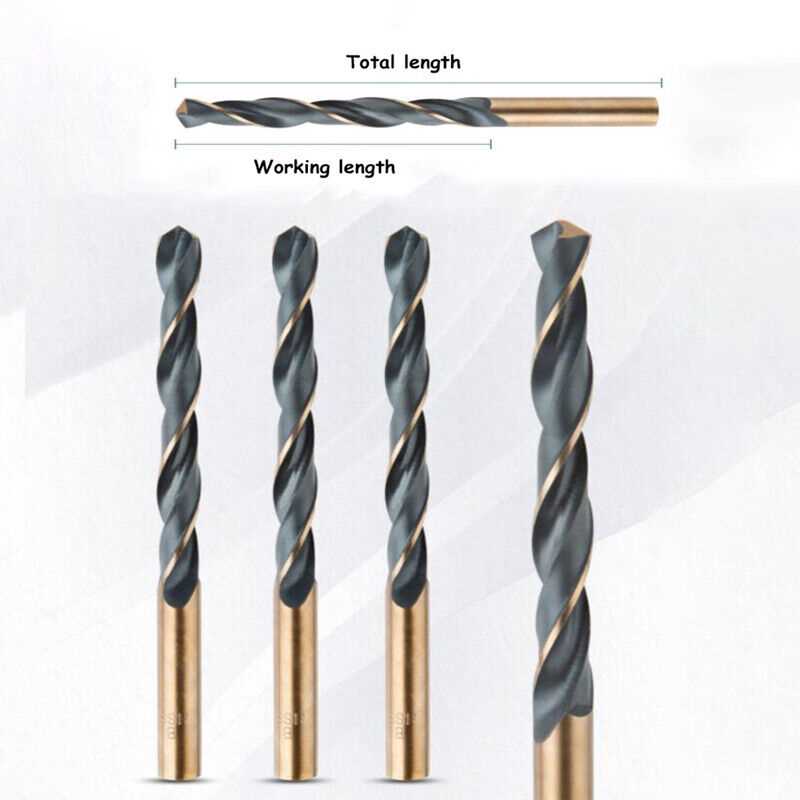

Lastly, it is important to consider the length and diameter of the drill bit. The length of the drill bit should be chosen based on the depth of the hole you need to drill. It is advisable to choose a drill bit that is long enough to drill the entire hole in one pass to avoid overheating and damaging the bit. The diameter of the drill bit should be chosen based on the size of the hole you need to drill. It is important to select a bit with the correct diameter to ensure a clean and precise hole.

Understanding the Properties of Hardened Steel

Hardened steel is a commonly used material in various industries due to its exceptional durability and strength. To effectively choose the right drill bit for hardened steel, it is important to understand the key properties of this material. Here are some important properties of hardened steel:

- Hardness: Hardened steel is known for its high hardness. It is typically hardened by heat treatment, which involves heating the steel to a specific temperature and then rapidly cooling it. This process helps to increase the hardness of the steel, making it resistant to abrasion and wear.

- Strength: Hardened steel has excellent strength, making it ideal for applications where high load-bearing capacity is required. It can withstand heavy loads without deforming or breaking.

- Toughness: Despite its high hardness, hardened steel also exhibits good toughness. Toughness refers to the ability of a material to absorb energy before fracturing. Hardened steel is able to withstand impact and shock without easily fracturing or breaking.

- Wear resistance: Hardened steel has excellent wear resistance, making it suitable for applications where the material comes into contact with abrasive surfaces. It can withstand repeated rubbing, sliding, and scraping without significant wear or deterioration.

- Corrosion resistance: Hardened steel often possesses good corrosion resistance due to the presence of alloying elements such as chromium. However, the level of corrosion resistance can vary depending on the specific composition of the steel.

These properties make hardened steel a versatile material that is used in a wide range of applications, such as tooling, construction, automotive, and manufacturing industries. Understanding these properties is crucial for selecting the appropriate drill bit that can effectively penetrate hardened steel without causing damage or excessive wear.

Factors to Consider When Choosing a Drill Bit

When selecting a drill bit for hardened steel, there are several important factors to consider. These factors can greatly impact your drilling performance and the overall success of your project. Here are some key considerations to keep in mind:

1. Material Compatibility

The first and most crucial factor to consider is the compatibility of the drill bit material with hardened steel. Hardened steel is an extremely hard and durable material, so it requires a drill bit that is specifically designed to handle its hardness. Look for drill bits made from high-speed steel (HSS), cobalt, or carbide, as these materials are known for their exceptional hardness and heat resistance.

2. Bit Type

There are different types of drill bits that are suitable for drilling into hardened steel. Two common types include twist bits and step bits. Twist bits are versatile and can be used for various materials, including hardened steel. Step bits, on the other hand, are ideal for creating larger holes in metal. Consider the specific needs of your project and choose the appropriate bit type accordingly.

3. Bit Size

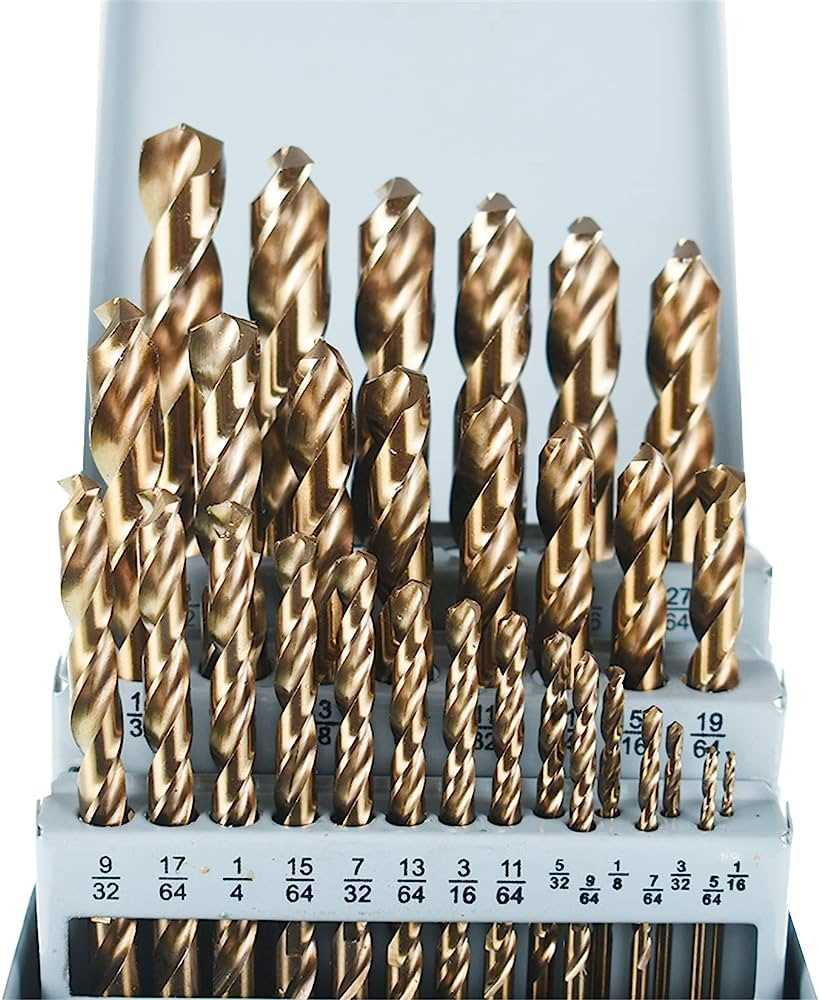

The size of the drill bit is another important factor to consider. For drilling into hardened steel, it is recommended to use a smaller drill bit size to start with and gradually increase the size as necessary. This helps prevent the bit from becoming too hot or breaking due to excessive heat and pressure. Refer to the manufacturer’s recommendations or consult a drilling expert for guidance on the appropriate bit size for your specific application.

4. Shank Type

The shank is the part of the drill bit that fits into the drill chuck. There are various shank types available, including round shanks, hex shanks, and SDS shanks. When choosing a drill bit for hardened steel, opt for a shank type that is compatible with your drilling machine. Consider factors such as ease of insertion and removal, torque transfer, and stability.

5. Coating

Many drill bits for hardened steel come with a coating or surface treatment that enhances their performance. Look for drill bits with coatings like titanium nitride (TiN), black oxide, or cobalt for increased hardness, lubricity, and heat resistance. These coatings can prolong the life of the bit and improve drilling efficiency.

6. Speed and Feed Rates

When drilling into hardened steel, it is important to use the appropriate speed and feed rates to avoid damaging the drill bit or the workpiece. Follow the manufacturer’s recommendations or consult machining guidelines to determine the optimal cutting speed and feed rate for your specific drill bit and material.

7. Budget

Last but not least, consider your budget when choosing a drill bit for hardened steel. Higher quality drill bits made from premium materials tend to be more expensive, but they also offer better performance and durability. It’s worth investing in a high-quality drill bit that will last longer and provide superior results, especially if you frequently work with hardened steel.

By considering these factors, you can choose the right drill bit for drilling into hardened steel, ensuring efficient and successful results for your projects.

Types of Drill Bits Suitable for Hardened Steel

When drilling through hardened steel, it is important to use the right type of drill bit to ensure a clean and precise hole. Here are some common types of drill bits that are suitable for drilling through hardened steel:

- Cobalt Drill Bits: Cobalt drill bits are made from a high-speed steel alloy that contains cobalt. These drill bits are known for their excellent heat resistance and hardness, making them ideal for drilling through hardened steel. They are also less prone to wear and can last longer compared to other types of drill bits.

- Carbide Drill Bits: Carbide drill bits are made from a combination of carbide (a compound of carbon and another element, usually tungsten) and cobalt. These drill bits are extremely tough and can handle high heat and pressure. They are especially effective for drilling through hardened steel with a high level of hardness.

- High-Speed Steel Drill Bits: High-speed steel (HSS) drill bits are another popular choice for drilling through hardened steel. These drill bits are made from a combination of steel and other elements like molybdenum, chromium, and vanadium. While not as hard as cobalt or carbide drill bits, HSS drill bits offer good heat resistance and durability at a more affordable price.

It is important to note that when drilling through hardened steel, using a drill bit with a high-speed setting and applying steady pressure is crucial to ensure proper cutting and prevent overheating.

High-Speed Steel (HSS) Drill Bits

High-Speed Steel (HSS) Drill Bits are commonly used for drilling through hardened steel. These drill bits are made from a special type of steel known as high-speed steel, which contains a combination of carbon, tungsten, chromium, vanadium, and other elements. This composition gives HSS drill bits their characteristic hardness and durability, making them ideal for drilling into tough materials like hardened steel.

Here are some key characteristics of High-Speed Steel (HSS) Drill Bits:

- Hardness: HSS drill bits have a higher hardness rating compared to regular steel drill bits, allowing them to cut through hardened steel with ease. This hardness is achieved through the special alloy composition of the HSS material.

- Heat resistance: HSS drill bits have excellent heat resistance, meaning they can withstand high temperatures generated during the drilling process without losing their hardness. This makes them suitable for prolonged use and reduces the chances of the drill bit becoming dull or overheated.

- Sharpness: HSS drill bits are known for their sharpness, which allows them to make clean and precise holes in hardened steel. The sharp cutting edges of the drill bit ensure efficient drilling and reduce the chances of the bit slipping or wandering off course.

- Versatility: HSS drill bits can be used for drilling into a wide range of materials, including wood, plastic, and non-hardened metals. This makes them a versatile choice for both DIY enthusiasts and professionals.

When using High-Speed Steel (HSS) Drill Bits for drilling hardened steel, it is important to use the correct drilling speed and apply moderate pressure to avoid overheating the drill bit or damaging the workpiece. Lubricating the drill bit with cutting oil or a lubricating spray can also help prolong its lifespan and improve drilling performance.

| Advantages | Disadvantages |

|---|---|

|

|

In summary, High-Speed Steel (HSS) Drill Bits are a reliable choice for drilling through hardened steel. Their hardness, heat resistance, and sharpness make them ideal for tackling tough materials, while their versatility allows them to be used for various drilling applications. Proper usage and maintenance can ensure the longevity of HSS drill bits, making them a worthwhile investment for any drilling needs.

Cobalt Drill Bits

Cobalt drill bits are a popular choice for drilling through hardened steel due to their high heat resistance and hardness. These drill bits are made from a combination of cobalt and other metals, which makes them extremely durable and capable of handling the rigors of drilling into hard materials.

One of the main advantages of cobalt drill bits is their ability to dissipate heat effectively. When drilling through hardened steel, the heat generated can quickly dull a regular drill bit. However, cobalt drill bits are designed to withstand high temperatures without losing their hardness or sharpness.

Another benefit of cobalt drill bits is their high strength and resistance to wear. The combination of cobalt and other metals creates a drill bit that is tougher than traditional high-speed steel bits, making it less likely to break or chip when used on hardened steel.

It is important to note that cobalt drill bits can be more expensive than traditional drill bits. However, their long-lasting durability and ability to cut through tough materials make them worth the investment, especially when working with hardened steel.

Best Practices for Using Cobalt Drill Bits

- Use a slow drilling speed to prevent overheating and maintain the integrity of the cobalt drill bit.

- Apply cutting fluid or lubricant to the drilling area to reduce friction and heat buildup.

- Secure the workpiece firmly in place to prevent movement during drilling, as this can cause inaccurate holes or damage to the drill bit.

- Start drilling with a smaller pilot hole before using a larger cobalt drill bit, especially when drilling into thicker or harder materials.

- Regularly inspect the cobalt drill bit for wear or damage, and replace it if necessary to maintain optimal performance.

Conclusion

Cobalt drill bits are an excellent choice for drilling through hardened steel due to their high heat resistance, hardness, and durability. While they may be more expensive than traditional drill bits, their performance and longevity make them a wise investment for anyone regularly working with hardened steel.

Carbide Drill Bits

Carbide drill bits are widely regarded as one of the best options for drilling through hardened steel. These drill bits are made from a combination of tungsten carbide and cobalt, which gives them exceptional hardness and durability. The carbide tip of the drill bit is what makes it particularly effective in drilling through tough materials like hardened steel.

Advantages of Carbide Drill Bits

- Hardness: Carbide drill bits are extremely hard and can maintain their sharpness for a long time even when drilling through tough materials.

- Durability: Due to their composition, carbide drill bits are highly resistant to wear and can last much longer than other types of drill bits.

- Heat Resistance: Carbide drill bits can withstand high temperatures generated during drilling, reducing the risk of tip damage or failure.

- Versatility: Carbide drill bits can be used for drilling a wide range of materials, including hardened steel, cast iron, stainless steel, and other tough alloys.

Considerations when Using Carbide Drill Bits

Although carbide drill bits offer numerous advantages, there are a few important considerations when using them:

- Cost: Carbide drill bits tend to be more expensive than other types of drill bits due to their high-quality materials and superior performance.

- Speed and Feed: When drilling through hardened steel, it’s crucial to use the correct speed and feed rates to prevent overheating and premature wear of the carbide tip.

- Proper Lubrication: Lubricating the drill bit and workpiece can help reduce heat and friction during drilling, prolonging the life of the carbide drill bit.

- Proper Technique: Using the correct drilling technique, such as applying steady pressure and avoiding excessive force, can help prevent damage to the carbide tip.

Overall, carbide drill bits are an excellent choice for drilling through hardened steel due to their exceptional hardness, durability, and heat resistance. By considering the aforementioned factors and using proper drilling techniques, carbide drill bits can provide excellent results and prolonged service life.

Diamond-Coated Drill Bits

Diamond-coated drill bits are an excellent option for drilling through hardened steel. With their super-hard diamond coating, these drill bits can cut through tough materials with ease. Here are some key features and benefits of diamond-coated drill bits:

1. Extreme Hardness

Diamond-coated drill bits are incredibly hard, often ranking as the hardest substance known to man. This extreme hardness allows them to maintain their sharpness and durability even when drilling through hardened steel.

2. Excellent Heat Resistance

Drilling through hardened steel generates a significant amount of heat. Diamond-coated drill bits have excellent heat resistance, which helps prevent the bit from overheating and becoming dull. The diamond coating dissipates heat effectively, ensuring that the drill bit stays sharp for a longer time.

3. Longer Lifespan

Due to their extreme hardness and excellent heat resistance, diamond-coated drill bits have a longer lifespan compared to other types of drill bits. They can withstand the wear and tear of drilling through hardened steel without losing their sharpness or becoming damaged.

4. Enhanced Cutting Speed

The diamond coating on these drill bits provides enhanced cutting speeds. This allows for quicker and more efficient drilling through hardened steel, saving time and effort.

5. Versatility

Diamond-coated drill bits are also versatile, as they can be used on various materials, including ceramics, glass, and composites, in addition to hardened steel. This makes them a valuable tool in any toolkit.

6. Pricier Option

One thing to keep in mind is that diamond-coated drill bits tend to be more expensive compared to other drill bit options. Their advanced technology and superior performance justify the higher price point, but it’s essential to consider the overall budget when choosing the right drill bit.

In conclusion, diamond-coated drill bits are an excellent choice for drilling through hardened steel. Their extreme hardness, heat resistance, longer lifespan, enhanced cutting speed, versatility, and overall performance make them a valuable tool for any DIY enthusiast or professional. Despite being pricier, the benefits offered by diamond-coated drill bits outweigh the additional cost.

Choosing the Right Drill Bit Size

When drilling into hardened steel, it’s crucial to choose the right drill bit size to prevent damage to the material and ensure a clean, precise hole. Here are some key factors to consider when selecting the correct drill bit size:

Diameter of the Hole

The most important factor in choosing the drill bit size is the diameter of the hole you need to create. Different applications require different hole sizes, and using the correct size drill bit is essential to achieve the desired result.

Material Thickness

The thickness of the hardened steel material also impacts the drill bit size selection. Thicker materials may require larger drill bits to ensure proper hole creation, while thinner materials may require smaller drill bits to prevent excessive material removal.

Drill Bit Compatibility

It’s crucial to choose a drill bit size that is compatible with your drill. Different drills have different chuck sizes, and selecting a drill bit that matches the chuck size ensures a secure fit and prevents slipping or wobbling during the drilling process.

Drilling Speed

The speed at which you plan to drill also plays a role in determining the appropriate drill bit size. If you intend to drill at high speeds, a larger drill bit may be necessary to handle the increased heat generated. Conversely, drilling at low speeds may require a smaller drill bit to account for reduced heat generation.

Manufacturer Recommendations

Always consult the manufacturer’s recommendations for drilling hardened steel. Manufacturers often provide specific guidelines and recommendations for drill bit sizes based on the type of steel being drilled and the desired hole size. Following these recommendations can help ensure optimal performance and prolong the life of your drill bits.

By taking into account the diameter of the hole, material thickness, drill bit compatibility, drilling speed, and manufacturer recommendations, you can select the right drill bit size for drilling hardened steel. Remember to always use appropriate safety precautions and consult professional advice when needed.

FAQ:

What is hardened steel?

Hardened steel is a type of steel that has been subjected to a heat treatment process called quenching and tempering, which makes it very strong and resistant to wear and tear.

Why is it difficult to drill hardened steel?

Drilling hardened steel can be difficult because it is extremely strong and has a high level of hardness. Regular drill bits may become dull or break when trying to penetrate hardened steel.

What kind of drill bit should I use for hardened steel?

For drilling hardened steel, it is recommended to use cobalt drill bits. These drill bits are made from high-speed steel with added cobalt, which increases their hardness and heat resistance.

Are there any other types of drill bits that can be used for hardened steel?

Yes, apart from cobalt drill bits, you can also use carbide drill bits and diamond-coated drill bits for drilling hardened steel. These drill bits are designed to withstand the hardness of the steel and provide efficient drilling.

Can regular drill bits be used for drilling hardened steel?

Regular drill bits are not recommended for drilling hardened steel as they may not be able to withstand the hardness and can become dull or break easily. It is better to use specialized drill bits specifically designed for drilling hardened steel.

What are some tips for drilling hardened steel?

When drilling hardened steel, it is important to use a slow speed and apply consistent pressure. Using cutting fluid or lubricant can also help reduce friction and heat generated during the drilling process. It is recommended to use a center punch to create a pilot hole before drilling. Regularly cooling the drill bit with water can also help prolong its life.

Where can I find cobalt drill bits for drilling hardened steel?

Cobalt drill bits can be found at most hardware stores or online retailers that sell tools and drill bits. It is important to check the specifications of the drill bits to ensure they are suitable for drilling hardened steel.

Video: