Choosing the Right Drill Bit for Glass: A Comprehensive Guide

When it comes to drilling into glass, choosing the right drill bit is crucial. Whether you’re a homeowner looking to hang a mirror or a professional working with glass on a regular basis, using the correct drill bit can make all the difference in the success of your project. In this comprehensive guide, we’ll explore the different types of drill bits available for drilling into glass and provide tips for selecting the right one for your specific needs.

Glass is a delicate material that requires special care and attention when drilling. Not all drill bits are suitable for use on glass, as they can easily chip or crack the surface. The most common types of drill bits for glass include diamond-tipped bits, carbide-tipped bits, and spear-point bits. Each type has its own strengths and weaknesses, so it’s important to understand their differences before making your decision.

Diamond-tipped drill bits are considered the best option for drilling into glass. They are extremely durable and can easily cut through the hard surface of glass without causing any damage. However, diamond-tipped bits can be quite expensive and may not be necessary for all projects. Carbide-tipped bits are a more affordable alternative that performs well on glass, but they may wear out more quickly. Spear-point bits, on the other hand, are designed specifically for drilling small holes in glass and are best suited for projects that require precision.

Regardless of the type of drill bit you choose, it’s important to take certain precautions when drilling into glass. Always wear safety goggles to protect your eyes from flying shards, and consider using a lubricant to keep the bit cool during drilling. Additionally, start drilling at a low speed and gradually increase it to prevent cracking or chipping. Remember to apply gentle pressure and let the drill bit do the work, rather than forcing it through the glass.

In conclusion, selecting the right drill bit for drilling into glass is essential for achieving successful results. By understanding the different types of drill bits available and considering the specific needs of your project, you can ensure that you choose the best option. Taking proper safety precautions and using the correct drilling techniques will also contribute to a smooth and successful drilling experience. So, the next time you need to drill into glass, you can do so confidently with the knowledge of which drill bit to use.

Understanding Different Types of Glass

Glass is a versatile material that is used in a wide range of applications, from windows and mirrors to decorative objects and tableware. However, not all glass is created equal. There are several different types of glass, each with its unique properties and characteristics. Understanding these different types of glass can help you choose the right drill bit for your specific project.

1. Annealed Glass

Annealed glass is the most common type of glass and is used in everyday applications like windows and glassware. It is produced by slowly cooling molten glass to relieve internal stresses, making it less likely to break. Annealed glass is relatively easy to drill and can be done with a standard drill bit.

2. Tempered Glass

Tempered glass, also known as safety glass, is specially treated to be four to five times stronger than annealed glass. It is commonly used in applications that require a higher level of safety, such as shower doors and car windows. Tempered glass is more challenging to drill due to its greater strength and is best drilled using a diamond-tipped drill bit.

3. Laminated Glass

Laminated glass is made up of two or more layers of glass with a layer of plastic interlayer in between. This type of glass is designed to provide increased security, as it remains intact even when broken. Laminated glass is commonly used in applications like windshields and glass floors. Drilling through laminated glass requires a diamond-tipped drill bit.

4. Frosted Glass

Frosted glass, also known as etched glass, has a textured surface that diffuses light and provides privacy. It is often used for decorative purposes and in bathroom windows and doors. Frosted glass can be drilled using a standard glass drill bit.

5. Tinted Glass

Tinted glass is produced by adding a pigment to the glass during the manufacturing process, giving it a colored appearance. It is commonly used in applications where privacy and heat resistance are required, such as car windows and buildings. Tinted glass can be drilled using a standard glass drill bit.

6. Stained Glass

Stained glass is made by adding metallic salts to molten glass to create colored patterns and designs. It is commonly used in windows and decorative art pieces. Drilling through stained glass requires a specialized glass drill bit with a diamond or carbide tip.

7. Mirrored Glass

Mirrored glass is coated with a thin layer of metal, typically silver, to create a reflective surface. It is commonly used in mirrors and decorative objects. Drilling through mirrored glass requires a diamond-tipped drill bit and care to prevent the delicate reflective coating from being damaged.

Conclusion

Understanding the different types of glass is essential when selecting the right drill bit for your project. Different types of glass have varying levels of hardness and require specific drill bits for successful drilling. By choosing the appropriate drill bit, you can ensure clean and precise holes in your glass without causing damage or breakage.

Factors to Consider When Choosing a Drill Bit for Glass

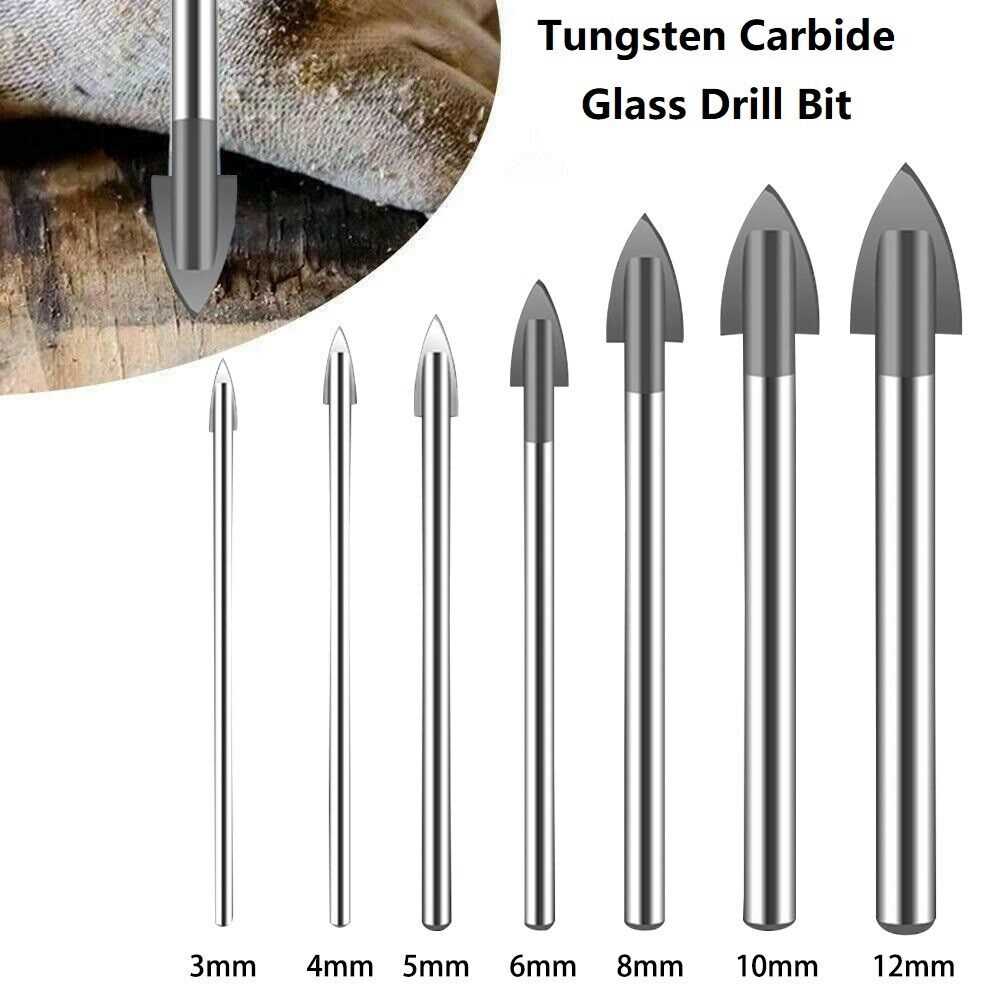

- Material: The material of the drill bit is an important factor to consider when choosing a drill bit for glass. Opt for a drill bit made specifically for drilling glass, such as a tungsten carbide or diamond-tipped drill bit. These materials are designed to withstand the hardness and brittleness of glass without causing cracks or breakage.

- Size: The size of the drill bit is also a key consideration. Choose a drill bit that is suitable for the size of the hole you need to make. It is important to use the right size to avoid causing unnecessary stress on the glass, which can lead to damage. Measure the diameter of the hole needed before selecting the appropriate drill bit size.

- Point Angle: The point angle of the drill bit refers to the angle at the tip of the bit. For drilling glass, a sharper point angle is preferred to reduce the likelihood of the glass cracking or chipping. Look for drill bits with a point angle of around 120 degrees for optimal results.

- Coating: Some drill bits for glass come with specialized coatings that help improve performance and durability. Look for drill bits with a titanium or diamond coating, as these can provide additional hardness and reduce friction during drilling.

- Shank: The shank of the drill bit is the part that is inserted into the drill. For drilling glass, it is important to choose a drill bit with a shank that fits securely into your drill. Look for drill bits with a 1/4-inch or 3/8-inch shank, as these sizes are commonly used for drilling glass.

- Speed and Pressure: When drilling glass, it is important to use a slow speed and apply minimal pressure. Glass is a delicate material that can easily crack or shatter under too much force. Start drilling at a low speed and gradually increase as needed, while maintaining a gentle and steady pressure.

High-Speed Steel (HSS) Drill Bits for Glass

When it comes to drilling through glass, using the right drill bit is essential. One popular option is High-Speed Steel (HSS) drill bits. These bits are made from a type of steel that can withstand high temperatures and friction, making them ideal for drilling through hard materials like glass.

Here are some key features and benefits of using HSS drill bits for glass:

- Durability: HSS drill bits are known for their durability and long lifespan. They can withstand the rigors of drilling through glass without getting damaged easily.

- Heat resistance: HSS drill bits are designed to handle high temperatures generated during the drilling process. This heat resistance prevents the drill bit from dulling or losing its sharpness.

- Fast cutting: HSS drill bits can cut through glass quickly and efficiently, saving you time and effort.

- Versatility: HSS drill bits can be used for drilling through various types of glass, including window panes, mirrors, and glass tiles.

When using HSS drill bits for glass, it’s important to follow these tips for best results:

- Use a lubricant: Applying a lubricant, such as water or glass cutting oil, can reduce friction and heat buildup during drilling. This helps to prolong the life of the drill bit and improve drilling efficiency.

- Start with a small hole: To prevent the glass from cracking or shattering, it’s recommended to start with a small pilot hole before drilling the desired size hole.

- Work at a low speed: Running the drill at a low speed can minimize the risk of overheating and improve the overall control of the drilling process.

- Use light pressure: Applying too much pressure while drilling can cause the glass to break. It’s best to let the drill bit do the work and apply gentle, even pressure.

In conclusion, High-Speed Steel (HSS) drill bits are a reliable and efficient option for drilling through glass. With their durability, heat resistance, and fast-cutting capabilities, they are well-suited for various glass drilling applications. By following the recommended tips, you can ensure a smooth and successful drilling experience.

Diamond Drill Bits for Glass

Diamond drill bits are the preferred choice for drilling through glass due to their superior cutting ability and durability. These drill bits have a tip coated with diamond particles, which allows them to cut through glass with ease. They are commonly used for creating precise holes in glass for various applications, such as jewelry making, DIY projects, and glassware production.

Advantages of Diamond Drill Bits

- Superior Cutting Power: Diamond drill bits are specifically designed to cut through hard materials like glass. The diamond particles on the tip of the bit make it incredibly sharp and efficient in drilling through glass without causing any cracks or fractures.

- Durability: Diamond drill bits are known for their long-lasting performance. The diamond coating makes the bit resistant to wear and tear, allowing it to last longer than other types of drill bits.

- Precision and Versatility: Diamond drill bits are available in various sizes, making them suitable for creating holes of different diameters in glass. They offer precise control, enabling users to drill holes of specific dimensions without any difficulty.

- Smooth Finish: When using diamond drill bits, you can expect a smooth and clean hole in the glass. This eliminates the need for additional polishing or sanding after drilling, reducing the time and effort required for your project.

Using Diamond Drill Bits for Glass

Here are some tips for using diamond drill bits effectively and safely:

- Choose the Right Size: Ensure that you select the appropriate size of diamond drill bit for your project. Measure the diameter of the hole you need and choose a drill bit that matches that size.

- Prepare the Glass: Before drilling, it is important to prepare the glass surface. Place it on a soft surface or use a clamp to secure it in place. Mark the spot where you want to drill the hole with a marker or tape to guide your drilling.

- Use Lubrication: Applying a lubricant such as water or oil on the drilling area helps to cool down the bit and keep it lubricated. This prevents overheating and reduces the chances of the glass cracking.

- Start Slowly: Begin drilling at a slow speed to allow the diamond tip to penetrate the glass smoothly. Apply gentle pressure and gradually increase the speed as the bit cuts through the glass.

- Work with Caution: Drill with caution and avoid exerting excessive force while drilling. Let the diamond particles on the tip of the drill bit do the cutting. Take breaks if necessary to prevent the bit from overheating.

By following these guidelines, you can effectively use diamond drill bits for drilling through glass and achieve professional results in your projects.

Carbide-Tipped Drill Bits for Glass

When it comes to drilling through glass, using the right drill bit is crucial. One option that is highly recommended for drilling through glass is a carbide-tipped drill bit. These drill bits are designed to withstand the hardness and brittleness of glass, making them the ideal choice for this task.

Advantages of Carbide-Tipped Drill Bits

- Highly durable: Carbide-tipped drill bits are known for their durability. The carbide tips are made from a combination of tungsten carbide and cobalt, which makes them extremely hard and able to withstand the demanding conditions of drilling through glass.

- Efficient drilling: Carbide-tipped drill bits have a sharp cutting edge that allows for efficient drilling through glass. This helps to reduce the amount of time and effort required to complete the drilling process.

- Less prone to chipping: Glass is a brittle material and is prone to chipping or cracking during drilling. Carbide-tipped drill bits are designed to minimize the risk of chipping, ensuring a clean and smooth hole in the glass.

- Versatile: Carbide-tipped drill bits can also be used for drilling through other hard materials such as porcelain, ceramic, and stone. This makes them a versatile tool to have in your toolkit.

Choosing the Right Carbide-Tipped Drill Bit

When choosing a carbide-tipped drill bit for glass, there are a few factors to consider:

- Size: The size of the drill bit should match the size of the hole you want to drill. Make sure to choose a drill bit with a diameter that is appropriate for your project.

- Depth: Consider the depth of the hole you need to drill. Some drill bits have a specific length or depth limit, so make sure to choose one that meets your requirements.

- Type: Carbide-tipped drill bits come in different types, such as straight shank or hex shank. Choose the type that is compatible with your drill and can provide optimal performance.

- Price: Lastly, consider the price of the carbide-tipped drill bit. While quality is important, it’s also essential to find a drill bit that fits within your budget.

Tips for Using Carbide-Tipped Drill Bits

To ensure successful drilling with carbide-tipped drill bits, follow these tips:

- Use a slow drilling speed: Glass is a delicate material, and drilling too fast can cause it to crack or shatter. Set your drill to a low speed and apply gentle pressure when drilling through glass.

- Use lubrication: Applying a lubricant such as water or oil to the drill bit can help reduce friction and heat, making the drilling process smoother and preventing damage to the glass.

- Wear safety goggles: When drilling through glass, small shards or splinters can be produced. Protect your eyes by wearing safety goggles to prevent any injuries.

Conclusion

Carbide-tipped drill bits are an excellent choice for drilling through glass. Their durability, efficiency, and ability to minimize chipping make them the ideal tool for this task. By choosing the right carbide-tipped drill bit and following proper drilling techniques, you can achieve clean and precise holes in your glass projects.

Step-by-Step Guide on How to Drill Glass

-

Gather Your Materials

Before you begin drilling glass, make sure you have all the necessary materials:

- Glass surface

- Protective gloves and goggles

- Marker or tape

- Drill with a glass drill bit

- Lubricant (such as water or oil)

- Masking tape or painter’s tape

- Clamp or vice grip (optional)

-

Prepare the Glass Surface

Before you start drilling, prepare the glass surface:

- Place masking tape or painter’s tape on the area you want to drill to provide a guide and prevent the drill bit from slipping.

- Mark the exact spot where you want to drill using a marker or tape.

- If possible, secure the glass in a clamp or vice grip to keep it steady.

-

Choose the Right Drill Bit

Select the appropriate glass drill bit for your project:

- Diamond-tipped drill bits are typically used for drilling glass.

- Choose a drill bit size based on the size of the hole you need.

-

Apply Lubricant

Apply a lubricant to the area you will be drilling:

- If you’re using water, place the glass under a steady stream or use a spray bottle to keep the area wet.

- If you’re using oil, apply a small amount to the area.

- The lubricant helps to cool the drill bit and prevent it from overheating.

-

Drill the Glass

Now it’s time to start drilling:

- Hold the drill perpendicular to the glass surface.

- Apply gentle pressure and start drilling at a slow speed.

- Keep the drill bit steady and maintain a consistent speed throughout the process.

- Periodically pause and apply more lubricant to prevent overheating.

- Continue drilling until you reach the desired depth or completely penetrate the glass.

-

Clean Up

Once you’ve finished drilling, clean up the glass surface:

- Remove any remaining tape or protective covering.

- Use a lint-free cloth or paper towel to wipe away any debris or lubricant.

- Inspect the hole to ensure it meets your requirements.

Safety Tips for Drilling Glass

1. Wear Protective Gear

When drilling glass, it’s important to protect yourself from potential hazards. Make sure to wear safety glasses or goggles to shield your eyes from flying glass shards. Additionally, consider wearing gloves to protect your hands from cuts or burns.

2. Choose the Right Drill Bit

Using the correct drill bit is crucial for drilling glass safely. Look for a diamond-coated or tungsten carbide drill bit specifically designed for glass. These types of drill bits are more durable and less likely to cause the glass to crack or shatter.

3. Start with a Pilot Hole

Before drilling the main hole, it’s recommended to start with a pilot hole. This small hole will help guide the larger drill bit and prevent it from slipping or wandering on the glass surface. Use a smaller-sized drill bit to create the pilot hole.

4. Use Lubrication

Using some form of lubrication while drilling can help reduce friction and heat, preventing the glass from cracking or breaking. Apply a small amount of water or a specialized glass cutting oil to the drill bit before drilling.

5. Go Slow and Steady

When drilling glass, it’s important to work slowly and steadily. Applying excessive pressure or drilling at high speeds can cause the glass to fracture. Use a low to medium speed setting on your drill and apply a gentle, consistent pressure to avoid any mishaps.

6. Secure the Glass

Ensure that the glass you are drilling is properly supported and secured. Placing a piece of scrap wood beneath the glass can provide stability and prevent it from cracking or sliding during drilling. If possible, consider using clamps or a vice to hold the glass in place.

7. Drill on a Stable Surface

Work on a stable surface, such as a workbench or table, that will not move or vibrate while drilling. Any sudden movements or vibrations can increase the risk of the glass breaking or cracking.

8. Take Breaks

Drilling glass can be a slow and tedious process. Take regular breaks to give the drill bit and the glass a chance to cool down. This will help prevent overheating and reduce the risk of the glass breaking due to thermal stress.

9. Clean Up and Dispose of Glass Properly

After drilling, be sure to clean up any glass shards or debris. Dispose of them safely in a puncture-resistant bag or container. Avoid sweeping or vacuuming glass fragments, as these can scatter and cause injury.

10. Practice on Scrap Glass First

If you’re new to drilling glass, it’s a good idea to practice on a piece of scrap glass before attempting your actual project. This will give you a chance to familiarize yourself with the drilling technique and reduce the risk of making mistakes or damaging valuable glass.

Conclusion

By following these safety tips, you can minimize the risk of accidents and achieve better results when drilling glass. Remember to always prioritize safety and take your time to ensure a successful drilling experience.

Maintaining and Storing Drill Bits for Glass

Proper maintenance and storage of drill bits for glass is essential to ensure their longevity and optimal performance. Here are some tips to help you take care of your drill bits:

Cleaning

After each use, it is important to clean the drill bits thoroughly to remove any glass residue or debris that may have accumulated. Use a soft brush or cloth to wipe away any dirt and ensure that the drill bits are spotless before storing them.

Sharpening

Over time, drill bits can become dull and lose their cutting effectiveness. To maintain their sharpness, it is recommended to sharpen them regularly using a diamond file or sharpening stone. Follow the manufacturer’s instructions for the proper sharpening technique.

Protective Coating

Applying a protective coating on the drill bits can help prevent rust and corrosion. There are specialized coatings available that are designed to be used on metal tools. Follow the manufacturer’s instructions for applying the coating and ensure that it is fully dry before storing the drill bits.

Storage

Proper storage is crucial to prevent damage to the drill bits. Here are some guidelines:

- Store the drill bits in a dry and clean area to prevent moisture and dust accumulation.

- Keep the drill bits in a dedicated storage case or box to protect them from accidental drops or impacts.

- Avoid storing the drill bits near heat sources or in direct sunlight, as this can cause them to warp or lose their temper.

- Make sure the drill bits are organized and separated to prevent them from rubbing against each other, which can cause chipping or dulling.

Regular Inspection

Periodically inspect your drill bits for any signs of wear, damage, or deformation. If you notice any issues, such as bent or cracked bits, it is important to replace them immediately to prevent accidents or poor drilling results.

Proper Handling

During use, handle the drill bits with care and avoid excessive force or pressure. Using the correct drilling technique, such as applying consistent pressure and using an appropriate speed, can help prolong the life of your drill bits.

By following these maintenance and storage guidelines, you can ensure that your drill bits for glass remain in good condition and provide you with optimal performance for your drilling needs.

FAQ:

What types of drill bits are recommended for drilling glass?

There are several types of drill bits that are commonly recommended for drilling glass. These include diamond drill bits, carbide tipped drill bits, and spear point drill bits. Each type of drill bit has its own advantages and disadvantages, so it’s important to choose the right one for your specific needs.

What are the advantages of using diamond drill bits for drilling glass?

Diamond drill bits are highly recommended for drilling glass because they are extremely durable and can create clean, precise holes. The diamond-tipped edges of these drill bits are incredibly hard and can easily cut through even the toughest glass surfaces. Additionally, diamond drill bits are less likely to shatter or chip the glass while drilling.

Can I use a regular drill bit to drill glass?

While it is possible to use a regular drill bit to drill glass, it is generally not recommended. Regular drill bits are not designed to cut through glass, so they are more likely to cause the glass to shatter or crack. It is best to use specialty drill bits that are specifically designed for drilling glass in order to achieve the best results and minimize the risk of damaging the glass.

What should I consider when choosing the right drill bit for glass?

When choosing the right drill bit for glass, there are several factors to consider. Firstly, you need to consider the type of glass you are drilling, as different types of glass may require different types of drill bits. Secondly, you should consider the size of the hole you need to drill, as different drill bits are available in different sizes. Finally, you should consider the durability and quality of the drill bit, as this will affect the longevity and effectiveness of the tool.

Are there any safety precautions I should take when drilling glass?

Yes, there are several safety precautions you should take when drilling glass. Firstly, it is important to wear safety glasses to protect your eyes from any flying glass shards or debris. Secondly, it is recommended to use a spray bottle filled with water to keep the drill bit and glass cool, as excessive heat can cause the glass to crack or break. Lastly, it is important to apply gentle, consistent pressure while drilling to avoid causing any unnecessary damage to the glass.

What are the common mistakes to avoid when drilling glass?

There are several common mistakes to avoid when drilling glass. Firstly, it is important to avoid applying too much pressure while drilling, as this can cause the glass to crack or shatter. Secondly, it is important to avoid drilling at too high of a speed, as this can generate excessive heat and damage the glass. Lastly, it is important to avoid using a dull or worn-out drill bit, as this can result in an uneven or jagged hole.

Video: