Choosing the Right Drill Bit: A Guide for Beginners

Drilling is a common task in many DIY projects, whether you’re hanging a picture, installing a shelf, or building a piece of furniture. However, choosing the right drill bit can be confusing, especially for beginners. With so many types and sizes available, it’s important to understand the different options and their uses in order to achieve the best results.

One of the first things to consider when selecting a drill bit is the material you’ll be drilling into. Different materials require different types of drill bits. For example, a wood drill bit is designed specifically for drilling into wood, while a masonry drill bit is used for drilling into concrete or brick. Using the wrong type of drill bit can result in a less effective or even damaged hole.

Another important factor to consider is the size of the hole you need to make. Drill bits come in a range of sizes, measured in diameter. The size of the hole you need will depend on the specific project you’re working on. If you’re unsure, it’s always better to start with a smaller hole and gradually increase the size if necessary. Remember, you can always enlarge a hole, but once it’s too big, there’s no going back.

Understanding the Purpose of Different Drill Bits

When it comes to drilling, choosing the right drill bit is crucial. Each type of drill bit is designed for a specific purpose, and using the wrong one can result in poor performance, damage to materials, or even injury. In this section, we will discuss the most common types of drill bits and their intended uses.

HSS (High-Speed Steel) Drill Bits

HSS drill bits are the most common and versatile type of drill bits. They are made from high-speed steel, which makes them strong and durable. HSS drill bits can be used to drill into wood, metal, and plastic, making them a popular choice for general-purpose drilling.

Wood Drill Bits

Wood drill bits, also known as lip and spur or brad-point bits, are designed specifically for drilling into wood materials. They have a center point and two raised spurs that help guide the bit into the wood and prevent splintering. Wood drill bits are available in various sizes to accommodate different hole diameters.

Masonry Drill Bits

Masonry drill bits, also called concrete or carbide drill bits, are designed for drilling into hard materials such as concrete, brick, or stone. They feature a carbide tip that helps to cut through the tough materials. Masonry drill bits should be used with a hammer drill to provide the necessary impact force for effective drilling.

Tile Drill Bits

Tile drill bits, as the name suggests, are specifically designed for drilling into tiles and other ceramics. They are made with a carbide tip that can withstand the hardness of the tile without cracking or chipping it. Tile drill bits often have a spear-shaped tip to help prevent wandering on the smooth surface of the tile.

Countersink Drill Bits

Countersink drill bits are used to create a recessed hole that allows the screw to sit flush with the material’s surface. These drill bits have a tapered end that creates a conical-shaped hole. Countersinking is commonly done in woodworking when a clean and finished appearance is desired.

Step Drill Bits

Step drill bits, also known as cone or pagoda drill bits, are designed to create holes with gradually increasing diameters. They are often used in sheet metal projects or when drilling holes in materials of varying thicknesses. Step drill bits eliminate the need for multiple drill bits and can save time and effort.

Spade Drill Bits

Spade drill bits, also referred to as paddle or flat wood bits, are mainly used for drilling large holes in wood. They have a flat, paddle-shaped blade and often come in sizes ranging from 6mm to 38mm. Spade drill bits can be used with both hand drills and power drills for quick and efficient drilling.

Conclusion

Understanding the purpose of different drill bits is essential for achieving the best results in your drilling projects. By selecting the right drill bit for the material and task at hand, you can ensure precision, efficiency, and prevent any potential damage. It is always recommended to use the manufacturer’s guidelines and safety precautions when working with power tools.

Types of Drill Bits and Their Applications

When it comes to drilling, there are several types of drill bits available, each designed for specific applications. Understanding the different types and their applications will help you select the right drill bit for your project.

1. Twist Drill Bits

- Twist drill bits are the most common type of drill bit and are suitable for most drilling tasks.

- They have a spiral-shaped groove called the flute, which helps to remove material from the hole.

- Twist drill bits can be used on various materials such as wood, metal, and plastic.

- They are available in different sizes and shapes, allowing you to drill holes of different diameters.

2. Masonry Drill Bits

- As the name suggests, masonry drill bits are designed for drilling into masonry materials such as concrete, brick, and stone.

- They have a carbide tip that is specially designed to penetrate hard materials.

- Masonry drill bits are usually used with a hammer drill or rotary hammer to provide the necessary impact for drilling into tough surfaces.

3. Spade Drill Bits

- Spade drill bits, also known as paddle bits, are commonly used to drill large, flat-bottomed holes in wood.

- They have a flat cutting tip with two spur-like cutting edges that help to create clean and precise holes.

- Spade drill bits are available in various sizes and are commonly used for drilling holes for plumbing and electrical work.

4. Forstner Drill Bits

- Forstner drill bits are ideal for drilling clean and precise flat-bottomed holes in wood.

- They have a center point and two radial cutting edges that give them exceptional cutting performance.

- Forstner drill bits are commonly used in woodworking for drilling holes for dowels, hinges, and other fittings.

5. Hole Saw Drill Bits

- Hole saw drill bits are used to create large holes in wood, plastic, and soft metals.

- They consist of a cylindrical saw blade with teeth and a pilot drill bit in the center.

- Hole saw drill bits are commonly used for tasks such as installing door knobs, plumbing work, and creating holes for electrical conduit.

6. Countersink Drill Bits

- Countersink drill bits are designed to create a conical recess for the head of a screw or bolt.

- They allow the screw or bolt to sit flush with the surface, giving a clean and professional appearance.

- Countersink drill bits are commonly used in woodworking and metalworking.

7. Step Drill Bits

- Step drill bits, also known as cone drill bits, are used for drilling holes with larger diameters.

- They have a stepped design that allows them to drill multiple hole sizes with a single bit.

- Step drill bits are commonly used in automotive and electrical work.

These are just a few examples of the many types of drill bits available. It’s important to choose the right drill bit for your specific application to achieve the best results. Consider the material you’re drilling into, the size of the hole you need, and any other specific requirements of your project.

Considerations for Choosing the Right Drill Bit

Choosing the right drill bit is essential for achieving accurate and clean holes in various materials. Here are some key considerations to keep in mind when selecting a drill bit:

Material

- Different drill bits are designed to work with specific materials. Consider the material you will be drilling into and choose a drill bit that is suitable for that material.

- For example, wood drill bits are designed with a pointed tip and wide flutes to quickly remove wood chips, while masonry drill bits have carbide tips for drilling into hard surfaces like concrete.

Size

- The size of the hole you need to drill will determine the size of the drill bit you should choose.

- Drill bits are typically measured in inches or millimeters and come in a range of sizes. Make sure to select the appropriate size for your specific drilling needs.

Type

- There are various types of drill bits available, each designed for specific applications.

- Some common types include twist drill bits, spade bits, hole saws, and step drill bits.

- Consider the type of hole you need to drill and choose a drill bit that is suitable for that specific task.

Coating

- Drill bits can also come with various coatings that provide additional benefits.

- For example, titanium-coated drill bits are more durable and resistant to heat, making them ideal for drilling into metal.

- Black oxide-coated drill bits are corrosion resistant and provide better lubrication, making them suitable for drilling into wood.

- Consider the coating that best suits your needs based on the material and conditions you will be drilling into.

Price

Lastly, consider your budget when choosing a drill bit. Different drill bits come at different price points, and while quality is important, you can usually find a suitable drill bit within your budget.

By considering these factors, you can choose the right drill bit for your specific drilling needs, ensuring accurate and clean holes every time.

Key Features to Look for in Drill Bits

1. Material

One of the key features to consider when choosing drill bits is the material they are made of. Common materials for drill bits include high-speed steel (HSS), cobalt, and carbide. HSS bits are versatile and suitable for most everyday drilling tasks, while cobalt bits are more durable and can withstand higher temperatures. Carbide bits, on the other hand, are extremely hard and are ideal for drilling through hard materials like concrete or tile.

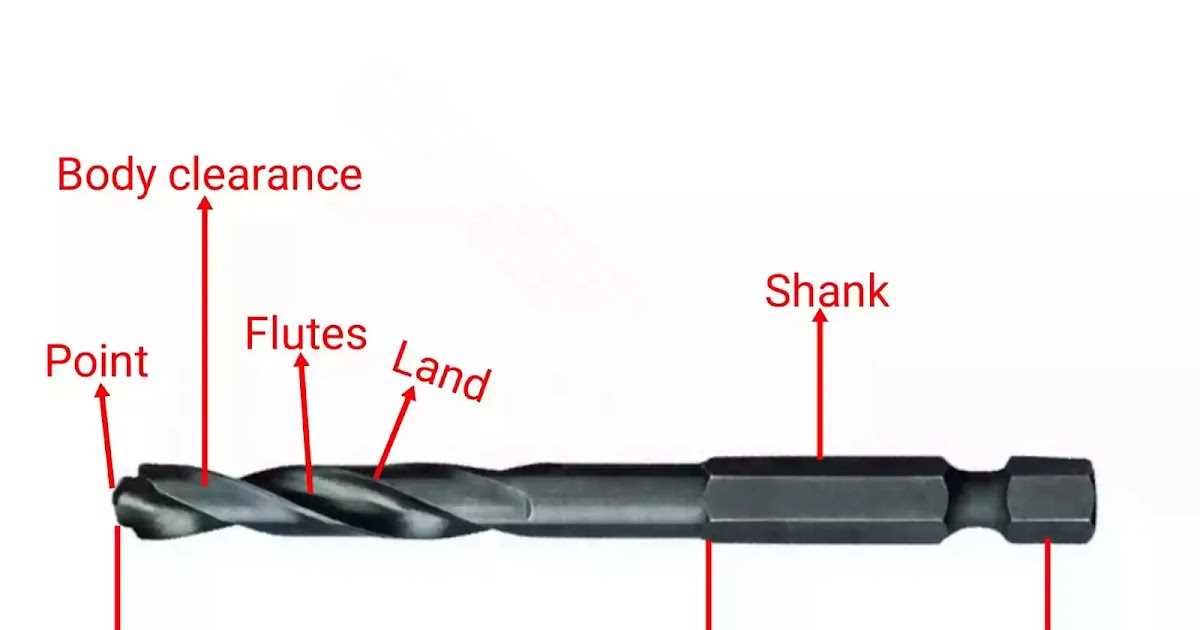

2. Size and Shank Type

Drill bits come in various sizes and different shank types. The size of the drill bit determines the diameter of the hole it will create. Common sizes range from 1/16 inch to 1/2 inch or larger. The shank is the part of the bit that fits into the drill chuck. Common shank types include round shanks and hex shanks. Round shanks are the most common and fit into standard drill chucks, while hex shanks are designed to be used with quick-change drill systems.

3. Point Angle

The point angle of a drill bit refers to the angle at which the tip of the bit is ground. Common point angles for drill bits include 118 degrees and 135 degrees. A 118-degree point angle is ideal for general-purpose drilling, while a 135-degree point angle is better suited for drilling through harder materials. It’s important to select a drill bit with the appropriate point angle for the intended drilling task to prevent the bit from wandering or overheating.

4. Flute Design

The flute design of a drill bit refers to the grooves or channels on the bit’s surface. Flutes help to remove the material that is being drilled and allow for better chip evacuation. Common flute designs include spiral, straight, and parabolic. Spiral flutes are the most common and are suitable for most drilling tasks. Straight flutes are typically used for drilling through soft materials, while parabolic flutes are designed for efficient chip removal in harder materials.

5. Coating

Many drill bits are coated with a special material to enhance their performance and durability. Common coatings include black oxide, titanium nitride (TiN), and cobalt. Black oxide coating helps to reduce friction and heat, while TiN coating increases the hardness of the bit and improves its wear resistance. Cobalt coating enhances the durability of the bit for drilling through tough materials. Choosing a coated drill bit can extend the lifespan of the bit and improve drilling efficiency.

6. Compatibility

Finally, it’s important to ensure that the drill bit you choose is compatible with your drill. Check the specifications of your drill to determine the suitable drill bit size and shank type. Using the wrong size or type of drill bit can result in improper drilling and potential damage to the drill or workpiece.

By considering these key features, you can select the right drill bit for your specific drilling needs. Whether you’re drilling through wood, metal, or concrete, choosing the right drill bit will result in more efficient and accurate drilling.

How to Select the Right Size for Drill Bits

When it comes to selecting the right size drill bits, there are a few important factors to consider. The size of the hole you want to drill, the material you are drilling into, and the type of drill you are using all play a role in determining the appropriate size.

1. Determine the size of the hole:

The first step in selecting the right size drill bit is to determine the size of the hole you want to create. Measure the diameter of the hole needed and choose a drill bit that matches or is slightly larger than the desired hole size.

2. Consider the material:

The material you are drilling into will also affect the size of the drill bit you need. Softer materials, like wood or plastic, can often be drilled with standard twist bits. However, harder materials, such as metal or masonry, may require specialized bits designed for those materials.

3. Check the drill’s chuck size:

Next, check the chuck size on your drill. The chuck is the part of the drill that holds the drill bit in place. Different drills have different chuck sizes, so it’s important to choose a drill bit that fits securely in your drill’s chuck.

4. Look for drill bit size markings:

Drill bits usually have size markings on them that indicate their diameter. These markings can be in inches, millimeters, or a combination of both. Look for these markings to ensure you are selecting the correct size. If you are unsure, consult a drill bit sizing chart or ask a professional for assistance.

5. Consider drill bit length:

In addition to the diameter, consider the length of the drill bit. Longer drill bits are useful for drilling deeper holes, while shorter bits are better for shallower holes. Make sure the length of the drill bit is suitable for the task at hand.

By considering these factors – hole size, material, chuck size, size markings, and length – you can choose the right size drill bits for your drilling needs. Remember to use appropriate safety precautions and consult the manufacturer’s guidelines when using power tools.

Tips for Extending the Lifespan of Drill Bits

Proper care and maintenance can significantly extend the lifespan of your drill bits and ensure they remain sharp and effective for longer. Here are some tips to help you get the most out of your drill bits:

1. Select the Right Drill Bit for the Job

Using the correct drill bit for the specific material you are drilling into is essential. Different drill bits are designed to handle various materials, such as wood, metal, or masonry. Using the wrong drill bit can result in damage to both the bit and the material.

2. Use the Appropriate Speed and Pressure

Drilling at the correct speed and applying the right amount of pressure can help prolong the life of your drill bit. Using excessive force or high speeds can cause the bit to overheat and become dull more quickly. Slow and steady drilling with moderate pressure is usually recommended.

3. Keep the Bit Cool

Excessive heat can cause drill bits to become dull and less effective. To keep the bit cool, consider using a lubricant or coolant while drilling. This can reduce friction and heat buildup. Additionally, taking breaks during prolonged drilling sessions can allow the bit to cool down.

4. Avoid Hard Surfaces

Avoid drilling directly into hard surfaces, such as metal or concrete, as much as possible. Instead, use a pilot hole or pre-drill smaller holes to help reduce the strain on the bit. This technique can help prevent excessive wear and extend the lifespan of the drill bit.

5. Store Properly

Proper storage is crucial for maintaining the sharpness and integrity of your drill bits. Store them in a clean, dry place where they won’t be subjected to moisture or damage. Consider using a drill bit organizer or case to keep them organized and protected.

6. Regularly Sharpen and Clean

Periodically sharpening your drill bits can help maintain their cutting ability and extend their lifespan. You can use a drill bit sharpener or a grinding wheel to achieve a sharp cutting edge. Additionally, cleaning the bit after each use can prevent debris buildup and corrosion.

7. Replace When Needed

Eventually, even with proper care, drill bits will reach the end of their lifespan. Signs that it’s time to replace a drill bit include dull edges, decreased cutting efficiency, or visible damage. Using worn-out drill bits can lead to poor results, increased drilling time, and potential accidents.

By following these tips, you can ensure that your drill bits last longer and continue to deliver optimal performance for your drilling needs.

Common Mistakes to Avoid When Using Drill Bits

Using drill bits may seem simple, but there are several common mistakes that beginners often make. By avoiding these mistakes, you can improve your drilling efficiency and extend the lifespan of your drill bits. Below are some common mistakes to avoid when using drill bits.

1. Using the Wrong Speed Setting

One common mistake is using the wrong speed setting on your drill. Different materials require different speeds to drill through them effectively. When drilling through hard materials like metal, use a slower speed, while softer materials like wood can be drilled at a higher speed. Consult the drill’s manual or do some research to determine the appropriate speed setting for the material you are drilling.

2. Applying Too Much Pressure

Applying too much pressure while drilling is another common mistake. While it may seem logical to push harder to make the drilling process faster, it can actually lead to overheating and wearing out your drill bits prematurely. Instead, let the drill bit do the work and apply a moderate and steady pressure. This will prevent the drill bit from overheating and ensure a clean and efficient drilling process.

3. Neglecting to Use Lubrication

Lubrication is essential for drilling through certain materials such as metal. Neglecting to use lubrication can cause your drill bit to overheat and wear out more quickly. Apply a few drops of lubricating oil or a suitable coolant to the drilling area to reduce friction and heat during the drilling process. This will not only extend the lifespan of your drill bits but also improve drilling efficiency.

4. Using Dull Drill Bits

Using dull drill bits is a mistake that can lead to poor drilling performance and frustration. Dull drill bits require more pressure to drill through materials, resulting in slower drilling speeds and a less clean finish. Keep your drill bits sharp by regularly sharpening or replacing them. This will ensure optimal drilling performance and help you achieve precise and clean holes.

5. Not Cleaning the Drill Bit

After drilling, it is important to clean the drill bit to remove any debris or material buildup. Neglecting to clean the drill bit can cause it to become clogged or ineffective. Use a brush or a piece of cloth to remove any residue on the drill bit. This will not take much time but can significantly improve the lifespan and performance of your drill bits.

| Mistake | Effect | Solution |

|---|---|---|

| Using the wrong speed setting | Inefficient drilling, potential damage to the material | Consult the manual or do research to determine the correct speed setting for the material |

| Applying too much pressure | Overheating, premature wear of drill bits | Apply moderate and steady pressure, let the drill bit do the work |

| Neglecting to use lubrication | Overheating, decreased lifespan of drill bits | Apply lubrication such as oil or coolant to reduce friction and heat |

| Using dull drill bits | Poor drilling performance, slower drilling speed | Regularly sharpen or replace drill bits to keep them sharp |

| Not cleaning the drill bit | Clogging, decreased lifespan of drill bits | Clean the drill bit after each use to remove debris or material buildup |

Avoiding these common mistakes when using drill bits will help you achieve better drilling results, increase the lifespan of your drill bits, and improve your overall drilling experience.

Recommendations for Beginner-Friendly Drill Bit Sets

If you’re new to drilling, it can be overwhelming to choose the right drill bit set for your needs. To make the process easier, consider the following recommendations:

1. Variety of Sizes

Look for a drill bit set that offers a wide range of sizes. This will ensure that you have the right bit for any job you encounter. A set with sizes ranging from 1/16 inch to 1/2 inch should cover most beginner-level projects.

2. Assorted Types of Bits

It’s important to have different types of bits for different materials. A beginner-friendly set should include a variety of bit types, such as twist bits, spade bits, and masonry bits. This will allow you to tackle a wider range of projects and materials.

3. Durable Materials

Choose a drill bit set made from durable materials like high-speed steel (HSS) or cobalt. These materials are stronger and will last longer, especially when drilling through tougher materials like metal or concrete.

4. Organization and Storage

Opt for a drill bit set that comes with a storage case or organizer. This will help you keep your bits organized and prevent them from getting lost. Look for sets with labeled compartments or a case that can be easily stored on a shelf or in a toolbox.

5. User-Friendly Design

Consider the design of the drill bits themselves. Look for features like a 135-degree split point, which provides better accuracy and reduces wandering. Also, check if the bits have a hex shank, as this can make it easier to secure the bits in your drill’s chuck.

6. Budget-Friendly Options

If you’re just starting out, you may not want to invest too much in a drill bit set. Look for budget-friendly options that still offer good quality. There are many affordable sets available that provide a decent selection of bits to get you started.

Remember, it’s always a good idea to read reviews and research different brands before making a final decision. By considering these recommendations and doing your due diligence, you’ll be able to choose a beginner-friendly drill bit set that meets your needs and helps you get started on your drilling projects with confidence.

FAQ:

What is a drill bit?

A drill bit is a cutting tool used in drilling machines to create holes in different materials such as wood, metal, and plastic. It consists of a shank, body, and tip made of various materials depending on the type of drilling required.

What are some common types of drill bits?

Some common types of drill bits include twist bits, spade bits, hole saws, masonry bits, and step bits. Each type is designed for specific materials and drilling applications.

What factors should beginners consider when choosing a drill bit?

Beginners should consider the material they will be drilling, the size and shape of the hole needed, and the type of drill they will be using. Additionally, they should look for drill bits that are high-quality and suitable for their specific drilling needs.

How do I know which drill bit size to use?

The drill bit size you should use depends on the desired hole diameter. You can refer to drill bit size charts, which provide the corresponding sizes in inches or millimeters. Alternatively, you can use a measuring tool to determine the size of an existing hole and choose a drill bit that matches.

What materials are drill bits made of?

Drill bits can be made of various materials, including high-speed steel (HSS), cobalt steel, carbide, and diamond. Each material has different properties and is suited for specific drilling applications. It is important to choose a drill bit made of the right material for the material being drilled.

What should I do if my drill bit gets dull?

If a drill bit becomes dull, it can be sharpened using a drill bit sharpener. However, if the bit is severely damaged or beyond repair, it may need to be replaced. Regularly inspecting and maintaining drill bits can help prolong their lifespan and ensure optimal drilling performance.

Video: